5 ProtocolManual1010 BJ

-

Upload

spider15891 -

Category

Documents

-

view

216 -

download

0

Transcript of 5 ProtocolManual1010 BJ

-

8/13/2019 5 ProtocolManual1010 BJ

1/118

Model 1010A

Software Protocol Manual

SLIP+ Application Pack BJ

15 December 2006

-

8/13/2019 5 ProtocolManual1010 BJ

2/118

Model 1010A - Software Protocol Manual

Copyright Enraf Contrec 2006

The instructions given herein cover the general description, installation, operation and maintenance of the subjectequipment. Enraf Contrec reserves the right, without prior notice, to make engineering refinements that may not

be reflected in this manual.

Should any questions arise which cannot be answered specifically by this manual, they should be directed to Enraf

Contrec for further detailed information and technical assistance.

Enraf Contrec will not accept any liability for either direct or consequential damages resulting from the use or

misapplication of the contents of this manual.

Microsoft and Windows are registered trademarks of Microsoft Corporation.

Adobe and Acrobat are registered trademarks of Adobe Systems Incorporated.

Enraf Contrec22 Hall Street Hawthorn East, Melbourne 3123 AUSTRALIA

Tel: +61 3 9804 4200 Fax: +61 3 9822 8329Email: [email protected]

Website: www.contrec.com.au

Publication No:SLIP+V3-001-SP1010A-BJ - 25/01/2006

-

8/13/2019 5 ProtocolManual1010 BJ

3/118

SLIP+V3-001-SP1010A-BJ - 25/01/2006 i

8.0

Contents

8.1 Overview 1

Description ................. ................ ................. ................ ................. ................ ................. ............... ................ ................. ................. ................ ................ ................ .................. 1

SLIP+ Commands ................ ................ ................ ................. ................. ................ ................ ................ .................. ................ ................ ................ ................. ............ 1

8.2 Frame Format 3

Description ................. ................ ................. ................ ................. ................ ................. ............... ................ ................. ................. ................ ................ ................ .................. 3

Frame Format ................ ................ ................ ................. ................. ................ ................. ................ ................ .................. ................ ................ ................ ................ .......... 3

Address Byte ............... ................. ................ ................ ................. ................. ................ ................ ................ .................. ................ ................ ................ ................. ............ 3Control Byte ............... ................ ................ ................ .................. ................ ................ ................ ................. ................. ................ ................. ................ ................ ............... 3

LRC ............... ................. ................. ................ ................ ................ .................. ................ ................ ................. ................ ................. ................ ................. ................ ................... .... 5

8.3 Byte Testing 7

Description ................. ................ ................. ................ ................. ................ ................. ............... ................ ................. ................. ................ ................ ................ .................. 7

Byte Testing ................. ................ ................ ................. ................. ................ ................ ............... ................. ................. ................ ................. ................ ................ ............... 7

8.4 Communication Procedures 9

Description ................. ................ ................. ................ ................. ................ ................. ............... ................ ................. ................. ................ ................ ................ .................. 9Load Scheduling ............... ................ ................. ................ ................. ................ ................. ................ ................. ................. ................ ................ ................ .................. 9

Instrument Flow Diagram ................. ................ .................. ................ ................ ................ ................ .................. ................ ................ ................. ................ 15

Remote Authorisation ............... ................. ................ ................. ................ ................. ................ ................. ................. ................ ................ ................ .............. 16

Displaying Messages and Getting Answers ................. ................ ................. ................. ................ ................. ................ ................ ........... 17

Communications Timeout ................ ................ .................. ................ ................ ................ ................ .................. ................ ................ ................. ................ 22

Retrieval of Loading Records ................ ................. ................ ................. ................ ................ .................. ................ ................ ................ ................ ...... 22

8.5 Error Status Codes 25

Description................. ................ ................. ................ ................. ................ ................. ............... ................ ................. ................. ................ ................ ................ ..............

25

8.6 Commands 29

Description ................. ................ ................. ................ ................. ................ ................. ............... ................ ................. ................. ................ ................ ................ .............. 29

Notes ............... ................. ................ ................. ................ ................ .................. ................ ................ ................ ................ .................. ................ ................ ................. ................ 29

AA - Alter Arm Name ................ ................ .................. ................ ................ ................ ................. ................. ................ ................. ................ ................ ........... 30

AI - Additive Injectors ................ ................ .................. ................ ................ ................ ................. ................. ................ ................. ................ ................ ........... 31

AM - Arm Status .............. ................ ................. ................ ................. ................ ................. ................ ................. ................. ................ ................ ................ .............. 32

AN - Net Accumulated Totals ................ .................. ................ ................ ................. ................ ................. ................ ................. ................ ................. .. 33

AP - Additive Parameters .............. ................ .................. ................ ................ ................. ................ ................. ................ ................. ................ ................. .. 34

AR - Additive Recipes ................ ................ .................. ................ ................ ................ ................. ................. ................ ................. ................ ................ ........... 37AS - Arm Settings ................ ................ ................ ................. ................. ................ ................ ................ .................. ................ ................ ................ ................. ........ 40

-

8/13/2019 5 ProtocolManual1010 BJ

4/118

8.0

ContentsSoftware Protocol Manual

ii SLIP+V3-001-SP1010A-BJ - 25/01/2006

AT - Accumulated Totals ................ ................ ................ ................. ................. ................ ................ ................ .................. ................ ................ ................ .. 42

AV - Application Version ............... ................ ................ ................. ................. ................ ................ ................ .................. ................ ................ ................ .. 43

BT - Batch Totals ................. ................. ................ ................ ................ .................. ................ ............... ................ ................ .................. ................ ................ .......... 44

CA - Control Arm ............... ................. ................ ................ ................ .................. ................ ............... ................ ................ .................. ................ ................ .......... 46

CC - Clear Power Cycle ............... ................ ................. ................ ................. ................ ................. ................ ................. ................. ................ ................ ....... 47

CM - Clear Message ............... ................. ................ ................ ................. ................. ................ ................ ................ .................. ................ ................ ................ .. 48

CP - Set or Clear PIN/Touch Numbers ............... .................. ................ ................ ................ ................ .................. ................ ................ .......... 49

DM - Display Message ............... ................. ................ ................ .................. ................ ................ ................ ................ .................. ................ ................ .......... 50

DN - Set Arm Density ............... ................ ................ ................ .................. ................ ................ ................. ................ ................. ................ ................. ............ 52

DP - Display Prompt .............. ................. ................ ................ ................. ................. ................ ................ ................ .................. ................ ................ ................ .. 53

ENQ - Operational State Enquiry ................ ................ .................. ................ ................ ................ ................ .................. ................ ................ .......... 55

FR - Flow Rates ................ ................ ................ ................ ................. ................. ................ ................. ................ ................ .................. ................ ................ ............... 59

GA - Get Answer ................. ................ ................. ................ ................ .................. ................ ................ ................ ................ .................. ................ ................ .......... 60GC - Get Card .............. .................. ................ ................ ................ .................. ................ ................ ................ ................. ................. ................ ................. ................ .... 62

GD - Get Date and Time ................ ................ ................ .................. ................ ................ ................ ................. ................. ................ ................. ................ .... 64

GH - Get Hidden ............... ................. ................ ................ ................ .................. ................ ................ ................. ................ ................. ................ ................. ............ 65

GK - Get Touch Key .............. ................. ................ ................ ................. ................. ................ ................ ................ .................. ................ ................ ................ .. 67

GT - Gross Totals ................ ................. ................ ................ ................ .................. ................ ............... ................ ................ .................. ................ ................ .......... 69

IA - Injector Accumulative Totals ................ ................ ................. ................ ................. ................ ................. ................. ................ ................ ....... 70

IT - Instantaneous Temperatures ............... ................ .................. ................ ................ ................. ................ ................. ................ ................. ............ 71

LT - Last Load Temperatures .............. ................. ................ ................. ................ ................. ................ ................. ................. ................ ................ ....... 72

MI - Message Initial ................ ................. ................ ................ ................. ................. ................ ................ ................ .................. ................ ................ ................ .. 73

MR - Manager Reset .............. ................. ................ ................ ................. ................. ................ ................ ................ .................. ................ ................ ................ .. 74

NT - Net Totals ................. ................ ................ ................ ................. ................. ................ ................. ................ ................ .................. ................ ................ ............... 75OP - Option Settings .............. ................. ................ ................ ................. ................. ................ ................ ................ .................. ................ ................ ................ .. 76

PD - Power Cycle Date and Time ............... ................ .................. ................ ................ ................ ................ .................. ................ ................ .......... 77

PR - Presets .............. ................. ................. ................ ................ ................ .................. ................ ................ ................. ................ ................. ................ ................. ............ 78

RA - Remote Authorise ................ ................ ................. ................ ................. ................ ................. ................ ................. ................. ................ ................ ....... 79

RC - Compartment Response .............. ................. ................ ................. ................ ................. ................ ................. ................. ................ ................ ....... 80

RD - Reset Date and Time ............... ................ ................. ................. ................ ................. ................ ................ .................. ................ ................ ............... 82

RL - Load Number Response .............. ................. ................ ................. ................ ................. ................ ................. ................. ................ ................ ....... 83

SM - Stop Arm ................ ................ ................. ................ ................ ................. ................. ................ ................ ................ .................. ................ ................ ................ .. 84

SO - System Options ................. ................ ................ ................. ................. ................ ................. ................ ................ .................. ................ ................ ............... 85

ST - Send Transaction................ ................ ................ ................ .................. ................ ................ ................. ................ ................. ................ ................. ............

86SV - Software Version ................ ................. ................ ................ .................. ................ ................ ................ ................ .................. ................ ................ .......... 88

SY - Send Entry ................ ................ ................ ................ ................. ................. ................ ................. ................ ................ .................. ................ ................ ............... 89

TC - Transaction Complete ................ ................ ................ .................. ................ ................ ................. ................. ................. ................. ................ ........... 91

TT - Terminate Transaction ................. ................ ................ .................. ................ ................ ................ ................... ................ ................ ................. ........ 92

VA - Valve Settings and Calibration ................. ................. ................ ................. ................ ................ .................. ................ ................ ............... 93

NOTES ................. ................ .................. ................ ................ ................. ................ ................. ................ ................. ................ ................. ................. ................ ................ ....... 94

8.7 Release Notes 97

Description ................ ................. ................. ................ ................ ................ .................. ................ ................ ................. ................ ................. ................ ................. ............ 97

Changes ............... ................ .................. ................ ................ ................. ................ ................. ................ ................. ................ ................. ................. ................ ................ ....... 97Release Date ................ .................. ................ ................ ................. ................ ................. ................ ................. ................ ................. ................. ................ ................ ....... 97

-

8/13/2019 5 ProtocolManual1010 BJ

5/118

8.0

ContentsSoftware Protocol Manual

SLIP+V3-001-SP1010A-BJ - 25/01/2006 iii

8.8 Appendix - Backward Compatibility 99

Description ................. ................ ................. ................ ................. ................ ................. ............... ................ ................. ................. ................ ................ ................ .............. 99Commands ............... ................. ................ ................ ................ .................. ................ ............... ................ ................ .................. ................ ................ ................. ................ 99

DM - Display Message .............. ................ .................. ................ ................ ................ ................. ................. ................ ................. ................ ................ ....... 100

DP - Display Prompt ................ ................ ................ .................. ................ ................ ................ ................... ................ ................ ................. ................ ........... 102

GA - Get Answer ................ ................ ................ .................. ................ ................ ................ ................. ................. ................ ................. ................ ................ ....... 104

GH - Get Hidden Answer .............. ................ .................. ................ ................ ................. ................ ................. ................ ................. ................ ............... 106

GK - Get Hidden Answer .............. ................ .................. ................ ................ ................. ................ ................. ................ ................. ................ ............... 108

SA - Send Answer ................ ................ ................ ................. ................. ................ ................ ................ .................. ................ ................ ................ ................. .... 110

-

8/13/2019 5 ProtocolManual1010 BJ

6/118

8.0

ContentsSoftware Protocol Manual

iv SLIP+V3-001-SP1010A-BJ - 25/01/2006

-

8/13/2019 5 ProtocolManual1010 BJ

7/118

SLIP+V3-001-SP1010A-BJ - 25/01/2006 1

8.1

Overview

Description

This manual provides the necessary information to design communications software compatible with the

Model 1010A loading system using the SLIP+ command set.

The 1010A unit communicates with a remote computer on either of two RS485/RS422/RS232 interfaces

using a baud rate of 300 to 19,200 bps, odd parity, and 8 data bits. Each of the two communication ports can

be configured with different communication parameters.

These communication parameters can be altered under the -COMMUNICATIONS- menu when the unit is

in programming mode. Refer to the Programming Manual for details.

Terminal designations and link positions for links on the S810CPU card are given in the Engineering

Manual for both the RS485, RS422 and RS232 interfaces. Since RS485 and RS422 allow multi-drop

communications one or more instruments can be connected to the RS422/485 interfaces and can be polled

by the computer.

In this document a 1010A unit is referred to as the "instrument" and the attached computer, Distributed

Control Systems (DCS) or Load Rack Computers (LRC) are referred to as the "computer".

SLIP+ Commands

This protocol manual describes a new set of commands that make up the SLIP+ interface of the 1010A

instrument. The instrument still uses the protocol called SLIP (Serial Link Interface Protocol) but uses an

altered set of commands to talk to the 1010A instrument. Some of the commands are very similar to the

older non-SLIP+ interface. The older protocol command set did not support greater than 4 arms. The newer

SLIP+ command set supports greater than 4 arms and is set up to be infinitely expandable with regard to

arm number.

The SLIP+ command set is currently supported by only the BJ application pack. Other application packs

may use the core SLIP+ command set as described here but may have addition commands added or in some

specialised applications the command format may change. If command format is changed for a specific

application then that shall be clearly stated in the accompanying software protocol manual Release Notes

for that application pack.

The core changes are to the ENQ, AT, IT, LT, NT, PR, ST, and SY commands. Most of the other commands

have retained their previous format.

In summary, the protocol remains unchanged, SLIP continues to be used. To allow for greater than 4 arm

operation the command set was changed and is not backward compatible with previous application packs.

-

8/13/2019 5 ProtocolManual1010 BJ

8/118

8.1

OverviewSoftware Protocol Manual

2 SLIP+V3-001-SP1010A-BJ - 25/01/2006

-

8/13/2019 5 ProtocolManual1010 BJ

9/118

SLIP+V3-001-SP1010A-BJ - 25/01/2006 3

8.2

Frame Format

Description

This section describes the framing format used to transfer commands and information between the

instrument and computer. All values shown with the suffix H are hexadecimal values.

Frame Format

All communications consists of 8-bit binary data with the frame format shown below:

Each frame is bracketed between two C0H bytes (decimal 192) and can contain a maximum number of 200

bytes.

Address Byte

The Address Byte is the second byte in a frame. It is derived by adding the instruments UNIT ADDRESS

value to 80H, providing a maximum of 32 addresses in the range 80H to 9FH. For example, an instrument

programmed with a unit address of 2 would have an address byte value of 82H. An instruments unit address

is entered in the UNIT ADDRESS parameter in the -COMMUNICATIONS- menu during programming.

When information is sent from the computer to an instrument, the Address Byte is used to direct the frame

to the desired instrument.

When information is sent from an instrument to a computer, the Address byte is used to indicate the

instrument transmitting the information.

Control Byte

The Control Byte is the third byte in the frame and should be one of the following:

C0H ADDRESS CONTROL INFORMATION LRC C0H

Control Byte HEX Value Description

ENQ 05H Used by the computer to poll the instruments.

STX 02H Used to indicate that the information field contains data.

ACK 06H Used by the instrument to indicate that a received frame is valid.

NAK 15H Used by the instrument to indicate that a received frame is not valid.

EOT 04H Used by the computer to indicate the end of transmission.

-

8/13/2019 5 ProtocolManual1010 BJ

10/118

8.2

Frame FormatSoftware Protocol Manual

4 SLIP+V3-001-SP1010A-BJ - 25/01/2006

An example of each of the ENQ (Enquiry), ACK (Acknowledge) and NAK (Negative Acknowledge)

frames are shown below. The address byte used in each frame is 81H.

ENQ - C0H 81H 05H 84H C0H

ACK - C0H 81H 06H 87H C0H

NAK - C0H 81H 15H 94H C0H

Information Field

1. The information field is an optional field and is only present when the STX control byte is used.

2. The general format for the information field is shown below:

3. The terminating byte ETX (03H) indicates the end of the information field. Alternatively, the byte

ETB (17H) indicates the end of the information field, with more information to follow in the next

frame.

4. The information field should contain a two byte alphanumeric command and an arbitrary number of

data fields.

5. The information in the command and data fields should be in the ASCII range of values 20H through

to 7FH.

6. The command and data fields are separated from each other by a NULL (0H) character.

Examples of Information Fields

Note: For ease of identification, each field within the information field has been defined by enclosure in

square brackets. The 0 between each field is the null character (0x00).

The frames below show the complete transmission frame for the two previous examples. The address byteused in each frame is 0x81.

The line below shows the complete frame, in hexadecimal values, transmitted to an instrument to send

transaction number 123. The line below that shows the ASCII characters, where possible, of the same frame.

The line below shows the complete frame, in hexadecimal values, transmitted to an instrument to send

accumulated totals. The line below that shows the ASCII characters, where possible, of the same frame.

COMMAND 0H Data Field 1 0H Data Field 2 0H ETX

Information Field Description

[ST] 0 [123] 0 [ETX] Send Transaction Number 123

[AT] 0 [ETX] Send Accumulated Totals

C0H 81H 02H 53H 54H 00H 31H 32H 33H 00H 03H B7H C0H

address STX S T null 1 2 3 null ETX

C0H 81H 02H 53H 54H 00H 31H 95H C0H

address STX A T null ETX

-

8/13/2019 5 ProtocolManual1010 BJ

11/118

8.2

Frame FormatSoftware Protocol Manual

SLIP+V3-001-SP1010A-BJ - 25/01/2006 5

LRC

1. Longitudinal Redundancy Checksum (LRC) byte should be equal to the Exclusive OR (XOR) of ALLthe bytes in the packet, excluding the (C0H) brackets and the LRC byte. It includes the address byte,

the control byte and all bytes in the information fields, if there are information fields in the frame.

2. The LRC register should be set to 0 at the beginning of each frame.

3. The LRC should be derived by the transmitting unit and then sent to the receiving unit.

4. The receiving unit should, in turn, check each byte for parity, derive the LRC from the information it

has received and then compare the LRC it received to the one it derived.

5. Once the correct closing C0H bracket has been received, the frame is deemed to be either correct or

incorrect and one of the following conditions would arise:

The following conditions should be met in order for a frame to be acceptable:

All bytes (including the frame bracketing bytes) should pass the parity check.

The address byte should match the units address.

The derived LRC should match the one received.

The two byte command within any information field should be valid for the unit addressed (must beone of the commands described in the Commands section of this manual).

A valid end of frame bracket should be received within 200ms after the opening bracket.

Receiving Unit Frame Correct Frame IncorrectInstrument Send data, if command calls for data to be sent,

else send ACK, NAK or BS.

Do Nothing

Computer Send next command or EOT Repeat Command

-

8/13/2019 5 ProtocolManual1010 BJ

12/118

8.2

Frame FormatSoftware Protocol Manual

SLIP+V3-001-SP1010A-BJ - 25/01/2006 6

-

8/13/2019 5 ProtocolManual1010 BJ

13/118

SLIP+V3-001-SP1010A-BJ - 25/01/2006 7

8.3

Byte Testing

Description

This procedure sets out the steps necessary to ensure that Frames are always correctly received.

Byte Testing

The communication protocol is a very simple technique for sending data across ordinary asynchronous lines

(e.g. modems).

Each frame is preceded and followed by a special FEND (frame end) character, C0H. The reason for bothpreceding and ending frames with FENDs is to improve performance when there is noise on the

asynchronous line. The FEND at the beginning of a frame serves to "flush out" any accumulated garbage

into a separate frame (which will be discarded by the upper layer protocol) instead of appending into an

otherwise good frame. Note that, two FEND characters in a row should not be interpreted as delimiting an

empty frame.

As frames are sent in 8-bit binary, if a FEND ever appears in the data, it is translated into the two byte

sequence FESC TFEND (a frame escape byte and a transposed frame end byte), before transmission.

Likewise, if the FESC character ever appears in the user data, it is replaced with the two character sequence

FESC TFESC (a frame escape byte and a transposed frame escape byte), before transmission.

As characters arrive at the receiver, they are appended to a buffer containing the current frame. Receiving

a FEND marks the end of the current frame. Receipt of a FESC puts the receiver into "escaped mode" which

causes the receiver to translate a following TFESC or TFEND back to FESC or FEND, respectively, before

adding it to the receive buffer and leaving escaped mode. (Receipt of any character other than TFESC or

TFEND while in escaped mode is an error; no action is taken and frame assembly continues. A TFEND or

TESC received while not in escaped mode is treated as an ordinary data character.)

This procedure may seem somewhat complicated, but it is easy to implement and recovers quickly from

errors. In particular, the FEND character is never sent over the channel except as an actual end-of-frame

indication. This ensures that any intact frame (properly delimited by FEND characters) will always be

received properly regardless of the starting state of the receiver or corruption of the preceding frame.

The special characters used are:

FEND (frame end) C0 (hex)

FESC (frame escape) DB (hex)

TFEND (transposed frame end) DC (hex)

TFESC (transposed f rame

escape)

DD (hex)

-

8/13/2019 5 ProtocolManual1010 BJ

14/118

8.3

Byte TestingSoftware Protocol Manual

8 SLIP+V3-001-SP1010A-BJ - 25/01/2006

-

8/13/2019 5 ProtocolManual1010 BJ

15/118

SLIP+V3-001-SP1010A-BJ - 25/01/2006 9

8.4

Communication Procedures

Description

All communications with the instrument are under control of the computer. The instrument does not initiate

any communications with the computer. It only responds to requests and commands from the computer. If

the instrument detects any parity error or LRC error on any incoming command, the command will be

ignored and no response will be sent from the instrument. The enquiry command (ENQ) will provide the

instrument status needed to determine computer program flow.

Commands from the computer can be received via either the Main or Auxiliary communications port. See

Programming Manual, section -COMMUNICATIONS- for more details on enabling communications.

Once a command is sent to the instrument, the computer should wait for a period of 300 milliseconds to

allow the instrument time to respond. If there is no reply from the instrument, the command should be sent

again and another timeout period of 300 milliseconds recommenced. We would suggest that a minimum of

four retries be sent before any decision is made on alternative programming strategies.

Some commands require an extended wait period of 3 to 5 seconds. An example is the AP command when

used to download information to the instrument. The instrument must update the non-volatile memory as

part of the command operation, during this time the instrument cannot respond to any other command until

it has completed the memory update. This is why these commands can only be used while the instrument is

in the idle state. These commands all still respond with an acknowledge within the extra wait period. Other

similar commands include AA, AR, DN, IA, RD, SE, and VS. Any other commands sent during this extra

wait period will be ignored.

Depending on the current status of the instrument, some commands may not be executed and will then return

a busy (BS) response to the computer. An example of such commands are the RD (Reset Date and Time),

ST (Send Transaction), and SY (Send Entry).

A detailed list of commands is presented in Commands on page 29.

Load Scheduling

A load schedule is a list of quantities of different products to be loaded into the compartments of a particular

tanker truck, by a particular driver. To distinguish orders which may have the same driver and truck, each

load has a unique load number. The load schedule is entered on the host computer connected to theinstrument, prior to the tanker arriving at the loading facility. Load scheduling involves retrieving

information from the instrument operator, verifying if this data constitutes a valid load and if so, sending

the required compartment load quantities to the instrument.

Generally load verification involves:

1. Load number, driver and truck verification.

2. Product and compartment verification.

To perform load scheduling, load scheduling must be enabled under the -COMMUNICATIONS-

configuration menu, see the Programming Manual for more details.

-

8/13/2019 5 ProtocolManual1010 BJ

16/118

8.4

Communication ProceduresSoftware Protocol Manual

10 SLIP+V3-001-SP1010A-BJ - 25/01/2006

The instrument and the computer will use three commands to exchange the required information and a

fourth to complete the transaction. These first three commands are the enquiry (ENQ), request for load (RL)

and request for compartment (RC). Load number, driver and truck verification are performed using the (RL)

command, while product and compartment verification is performed using the (RC) command. The fourth

command is the transaction complete (TC) command, it is used to tell the instrument that the loading

process has completed.

The instrument response to the ENQ command depends upon what section of the instruments program is

executing when it receives the ENQ command, and the configuration of the instrument. Valid responses to

the ENQ command are SS (Send Status), RL (Request for Load), RC (Request for Compartment), DM

(Display Message), DP (Display Prompt), MT (Message Taken), GA (Get Answer), GH (Get HiddenAnswer), GK (Waiting for Touch Key), KA (Touch Key Read) PL (Post Loading Status) and AA (Answer

Available).

All of the above responses include the current instrument status, status of the gantry arms, last transaction

number, first arm number and the number of arms. See ENQ - Operational State Enquiry on page 55for

more detail.

The instrument will respond with an SS (System Status) response if none of the other responses are

applicable, I.e. if the instrument is not requesting load or compartment authorisation, it is not displaying a

message or getting an answer from the operator, and a message has not been taken or an answer is not

available).

The instrument will respond with a different Command Field if any other response is valid, I.e. if the

instruments requesting a load or compartment authorisation. See Command Fields on page 56for more

details.

The current status of the Instrument can be determined by examining the value of the status byte of

parameter a in the SS response. The status can have a value from 0 to 255 (ie. 8 bits, with each bit

representing an off/on state for up to 8 parameters). For example, bit 7 indicates whether the instrument is

in the idle state, 0 indicating that the instrument is in the idle state, 1 indicating the instrument is no longer

in the idle state.

The current state of up to four loading arms can be determined by examining the value of the arm status

bytes, parameters e & f in the SS response. The arm status parameters (eArms 1 & 2, farms 3 & 4)

can have a value from 0 to 255 (ie. 8 bits, with each bit representing an off/on state for up to 8 parameters).For example, bit 7 of parameter e indicates whether arm 1 of the instrument is presently loading, 0

indicating that the arm is presently not loading, 1 indicating the instrument is currently loading.

For any of the above parameters, an used bit will be set to 0 by default.

In conclusion the response to the ENQ command is used to determine the present state of the instrument.

Once this has been determined the appropriate action can be taken.

-

8/13/2019 5 ProtocolManual1010 BJ

17/118

8.4

Communication ProceduresSoftware Protocol Manual

SLIP+V3-001-SP1010A-BJ - 25/01/2006 11

Load Scheduling - Sequence of Events

Load Scheduling begins with the computer monitoring the instrument status using the ENQ command. Theinstrument always begins from the idle state. While in the idle state the computer may send messages to the

operator using the following commands; DM, DP, GA, GC, GH, and GK. These messages can be used to

gain information about the operator/driver/truck for use in determining whether the operator has an

authorised load in the load schedule database.

The instrument moves from the idle state once the operator has responded to the initial message by either

pressing the Enter key or connecting the system permissives.

RL State

The instrument moves from the idle state once the operator has responded to the initial message by either

pressing the Enter key or connecting the system permissives. If authorisation is enabled the following

prompt will be presented to the operator.

Once the touch key or other authorisation has taken place the operator is prompted to enter a load number.

The instrument will now respond to the ENQ command with an RL (request for load authorisation). The

instrument will prompt the operator with please wait, see below. During this state the computer may send

message to the operator using the DM, DP, GA, GC, GH, and GK commands.

An RL response from the instrument to the ENQ command from the computer has five extra parameters in

addition to the instrument status, these are:

1. Load number

2. Driver index number

3. Vehicle index number

4. Driver PIN/touch key

5. Truck PIN/touch key

SYSTEM AVAILABLE

PRESS ENTER

PRESENT TRUCK

TOUCH KEY

LOAD NUMBER

> 1

PLEASE WAIT

-

8/13/2019 5 ProtocolManual1010 BJ

18/118

8.4

Communication ProceduresSoftware Protocol Manual

12 SLIP+V3-001-SP1010A-BJ - 25/01/2006

If the driver and/or truck PIN/touch key numbers are verified by the instrument, the respective driver/truckindex fields of the RL response will contain numbers of the range 1 to 500. The number corresponds to the

location in the instruments memory where the PIN or touch key number was found. The last two fields will

thus contain the actual driver and/or truck PIN/touch key numbers. This allows for remote authorisation of

the driver and/or truck. The computer should now verify if the load number, driver and truck correspond to

a load in the load schedule database.

The driver and/or truck PIN/touch key numbers are downloaded to the instrument when the instrument is in

the idle state using the CP command.

Note: Driver and/or truck authorisation can be disabled, in this case these fields will contain 0and so will the corresponding driver and/or truck PIN/touch key number fields. Only the

load number need be verified in this case. Alternatively the load number prompt can alsobe disabled, in this case the load number field will contain 0. This would require the

computer to prompt the driver for information using the messaging commands, DM, DP,

GA, GC, GH, and GK. Then verify the obtained information before authorising the load.

If any of the parameters in the RL do not constitute a valid load, the computer should send to the instrument

an RL command with the first parameter N to signify NO to the load request. The second parameter being

the reason the request for load has been refused (e.g. INVALID LOAD NO). The first 30 characters of

the reason will be displayed on the instrument. After the operator has acknowledge the reason by pressing

ENTER, the operator is then prompted to re-enter the driver and/or truck PIN/touch key numbers and/or

load number.

If the parameters in the RL request from the instrument are valid, the computer sends an RL command with

the first parameter being Y to signify YES to the load request. The second parameter being a unique

number generated by the computer that is stored in the transaction within the instrument. If the RL

command from the computer to the instrument contains the third and fourth parameters, these parameters

are the driver and truck index numbers to be stored in the transaction within the instrument. If used both the

index numbers should be greater than 500. This allows the computer to determine if the driver and/or truck

were remotely authorised. This is because the driver and/or truck PIN/touch key numbers verified inside the

instrument will have index numbers in the range 1 to 500.

RC State

If the load is verified by the computer, as indicated by an affirmative RL command, the instrument prompts

the operator to enter an arm number to from which loading will commence.

If a valid arm number has been entered the instrument then prompts the operator to enter the compartment

which that arm is to be used to fill.

SELECT ARM

(1-4) > 1

COMPARTMENT NUMBER

> 1

-

8/13/2019 5 ProtocolManual1010 BJ

19/118

8.4

Communication ProceduresSoftware Protocol Manual

SLIP+V3-001-SP1010A-BJ - 25/01/2006 13

After the arm and compartment numbers have been entered, the instrument will reply with an RC (requestfor compartment authorisation) response to the next ENQ command from the computer. The instrument will

prompt the operator with please wait, see below. During this state the computer may send message to the

operator using the DM, DP, GA, GC, GH, and GK commands.

An RC response from the instrument to the ENQ command from the computer has four extra parameters in

addition to the instrument status, these are:

1. Load number

2. Arm number

3. Compartment number

4. Returned quantity

The computer should now check that the specified loading arm and compartment number match in the load

schedule database. If this is correct, the computer should send a RC command to the instrument with the

first parameter Y to signify YES to the compartment request. The second parameter is the preset quantity

to be loaded, and the third parameter is the maximum quantity that the operator can select as a preset.

If the ask preset prompt has been disabled the third parameter is ignored. The second parameter is used as

the preset for the load and the operator cannot change the preset amount.

Note: The second and third parameters of the RC Y response cannot exceed the maximumpreset value programmed into the instrument. If they do exceed this value they will be

ignored and the maximum preset value used in their place. See Programming Manual,

section 6.7, OPTIONS for details.

If any of the parameters in the RC do not constitute a valid compartment, the computer should send to the

instrument an RC command with the first parameter N to signify NO to the compartment request. The

second parameter being the reason the request for load has been refused (e.g. INVALID COMP NO). The

first 30 characters of the reason will be displayed on the instrument. After the operator has acknowledge the

reason by pressing ENTER, the instrument will take action based on the third parameter. This parameter

tells the instrument to either return to the arm selection prompt, continue to the ask load another

compartment prompt, or continue to the Post loading State where the loading process completes.

If the instrument receives an affirmative RC command, the instrument will prompt the operator for the

preset quantity, displaying the preset value the computer sent in the RC command (see prompt below). This

quantity may be altered by the operator, up to a maximum value sent from the computer.

PLEASE WAIT

PRESET QUANTITY

> 7500 L

http://../6.0%20-%20Programming%20Manual/PM_Options.pdfhttp://../6.0%20-%20Programming%20Manual/PM_Options.pdf -

8/13/2019 5 ProtocolManual1010 BJ

20/118

8.4

Communication ProceduresSoftware Protocol Manual

14 SLIP+V3-001-SP1010A-BJ - 25/01/2006

If the computer sent 0 as the preset quantity in the RC command the instrument will change the preset

prompt to that shown below:

Once a valid preset has been entered by the operator the instrument will then prompt the operator to start

the load.

As further arms are started within the same load, further compartment authorisation requests from the

instrument will be made by sending an RC response to the ENQ command. See Instrument Flow Diagram

on page 15.

PL State

Once all loading has completed the instrument enters the PL state. Any final messages for the operator can

be posted using the DM, DP, GA, GC, GH, and GK commands. The instrument will prompt the operator

with please wait, see below.

Once any messaging has been completed the computer sends to the instrument the TC (Transaction

Complete) command. The instrument then moves from the PL state to the disconnect prompt if permissives

are enabled. If no permissives are enabled or they have been disconnected the instrument prompts that the

load has completed for 5 seconds before reverting to the idle state, from which a new transaction can begin.

While in the idle state the last transaction number stored in the instrument can then be compared to that

stored in the computer database. If the instrument stores higher transaction numbers than that stored in the

computer database, the computer should upload the data from the instrument using the ST (Send

Transaction). See Retrieval of Loading Records on page 22.

ENTER PRESET QUANTITY

> 0 L

PRESS START

OR CANCEL

PLEASE WAIT

-

8/13/2019 5 ProtocolManual1010 BJ

21/118

8.4

Communication ProceduresSoftware Protocol Manual

SLIP+V3-001-SP1010A-BJ - 25/01/2006 15

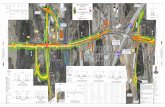

Instrument Flow Diagram

Select Arm Prompt

Load Authorised (RL Y)

Load Not Authorised

- Force Disconnect

(2)

Load Another

Compart?

Load Another

Comp Now?

NOOR Timeout OR Cancel

Program Start

Start OR Timeout OR Cancel

Start/Cancel Prompt

"LOADING COMPLETE"

Message

Idle State

Displays "SYSTEM

AVAILABLE" or

"CONNECT...."

RL State

Remote Load Authorise

Questions Asked

RC State

Remote

Compartment

Authorise

Questions

Asked

System Connected

OR Enter Pressed

Compartment

Not Authorised

Loading StateDisplays ARM status

information

Enter Preset Prompt

PL State

Post Loading

QuestionsAsked

Compartment Authorised

(RC Y)

YES

Loading

Compartment Not

Authorised

- Force Disconnect

ARM # Selected

Transaction at this

bay is Complete

YES

Compartment Not

Authorised - Skip

load another

compart prompt

Overfill AND/OR Vapour Recovery

Permissive Disconnected

Select Compartment

Prompt

Compartment # Selected

Timeout

OR Cancel

Timeout

OR Cancel

Overfill or

Vapour Recovery

permissive

disconnected

AND

Start button

has not been

pressed

"LOADING COMPLETE

DISCONNECT"

Prompt - if configured for

permissives

Enter Load Number

Load # Entered

RC N

"Message" 1

RC N

"Message" 0

RC N

"Message" 2

RL N

"Message"

NOTES:

a) Unit must be configured for LOAD SCHEDULING mode.

b) Only prompts can Timeout OR Cancel (via operator).

c) Some states and prompts depend on how the initial message

is configured - if configured for permissives or not.

Overfill or

Vapour Recovery

disconnected

OR Timeout

OR Cancel

A Batch Completes

OR Start Butt on

pressed

YES

NOStart Button

been pressed?

Is a load in

progress?

YES

NO

Timeout

OR Cancel

Valid Preset Selected

NO OR timeout

Message times out

RL N

"Message" SLoad Not Authorised

- Skip Disconnect (Retry)

-

8/13/2019 5 ProtocolManual1010 BJ

22/118

8.4

Communication ProceduresSoftware Protocol Manual

16 SLIP+V3-001-SP1010A-BJ - 25/01/2006

Remote Authorisation

Remote Authorisation is used to remotely authorise a driver and/or truck so that they can begin the loading

process. Remote Authorisation can involve authorising a driver, a truck or both. It can be used with any kind

of authorisation such as PIN, touch key, or card. Remote Authorisation is used primarily where there are

greater than 500 driver and/or truck PIN/touch key/card numbers, therefore they cannot all be stored within

the 1010 instrument. (The instrument can only hold 500 driver and 500 truck PIN/touch key/card numbers)

The driver and/or truck PIN/touch key/card numbers are entered into the host computer connected to the

instrument, prior to loading taking place. Remote Authorisation involves retrieving driver and/or truck

PIN/touch key/card numbers from the instrument operator, verifying if this driver and/or truck PIN/touch

key/card numbers constitutes an authorised operator and if so, sending the instrument authorisation.

Generally Remote Authorisation involves:

1. Retrieving driver and/or truck PIN/touch key/card numbers from the instrument.

2. Verifying driver and/or truck PIN/touch key/card numbers.

3. Authorising the instrument.

To perform Remote Authorisation, the instrument and the computer will use two commands to exchange

the required information. These commands are the enquiry (ENQ) and request for authorisation (RA).

Once the operator has responded to the instruments prompts by entering the PIN/touch key/card numbers

the instrument will enter the RA state. I.e. the instrument response to the ENQ command is RA (Remote

Authorisation), this indicates that the instrument is waiting for a remote authorisation from the computer.

An RA response from the instrument to the ENQ command from the computer includes four extra

parameters in addition to the instrument status parameters, these are:

1. Driver index number

2. Vehicle index number

3. Driver PIN/touch key/card number

4. Truck PIN/touch key/card number

The computer will be able to get the driver and/or truck PIN/touch key/card numbers from the ENQ

command response. The computer will then verify the numbers and send either an affirmative or negative

RA response back to the instrument.

If any of the parameters in the RA response do not constitute a valid authorisation, the computer should send

to the instrument an RA command with the first parameter N to signify NO to the remote authorisation

request. The second parameter being the reason the request for remote authorisation has been refused (e.g.

INVALID DRIVER PIN). The first 30 characters of the reason will be displayed on the instrument. Afterthe operator has acknowledge the reason by pressing ENTER, the operator is then prompted to re-enter the

driver and/or truck PIN/touch key numbers and/or load number.

If the parameters in the RA response from the instrument are valid, the computer sends an RA command

with the first parameter being Y to signify YES to the remote authorisation request. The second and third

parameters being the driver and truck index numbers respectively that are to be stored in the transaction

within the instrument.

After the instrument receives an affirmative remote authorisation, it will then prompt for load number (if

enabled), and then go to RL state (if Load Scheduling is enabled).

-

8/13/2019 5 ProtocolManual1010 BJ

23/118

8.4

Communication ProceduresSoftware Protocol Manual

SLIP+V3-001-SP1010A-BJ - 25/01/2006 17

Note: Driver and/or truck authorisation must be enabled under the SYSTEM configuration menu before

remote authorisation is enabled under the COMMUNICATIONS configuration menu. When remote

authorisation is enabled the COMMS TIMEOUT is automatically enabled. This timeout is the timeallowed for the instrument to detect computer communications before a communications timeout error

is reported. For example, if the instrument is sitting in the idle state and does not receive any computer

communications within the timeout period an error will be displayed to the operator. As soon as

communications are restored the error is cleared.

Displaying Messages and Getting Answers

Developers writing a communications interface to the 1010 may require additional messages to be sent to

the operator, and subsequent responses from the operator. Several commands (DM, DP, GA, GC, GH, and

GK) involve sending text messages to the instrument display to inform or prompt the operator.

Typically the commands have the following structure:

Control Byte Information Fields

STX [DM] 0 [a] 0 [b] 0 [c] 0 [d] ... [h] 0 [ETX]

where

a = line 1 (top line) [justify character& message]

b = line 2 [justify character& message]

c = line 3 [justify character& message]

d = line 4 [justify character& message]

e = line 5 [justify character& message]

f = line 6 [justify character& message]

g = line 7 [justify character& message]

h = line 8 (bottom line) [justify character& message]

justify characteroptions:

| centre justified (vertical bar, 7EH)

or _ left justified (underscore, 5FH)

or + right justified (plus sign, 2BH)or a number between 0 and 30 in the justify field will justify the text that

number of spaces from the left (must be two characters, ie 03 for 3 spaces)

messageoptions:

-1 leave line as is (if previous message still being displayed)

or -2 clear line (if previous message still being displayed)

or up to 30 characters of text (in addition to thejustify character)

-

8/13/2019 5 ProtocolManual1010 BJ

24/118

8.4

Communication ProceduresSoftware Protocol Manual

18 SLIP+V3-001-SP1010A-BJ - 25/01/2006

The instrument has a 8 line x 30 character display. Up to 8 lines can be displayed, however, due to the factthat the meter totals have to remain on the screen at most times this is not always possible. Therefore the

only time a full screen message (a message of up to 8 lines) can be displayed is during the idle, RL or RA

states. If in Load Scheduling mode messages can only be displayed during the idle, RA, RC, and PL states.

Only two line messages can be displayed during the RC and PL states. These two line messages are

displayed on the bottom two lines on the 8 x 30 display. All two line message should contain either -1 or

-2 for the first six line parameters.

The commands all have a similar structure and involve the use of a Justification Character to set the spacing

on each of 8 lines of text. The Justify Character is the first character of each parameter of the command.

If sending a message while the instrument is in the idle state, you can send either a two line message or a

full screen message.

To display a two line message to the operator (ignoring the field separator nulls):

This results in the following being displayed:

DM -2 -2 -2 -2 -2 -2 |PLEASE WAIT -2 ETX

ARM 1 l i t r e ARM 2 l i t r e

ARM 3 l i t r e ARM 4 l i t r e

PLEASE WAIT

-

8/13/2019 5 ProtocolManual1010 BJ

25/118

8.4

Communication ProceduresSoftware Protocol Manual

SLIP+V3-001-SP1010A-BJ - 25/01/2006 19

To display a full screen message to the operator (ignoring the field separator nulls):

This results in the following being displayed:

The instrument is able to determine a two line message by checking the first six line parameters to see that

they are all either -1 or -2. If any of these first six message parameters is not a -1 or -2 then the

instrument will assume that you wish to display a full screen message and will clear the meters from the

screen and display the message.

Once messaging has started with either full screen or two line it is suggested to continue with the same type

of messaging until complete. Otherwise the screen will be cleared each time a full screen message is placed

after a two line message slowing down prompting to the screen.

It is suggest not to use the CM command after each message has been displayed as this will clear the screen

and re-display the meter totals which takes extra time and will result in poor useability. Instead it is

suggested to use one message command directly after the other, for example a DM command then

immediately the GA command. This also allows for creative interfaces such as scrolling menus, see

Messaging Commandsfor more details. Therefore the CM command should only be used once all

messaging has been completed to return the instrument to its original state.

Note: The Justify Character must always be entered otherwise the first character of the line of

text will be taken as the Justify Character and it will not be displayed.

DM -2 -2 |CONTREC -2 -2 -2 |PLEASE WAIT -2 ETX

CONTREC

PLEASE WAIT

-

8/13/2019 5 ProtocolManual1010 BJ

26/118

8.4

Communication ProceduresSoftware Protocol Manual

20 SLIP+V3-001-SP1010A-BJ - 25/01/2006

Messaging Commands

To display a message to the operator with out any response, such as BAY CLOSED, the DM command

is used. The message can either be cleared by the computer by using the CM command or any other message

command can be sent to replace the displayed message.

The DP command requires a response from an operator by pressing the ENTER/YES key. The message can

either be cleared by the computer by using the CM command or any other message command can be sent

to replace the DP. If after an automatic timeout period sent as part of the DP command the message will

automatically be cleared.

After the instrument has received the DM or DP command, the instrument response to the ENQ command

will be DM or DP respectively. After the operator has acknowledged a DP command by pressing the

ENTER/YES key, the instrument display will show 'PLEASE WAIT', and the response to the ENQ

command from the computer will now be MT (message taken). The host computer knowing the state of the

instrument from the ENQ response can then return the instrument to its normal operating mode by sending

a CM command or continue with other messages as required.

To get an answer from the instrument operator in the form of data, the GA, GC, GH, or GK commands are

used. For example if using the GA command to get a response form the operator: The operator must answer

the displayed question by either entering a number and pressing ENTER, or by pressing the YES, NO,

DISPLAY, ALPHA/LINE, STOP or START keys. After the instrument has received the GA command, the

instrument response to the ENQ command will be GA. After the operator has answered the message, the

instrument will display the answer and the message 'PLEASE WAIT'. The instrument response to the ENQ

command from the computer will now be AA (Answer Available). The answer is returned as the last

parameter in the AA ENQ response.

To retrieve a PIN or Password GH is used to hide the operators response. If a touch key or swipe card is

fitted to the instrument then the following commands may be available, GK (Get Touch Key) and GC (Get

Swipe Card). These commands allow a message to be displayed, prompting the operator to touch their key

or swipe their card.

ENQ response after a message has been acknowledge by the operator:

After using either the DM, DP, GA, GC, GH or GK commands, the instrument can be returned to its original

display with the CM command. The DM, DP, GA, GC, GH & GK commands must be used carefully,

otherwise the operator may become confused.

These commands can only be used for full screen messaging when the instrument is in the idle, RL or RA

states. The RL and RA states requiring Load Scheduling and Remote Authorise respectively to be enabled.

DM (Display Message) DP (Display Prompt) GC (Get Swipe Card)

GA (Get Answer) GH (Get Hidden Answer) GK (Get Touch Key)

SA (Send Answer) CM (Clear Message)

M T ( Me ss ag e T ak en ) A A ( An sw er A va il ab le ) C A ( Sw ip e C ar d A va il ab le )KA (Touch Key Answer

Available)

-

8/13/2019 5 ProtocolManual1010 BJ

27/118

8.4

Communication ProceduresSoftware Protocol Manual

SLIP+V3-001-SP1010A-BJ - 25/01/2006 21

Simple scrolling menu example using the GA command

To display a full screen message containing a scrolling menu (ignoring the field separator nulls):

The ENQ response changes from SS to GA. The following is displayed:

The operator presses the DISPLAY key and the ENQ response changes from GA to AA with the last

parameter indicating the key that was pressed, a D in this case.

The computer can now display second menu page to the operator (ignoring the field separator nulls):

The ENQ response changes from AA to GA. The following is displayed:

If complete the screen can be cleared using the CM command.

GA |ITEM 1 -2 |ITEM 2 -2 |ITEM 3 -2 |PRESS DISPLAY TO SCROLL -2 ETX

ITEM 1

ITEM 2

ITEM 3

PRESS DISPLAY TO SCROLL

DM |ITEM 4 -2 |ITEM 5 -2 |ITEM 6 -2 |PRESS DISPLAY TO SCROLL -2 ETX

ITEM 4

ITEM 5

ITEM 6

PRESS DISPLAY TO SCROLL

-

8/13/2019 5 ProtocolManual1010 BJ

28/118

8.4

Communication ProceduresSoftware Protocol Manual

22 SLIP+V3-001-SP1010A-BJ - 25/01/2006

Communications Timeout

When either Load Scheduling and/or Remote Mode are selected, the instrument automatically enables the

COMMS TIMEOUT function. This function sets the amount of time that the instrument will allows

without communications from the host. This timeout period can be altered from the -COMMUNCATIONS-

menu (See the Programming Manual).

Once this timeout period has elapsed the instrument assumes that communications have failed and allows

any load currently in progress to complete before forcing the operator to the disconnect prompt. It then

displays a Communcations failure error message until communications are restored.

Retrieval of Loading Records

ST (Send Transaction)

SY (Send Entry)

Loading data for each truck is stored in two sections in the instruments. The two sections are called

TRANSACTION and ENTRY. The transaction contains information about the load that is common to all

the compartments loaded, eg driver, truck, date, start time, load number etc. The entry data contains

information for each compartment/batch that the instrument has attempted to load, eg compartment number,

arm number, preset quantity, gross loaded etc.

The instrument stores the last 200 transactions in battery backed memory. If the computer database is

destroyed or cleared, the last 200 transactions can be read from the instrument. There is no restriction on the

order in which transactions or entries must be uploaded. Each transaction records the number of entries

associated with it, by storing the first entry and the last entry in the entry start and entry stop fields of the

transaction. Each entry records the transaction with which it is associated by storing the transaction number

in its transaction number field. Entries are stored in a circular buffer, 1400 entries long. The entries are

numbered 0 to 1399 inclusive.

When a transaction is uploaded to the computer, the entry start and entry stop fields should be examined to

determine which entries should be uploaded from the instrument. If the transaction has an entry start value

of 1398 and an entry stop value of 1, the entry numbers associated with the transaction are 1398, 1399, 0

and 1.

Programming tip for C programmers:

/* if entry_start = 1398 and entry_stop = 1, add 1400 to entry_stop*/ if (entry_stop < entry_start)

entry_stop += 1400;

/* When requesting entries from the 1010, use the modulus operator with

1400 to request the entry. */

for (i=entry_start; i

-

8/13/2019 5 ProtocolManual1010 BJ

29/118

8.4

Communication ProceduresSoftware Protocol Manual

SLIP+V3-001-SP1010A-BJ - 25/01/2006 23

Retrieval of Batch Records During the Loading Process

It is recognised that from time to time entry/batch information is required before the load operation iscomplete. Because the ST and SY commands can only be used while the instrument is in the idle state, the

BT command must be utilised during the loading process to obtain entry/batch information.

The computer must monitor the loading process via the ENQ command. Once it is established that a

particular batch has completed (arm completed bit set - See Arm Status Byte (applies to all arm status

bytes) on page 57.) the BT command can then be used to obtain the batch information. The BT command

is not available while a batch is in progress.

-

8/13/2019 5 ProtocolManual1010 BJ

30/118

8.4

Communication ProceduresSoftware Protocol Manual

24 SLIP+V3-001-SP1010A-BJ - 25/01/2006

-

8/13/2019 5 ProtocolManual1010 BJ

31/118

SLIP+V3-001-SP1010A-BJ - 25/01/2006 25

8.5

Error Status Codes

Description

When an instrument detects an external error or fault condition, the error code for that condition is recorded

in the entry segment of the transaction file.

The following Error Status codes are valid for the 1010A- unit.

Error Status 1 - ESD/Emergency Stop

This error is recorded if the emergency stop signal is detected by the instrument. All arms are stopped and

the unit is disabled from further use until restored by a manager reset (MR). The MR bit in the ENQ command

will also be set indicating that a MR is required.

Error Status 2 - Overfill Disconnected

This error is recorded if the overfill has been disconnected or tripped, and has not been reconnected or cleared

within the programmed Clear/Reconnect time. All current batches in progress are terminated.

Error Status 3 - Vapour Recovery Disconnected

This error is recorded if the vapour recovery hose has been disconnected from its coupling and has not been

reconnected within the programmed Clear/Reconnect time. All current batches in progress are terminated.

Error Status 4- Flowmeter ErrorThis error is recorded when a flowmeter pulse error is detected on an arm during a batch. The instrument must

be configured for a dual pulse flowmeter. The batch will be terminated.

Error Status 5- Flowmeter Timeout

This error is recorded if there is an absence of flowmeter pulses for a time exceeding the no flow timeout

period during a load. The batch will be terminated.

Error Status Codes(*MA unit only)

0 - No Error 7 - Valve Fault 14 - No Additive

1 - ESD/Emergency Stop 8 - Deadman Timeout 15 - Remote Stop2 - Overfill Disconnected 9 - Expansion Comms Timeout* 16 - LCD Failure

3 - Vapour Rec. Disconnected 10 - Power Failure 17 - Phase Error

4 - Flowmeter Error 11 - High Additive

5 - Flowmeter Timeout 12 - Low Additive 99 - Transaction File in use

6 - Temperature Fault 13 - Additive Comms 100 - Illegal Flow

-

8/13/2019 5 ProtocolManual1010 BJ

32/118

8.5

Error Status CodesSoftware Protocol Manual

26 SLIP+V3-001-SP1010A-BJ - 25/01/2006

Error Status 6- Temperature Fault

This error is recorded when a temperature sensor fault is detected on an arm during a batch. The batch will

be terminated and an error recorded. This disables the arm from further use, and requires a manager reset

(MR) to re-enable the arm. The MR bit in the ENQ command will also be set indicating that a MR is required.

Error Status 7- Valve Fault

This error is recorded at the completion of a batch when the flowrate is outside the deadband limit during

prestop. No batch termination.

Error Status 8- Deadman Timeout

This error is recorded and all batches are cancelled when the operator has not pressed any key for five minutes

since starting a load. Typically, an external reminder indicator would have been activated after 2 minutes.

All loads are paused when the operator has not pressed any key for three minutes since starting a load. Only

after the 5 minutes without any key presses is this error recorded and the transaction terminated.

Error Status 9- Expansion Comms Timeout

This error is recorded when the expansion communications between a unit and modules fails during a batch.

The transaction is terminated and the fault must be fixed before the unit can be used again.

Error Status 10- Power Failure

This error is recorded when the instrument detected a power failure during loading.

Error Status 11- High Additive

This error is recorded when an attached Model 1020 additive injection controller cannot slow down the

additive delivery for an additive injector during a batch. The batch is terminated.

Error Status 12- Low Additive

This error is recorded when an attached Model 1020 additive injection controller cannot deliver enough

additive for an additive injector during a batch. The batch is terminated.

Error Status 13- Additive Comms

This error is recorded when communications with an attached Model 1020 additive injection controllers fails,

and all active arms are stopped. The transaction is terminated.

Error Status 14- No Additive

This error is recorded when an attached Model 1020 additive injection controller detects no additive flow for

an additive injector during a batch. The batch is terminated.

Error Status 15- Remote Stop

This error is recorded when a valid external remote stop (SM command) is received by the instrument. The

specified batch (indicated by arm number) is terminated.

-

8/13/2019 5 ProtocolManual1010 BJ

33/118

8.5

Error Status CodesSoftware Protocol Manual

SLIP+V3-001-SP1010A-BJ - 25/01/2006 27

Error Status 16- LCD Failure

This error is recorded when a LCD failure is detected on the graphic display. The batch will be terminatedand the instrument restarted. On restart a warning message will be displayed.

Error Status 17- Phase Error

This error is recorded when a flowmeter phase error is detected on an arm during a batch. The instrument

must be configured for a dual pulse flowmeter. The batch will be terminated.

Error Status 99 - Transaction File in use

This error is recorded when either the transaction and/or entry are not completed successfully or there has

been an attempted access of the transaction file using the BT command while the transaction and/or entry are

still being written to/used internally by the instrument.

Error Status 100 - Illegal Flow

This error is recorded when an unauthorised flow has been detected. A new entry and/or transaction is created

to record the event.

-

8/13/2019 5 ProtocolManual1010 BJ

34/118

8.5

Error Status CodesSoftware Protocol Manual

28 SLIP+V3-001-SP1010A-BJ - 25/01/2006

-

8/13/2019 5 ProtocolManual1010 BJ

35/118

SLIP+V3-001-SP1010A-BJ - 25/01/2006 29

8.6

Commands

Description

The following section describes the command format for the 1010A-BJ instrument or instrument

compatible with the Model 1010A loading system using the SLIP+ command set. For other instruments

please refer to the appropriate software protocol manual.

Notes

The two byte command within any information field should be valid for the unit addressed (must be

one of the commands described in this section of this manual). Otherwise the unit being address will

not respond (not even with a NAK response).

For backward compatibility purposes, allowances should be made for extra parameters to be added

to a command in the future.

For backward compatibility purposes, allowances should be made for extra characters to be added

to parameters.For backward compatibility purposes, the instrument supports the use of the older DM,

DP, GH, and GK commands. See the Appendix for details.

-

8/13/2019 5 ProtocolManual1010 BJ

36/118

8.6 AA - Alter Arm Name

CommandsSoftware Protocol Manual

30 SLIP+V3-001-SP1010A-BJ - 25/01/2006

AA - Alter Arm Name

Description

Remotely set the load arm name to be displayed on the instrument.

Send

Receive

Notes

The arm name can also be edited from within the arm configuration menu.

Related Commands

None.

Constraints

Instrument must be in the idle state.

This command requires extra time as the instrument must update the non-volatile memory. A minimumof 3 extra seconds should be allowed for both waiting for an acknowledge (ACK) response and before

another command is sent to the instrument.

Control Byte Information Fields

STX [AA] 0 [a] 0 [b] 0 [ETX]

where

a = arm number [x]

b = arm name [xxxxxxxx]

Control Byte Information Fields

ACK

NAK If the requested arm number does not exist

If the number of parameters is less than 2

If the number of characters within parameter b exceeds 8

-

8/13/2019 5 ProtocolManual1010 BJ

37/118

AI - Additive Injectors 8.6

CommandsSoftware Protocol Manual

SLIP+V3-001-SP1010A-BJ - 25/01/2006 31

AI - Additive Injectors

Description

Returns the additive parameter settings for the particular 1010 unit being addressed.

Send

Receive

Notes

None

Related Commands

AP, AS.

Constraints

Instrument must be in the idle state.

Control Byte Information Fields

STX [AI] 0 [ETX]