43._FabSS_Plating.pdf

-

Upload

danilo-de-juras -

Category

Documents

-

view

215 -

download

0

Transcript of 43._FabSS_Plating.pdf

Standards Information BookletFabricating of Steel Structures (Plating)

National/Scottish Vocational Qualification

CONTENTS

1. WHAT IS AN N/SVQ? ~ 41.1 WHAT IS THE PROCESS INVOLVED IN ACHIEVING AN N/SVQ? 51.2 WHAT WILL BE ASSESSED? 81.3 HOW WILL ASSESSMENT TAKE PLACE? 81.4 SIMULATION REQUIREMENTS 101.5 ASSESSMENT OF CANDIDATES WITH PARTICULAR ASSESSMENT

REQUIREMENTS 101.6 RECOMMENDED PRIOR LEARNING 121.7 CAREER DEVELOPMENT WITHIN THE ENGINEERING

CONSTRUCTION INDUSTRY 121.8 KEY SKILLS 14

2. QUALIFICATION STRUCTURE ~ 152.1 FABRICATING OF STEEL STRUCTURES (PLATING) N/SVQ 152.2 UNIT SUMMARIES 16

3. FABRICATING STEEL STRUCTURES STANDARDS ~ 18MANDATORY UNITS 18Unit FSS1: Shape components of fabricated steel structures by materialremoval using hand tools (powered and unpowered) (ECITB/ECS 3.03) 18

Unit FSS2: Prepare work areas for the fabrication of steel structures(Plating) (ECITB/ECS 2.11) 22

Unit FSS3: Prepare materials for the fabrication of steel structures(Plating) (ECITB/ECS 2.12) 24

Unit FSS4: Prepare equipment for the fabrication of steel structures(Plating) (ECITB/ECS 2.13) 26

Unit FSS5: Reinstate the work area after completing the fabricationof steel structures (Plating) (ECITB/ECS 2.15) 28

Unit CO1: Contribute to effective working relationships (ECITB/ECS 8.02) 30Unit CO2: Work safely, minimise risk and comply with emergency procedures(ECITB/ECS 7.06) 32

Unit CO3: Identify and deal with hazards in the work environment(ECITB/ECS 7.04) 34

TECHNICAL OPTIONS 36Unit FSS6: Assemble components of steel fabrications (Plating) to meetspecification (ECITB/ECS 3.12) 36

Unit FSS7: Store steel structure fabrication related resources forfurther use (ECITB/ECS 2.16) 39

Unit FSS8: Manually form components to specification (ECITB/ECS 3.16) 41Unit QSE 9 Join materials by manually controlled welding process(ECITB/ECS 3.09) 43

3

IntroductionThis booklet has been developed to provide anyone considering a National or ScottishVocational Qualification (N/SVQ) with an introduction to the awards currentlyavailable through ECITB. This booklet contains a copy of the National OccupationalStandards (NOS) for the vocational qualification/s (VQs) listed on the front cover ofthis booklet as well as: a summary of the way in which N/SVQs are constructed; whatthe process is in achieving an N/SVQ; and how it is assessed.

Should you have any queries, or require any further information regarding the awardsoffered by ECITB please contact the VQ Administrator at:

ECITB Blue CourtChurch LaneKings LangleyHertfordshireWD4 8JP

Tel: 01923 260000e-mail: [email protected] Body website: http://awardingbody.ecitb.org.ukwebsite: www.ecitb.org.uk

4

1. What is an N/SVQ?National/Scottish Vocational Qualifications (N/SVQs) are work-based qualificationswhich are based on the National Occupational Standards (NOS) of that particularsector of industry. NOS are developed by employers and professional bodies inconjunction with the Standard Setting Body and describe what is meant byoccupational competence within a particular job role.

All N/SVQs are structured in such a way that they can be broken down into thefollowing common parts:• Units;• Performance Statements;• Scope;• Evidence requirements; and• Knowledge statements.

Each of these parts is further described below.

An N/SVQ is divided into units, each of which describes anactivity which the candidate will be expected to performcompetently.

Performance Statements are a group of sentences whichdescribe the level and quality of the performance expected ofthe candidate during a particular activity or unit.

The Scope of a unit describes the various circumstances inwhich the candidate would be expected to perform in order tobe deemed competent.

The evidence requirements of a unit define the amount and typeof evidence necessary to demonstrate that the candidate hassuccessfully met the standard described in the performancecriteria and in the circumstances outlined in the Scope.

In addition to performing an activity to a certain standard thecandidate is required to demonstrate a knowledge andunderstanding of the key principles and facts which underpincompetent performance. These key principles and facts areoutlined within the Knowledge Statements section of the unit.

Units

PerformanceStatements

Scope

Evidencerequirements

KnowledgeStatements

5

1.1 What is the process involved in achieving an N/SVQ?Once a candidate has been registered with the awarding body, in this case ECITB, theywill be ready to begin working towards their N/SVQ. They will then be introduced tothe Assessor who will offer support and guidance as the candidate progresses throughthe stages of the qualification. The Assessor will firstly introduce the candidate tothe other key members of the N/SVQ system. These will include:• the Expert Witness Adviser;• Internal Verifier;• the approved centre;• the centre co-ordinator;• the External Verifier;• the Lead Verifier;• the awarding body;• the Standard Setting Body; • the Qualifications and Curriculum Authority (QCA) and• the Scottish Qualifications Authority (SQA).

The Assessor will also explain what roles each of these key members will play inassuring the quality of the N/SVQ system. This is vitally important as it helps toensure that the assessment of qualifications is valid and reliable and that certificatesare only awarded to those candidates who do successfully meet the standardsrequired.

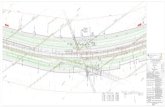

The diagram below illustrates the flow of information between each of the keymembers.

Assessor

T

CandidateInternalverifier

Approved Centre

ExternalVerifier

Awarding Body Standards Setting Body

Ofqual/SQA

Lead verifier

ExpertWitness Adviser

6

* Replacement qualifications for D Units from September 2002.

Who’s who What is their role?

CandidatesIndividuals seeking validation for theirachievements and competence.

• Show they can perform to national standards in order to beawarded a VQ and demonstrate the specified knowledge,understanding and skills.

• Take some responsibility for the quality of evidence providedto Assessors.

AssessorsAppointed by an approved centre toassess a candidate’s evidence. In directcontact with candidates. Hold D32 andD33 or A1*.

• Judge candidates’ evidence against the national standards.• Advise candidates on opportunities to collect evidence.• Decide whether the candidate has demonstrated competence,

give feedback on the decision and record it.• Ensure that their assessment practice meets awarding body

guidance and D32 and D33 or A1*.

Internal VerifiersAppointed by an approved centre toensure consistency and quality ofassessment. Hold D34 or V1*, and D32and D33 or A1*.Work to the ECITB Code of Practice.

• Work with Assessors to ensure the quality and consistency ofassessment.

• Sample candidate assessments to ensure consistent assessment.• Ensure that their own verification practice meets D34 or V1*.• Ensure that assessment and verification records and documents

are fit for purpose and meet awarding body requirements.• Ensure that requests for certificates to the awarding body are

based on assessments of consistent quality.• Provide support and guidance for the centre’s Assessors.

Approved centresOrganisations approved by awardingbodies to assess and verify qualifications.

• Manage assessment and verification on a day-to-day basis.• Have effective assessment practices and internal verification

procedures.• Meet awarding body requirements for qualification delivery.• Have sufficient competent Assessors and Internal Verifiers with

enough time and authority to carry out their roles effectively.

Centre co-ordinatorsMay take on some Internal Verifierfunctions, particularly relating toadministration. Not all centres have co-ordinators.

• Act as a contact for the awarding body and the ExternalVerifier.

• Ensure that there are accurate assessment and verificationrecords for the qualification.

• Request certificates from the awarding body.

The following tables summarise the roles which each of the key members perform inquality assuring the N/SVQ system.

Expert Witness Adviser (EWA)Appointed by an approved centre toassess a candidate’s evidence. In directcontact with candidates.

• Can carry out direct observation of the candidate against the criteriafor the mandatory assessor observation of Performance Statementsand Scope coverage where the practicalities of having an assessoravailable to observe the candidate at work are prohibitive.

• The EWA shall meet the criteria for assessor occupational expertiseas specified by the ECITB Standards Setting Body AssessmentStrategy.

• A registered EWA can provide mandatory direct observation of anycandidate in the relevant qualification for any approved centre as longas the assessor/EWA procedures are followed.

7

Who’s who What is their role?

Lead VerifiersAppointed by the ECITB Awarding Bodyto manage teams of External Verifiers.

• Manage the workload of the External Verifiers.• Monitor performance of the External Verifiers.• Provide advice and guidance to External Verifiers.• Carry out all new centre approvals.• Approve post-approval monitoring reports and ensure all

actions are implemented.• Approve any recommendations for sanctions on centres.• Resolve disputes.

Awarding bodiesAn organisation approved by theQualifications and Curriculum Authority(QCA) and Scottish QualificationsAuthority (SQA) to award N/SVQs.

• Ensure the quality and consistency of assessment forqualifications nationally.

• Produce guidance for centres.• Appoint, support and develop External Verifiers, allocate

them to centres and monitor their work.• Approve and monitor centres against the approved centre

criteria.• Collect information from centres to inform national decisions

about qualification delivery.• Provide information to QCA and SQA.

Standards Setting Bodies (SSBs)Develop the National OccupationalStandards (NOS) on which VQs arebased.

• Work with industry to develop National OccupationalStandards.

• Work with awarding bodies to produce assessment strategies.• Provide information about, and clarification of, the National

Occupational Standards.

Regulatory AuthoritiesQCA is the accrediting body forqualifications in England, Wales andNorthern Ireland.SQA is the accrediting body forqualifications in Scotland.

• Accredit qualifications put forward by awarding bodies ifthey meet the published criteria.

• Ensure the quality of the overall qualification system throughwork with awarding bodies.

• Monitor the performance and effectiveness of awardingbodies through quality audits.

* Replacement qualifications for D Units from September 2002

External VerifiersAppointed by the ECITB Awarding Bodyto monitor the work of approved centres.They are the key link between theawarding body and the centre. Hold D35or V2* and D32 and D33 or A1*. Work to the ECITB Code of Practice.

• Make sure that decisions on competence are consistent acrosscentres.

• Make sure that the quality of assessment and verificationmeets national standards.

• Sample candidate assessments and monitor assessment andverification practices in centres.

• Provide advice, guidance and feedback to centres.• Make regular visits to centres and assessment locations.• Ensure that their own verification practice meets D35 or V2*

and D32 and D33 or A1*. • Approve recommendations for appointment of new Assessors

and Internal Verifiers.

8

1.2 What will be assessed?Once the candidate has decided with the Assessor which route they will take through thequalification, i.e. the units which will be undertaken, they are ready to begin assessment.Broadly speaking two aspects of the candidate’s working practice will be assessed: theirperformance; and their knowledge and understanding. The Assessor will work with thecandidate to plan how, when and where evidence will be gathered to cover these aspects.

1.3 How will assessment take place?There are a variety of methods through which evidence of the candidate’s competencecan be gathered. There are also different methods by which to collect performance andknowledge evidence.

In relation to performance evidence there are five main assessment methods:• Direct observation of the candidate’s performance by the Assessor and or EWA;• Testimony from a witness such as a candidate’s colleague, this is also observation of

the candidate;• Documentary evidence (such as permits to work, work specifications etc.) which relate

to work successfully completed by the candidate on a past occasion; and • Demonstration of a task by the candidate at the Assessor’s request. This is known as

‘Simulation’• Questioning of the candidate to establish knowledge and understanding requirements

These options give an Assessor and the candidate some flexibility in how they are able toprove competence. However, some of these assessment methods are less reliable and assuch their use may be limited within the qualification. If this is the case the guidancecontained within the National Occupational Standards will provide further clarification.Direct observation of the candidate by the Assessor is the most reliable, and often themost straightforward, method of gathering evidence. The approved centre and theassessment team responsible for assessing the candidate will determine whetherobservation or some of the other assessment methods listed above offer the bestassessment solution for each individual candidate.

In relation to evidence of knowledge and understanding there are two main assessmentmethods:• Performance evidence gathered in the course of working towards the unit; and • Questioning of the candidate.

In some instances, it will be self-evident from the candidate’s performance that theyhave acquired the necessary knowledge and understanding e.g. where the unit requiresknowledge of how to carry out a specific task and by carrying it out effectively thecandidate demonstrates that they know what to do.

However, knowledge of why something is done in a certain way cannot be demonstratedthrough performance alone. Another assessment method must be used involvingquestioning of the candidate.

KNOWLEDGE & UNDERSTANDING LEVELSThe Knowledge and Understanding levels are expected to be interpreted as follows:

An appreciationThe expression “an appreciation” is intended to indicate a level of knowledge andunderstanding equating to an awareness of the existence, scope of and background to the

9

matters covered by the knowledge and understanding statement. You will be expected toknow how to find further detail and who in your organisation can provide you with theinformation that you may need. Having obtained the information, you will be expected tocheck your interpretation of the information gathered and then to be able to apply it toyour situation.

Working Knowledge (Please note this descriptor)The expression “working knowledge and understanding” is intended to indicate theminimum level of knowledge and understanding sufficient to perform your role in a mannerthat would normally be associated with the minimum acceptable performance of acompetent person undertaking your role. You will be able to identify and apply relevantinformation, procedures and practices to your usual role in your expected workingenvironments needing only occasional recourse to reference materials. You will know,understand and be able to describe, in your own words, the principles underlying yourworking methods. It is not intended that a “working knowledge and understanding” infersthe ability to quote “chapter and verse”. Rather you must know what supportinginformation is available, how and where to find it and from whom to seek further guidanceand information to confirm any additional required detail. You must be able to interpretand apply the information obtained to your role, your working practice and in yourexpected working environments.

Detailed KnowledgeThe expression “detailed knowledge and understanding” is intended to indicate anenhanced level of knowledge sufficient that you, as a competent person, need to refer tosource material and references for specific detail or interpretations as an exceptionrather than the rule and then usually only when faced with unfamiliar situations. You willbe able to understand and explain to others the application of the principles and theoriesunderpinning the procedures, practices and policies affecting your work. You will be ableto analyse data and situations and make valid judgements about your working situation onthe basis of those procedures, practices and policies. You will be able to proposesolutions to problems arising in the course of your normal role and in your expectedworking environments. Competent persons having a “detailed knowledge andunderstanding” will be capable of applying their knowledge and understanding for thebenefit of themselves and others and will be able to explain relevant matters to workcolleagues when providing guidance and additional information.

Expert KnowledgeThe expression “expert knowledge and understanding” is intended to indicate a very highlevel of knowledge and understanding sufficient that the competent person only needs torefer to source material and references in the rarest of circumstances pertaining tocircumstances not usually encountered in their usual working regime. You will understandand be able to explain the application, limitations and interrelationship between principles,theories and concepts that underpin your role. You will be able to use your theoreticalknowledge to enhance and underpin your understanding of the procedures, policies andpractices relevant to your role and will be able to propose considered and valid variationsfrom the norm based on your expertise. You will be able to use your knowledge andunderstanding to evaluate and interpret complex situations pertaining to your individualworking practice and to the working practices of colleagues in similar roles. You will be ableto generate and propose valid solutions to problems encountered in your role. Competentpersons having an “expert knowledge and understanding” will be capable of passing on theirknowledge and understanding to and developing less knowledgeable colleagues.

10

1.4 Simulation requirementsDemonstration, as outlined above, is one of the assessment methods available tocandidates and Assessors through which to observe a candidate’s competence. Howeverits use has been limited to certain specific units in which it may be possible to gather thenaturally occurring workplace evidence normally required.

Reference needs to be made to the standards to confirm the status of each unit,however, as a rule simulation is only permissible where one or more of the followingcharacteristics apply:a) health and safety could be compromised by seeking workplace evidence;b) the behaviour or situation under which assessment occurs happens infrequently in the

workplace;c) the responsibility for the work rests with the candidate, but it is typically either

delegated or carried out jointly with another and the candidate has limited opportunityto demonstrate it directly and individually;

d) there would be unacceptable commercial or operational risk in securing workplaceassessment;

e) facilities would need to be placed in an unacceptable operating state to allow forassessment to take place.

A statement within each unit clearly identifies whether or not simulation is permittedwithin the assessment for that unit.

Where simulation is permitted, the simulated activity must be designed to reflect theactivity as it would be carried out in a typical workplace environment, including:a) the presence, actions and capabilities of other interacting personnel;b) the urgency with which the activity must be carried out and the time needed to

complete it;c) the number and sequence of actions needed to complete the activity;d) the number and complexity of the factors affecting the activity;e) the skills and knowledge needed to carry out the activity;f) the nature and availability of resources needed to carry out the activity;g) access to references and sources of advice and assistance that could be needed if

problems arise;h) the type of documentation to be completed;i) the standards to which the activity must be carried out, including any practices and

procedures which must be followed;j) the outcomes which the activity will produce;k) access to normal/usual workplace instructions.

1.5 Assessment of candidates with particular assessment requirementsEqual Opportunities, Reasonable Adjustments and Special Considerations.

Access to fair assessmentThe ECITB awarding body requires approved centres to demonstrate a clear commitmentto access to fair assessment, equal opportunities, reasonable adjustments and specialconsiderations and to operate a Fair Assessment Policy in all matters concerning theassessment of candidates for the award of VQs and/or certificates or unit credits and inany appeals against approved centre decisions.

The policy must take account of full current legislation in the area of access to fairassessment and equal opportunities. This must include:

11

• The Race Relations Act Amendment• The Disability Discrimination Act• The SEN and Disability Rights in Education Act• The Human Rights Act

The approved centre must ensure that relevant staff in the assessment team receivestraining in the relevant sections of current legislation and that sufficient and appropriateinformation with regard to the content of this procedure is passed to all members of theapproved centre assessment team.

The approved centre must maintain records of assessment and verification decisions,which demonstrate that:• Assessment decisions only discriminate between candidates on the basis of the

competence defined by the occupational standards specified in the VQ • Assessment judgements are made regardless of age, gender, ethnic origin, disability or

employment status (employed or unemployed)

Arrangements for candidates with particular assessment requirements

PrinciplesApproved centres must ensure that there are no unnecessary barriers to assessment,which prevent candidates from effectively demonstrating their attainment. Arrangementsfor candidates with particular assessment requirements (special arrangements) must alsoensure that such candidates are not given, or do not appear to be given, an unfairadvantage. Special arrangements are generally not appropriate where the candidate'sparticular difficulty directly affects performance in the actual attributes that are thefocus of assessment.

Approved centres must make special arrangements according to the needs of theindividual candidate, reflecting the candidate's usual method of working, the assessmentrequirements as set out in the specification and any guidelines set down by the regulatoryauthorities. Any special arrangements must ensure that the validity, reliability andintegrity of the assessment are preserved and that certificates accurately reflectcandidate attainment.Approved centres are only required to do what is ‘reasonable’ in terms of giving access.What is reasonable will depend on the individual circumstances, cost implications and thepracticality and effectiveness of the adjustment. As stated above the NOS must betaken into consideration, as must any safety and health implications.

There are two ways in which access to fair assessment can be maintained• Through reasonable adjustments• Through special consideration

Reasonable AdjustmentsA reasonable adjustment is any action that helps to reduce the effect of a disability thatplaces the candidate at a substantial disadvantage in the assessment situation.

Reasonable adjustments must not affect the integrity of what needs to be assessed, butmay involve:• Changing standard assessment arrangements, for example allowing candidates extra

time to complete the assessment activity• Adapting assessment materials, such as providing materials in Braille

12

• Providing access facilitators during assessment, such as a sign language interpreter ora reader

• Re-organising the assessment room, such as removing visual stimuli for an autisticcandidate.

Reasonable adjustments will not be taken into consideration during the assessment of thecandidates work.

Special ConsiderationSpecial consideration is given following an assessment to candidates who are present forthe assessment but may have been disadvantaged by temporary illness, injury or adversecircumstances, which arose at or near the time of assessment. Special consideration should not give the candidate an unfair advantage neither should itsuse cause the user of the certificate to be misled regarding a candidate’s achievements.The candidate’s result must reflect his or her achievement in the assessment and notnecessarily his or her potential ability.

Where an assessment requires a competence, criteria or standard to be met fully, it maynot be possible to apply special consideration. In some circumstances it may be moreappropriate to offer the candidate an opportunity to retake the assessment at a laterdate or to extend the registration period so that the candidate has more time tocomplete the assessment activity.

Approved centres must make provision for special consideration to ensure that candidateswho suffer temporary illness, injury or indisposition at the time of assessment aretreated fairly. Such assessment should be made available to the candidate as soon as isreasonably practical within the guidelines of access to fair assessment. Where this is notpossible, the awarding body will consider each individual case for special consideration,identifying the minimum requirements for an award to be made.

ProceduresApproved centre assessment team should refer to the written procedures provided withinthe ECITB Vocational Qualifications Quality Assurance Procedures Manual for furtherguidance and information or to their own Approved Centre Operations Manual.

Monitoring and reporting The awarding body will monitor, evaluate and report annually on the use of specialarrangements by its approved centres. Relevant data will be shared with the regulatoryauthorities on request.

1.6 Recommended prior learningThere is no prior knowledge, attainment or experience required for this qualification.Existing workers are expected to be competent by virtue of their length of service andexperience and satisfactory performance in their roles, and will need to achieve thequalification in order to have this competence validated.

1.7 Career development within the engineering construction industry The ECITB’s Apprenticeship programme is its main vehicle for recruiting and trainingyoung people to meet the future skills requirements of the industry. N/SVQs at Level 3are an integral part of this scheme.

The ECITB provides an alternative training route towards N/SVQs for those who havenot completed an apprenticeship but seek to have their competence validated.Information on the scheme is available on request from ECITB offices.

13

Aprogressive

trainingroute

Unit No Application Communication Information Improving own learning Problem Workingof number Technology and performance solving with others

CO1 2 2 2 2 2 2CO2 2 2 2 1 2 2CO3 2 2 2 1 2 1FSS1 2 2 1 1 2 1FSS2 2 2 1 1 2 2FSS3 2 2 1 1 2 2FSS4 2 2 1 1 2 2FSS5 2 2 1 1 2 2FSS6 2 2 1 1 2 1FSS7 2 2 1 1 2 2FSS8 2 2 1 1 2 1QSE9 2 2 1 1 2 1

14

1.8 Key SkillsThis section outlines the relationships between the qualification in Fabricating of SteelStructures (Plating), and the nationally recognised ‘Key Skills’. Key Skills define thosegeneric work-related skills that individuals need in order to be effective, flexible andadaptable workers. These include: • Application of number • Communication• Information Technology• Improving own learning and performance• Problem solving• Working with others

There are five levels of Key Skills, level 5 being the most advanced. In the tablesbelow the numbers in each of the cells represent a link between the relevant ECITBunit and the Key Skill at that level. This means that in the course of working towardsthat unit of the N/SVQ the candidate may also demonstrate communication skills, forexample, to Key Skills level 2.

The tables below summarise the links between each of the units in the Fabricating ofSteel Structures (Plating) qualification, and the Key Skills areas.

15

2. Qualification Structure ~2.1 Fabricating of Steel Structures (Plating) N/SVQ

Candidates must achieve TEN units made up of: • all EIGHT of the Mandatory units;

plus• TWO further units from the Technical Options.

MANDATORY UNITS - Candidates must achieve all EIGHT unitsUnit Title and Ref. NumberUnit FSS1: Shape components of fabricated steel structures by material removal using hand tools (powered andunpowered)Unit FSS2: Prepare work areas for the fabrication of steel structures (Plating)Unit FSS3: Prepare materials for the fabrication of steel structures (Plating)Unit FSS4: Prepare equipment for the fabrication of steel structures (Plating)Unit FSS5: Reinstate the work area after completing the fabrication of steel structures (Plating)Unit CO1: Contribute to effective working relationshipsUnit CO2: Work safely, minimise risk and comply with emergency proceduresUnit CO3: Identify and deal with hazards in the work environment

TECHNICAL OPTIONS - Candidates must achieve any TWO units.Unit Title and Ref. NumberUnit FSS6: Assemble components of steel fabrications (Plating) to meet specificationUnit FSS7: Store steel structure fabrication related resources for further useUnit FSS8: Manually form components to specificationUnit QSE9: Join materials by manually controlled welding process

16

2.2 Unit SummariesMandatory units

Unit FSS1: Shape components of fabricated steel structures by materialremoval using hand tools (powered and unpowered)This unit is about shaping materials using the appropriate materials and techniques andchecking that the specification has been met.

Unit FSS2: Prepare work areas for the fabrication of steel structures(Plating)This unit is about ensuring that the work area is ready and suitable for the engineeringactivities to be carried out.

Unit FSS3: Prepare materials for the fabrication of steel structures(Plating)This unit is about obtaining and preparing materials using the appropriate equipment.

Unit FSS4: Prepare equipment for the fabrication of steel structures(Plating)This unit is about obtaining and conducting the appropriate safety checks andpreparations in relation to equipment.

Unit FSS5: Reinstate the work area after completing the fabrication ofsteel structures (Plating)This unit is about separating and correctly storing equipment, components andmaterials for reuse as well as waste items for disposal. It also involves restoring thework area to a safe condition.

Unit CO1: Contribute to effective working relationshipsThis unit is about establishing and maintaining productive working relationships.

Unit CO2: Work safely, minimise risk and comply with emergency proceduresThis unit is about working in line with health and safety regulations and legislation atall times and dealing appropriately with risks of injury to people or damage to property.

Unit CO3: Identify and deal with hazards in the work environmentThis unit is about checking for and identifying potential hazards. It also involvestaking the appropriate action to minimise the risks posed.

17

Technical options

Unit FSS6: Assemble components of steel fabrications (Plating) to meetspecificationThis unit is about assembling components in the correct position and securing themusing specified connectors and devices.

Unit FSS7: Store steel structure fabrication related resources for furtheruseThis unit is about storing resources safely, and clearly identified, in a suitable positionin the appropriate storage location.

Unit FSS8: Manually form components to specificationThis unit is about shaping materials to the required specification using appropriatemethods and techniques and ensuring that all the required shaping operations havebeen completed to the required standard.

Unit QSE9: Join materials by manually controlled welding processThis unit is about producing joints as specified using the appropriate thermal joiningtechnique and to the required quality and dimensional accuracy.

3. Fabricating Steel Structures StandardsMandatory UnitsUnit FSS1: Shape components of fabricated steel structures by material removal using handand powered tools (ECITB/ECS 3.03)

18

Performance Statements You must:

Knowledge statementsYou must have knowledge and understanding of:

a. Work safely at all times, complyingwith health and safety and otherrelevant regulations and guidelines

b. Follow relevant specifications for thecomponent to be produced

c. Obtain the appropriate tools andequipment for the shaping operationsand check they are in a safe and usablecondition

d. Shape the materials using appropriatemethods and techniques

e. Check that all the required shapingoperations have been completed to therequired specification

f. Deal promptly and effectively withproblems within your control andreport those that cannot be solved

i. Health and safety legislation, regulations and safe workingpractices and procedures. You must have a working knowledge and understanding ofwhat your responsibilities are in respect of health and safetylegislation, regulations, safe working practices, local, nationaland site specific procedures. This could be expected toinclude relevant sections of Health and safety at Work Act,PUWER, LOLER, COSHH, RIDDOR, Construction PPE,Confined Space, Abrasive Wheels, Electricity at Work,Manual Handling, Risk Assessment, CDM, VDU, COMAH, andRSI regulations. Permit to work system, method statements,working at heights and over water, and local guidance notes.

ii. Engineering drawings and related specifications. You must have a working knowledge and understanding of thespecifications to which you will be expected to work, includingtechnical drawings (component, assembly, generalarrangements, isometrics, 1st and 3rd angle projections),method statements and product worksheets, tolerances.

iii.Hand tool shaping methods and techniques. You must have a working knowledge and understanding ofwhich shaping techniques are available and suitable forachieving different specifications, and what the standardpractices are for using the techniques applied, including anysequencing of stages of work, and what ways these cansafely be modified to meet particular needs. This could beexpected to include methods of securing the workpiece ifrequired.

iv.Material handling and preparation methods. You must have a working knowledge and understanding of thetypes of preparations needed for different materials, whatthe handling characteristics are of the materials used andhow that affects shaping. This could be expected to includehot and cold working.

v. Types and application of hand and powered tools. You must have a working knowledge and understanding oftypes and application of hand and powered tools, and how toensure that powered tools are set up, used and closed downsafely. This could be expected to include compressed gases,pneumatics, hydraulics, electrical and manually operated.

19

vi.Tool and equipment care and control procedures. You must have a working knowledge and understanding ofwhat your responsibilities are for ensuring the care andsecurity of tools and equipment used in your role. This couldbe expected to include, pre, in use, post checks.

vii.Reporting lines and procedures. You must have a working knowledge and understanding of yourresponsibilities with regard to the reporting lines andprocedures in your working environment.

viii.Compliance checking methods and methods. You must have a working knowledge and understanding of howto make an adequate check of compliance with specifications,and which equipment and methods can be used for checkingcompliance.

ix.Identification of defects in products and assets. You must have a working knowledge and understanding of thetypical defects and variations that arise and how to identifythem. This could be expected to include lamination, prepangles, distortion, mis-shaping, corrosion.

x. Quality control systems and documentation procedures. You must have a working knowledge and understanding of whyit is important to maintain records of the checks made, andthe assessments that result from those checks, whatinformation should be entered on those records and wherethey should be kept.

xi.Inspection care and control. You must have a working knowledge and understanding of thecare and control of testing and measuring equipment.

xii.Measurement systems. You must have an appreciation of both imperial and metricmeasurement systems.

Knowledge statementsYou must have knowledge and understanding of:

20

Scope of this standard

1 Level and extent of responsibilityIn the context of this standard,responsibility extends to theinterpretation of given specifications,selecting techniques and makingvariations to procedures at yourdiscretion during the course of theshaping, to achieve the best possibleresult in the conditions applying. Insome cases, you may still be expectedto refer to others for finalauthorisations.

2 Shaping methods and techniques to be used The shape of the engineering productto be achieved requires three or moresequential stages to be followed e.g.preparation, process, finish, andtypically involves applying two or moretechniques to achieve the desiredresult. The order of the stages beingcritical to the result. Patterns andtemplates may be used.

Typical techniques could include:• Thermal cutting• Filing• Grinding• Sawing• Chiselling• Abrasive Finishing• Drilling• Shearing• Punching• Nibbling

3 Operations to be performed and complexity of shape to be achievedThe number of surfaces, angles anddimensions to be produced may bemultiple and varied. The shape to beproduced is not standard within theengineering sector but it will usuallyrepresent a variation on a commontheme.

4 Quality standards and accuracy to be achievedThe dimensional tolerances and surfacefinishes to be achieved are critical andacceptance levels may or may not beeasily achieved. The shaped materialwill be expected to comply tospecification (within approvedtolerances, either metric or imperial)in respect of dimensional accuracy andsurface finish. The shaped materialwould normally form a part of a largerengineering asset and the relationshipof the shaped product to the largerasset is critical.

The specifications to which a candidatewould be expected to work to couldinclude:

• Technical drawings (Component,Assembly, General arrangements,Isometrics)

• Method statements• Fabrication Specifications that would

comprise:? Cutting list? Material list? Welding procedures etc.

Unit FSS1: Shape components of fabricated steel structures by material removal using handand powered tools (ECITB/ECS 3.03) (continued)

21

5 Materials to be usedThe materials worked on haveproperties which can mean that shapingthem requires modification to thetypical approach used in that sector.

Typical materials could include:• Ferrous and Non-ferrous metals• Rubber• Composites and sealing materials• Polymers• Wood

The form these materials take couldbe:

• Commercial materials (mesh, chequer,grid)

• Cladding• Rolled sections• Tube• Formed sections• Plate• Fabricated sections.

6. Type of product or assets to bechecked• Fabricated components• Completed product

7. Inspection, test and record-keepingprocedures to be followed• Material tracability• NDT reports

8. Aspects, characteristics andcomplexity of checks to be made• Tolerance• Correct materials• NDT reports• Compliance• Positional dimensions• Component qualities• Nature of connections

22

Performance Statements You must:

Knowledge statementsYou must have knowledge and understanding of:

Unit FSS2: Prepare work areas for the fabrication of steel structures (ECITB/ECS 2.11)

a. Work safely at all times, complyingwith health and safety and otherrelevant regulations and guidelines

b. Ensure that the work environment issuitable for the work activities to beundertaken

c. Ensure that all necessary servicesupplies are connected and ready foruse

d. Prepare the work areas so that theyare ready for the engineering activitiesto be carried out

e. Make sure that required safetyarrangements are in place to protectother workers from activities likely todisrupt normal working

f. Report completion of preparations inline with organisational procedures

g. Deal promptly and effectively withproblems within your control andreport those that cannot be resolved

i. Health and safety legislation, regulations and safe workingpractices and procedures. You must have a working knowledge and understanding ofwhat your responsibilities are in respect of health and safetylegislation, regulations, safe working practices, local, nationaland site specific procedures. This could be expected toinclude relevant sections of Health and safety at Work Act,PUWER, LOLER, COSHH, RIDDOR, Construction PPE,Confined Space, Abrasive Wheels, Electricity at Work,Manual Handling, Risk Assessment, CDM, VDU, COMAH, andRSI regulations. Permit to work system, method statements,working at heights and over water, and local guidance notes.

ii. Work area preparation requirements and methods. You must have a working knowledge and understanding ofwhat the work area preparation requirements and methodsare in relation to ensuring the location and condition of workenvironments are appropriate in terms of layout, safety andaccessibility, taking into account relevant local and nationalagreements.

iii.The consequences of not preparing work areas correctly. You must have a working knowledge and understanding of thepotential problems and consequences of not preparing workareas correctly in relation to hazards which may occur.

iv.Service supply and connection procedures. You must have a working knowledge and understanding ofpotential problems and consequences of not preparing thework areas concerning service supply and connectionprocedures e.g. electricity, gases, water, compressed air.

v. Reporting lines and procedures. You must have a working knowledge and understanding of yourresponsibilities with regard to the reporting lines andprocedures in your working environment

23

Scope of this standard

1. Level and extent of responsibilityIn the context of this standard,responsibility extends to determiningand then implementing the preparationsnecessary where specifications ofrequirements may be absent orincomplete in some way. In somecases, you may still be expected torefer to others for finalauthorisations.

2. Type of work area to be preparedExamples of work areas would include:

• Engineering construction sites• Controlled operational and offshore

installations• Fabrication yards• Existing plant and structures• Working on access structures

(scaffold)• Onshore and offshore installations• Working inside plant and systems• Tunnels• Confined spaces• Shafts• At height

3. Type of work area preparationsWork area preparations could involveensuring that the environment, e.g.adverse weather conditions, location,layout, safety and accessibility aresuitable for undertaking the plannedengineering activities and storingrequired resources. It may alsoinclude the isolation or provision ofservices.

4. Type of work area protection and safety requirementsWork area protection and safety willtake into account any hazards due todiffering working operations which mayinclude:

• Noise• Fume• High intensity light from welding arcs• Electrical• Pneumatic• Hydraulic • Moving materials• Access• Egress• Grinding• Welding.

Unit FSS2: Prepare work areas for the fabrication of steel structures (ECITB/ECS 2.11)(continued)

24

Performance Statements You must:

Knowledge statementsYou must have knowledge and understanding of:

Unit FSS3: Prepare materials for the fabrication of steel structures (ECITB/ECS 2.12)

a. Work safely at all times, complyingwith health and safety and otherrelevant regulations and guidelines

b. Obtain the required materials andcheck them for quantity and quality

c. Determine how the materials need tobe prepared

d. Carry out the preparations usingsuitable equipment

e. Report completion of preparations inline with organisational procedures

f. Deal promptly and effectively withproblems within your control andreport those that cannot be solved

i. Health and safety legislation, regulations and safe workingpractices and procedures. You must have a working knowledge and understanding ofwhat your responsibilities are in respect of health and safetylegislation, regulations, safe working practices, local, nationaland site specific procedures. This could be expected toinclude relevant sections of Health and safety at Work Act,PUWER, LOLER, COSHH, RIDDOR, Construction PPE,Confined Space, Abrasive Wheels, Electricity at Work,Manual Handling, Risk Assessment, CDM, VDU, COMAH, andRSI regulations. Permit to work system, method statements,working at heights and over water, and local guidance notes.

ii. Identification of materials and recognition of defects. You must have a working knowledge and understanding of howto link selected materials with a certificate of conformity,drawing, method statement or equivalent. This could beexpected to include how to recognise defects such as surfacedistortion and/or dimensional.

iii.Material handling and preparation methods and techniques. You must have a working knowledge and understanding of thetypes of handling and preparation methods and techniquesneeded for different materials. What the handlingcharacteristics are of materials used, and how this affectshandling and preparation. This could include hot and coldworking.

iv.Tool and equipment care and control procedures. You must have a working knowledge and understanding ofwhat your responsibilities are for ensuring the care andsecurity of tools and equipment used in your role. This couldbe expected to include, pre, in use, post checks.

v. Reporting lines and procedures. You must have a working knowledge and understanding of yourresponsibilities with regard to the reporting lines andprocedures in your working environment.

25

Scope of this standard

1. Level and extent of responsibilityIn the context of this standard,responsibility extends to determiningand then implementing the preparationsnecessary where specifications ofrequirements may be absent orincomplete in some way. In somecases, you may still be expected torefer to others for finalauthorisations.

2. Type and complexity of material preparationsPreparations involve non-standardtreatments and may require checkingof documentation. Typical preparationscould include:

• Identification• Visual check for distortion• Surface condition (contamination and

physical)• Protecting/preserving• Security• Measurement• Checking quality and quantity• Setting out• Storage• Post heat treatments• Test certificates• Documentation (delivery notes,

certificates of conformity)• Hard stamping• Colour codes• Match marking• Batch numbers• Cleaning (de-greasing, wire brushing,

pickling).

3. Types of materialsMaterials could include materialsand/or components used in theengineering activity. Typical materialscould include:

• Ferrous• Non ferrous• Plastics• Wood• Sealants• Composites.

Unit FSS3: Prepare materials for the fabrication of steel structures (ECITB/ECS 2.12)(continued)

26

Performance Statements You must:

Knowledge statementsYou must have knowledge and understanding of:

Unit FSS4: Prepare equipment for the fabrication of steel structures (ECITB/ECS 2.13)

a. Work safely at all times, complyingwith health and safety and otherrelevant regulations and guidelines

b. Obtain all the required equipment andensure that it is in safe and usablecondition

c. Carry out the necessary preparationsto equipment in line with workrequirements

d. Make sure that required safetyarrangements are in place to protectothers from activities likely to disruptnormal working

e. Report completion of preparations inline with organisational procedures

f. Deal promptly and effectively withproblems within your control andreport those that cannot be solved

i. Health and safety legislation, regulations and safe workingpractices and procedures. You must have a working knowledge and understanding ofwhat your responsibilities are in respect of health and safetylegislation, regulations, safe working practices, local, nationaland site specific procedures. This could be expected toinclude relevant sections of Health and safety at Work Act,PUWER, LOLER, COSHH, RIDDOR, Construction PPE,Confined Space, Abrasive Wheels, Electricity at Work,Manual Handling, Risk Assessment, CDM, VDU, COMAH, andRSI regulations. Permit to work system, method statements,working at heights and over water, and local guidance notes.

ii. Equipment preparation methods and procedures. You must have a working knowledge and understanding ofequipment preparation methods and procedures in relation tochecking the working condition and operation of equipmentused in your workplace. This could be expected to includesafety checks, inspections and visual checks whenappropriate.

iii.Types of equipment. You must have a working knowledge and understanding ofwhat types of equipment may be used. This could beexpected to include fixed (machine) and/or portable (hand ormachine).

iv.Tool and equipment care and control procedures. You must have a working knowledge and understanding ofwhat your responsibilities are for ensuring the care andsecurity of tools and equipment used in your role. This couldbe expected to include, pre, in use, post checks.

v. Reporting lines and procedures. You must have a working knowledge and understanding of yourresponsibilities with regard to the reporting lines andprocedures in your working environment.

27

Scope of this standard

1. Level and extent of responsibilityIn the context of this standard,responsibility extends to determiningand then implementing the preparationsnecessary where specifications ofrequirements may be absent orincomplete in some way. In somecases, you may still be expected torefer to others for finalauthorisations, even though you remainresponsible for identifying andimplementing decisions.

2. Equipment safety checksEquipment safety checks could include:

• Visual checks• Operator authorised maintenance• Portable appliance testing

3. Types of equipment to be preparedEquipment to be prepared couldinclude:

• Protective clothing/equipment (PPE)• Safety equipment/harnesses• Lifting and Handling equipment (colour

coding)• Access and egress equipment (e.g.

ladders, steps, trestles, youngmanboards, temporary staging, accesshoists, “cherry pickers”)

• Tools fixed (machine), portable (handor machine).

4. Types of equipment preparationEquipment preparation could involveselection, inspection (visual), changingsettings or pressure as well as routinechecks on its condition, operation,suitability and safety.

Unit FSS4: Prepare equipment for the fabrication of steel structures (ECITB/ECS 2.13)(continued)

28

Performance Statements You must:

Knowledge statementsYou must have knowledge and understanding of:

Unit FSS5: Reinstate the work area after completing the fabrication of steel structures(ECITB/ECS 2.15)

a. Work safely at all times, complyingwith health and safety and otherrelevant regulations and guidelines

b. Separate equipment, components, andmaterials for re-use from waste itemsand materials

c. Store reusable materials andequipment in an appropriate location

d. Dispose of waste materials in line withorganisational and environmental safeprocedures

e. Restore the work areas to a safecondition in accordance with agreedrequirements and schedules

f. Deal promptly and effectively withproblems within your control andreport those that cannot be solved

i. Health and safety legislation, regulations and safe workingpractices and procedures. You must have a working knowledge and understanding ofwhat your responsibilities are in respect of health and safetylegislation, regulations, safe working practices, local, nationaland site specific procedures. This could be expected toinclude relevant sections of Health and safety at Work Act,PUWER, LOLER, COSHH, RIDDOR, Construction PPE,Confined Space, Abrasive Wheels, Electricity at Work,Manual Handling, Risk Assessment, CDM, VDU, COMAH, andRSI regulations. Permit to work system, method statements,working at heights and over water, and local guidance notes.

ii. Work area restoration requirements.You must have a working knowledge and understanding of thetypical requirements and schedules for restoring the workarea. This could be expected to include working inaccordance with clients instructions.

iii.Material and equipment stores procedures. You must have a working knowledge and understanding of theappropriate storage procedures for materials and equipment.

iv.Waste disposal methods and procedures. You must have a working knowledge and understanding ofappropriate methods for the disposal of waste in relation tolegislation, regulation and procedure for waste segregation.

v. Reporting lines and procedures. You must have a working knowledge and understanding of yourresponsibilities with regard to the reporting lines andprocedures in your working environment.

29

Scope of this standard

1. Level and extent of responsibilityIn the context of this standard,responsibility is limited to workingwithin agreed specifications andfollowing clearly defined procedureswith regard to the storage ofresources, but extends to thediscretion to achieve satisfactoryrestoration of the work area accordingto local user needs. In some cases, youmay still be expected to refer toothers for final authorisations, eventhough you remain responsible foridentifying and implementing decisions.

2. Nature and complexity of work areas to be restoredWork areas may be open or restrictedspaces. There are likely to bedifferent working conditions to betaken into account.

The typical work environment couldinclude:

• Engineering construction sites• Controlled operation/Live plant • Offshore installations

3. Resources to be storedTypical resources could include:

• Consumables• Assembly/alignment aids• Alignment aids• Storing/stacking equipment• Lifting equipment• Safety equipment• Personal protection

equipment/shielding equipment• Excess materials • Process and ancillary equipment• Industrial gas cylinders• Tools/equipment• Protection sheeting equipment• Re-usable components/assemblies

4. Disposal of hazardous and non-hazardous materials by segregation

Typical non hazardous waste wouldinclude:

• Packaging/protecting materials• Swarf• Material offcuts• Replaced ‘lifed’/past use by date

consumables

Typical hazardous waste could include• Used oils/coolants• Sharp objects/offcuts

Unit FSS5: Reinstate the work area after completing the fabrication of steel structures(ECITB/ECS 2.15) (continued)

30

Performance Statements You must:

Knowledge statementsYou must have knowledge and understanding of:

Unit CO1: Contribute to effective working relationships (ECITB/ECS 8.02)

a. Establish and maintain productiveworking relationships

b. Deal with disagreements in an amicableand constructive way so that goodrelationships are maintained

c. Keep others informed about work plansor activities which affect them

d. Seek assistance from others in a politeand courteous way without causingundue disruption to normal workactivities

e. Respond in a timely and positive waywhen others ask for help orinformation

i. Creating and maintaining working relationships. You must have a working knowledge and understanding of howto create and maintain working relationships, and why it isimportant to do so.

ii. Problems affecting relationships. You must have a working knowledge and understanding ofwhat the types of problems are that can affect relationships,and what actions can be taken to deal with specificdifficulties.

iii.Lines of communication and responsibilities. You must have a working knowledge and understanding ofwhat your own and others responsibilities are.

iv.Training and development opportunities. You must have an appreciation of the types of training anddevelopment opportunities offered by your organisation. Thiscould be expected to include an appreciation of your owncompetence and areas for development.

31

Scope of this standard

1. Groups of people with which relationships should be maintainedWorking relationships need to befostered with other people with whomyou come into contact as part of yourwork role either on a frequent orregular basis, or occasionally only.

Typical relationships could be with:• Those for whom you have responsibility• Those to whom you are responsible• Clients• Colleagues• Other disciplines• Suppliers• Security/safety personnel.

2. CommunicationsEffective working relations requirecommunication with others.

Communications could include:• Formal/informal• Written• Verbal.

Examples could include:• Tool box talks• Inductions• Safety feedback• Production loop• Complaints• Liaison between training and workplace

contacts• Appraisals/performance reviews.

Unit CO1: Contribute to effective working relationships (ECITB/ECS 8.02)(continued)

32

Performance Statements You must:

Knowledge statementsYou must have knowledge and understanding of:

Unit CO2: Work safely and comply with emergency procedures (ECITB/ECS 7.06)

a. Work safely at all times, complyingwith health and safety and otherrelevant regulations and guidelines

b. Call for expert help in the event ofcontingencies occurring, using warningsystems as appropriate

c. Take prompt and appropriate action tominimise risk of personal and thirdparty injury as a first priority and thendamage to property and equipment

d. Follow shutdown and evacuationprocedures promptly and correctly

e. Deal safely with dangers that can becontained using appropriate equipmentand materials, in accordance withorganisational policy and procedures

i. Health and safety legislation, regulations and safe workingpractices and procedures. You must have a working knowledge and understanding ofwhat your responsibilities are in respect of health and safetylegislation, regulations, safe working practices, local, nationaland site specific procedures. This could be expected toinclude relevant sections of Health and safety at Work Act,PUWER, LOLER, COSHH, RIDDOR, Construction PPE,Confined Space, Abrasive Wheels, Electricity at Work,Manual Handling, Risk Assessment, CDM, VDU, COMAH, andRSI regulations. Permit to work system, method statements,working at heights and over water, and local guidance notes.

ii. First aid procedures. You must have a working knowledge and understanding of thesources of competent assistance including the location oflocal first-aid facilities and first-aiders and systems foralerting relevant professional authorities.

iii.Evacuation procedures. You must have a working knowledge and understanding ofwhat the procedures for shutdown and evacuation are, andwhere information on shutdown and evacuation procedures canbe obtained.

iv.Contingency reporting documentation and systems. You must have a working knowledge and understanding ofcontingency reporting documentation and systems relevant tothe procedures at the workplace. This could be expected toinclude local or company reporting procedures for near missor accidents.

v. Reporting lines and procedures. You must have a working knowledge and understanding of yourresponsibilities with regard to the reporting lines andprocedures in your working environment.

33

Scope of this standard

1. Level and extent of responsibilityIn the context of this standard,responsibility is limited to workingwithin an overall risk control strategywhich has been developed by safetyspecialists and which includes detailedcriteria for identifying risks togetherwith clearly defined procedures foraction which must be followed. Insome cases, you may be expected torefer to others for finalauthorisations, even though you remainresponsible for identifying andimplementing decisions.

2. Types of contingenciesAccidents and incidents by their verynature are unexpected but the riskcontrol strategy sets out theresponses that you should follow inorder to limit risks arising.

3. Actions to be takenTypes of action to be taken couldinclude:

• isolation of hazard/containment• stopping activities• reporting to appropriate person• restriction of others exposure to

hazard• implementation of alarm and evacuation

procedures to assembly point.

Unit CO2: Work safely and comply with emergency procedures (ECITB/ECS 7.06)(continued)

34

Performance Statements You must:

Knowledge statementsYou must have knowledge and understanding of:

Unit CO3: Deal with hazards in the work environment (ECITB/ECS 7.04)

a. Work safely at all times, complyingwith health and safety and otherrelevant regulations and guidelines

b. Recognise industrial processes, tools,equipment and materials that have thepotential to cause harm

c. Check for hazards in the workplace inline with agreed and approvedprocedures

d. Identify any potential hazards andtake appropriate action to minimise therisk from them

e. Report any hazards identified and anyactions you have taken

i. Health and safety legislation, regulations and safe workingpractices and procedures. You must have a working knowledge and understanding ofwhat your responsibilities are in respect of health and safetylegislation, regulations, safe working practices, local, nationaland site specific procedures. This could be expected toinclude relevant sections of Health and safety at Work Act,PUWER, LOLER, COSHH, RIDDOR, Construction PPE,Confined Space, Abrasive Wheels, Electricity at Work,Manual Handling, Risk Assessment, CDM, VDU, COMAH, andRSI regulations. Permit to work system, method statements,working at heights and over water, and local guidance notes.

ii. Hazard spotting and safety assessment methods andtechniques.You must have a working knowledge and understanding ofhazard spotting and safety assessment methods andtechniques, which could include relevant procedures in yourworkplace.

iii.Types of hazards involving processes, tools, equipment andmaterials. You must have a working knowledge and understanding ofwhat the sorts of hazards which may arise are, and what yourresponsibilities are for dealing with hazards.

iv.Effects of hazards on persons, property and theenvironment. You must have a working knowledge and understanding of theeffects of hazards on persons, property and the environment,including personal injury, chemical fluid spill and damage toproperty.

v. Actions to minimise risk from hazards.You must have a working knowledge and understanding of thetypes of actions required to deal with hazards.

vi.Safety reporting procedures and documentation. You must have a working knowledge and understanding of whoshould be informed of actions taken to deal with hazardoussituations, and what should be included in reports.

vii.Reporting lines and procedures. You must have a working knowledge and understanding of yourresponsibilities with regard to the reporting lines andprocedures on the work site.

35

Scope of this standard

1. Level and extent of responsibility In the context of this standard,responsibility is limited to workingwithin an overall risk control strategywhich has been developed by safetyspecialists and which includes detailedcriteria for identifying risks togetherwith clearly defined procedures foraction which must be followed. Insome cases, you may be expected torefer to others for finalauthorisations, even though you remainresponsible for identifying andimplementing decisions.

2. Type of hazards and risks arisingHazards and risks may arise from theuse of resources, from the featureswithin the immediate workingenvironment, processes, equipment orfrom third parties.

Typical hazards could include:Use of resources:

• Volatile/toxic materials• Hot/heavy/sharp objects• Stacked items/falling objects• Unshielded processes/emissions

(ionisation regulations)• Nearby/faulty power supplies• Incorrect fitting• Noise.

Immediate working environment:• Insufficient/inadequate lighting• Trailing cables• Fire• Inadequate atmosphere• Weather conditions• Scaffold/construction traps• Bomb alerts/suspicious packages.

3. Hazard checking methods to be usedHazards can be identified andminimised using the criteria andprocedures specified in the riskcontrol strategy within which youoperate.

4. The type of workplace and environmentTypes of workplace and environmentinclude:

• Offshore oil and gas plants• Onshore oil and gas plants• Power stations• Fabrication yards• Chemical plants• Engineering Construction Sites• Live plant/controlled operation

5. Type of action to be takenAccidents and incidents by their verynature are unexpected but the riskcontrol strategy sets out theresponses that you should follow inorder to limit risks arising.

Types of action to be taken couldinclude:

• isolation of hazard• stopping activities• reporting to appropriate person.

Unit CO3: Deal with hazards in the work environment (ECITB/ECS 7.04) (continued)

36

Performance Statements You must:

Knowledge statementsYou must have knowledge and understanding of:

Technical OptionsUnit FSS6: Assemble components of steel fabrications to meet specification (ECITB/ECS 3.12)

a. Work safely at all times, complyingwith health and safety and otherrelevant regulations and guidelines

b. Follow the relevant instructions,assembly drawings and any otherspecifications

c. Ensure that the specified componentsare available and that they are in ausable condition

d. Use the appropriate methods andtechniques to assemble the componentsin their correct positions

e. Secure the components using thespecified connectors and securingdevices

f. Check the completed assembly toensure that all operations have beencompleted and the finished assembly

meets the required specification

g. Deal promptly and effectively with problems within yourcontrol and report those that cannot be solved

i. Health and safety legislation, regulations and safe workingpractices and procedures. You must have a working knowledge and understanding ofwhat your responsibilities are in respect of health and safetylegislation, regulations, safe working practices, local, nationaland site specific procedures. This could be expected toinclude relevant sections of Health and safety at Work Act,PUWER, LOLER, COSHH, RIDDOR, Construction PPE,Confined Space, Abrasive Wheels, Electricity at Work,Manual Handling, Risk Assessment, CDM, VDU, COMAH, andRSI regulations. Permit to work system, method statements,working at heights and over water, and local guidance notes.

ii. Assembly drawings and related specifications. You must have a working knowledge and understanding of whyit is important to have the required specifications to handbefore beginning work, the specifications to which you areexpected to work, including product worksheets, methodstatements and technical drawings (component, assembly,general arrangement, isometrics), and how to interpret them.

iii.Preparation methods and techniques.You must have a working knowledge and understanding ofpreparation methods and techniques. This could be expectedto include surface checks, surface preparations, datums,alignment aids, angles and orientation.

iv.Assembly methods and techniques.You must have a working knowledge and understanding ofwhat methods can be used for assembling components in yourwork environment. How to determine the correct orientationfor components, why the order of assembling of componentsis important and using appropriate assembly documentation.

v. Quality control procedures and recognition of assemblydefects. You must have a working knowledge and understanding ofassembly defects such as distortion, misshape, and out oftolerance.

vi.Handling equipment and procedures.You must have a working knowledge and understanding ofwhat the handling requirements are of different componentsand assemblies.

37

vii.Tool and equipment care and control procedures. You must have a working knowledge and understanding ofwhat your responsibilities are for ensuring the care andsecurity of tools and equipment used in your role. This couldbe expected to include tools and equipment used for assemblyand inspection.

viii.Reporting lines and procedures. You must have a working knowledge and understanding of yourresponsibilities with regard to the reporting lines andprocedures in your working environment.

ix.Compliance checking methods and techniques. You must have a working knowledge and understanding of howto make an adequate check of compliance with specifications,and which equipment can be used for checking compliance.

x. Identification of defects in products and assets. You must have a working knowledge and understanding of thetypical defects and variations that arise and how to identifythem.

xi.Quality control systems and documentation procedures. You must have a working knowledge and understanding of whyit is important to maintain records of the checks made, theassessments that result from those checks, what informationshould be entered on those records, and where they shouldbe kept.

xii.Measurement systems. You must have a working knowledge and understanding of bothimperial and metric measurement systems.

Knowledge statementsYou must have knowledge and understanding of:

38

Scope of this standard

1. Level and extent of responsibility In the context of this standard,responsibility for the work outputextends to the interpretation of givenspecifications, selecting appropriatecomponents, choosing and/or modifyingprocedures to achieve the bestpossible results in the conditionsapplying. In some cases, you may stillbe expected to refer to others forfinal authorisation.

2. Type and complexity of assembly tobe produced and checkedThe assemblies can be achievedthrough the making of connectionswhich are several in number and/ormay be difficult to access. Themajority of components may be of afragile nature.

Typical assemblies could be:• Platework assemblies• Steel section assemblies• Tubework assemblies

3. Assembly methods and techniques to be usedThe assembly may require theapplication of more than onetechnology and/or several differenttechnologies. The assembly is made byfollowing procedures which may notaccount for every stage involvedand/or need to be modified to achieveoptimum results. The assembly willrequire sequential procedures and willbe expected to comply tospecifications in terms of both themethods and equipment used and theassemblies produced.

Typical assembly techniques couldinvolve the use of:

• Clamping• Sealing• Tack welding • Threaded fasteners• Bonding.

4. Type of components used• Rolled sections• Formed section• Plate sections• Fabricated sections• Tube• Commercial materials and components.

5. Quality standards and accuracy to be achievedAny tolerances to be achieved in thecloseness of fit of connections madeare critical, with quality andacceptance levels high and may not beeasily achieved.

6. Aspects, characteristics and complexity of checks to be madeAspects checked could include:

• positional dimensions• component qualities• nature of connections.

Unit FSS6: Assemble components of steel fabrications to meet specification (ECITB/ECS 3.12)(continued)

39

Performance Statements You must:

Knowledge statementsYou must have knowledge and understanding of:

Unit FSS7: Store steel structure fabrication related resources for further use (ECITB/ECS 2.16)

a. Work safely at all times, complyingwith health and safety and otherrelevant regulations and guidelines

b. Determine how the resources are to bestored

c. Use correct safe handling techniques

d. Remove and dispose of all unnecessarypackaging equipment

e. Store resources safely in a suitableposition in the appropriate storagelocation

f. Clearly identify the stored resourcesand complete any necessarydocumentation

g. Deal promptly and effectively withproblems within your control andreport those that cannot be solved

i. Health and safety legislation, regulations and safe workingpractices and procedures. You must have a working knowledge and understanding ofwhat your responsibilities are in respect of health and safetylegislation, regulations, safe working practices, local, nationaland site specific procedures. This could be expected toinclude relevant sections of Health and safety at Work Act,PUWER, LOLER, COSHH, RIDDOR, Construction PPE,Confined Space, Abrasive Wheels, Electricity at Work,Manual Handling, Risk Assessment, CDM, VDU, COMAH, andRSI regulations. Permit to work system, method statements,working at heights and over water, and local guidance notes.

ii. Storage methods and procedures. You must have a working knowledge and understanding of theappropriate storage procedures for materials and equipment.

iii.Waste disposal methods and procedures. You must have a working knowledge and understanding ofappropriate methods for the disposal of waste in relation tolegislation, regulation and procedure for waste segregation.

iv.Reporting lines and procedures. You must have a working knowledge and understanding of yourresponsibilities with regard to the reporting lines andprocedures in your working environment.

40

Scope of this standard

1. Level and extent of responsibilityIn the context of this standard,responsibility is limited to workingwithin agreed specifications andfollowing clearly defined procedureswith regard to the storage ofresources, but extends to thediscretion to achieve satisfactoryrestoration of the work area accordingto local user needs. In some cases, youmay still be expected to refer toothers for final authorisations, eventhough you remain responsible foridentifying and implementing decisions.

2. Storage environmentsStorage environments may include:

• Ferrous and non ferrous areas• Plate, section, tube areas and racks• Rigging lofts• Cylinder storage• Material stores

3. Handling techniques and proceduresHandling techniques and proceduresmay include:

• Manual handling• LOLER• Kinetic lifting

4. Type of resources to be storedTypical resources could include:

• Consumables• Assembly/alignment aids• Storing/stacking equipment• Lifting equipment• Safety equipment• Personal protection

equipment/shielding equipment• Excess materials • Process and ancillary equipment• Industrial gas cylinders• Tools/equipment• Protection sheeting equipment• Re-usable components/assemblies

5. Record keeping systemsAppropriate documentation eitherpaper or electronic.

Unit FSS7: Store steel structure fabrication related resources for further use (ECITB/ECS 2.16) (continued)

41

Performance Statements You must:

Knowledge statementsYou must have knowledge and understanding of:

Unit FSS8: Manually form components to specification (ECITB/ECS 3.16)

a. Work safely at all times, complyingwith health and safety and otherrelevant regulations and guidelines

b. Follow the correct component drawingand any other related specificationsfor the component to be produced

c. Determine what has to be done andhow this will be achieved

d. Use the appropriate tools andequipment for the pressure shapingoperations and check that they are in asafe and usable condition

e. Shape the materials to the requiredspecification using appropriatemethods and techniques

f. Check that all the required shapingoperations have been completed to therequired standard

g. Deal promptly and effectively withproblems within your control andreport those that cannot be solved

i. Health and safety legislation, regulations and safe workingpractices and procedures. You must have a working knowledge and understanding of what yourresponsibilities are in respect of health and safety legislation,regulations, safe working practices, local, national and site specificprocedures. This could be expected to include relevant sections ofHealth and safety at Work Act, PUWER, LOLER, COSHH,RIDDOR, Construction PPE, Confined Space, Abrasive Wheels,Electricity at Work, Manual Handling, Risk Assessment, CDM, VDU,COMAH, and RSI regulations. Permit to work system, methodstatements, working at heights and over water, and local guidancenotes.

ii. Engineering drawings and related specifications. You must have a working knowledge and understanding of thespecifications to which you will be expected to work, includingtechnical drawings (component, assembly, general arrangements,isometrics, 1st and 3rd angle projections), method statements andproduct worksheets, tolerances.

iii.Hand forming methods and techniques.You must have a working knowledge and understanding of the forming

methods and techniques to include hot and cold working, usingappropriate tools and equipment.

iv. Influence of material characteristics relevant to hand formingoperations.You must have a working knowledge and understanding of materialsand their characteristics when being formed by hot and cold, handor mechanical methods, including ferrous and non ferrous, andtheir reaction to the forming process.