4016-61TRG2 4000 4016-61TRG3 · 2018-04-11 · Perkins Engines Company Limite d Peterborough, PE1...

Transcript of 4016-61TRG2 4000 4016-61TRG3 · 2018-04-11 · Perkins Engines Company Limite d Peterborough, PE1...

Perkins Engines Company LimitedPeterborough, PE1 5FQ, United KingdomTel: +44 (0)1733 583000Fax: +44 (0)1733 582240www.perkins.com

Copyright © 2013 Perkins Engines Company Limited, all rights reserved. No part of this document may be reproduced in any form or by any means, without prior written permission of Perkins Engines Company Limited. The information in this document is substantially correct at the time of printing and may be altered subsequently.

Series

1 of 13

Publication No. TPD1822, November 2013.

Basic technical dataNumber of cylinders.. ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... 16

Cylinder arrangement .... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... .... 60° Vee

Cycle .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... .... 4 stroke

Induction system...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... Turbocharged

Combustion system .. ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .. Direct injection

Compression ratio.. .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ..13:1

Bore.. .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ....160 mm

Stroke .. ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ....190 mm

Cubic capacity .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... .... 61..123 litres

Direction of rotation.... ...... .... ...... .... ...... .... ...... ..Anticlockwise viewed on flywheel

Firing order ...... ..1A, 1B, 3A, 3B, 7A, 7B, 5A, 5B, 8A, 8B, 6A, 6B, 2A, 2B, 4A, 4B

Cylinder 1 .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ..Furthest from flywheel

Note: Cylinders designated ‘A’ are on the right hand side of the engine when viewed from the flywheel end..

Weight of Electrounit (engine only)Dry...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... .... 5570 kg

Wet .... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... .... 5847 kg

Overall dimensions of ElectrounitHeight .. ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... 2068 mm

Length.... ...... ...... ...... ...... ...... .... .... .... ...... .... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... 3350 mm

Width...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... .... ...... .... ...... .... ...... ...... ...... ...... ...... ....1652 mm

Centre of gravityForward of rear face of cylinder block .... ...... .... ...... .... ...... .... ...... .... ...... .... ....900 mm

Above crankshaft centre line (wet).... ...... ...... ...... ...... ...... ...... ...... ...... .... ...... .... ...... 50 mm

Moments of inertiaEngine.... ...... ...... .... .... ...... .. .. ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ......11..15 kgm²

Flywheel...... ...... ........ ...... .... .. ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ......9..57 kgm²

Cyclic irregularity, engine/flywheel Prime power4016-61TRG1 .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... ....1:290

4016-61TRG2 .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... ....1:277

4016-61TRG3 .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... ....1:260

RatingsSteady state speed stability at constant load ...... ...... .... .... ...... ...... ...... ...... ± 0..25%

Electrical ratings are based on average alternator efficiency and are for guidance only (0..8 power factor being used)..

Operating pointEngine speed ...... ...... ...... ...... ...... ...... ...... ...... ...... .. .... ...... .... ...... .... .. .... ...... ...... ...... ...... .. 1500 rpm

Inlet manifold mixture temperature ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... 45°C

Cooling water exit temperature.. ...... ...... ...... ...... .... ...... .... .. .. ...... ...... ...... ...... ...... .... < 98°C

Fuel dataTo conform to BS2869 class A2 or BS EN590..

PerformanceSound pressure level 1500 rpm

4016-61TRG1 .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... 110 dB(A)

4016-61TRG2 .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... 111 dB(A)

4016-61TRG3 .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... 112 dB(A)

Note: All data based on operation to ISO 3046/1, BS 5514 and DIN 6271 standard reference conditions..

Note: For engines operating in ambient conditions other than the standard reference conditions stated below, a suitable derate must be applied

Note: Derate tables for increased ambient temperature and/or altitude are available, please contact Perkins Applications Department..

Test conditionsAir temperature.. ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... .... .. .... ...... .. .. ...... ...... ...... ...... ...... .. 25°C

Barometric pressure.... ...... ...... ...... ...... ...... ...... ...... .... .. .... ...... .. .. ...... ...... ...... ...... ...... ...... 100 kPa

Relative humidity...... ...... ...... ...... ...... ...... ...... ...... ...... ...... .... ...... .... ...... ...... ...... ...... ...... ...... ...... .. ..50%

Air inlet restriction at maximum power (nominal) .... .. .... ...... ...... ...... ...... .. 2..5 kPa

Exhaust back pressure (nominal) .. ...... ...... ...... ...... .......... ...... .... .... ...... ...... ...... ...... .. 3 kPa

Fuel temperature (inlet pump)...... ...... ...... ...... ...... .... ...... .... .... .. ...... ...... 58°C maximum

40004016-61TRG14016-61TRG24016-61TRG31269 - 2074 kWm (Gross) @ 1500 rpm Emissions compliant

Electrounit

Perkins Engines Company LimitedPeterborough, PE1 5FQ, United KingdomTel: +44 (0)1733 583000Fax: +44 (0)1733 582240www.perkins.com

Copyright © 2013 Perkins Engines Company Limited, all rights reserved. No part of this document may be reproduced in any form or by any means, without prior written permission of Perkins Engines Company Limited. The information in this document is substantially correct at the time of printing and may be altered subsequently.

2 of 13

Publication No. TPD1822, November 2013.

General installation

4016-61TRG1

Designation Units Baseload power Prime power Standby power

Gross engine power kWb 1269 1648 1774

Gross BMEP kPa 1661 2157 2322

Combustion air flow m³/min 125 160 170

Exhaust gas temperature, after turbo °C 425 440 460

Exhaust gas flow (max..) at atmospheric pressure m³/min 400

Boost pressure ratio :1 3..7

Mechanical efficiency % 89 91 92

Overall thermal efficiency % 37 36 36

Friction power and pumping losses kWm 160

Mean piston speed m/s 9..5

Engine coolant flow (minimum) litres/s 23

Typical Genset electrical output 0..8pf 25°C (100 kPa)kWe 1120 1480 1600

kVA 1400 1850 2000

Assumed alternator efficiency % 95

Note: All quoted gross engine powers include an allowance of 1..5% for installation variances..

Note: Not to be used for CHP design purposes (indicative figures only).. Consult Perkins Engines Company Limited.. Assumes complete combustion..

Rating definitionsBaseload powerUnlimited hours usage with an average load factor of 100% of the published Baseload power.. No overload is permitted on Baseload power..

Prime powerUnlimited hours usage with an average load factor of 80% of the published Prime power over each 24 hour period.. A 10% overload is available for 1 hour in every 12 hour operation..

Standby powerLimited to 500 hours annual usage with an average load factor of 80% of the published Standby power rating over each 24 hour period.. Up to 300 hours of annual usage may be run continuously.. No overload is permitted on Standby power..

Energy balance

4016-61TRG1

Designation Units Baseload power Prime power Standby power

Energy in fuel kWt 3183 4239 4608

Energy in power output (gross) kWb 1269 1648 1774

Energy to exhaust kWt 1115 1479 1580

Energy to coolant and oil kWt 456 529 565

Energy to radiation kWt 73 111 130

Energy to charge cooler kWt 270 472 541

Note: Not to be used for CHP design purposes (indicative figures only).. Consult Perkins Engines Company Limited..

Perkins Engines Company LimitedPeterborough, PE1 5FQ, United KingdomTel: +44 (0)1733 583000Fax: +44 (0)1733 582240www.perkins.com

Copyright © 2013 Perkins Engines Company Limited, all rights reserved. No part of this document may be reproduced in any form or by any means, without prior written permission of Perkins Engines Company Limited. The information in this document is substantially correct at the time of printing and may be altered subsequently.

3 of 13

Publication No. TPD1822, November 2013.

General installation

4016-61TRG2

Designation Units Baseload power Prime power Standby power

Gross engine power kWb 1437 1774 1985

Gross BMEP kPa 1881 2322 2598

Combustion air flow m³/min 140 169 184

Exhaust gas temperature, after turbo °C 420 440 460

Exhaust gas flow (max..) at atmospheric pressure m³/min 460

Boost pressure ratio :1 4

Mechanical efficiency % 90 92 93

Overall thermal efficiency % 40 39 37

Friction power and pumping losses kWm 160

Mean piston speed m/s 9..5

Engine coolant flow (minimum) litres/s 23

Typical Genset electrical output 0..8pf 25°C (100 kPa)kWe 1280 1600 1800

kVA 1600 2000 2250

Assumed alternator efficiency % 95

Note: All quoted gross engine powers include an allowance of 1..5% for installation variances..

Note: Not to be used for CHP design purposes (indicative figures only).. Consult Perkins Engines Company Limited.. Assumes complete combustion..

Rating definitionsBaseload powerUnlimited hours usage with an average load factor of 100% of the published Baseload power.. No overload is permitted on Baseload power..

Prime powerUnlimited hours usage with an average load factor of 80% of the published Prime power over each 24 hour period.. A 10% overload is available for 1 hour in every 12 hour operation..

Standby powerLimited to 500 hours annual usage with an average load factor of 80% of the published Standby power rating over each 24 hour period.. Up to 300 hours of annual usage may be run continuously.. No overload is permitted on Standby power..

Energy balance

4016-61TRG2

Designation Units Baseload power Prime power Standby power

Energy in fuel kWt 3609 4572 5312

Energy in power output (gross) kWb 1437 1774 1985

Energy to exhaust kWt 1259 1586 1854

Energy to coolant and oil kWt 454 535 584

Energy to radiation kWt 111 149 234

Energy to charge cooler kWt 348 528 655

Note: Not to be used for CHP design purposes (indicative figures only).. Consult Perkins Engines Company Limited

Perkins Engines Company LimitedPeterborough, PE1 5FQ, United KingdomTel: +44 (0)1733 583000Fax: +44 (0)1733 582240www.perkins.com

Copyright © 2013 Perkins Engines Company Limited, all rights reserved. No part of this document may be reproduced in any form or by any means, without prior written permission of Perkins Engines Company Limited. The information in this document is substantially correct at the time of printing and may be altered subsequently.

4 of 13

Publication No. TPD1822, November 2013.

General installation

4016-61TRG3

Designation Units Baseload power Prime power Standby power

Gross engine power kWb 1600 1975 2074

Gross BMEP kPa 2094 2585 2857

Combustion air flow m³/min 153 183 190

Exhaust gas temperature, after turbo °C 430 460 475

Exhaust gas flow (max..) at atmospheric pressure m³/min 460

Boost pressure ratio :1 4

Mechanical efficiency % 91 93 93

Overall thermal efficiency % 40 38 37

Friction power and pumping losses kWm 160

Mean piston speed m/s 9..5

Engine coolant flow (minimum) l/s 23

Typical Genset electrical output 0..8pf 25°C (100 kPa)kWe 1440 1800 1850

kVA 1800 2250 2350

Assumed alternator efficiency % 96

Note: All quoted gross engine powers include an allowance of 1..5% for installation variances..

Note: Not to be used for CHP design purposes (indicative figures only).. Consult Perkins Engines Company Limited.. Assumes complete combustion..

Rating definitionsBaseload powerUnlimited hours usage with an average load factor of 100% of the published Baseload power.. No overload is permitted on Baseload power..

Prime powerUnlimited hours usage with an average load factor of 80% of the published Prime power over each 24 hour period.. A 5% overload is available for 1 hour in every 12 hour operation..

Standby powerLimited to 500 hours annual usage with an average load factor of 80% of the published Standby power rating over each 24 hour period.. Up to 300 hours of annual usage may be run continuously.. No overload is permitted on Standby power..

Energy balance

4016-61TRG3

Designation Units Baseload power Prime power Standby power

Energy in fuel kWt 4010 5241 5594

Energy in power output (gross) kWb 1600 1975 2074

Energy to exhaust kWt 1400 1837 1976

Energy to coolant and oil kWt 497 597 600

Energy to radiation kWt 86 186 241

Energy to charge cooler kWt 427 646 703

Note: Not to be used for CHP design purposes (indicative figures only).. Consult Perkins Engines Company Limited..

Perkins Engines Company LimitedPeterborough, PE1 5FQ, United KingdomTel: +44 (0)1733 583000Fax: +44 (0)1733 582240www.perkins.com

Copyright © 2013 Perkins Engines Company Limited, all rights reserved. No part of this document may be reproduced in any form or by any means, without prior written permission of Perkins Engines Company Limited. The information in this document is substantially correct at the time of printing and may be altered subsequently.

5 of 13

Publication No. TPD1822, November 2013.

Cooling system

For details of recommended coolant specifications, please refer to the Operation and Maintenance Manual (OMM) for this engine model..

Maximum pressure in crankcase water jacket ...... .. .... .... .... ...... ...... ...... .. 170 kPaMaximum top tank temperature (standby)...... ...... ...... ...... .. .... ...... ...... ...... ...... ......98°CMaximum static pressure on pump ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... .. .... 70 kPa

Total coolant capacity:Electrounit (engine only) .. ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... .... 95 litresMaximum permissible restriction to coolant pump flow .. .... ...... .... ...... 30 kPaThermostat operating range .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... 71 - 85°CAmbient cooling clearance (Standby power) based on air temperature at fan of 6°C above the ambient .... .... ...... .... dependent on radiator selectionTemperature rise across the engine (Standby power) with inhibited coolant @ 1500 rpm ...... .... ...... .... ...... 5 - 9°C (depending on rating)Coolant temperature shutdown switch setting.. .. ...... .... ...... .... ...... 101°C (rising)Coolant immersion heater capacity (2 of).. .... ...... .... ...... .... ...... .... ..4 kWe (each)

Water jacket cooling data

Coolant flow 21 litres/s

Coolant exit temperature (max) 98ºC

Coolant inlet temperature (min) 70ºC

Coolant inlet temperature (max) 80ºC

Water Jacket coolant pumpSpeed .. ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... 1..4 x e rpmMethod of drive .. ...... ...... ...... ...... .... .... ...... .... ...... .... ...... .... ...... .... .... ...... ...... ...... Engine driven

Secondary water circuitCoolant flow 12 litres/s

Maximum permissible restriction to coolant pump flow 60 kPa

Coolant inlet temperature (min) 10ºC

Coolant inlet temperature (max) refer to derate charts

Lubrication system

Total system capacityMaximum sump capacity ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... 213 litresMinimum sump capacity .. ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... 157 litresOil temperature at normal operating conditions.... ...... .... ...... .... ...... .... ...... .... 95 ºCOil temperature (in rail) - Maximum continuous operations .... .... ...... 105 ºC

Lubricating oil pressureAt rated speed ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... .... .... ...... ...... ...... ...... ..400 kPaMinimum @ 80 ºC ...... ...... ...... ...... ...... ...... .. ...... .... ...... .... .... ...... ...... ...... ...... ...... ...... ...... 340 kPaOil filter screen spacing ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... 40 micronsSump drain plug tapping size ...... ...... ...... ...... .. .... .... ...... .... ...... ...... ...... ...... ...... ...... ...... ...... ..G1Oil pump speed and drive method.. ...... .... ...... .... ...... 1..4 x e rpm engine drivenShutdown switch - pressure setting...... .... ...... .... ...... .... ...... .... ...... 193 kPa (falling)

Oil consumption

Prime power after running in (typically after 250 hours) 0..52 g/kWhr

Oil flow rate from pump 6..7 litres/sec

Recommended SAE viscosity

Multigrade oil conforming to API CG 15W/40 CH4 must be used..

Note: For additional notes on lubricating oil specifications, refer to the OMM..

Induction system

Maximum air intake restriction of engineClean filter.. ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... .... ...... .... .... .. ...... 1..24 kPaDirty filter...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... ...... .... .. ...... .... ...... .... ...... ...... ...... ...... 3..71 kPaAir filter type...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... ..Donaldson

Exhaust system

Maximum back pressure for total systemExhaust outlet size (internal).... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... 2 x 254 mmExhaust outlet flange size ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... ..10 inch Table DBack pressure for total system at standby power ...... .... ...... .... ...... .... ..3..91 kPa

Note: For recommended pipe sizes see the Installation Manual..

Perkins Engines Company LimitedPeterborough, PE1 5FQ, United KingdomTel: +44 (0)1733 583000Fax: +44 (0)1733 582240www.perkins.com

Copyright © 2013 Perkins Engines Company Limited, all rights reserved. No part of this document may be reproduced in any form or by any means, without prior written permission of Perkins Engines Company Limited. The information in this document is substantially correct at the time of printing and may be altered subsequently.

6 of 13

Publication No. TPD1822, November 2013.

Fuel systemRecommended fuel to conform to .. ...... .... ..BS2869 Class A2 or BS EN590Type of injection system.... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .. Direct injectionFuel injection pump.... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... Combined unit injectorFuel injector pressure .... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ..140 MpaLift pump type .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... DFMFuel delivery .... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... .. 1380 litres/hrHeat retained in fuel to tank.. .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... ..14 kWFuel inlet temperature to be less than .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... 58°CMaximum suction head at pump inlet .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... ....2..5 mMaximum static pressure head .... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... see manualFuel filter spacing .... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... 10 micronsGovernor type .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... ....ElectronicGoverning to .... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ....ISO 8528-5 2004Torque at the governor output shaft...... .... ...... .... ...... .... ...... .... ...... .... ...... .. 1..631 kgmTolerance on fuel consumption to.... ...... .... ...... .... ...... .... ...... .... ....ISO 8528-1 1993

Fuel consumption

4016-61TRG1

Rating g/kWh litres/hr

Standby 234 480

Prime power 233 447

Base load power 229 337

At 75% Prime power 229 337

At 50% Prime power 223 212

At 25% Prime power 230 109

4016-61TRG2

Rating g/kWh litres/hr

Standby 221 513

Prime power 214 442

Base load power 209 347

At 75% Prime power 206 317

At 50% Prime power 204 209

At 25% Prime power 210 107

4016-61TRG3

Rating g/kWh litres/hr

Standby 224 537

Prime power 220 503

Base load power 208 385

At 75% prime power 207 355

At 50% prime power 204 233

At 25% prime power 210 118

Note: Fuel consumption calculated on gross rated power, based on an assumed density of 0..862..

Note: All figures in the table above are based on gross mechanical output, for fuel consumption based on electrical output of the generating set contact your OEM..

Electrical systemVoltage ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ......24 voltsAltenator type.. .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... Insulated returnAlternator output ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... .. 55 ampsStarter motor type .. .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ..2 x 24 volt electricStarter motor power .. ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ....16..4 kWNumber of teeth on flywheel .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ....156Number of teeth on starter pinion.... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... 12Minimum cranking speed (0°C) .... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ....120 rpmStarter solenoid pull-in current @ -25 °C max .. .... ...... .... ...... .... ...... .... .. 30 ampsStarter solenoid hold-in current @ -25 °C max .... ...... .... ...... .... ...... .... ...... 9 ampsStop solenoid hold-in current .. ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... 1..1 amps

Engine mountingMaximum static bending moment at rear face of block .... .... ...... .... 1356 Nm

Cold start recommendations

Temperature range down to -10°C (14°F)Oil ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... API CG 15W/40Starter ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... 2 x 24 voltsBattery ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... 4 x 12 volts x 286 AhMax breakaway current .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... 2000 ampsCranking current ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... 957 ampsAids.... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... Block heatersMinimum mean cranking speed .. .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ....120 rpm

Note: Battery capacity is defined by the 20 hour rate..

Note: The oil specification should be for the minimum ambient temperature as the oil will not be warmed by the immersion heater..

Note: Breakaway current is dependant on battery capacity available..Cables should be capable of handling transient current which may be up to double the steady cranking current..

Perkins Engines Company LimitedPeterborough, PE1 5FQ, United KingdomTel: +44 (0)1733 583000Fax: +44 (0)1733 582240www.perkins.com

Copyright © 2013 Perkins Engines Company Limited, all rights reserved. No part of this document may be reproduced in any form or by any means, without prior written permission of Perkins Engines Company Limited. The information in this document is substantially correct at the time of printing and may be altered subsequently.

7 of 13

Publication No. TPD1822, November 2013.

Emissions

RatingGerman

TA Luft @ <3 MWGerman

TA Luft @ >3 MWFrench Limits

2000 @ <500 hours/yearFrench Limits

1500 @ >500 hours/year

4016-61TRG1 - Spill timing 10°

Baseload N/A N/A N/A No

Prime power N/A Yes Yes No

4016-61TRG2 - Spill timing 11°

Baseload N/A Yes Yes No

Prime power N/A Yes Yes No

4016-61TRG3 - Spill timing 11°

Baseload N/A Yes Yes No

Prime power N/A Yes Yes No

German TA Luft legislation (1986) limits:

lNOx ≤ 2000 mg/Nm³lCO ≤ 650 mg/Nm³lHC ≤ 150 mg/Nm³lPM ≤ 50 mg/Nm³

All tests were conducted using an engine installed and serviced to Perkins Engines Company Limited recommendations..

Applied load is a percentage of generator electrical output efficiency as published in the general installation section of this data sheet..

Typical load acceptance

Initial load acceptance when engine reaches rated speed (15 seconds maximum after engine starts to crank)

2nd load step after speed recovery

Prime power %Load kWm nett/

kWe

Transient frequency

deviation %

Frequency recovery time

secondsPrime power %

Load kWm nett/kWe

Transient frequency

deviation %

Frequency recovery time

seconds

4016-61TRG1

60 944 / 920 ≤ -10 5 40 614 / 600 ≤ -10 5

4016-61TRG2

56 944 / 920 ≤ -10 5 44 740 / 720 ≤ -10 5

4016-61TRG3

50 944 / 920 ≤ -10 5 50 944 / 920 ≤ -10 5

The figures shown in the table above were obtained under the following test conditions:

Engine block temperature (cold) .. .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... 45°CAmbient temperature ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... 25°CGoverning mode ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... IsochronousAlternator inertia ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... 55 kgm²Under frequency roll off (UFRO) point set to ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... 49..5 HzUFRO rate set to ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... .. 16 volts/HzLAM on /off.... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... On

All tests were conducted using an engine installed and serviced to Perkins Engine Company Limited recommendations..

The information given on this Technical Data Sheet is for guidance only.. For ratings other than those shown, please contact Perkins Engines Company Limited..

Perkins Engines Company LimitedPeterborough, PE1 5FQ, United KingdomTel: +44 (0)1733 583000Fax: +44 (0)1733 582240www.perkins.com

Copyright © 2013 Perkins Engines Company Limited, all rights reserved. No part of this document may be reproduced in any form or by any means, without prior written permission of Perkins Engines Company Limited. The information in this document is substantially correct at the time of printing and may be altered subsequently.

8 of 13

Publication No. TPD1822, November 2013.

Noise DataNoise levelsThe figures for total noise levels are typical for an engine running at the continuous Baseload power rating in a semi-reverberant environment and measured at a distance of one metre from the periphery of the engine (sound pressure level re: -20 x 10-6 pa)..

Ambient noise level .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... .... ...... ..78 dB(A)

Octave analysisThe following histogram shows an octave band analysis at the position of the maximum noise level..

7

45

6

1

2

3Engine

Rear

Front

Frequency, Hz

No

ise,

dB

(A)

120

110

100

90

80

70

60

31..5 63 125 250 500 1000 2000 4000 8000 16000

1/3 octave analysis (1500 rpm) at position 7

POSITION 1

4016-61TRG1 107 dB(A)

4016-61TRG2 107 dB(A)

4016-61TRG3 107 dB(A)POSITION 2

4016-61TRG1 110 dB(A)

4016-61TRG2 111 dB(A)

4016-61TRG3 111 dB(A)

POSITION 3

4016-61TRG1 110 dB(A)

4016-61TRG2 110 dB(A)

4016-61TRG3 111 dB(A)

POSITION 4

4016-61TRG1 109 dB(A)

4016-61TRG2 111 dB(A)

4016-61TRG3 111 dB(A)

POSITION 7

4016-61TRG1 110 dB(A)

4016-61TRG2 111 dB(A)

4016-61TRG3 112 dB(A)

POSITION 6

4016-61TRG1 110 dB(A)

4016-61TRG2 110 dB(A)

4016-61TRG3 111 dB(A)

POSITION 5

4016-61TRG1 109 dB(A)

4016-61TRG2 109 dB(A)

4016-61TRG3 111 dB(A)

Perkins Engines Company LimitedPeterborough, PE1 5FQ, United KingdomTel: +44 (0)1733 583000Fax: +44 (0)1733 582240www.perkins.com

Copyright © 2013 Perkins Engines Company Limited, all rights reserved. No part of this document may be reproduced in any form or by any means, without prior written permission of Perkins Engines Company Limited. The information in this document is substantially correct at the time of printing and may be altered subsequently.

9 of 13

Publication No. TPD1822, November 2013.

4016-61TRG1 - Left side view

2128

189

1846

73.5

FUE

L LE

AK-O

FFCO

NN, N

O F

UEL

COO

LER

FITT

ED.

178

PRIM

ARY

WAT

ERO

UTLE

T CO

NN.

1 EA

CH S

IDE.

1700

25

320

480

866

391

3

398

WAT

ERIN

LET

3392

OVE

RALL

LEN

GTH

G 3/

8" TA

PPIN

G FO

RLU

B. O

IL TE

MP.C

ONN

.

AIR

FILT

ER IN

LET

2 EA

CH S

IDE

REAR

LIF

TING

BRA

CKET

ENGI

NE O

NLY

1 EA

CH S

IDE

CRAN

KCAS

E IN

SPEC

TIO

N CO

VERS

OIL

CO

OLE

R DR

AIN

TAP

1 EA

CH S

IDE

LUB.

OIL

CO

OLE

R1

EACH

SID

E

LUB.

OIL

FIL

LER

LUB.

OIL

DIP

STIC

K

LOW

OIL

PRE

SSUR

E SW

ITCH

1 EA

CH S

IDE.

SIDE

VIE

W B

BAN

K

FUEL

LEA

K-O

FFCO

NNEC

TOR

24V

AIR

SHUT

-OFF

VALV

EEN

ERGI

SED

TO C

LOSE

.1

EACH

SID

E

q C

RANK

SHAF

TFRONT FACE C/CASE

REAR FACE C/CASE

REAR FACE FLYWHEEL HSG

SUM

P DR

AIN

PLUG

G1"

1 EA

CH S

IDE

G 1/

4" TA

PPIN

G FO

RLU

B.O

IL P

RESS

CO

NN.

SECO

NDAR

Y W

ATER IN

LET

TORS

IONA

L VIB

RATI

ON

DAM

PER

(SIN

GLE

STAN

DARD

AND

TWIN

OPT

IONA

L)

SECO

NDAR

Y W

ATER

PUM

P

Perkins Engines Company LimitedPeterborough, PE1 5FQ, United KingdomTel: +44 (0)1733 583000Fax: +44 (0)1733 582240www.perkins.com

Copyright © 2013 Perkins Engines Company Limited, all rights reserved. No part of this document may be reproduced in any form or by any means, without prior written permission of Perkins Engines Company Limited. The information in this document is substantially correct at the time of printing and may be altered subsequently.

10 of 13

Publication No. TPD1822, November 2013.

4016-61TRG1 - Front view

12.5

REA

R LI

FTIN

G BR

ACKE

T

Ø26

.5 R

EAR

LIFT

ING

BRAC

KET

237

237

938

631

REAR

LIF

TING

BRAC

KET

370

1272

315

315

729

385

554

509

REAR

LIF

TING

BRA

CKET

509

REAR

LIF

TING

BRA

CKET

475

475

182

353

681

681

275

106

275

150

FRO

NT V

IEW

EXHA

UST

OUT

LET

ELBO

W1

EACH

SID

E.SE

E FL

ANGE

DET

AIL.

SYST

EM P

IPEW

ORK

MUS

T BE

ADEQ

UATE

LY S

UPPO

RTED

TOEN

SURE

THAT

NO

LOAD

ISEX

ERTE

D O

N TU

RBO

CHAR

GERS

AIR

FILT

ER R

ESTR

ICTI

ON

INDI

CATO

R. 2

EACH

SID

E.

n

20 H

OLE

FRO

NT L

IFTI

NG B

RACK

ET (E

NGIN

E O

NLY)

1 E

ACH

SIDE

.

FUEL

LEA

K-O

FF C

ONN

TO S

UIT

15m

m O

/D P

IPE.

`BIT

E` T

YPE

NON

RETU

RNVA

LVE

SUPP

LIED

1 EA

CH S

IDE

(NO

FUE

L CO

OLE

R)

FUEL

INLE

T CO

NNEC

TIO

N n

15(O

UTSI

DE) S

TEEL

PIP

E.M

AXIM

UM F

UEL

LIFT

2.5

MET

RES

WHE

N FU

EL TA

NK O

UTLE

T IS

LOW

ER TH

AN L

IFT

PUM

P IN

LET

ANO

N-RE

TURN

VALV

E M

UST

BEFI

TTED

AT

FUEL

TANK

. IF M

AXFU

EL L

IFT

FIGU

RE IS

EXC

EEDE

DCO

NSUL

T PE

RKIN

S TEC

HNIC

AL D

EPT. TW

IN F

UEL

FILT

ER/

WAT

ER S

EPAR

ATO

R

THER

MO

STAT

HO

USIN

G1

EACH

SID

E

ELEC

TRO

NIC

ACTU

ATO

R1

EACH

SID

E

q C

RANK

SHAF

T

q CRANKSHAFT

n

76 P

RIM

ARY

WAT

ER IN

LET

BOTH

SID

ES

77 O

/DIA

PRI

MAR

Y W

ATER

O

UTLE

T CO

NNEC

TIO

N 1

EACH

SID

E

76.2

O/D

IA S

ECO

NDAR

Y W

ATER

OUT

LET

CONN

ECTI

ON

76.2

O/D

IA S

ECO

NDAR

YW

ATER

INLE

T CO

NNEC

TIO

N

REAR

LIF

TING

BRA

CKET

1 EA

CH S

IDE

Perkins Engines Company LimitedPeterborough, PE1 5FQ, United KingdomTel: +44 (0)1733 583000Fax: +44 (0)1733 582240www.perkins.com

Copyright © 2013 Perkins Engines Company Limited, all rights reserved. No part of this document may be reproduced in any form or by any means, without prior written permission of Perkins Engines Company Limited. The information in this document is substantially correct at the time of printing and may be altered subsequently.

11 of 13

Publication No. TPD1822, November 2013.

4016-61TRG1 - Right side view

11.6

FRO

NT

LIFT

ING

BRA

CKE

T

28.5

LEA

K O

FF

CON

NEC

TIO

NN

O F

UEL

CO

OLE

RFI

TTED

20 F

UEL

INLE

TCO

NN

ECTI

ON

.

70

SECO

ND

ARY

WAT

ERO

UTL

ET

1820

REA

R LI

FTIN

G B

RAC

KET

SID

E VI

EW A

BA

NK

H.W

.PRO

TEC

TIO

N S

WIT

CH

1 E

AC

H S

IDE

EXH

AU

ST G

AS

HIG

H T

EMP

PRO

TEC

TIO

N M

OD

ULE

DU

AL

24V

STA

RTER

S

LUB

OIL

FIL

TERS

3 EA

CH

SID

E

STA

RTER

REL

AYS

FUEL

HA

ND

PRI

MIN

G P

UM

P

FUEL

LIF

T PU

MP

LUB.

OIL

PU

MP

24 V

ALT

ERN

ATO

R

CRA

NKC

ASE

BRE

ATH

ER 1

EA

CH

SID

ESU

PPLI

ED W

ITH

FLE

XIBL

E PI

PE51

INSI

DE

x 86

5 LG

q C

RAN

KSH

AFT

G 3

/8" T

APP

ING

FO

RLU

B. O

IL T

EMP.

CON

N.

G3/

8"; G

1/2"

AN

D R

p 1/

2" T

APP

ING

SIN

TH

ERM

OST

AT H

OU

SIN

G1

EAC

H S

IDE

FRONT FACE C/CASE

G 1

/4" T

APP

ING

FO

RLU

B. O

IL P

RESS

CO

NN

.

ELEC

TRO

NIC

CO

NTR

OL

UN

IT F

OR

AC

TUAT

OR

Perkins Engines Company LimitedPeterborough, PE1 5FQ, United KingdomTel: +44 (0)1733 583000Fax: +44 (0)1733 582240www.perkins.com

Copyright © 2013 Perkins Engines Company Limited, all rights reserved. No part of this document may be reproduced in any form or by any means, without prior written permission of Perkins Engines Company Limited. The information in this document is substantially correct at the time of printing and may be altered subsequently.

12 of 13

Publication No. TPD1822, November 2013.

4016-61TRG1 - Rear view

11°

70 REQUIRED FORSUMP REMOVAL

25

1660 OVERALL WIDTH

2076OVERALLHEIGHT

210 210

630 630

1225 qAIR FILTER

235.4

650.5

249

178178

39 REQUIRED FORFILTER REMOVAL

A BANKB BANK

REAR VIEW

ROTATION

SUMP DRAIN PLUG

q C

RANK

SHAF

T

q CRANKSHAFT

16 HOLES M12 x 21 DEEPEQUALLY SPACED AS SHOWNON n 851 (33.5") PC(SAE J617 '00')

FLYWHEEL STANDARD BUILDSAE J620 SIZE 18OPTION BUILD SAE J620 SIZE 21SEE DETAIL VIEWS

Perkins Engines Company LimitedPeterborough, PE1 5FQ, United KingdomTel: +44 (0)1733 583000Fax: +44 (0)1733 582240www.perkins.com

Copyright © 2013 Perkins Engines Company Limited, all rights reserved. No part of this document may be reproduced in any form or by any means, without prior written permission of Perkins Engines Company Limited. The information in this document is substantially correct at the time of printing and may be altered subsequently.

13 of 13

Publication No. TPD1822, November 2013.

2

Ø439.959 Ø486.959

Ø476.784476.684 Ø581.62

581.37

Ø628

10

15.7

Ø100.035 100.000

STANDARD BUILD

DETAIL OF SAE J620 SIZE 18FLYWHEEL AND SAE J617 No. 00 FLYWHEEL

HOUSING (METRIC TAPPINGS)

SCALE 1:5

6 HOLES M16 x 30DEEP EQUI SPACEDON n 543 (21.38") PC

Ø226.073

25.5 x 4

546

FRO

NT FA

CE C

/CAS

E

OPTION BUILD

DETAIL OF PULLEY OPTION

SCALE 1:5

CRANKSHAFT PULLEY5 GROOVE FOR SPC ANDC SECTION BELTS TOBS3790:1995

Ø250Ø406

8 HOLES DRILL �22 THRO

EQUI-SPACEDON 356.P.C.DIA

22°

DETAIL OF EXHAUST OUTLET FLANGE(B.S.10 TABLE D)

SCALE 1:5

Ø535.868

Ø525.493525.393

Ø480.868

5.7

10

Ø628

Ø100.035 100.000 Ø582.822

582.572

OPTION BUILD

DETAIL OF OPTIONAL SAE J620 SIZE 21FLYWHEEL AND SAE J617 No. 00 FLYWHEEL

HOUSING (METRIC TAPPINGS)

SCALE 1:5

12 HOLES M16 x 30DEEP EQUI SPACEDON n 641.35 (25.25") PC

480

275

OPTION BUILD

SCALE 1:10

DETAIL OF SECONDARY WATER INLET POSITIONFOR OPTION BUILD WITHOUT SECONDARY

WATER PUMP

FRO

NT FA

CEC/

CASE

q CRANKSHAFT

175.6

4

154

70

60

91

435

2254

112.5

98

451

135

222

500

1000

8 HOLES n 22

REA

R FA

CE

FLY

WH

EEL

HSG

PLAN VIEW OF SUPPORT PADS

FRO

NT

FAC

E C

/CA

SE

LC CRANKSHAFT

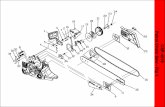

4016-61TRG1 - Accessories view