4.00pm Mike Cobb, Criterion LLC.ppt.ppt...

Transcript of 4.00pm Mike Cobb, Criterion LLC.ppt.ppt...

![Page 1: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/1.jpg)

LEAN TransformationApplying Lessons Learned

Nuclear Construction Summit USA 200926-27 October 2009

Washington, DC

Mike Cobb PhD

Managing Principal

Criterion LLC

Applying Lessons Learned to Nuclear New Build

![Page 2: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/2.jpg)

The Nuclear Renaissance

requires a

Transformation

Doing things

RADICALLY DIFFERENTLY

not just better

![Page 3: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/3.jpg)

The Last U.S. New Build Cycle:

What Went Wrong?

� Two phase licensing process

� Build before design completion

� Inadequately defined scope

� Poor scope control� Poor scope control

� “Custom” designs

� Overly aggressive schedules

� Poor schedule integrationJim Carter

Navigant Consulting

Financing New Nuclear Construction Workshop

Kansas Corporation Commission

December 2008

![Page 4: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/4.jpg)

The Last U.S. New Build Cycle:

What Went Wrong?

� Inaccurate/ineffective status reporting

� Failure to adjust to changes

� Lack of risk identification & management

� Poor constructability, maintainability, � Poor constructability, maintainability,

testability

� Unachievable budgets

� Limited accountabilityJim Carter

Navigant Consulting

Financing New Nuclear Construction Workshop

Kansas Corporation Commission

December 2008

![Page 5: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/5.jpg)

The Last U.S. New Build Cycle:

What Went Wrong?

� Unstructured problem identification,

resolution & documentation

� Marginal owner involvement

� Ineffective contract administration � Ineffective contract administration

� Barriers to productive communication

� Organizational silosJim Carter

Navigant Consulting

Financing New Nuclear Construction Workshop

Kansas Corporation Commission

December 2008

![Page 6: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/6.jpg)

The Last U.S. New Build Cycle:

What Went Wrong?

� Marginally qualified personnel / labor shortage

� Inadequate provisions for commissioning &

turnover

� Cumbersome document control & retrievability � Cumbersome document control & retrievability

� Lack of vendor O&M information

� Poor configuration controlJim Carter

Navigant Consulting

Financing New Nuclear Construction Workshop

Kansas Corporation Commission

December 2008

![Page 7: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/7.jpg)

The Last U.S. New Build Cycle:

What Went Wrong?

� Poor dispute avoidance policies and

practices

� Vague contract language, unsupportive of

ongoing project needsongoing project needs

Jim Carter

Navigant Consulting

Financing New Nuclear Construction Workshop

Kansas Corporation Commission

December 2008

![Page 8: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/8.jpg)

“I don’t think any [nuclear] plant built

in the U.S. has ever come in on time

and budget.”and budget.”

Industry Participant

CH2M HILL Strategic View Roundtable

“Scenarios for New Commercial Nuclear Power”

2008

![Page 9: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/9.jpg)

“Owners must take a more active,

informed and disciplined approach to

managing contract and project

execution.”execution.”

David Haarmeyer

PowerAdvocate

Nuclear Power International

September 2008

![Page 10: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/10.jpg)

“Balancing all the optimism

surrounding this nuclear renaissance

is a considerable body of

uncertainty.”uncertainty.”

Dr. Dale Klein, NRC Commissioner and Former Chairman

Global Nuclear Renaissance Summit, Washington, DC

December 2006

![Page 11: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/11.jpg)

We can’t repeat the mistakes of

the past .....

![Page 12: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/12.jpg)

What can we learn from recent and

current foreign new build activity?

� Shika-2

� Tomari-3

Shimane-3

� Olkiluoto-3⇔

� Shimane-3

![Page 13: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/13.jpg)

Best Practices + LEAN Practices =

Transformation

![Page 14: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/14.jpg)

What is LEAN?

� Reduce/eliminate WASTE

� Add VALUE� Add VALUE

� Increase SATISFACTION

![Page 15: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/15.jpg)

The Evolution of LEAN

LEAN

Nuclear

New Build .....

The New

Frontier

![Page 16: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/16.jpg)

LEAN Principles

� Waste Elimination (anything that does not add value)

� Value

� Value Stream

� Batch to Flow� Batch to Flow

� Push to Pull

� Quality

� Continuous Improvement

![Page 17: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/17.jpg)

LEAN Tools

� Value Stream Mapping

� 6S (sort, set in order, shine, standardize, sustain, safety)

� Kanban (JIT signaling)

� Kaizen (CI events)

� Mistake Proofing

� Visual Control

![Page 18: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/18.jpg)

LEAN Thinking� Orientation, Training and Culture Change

� Visioneering and LEAN Simulation

� Pull vs Push

The Internal Customer� The Internal Customer

� Interconnectivity and Collaboration across Disciplines

![Page 19: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/19.jpg)

The Widget Factory Model

![Page 20: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/20.jpg)

The Factory Floor The Paint Department

The Fabrication Departments The Assembly Departments

![Page 21: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/21.jpg)

LEAN � Six Sigma

� Often confused with each other

� Very different but complementary

� Six Sigma focuses on process outputs

� LEAN focuses on:� LEAN focuses on:

� Processes

� Interactions between processes across the

value chain

![Page 22: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/22.jpg)

LEAN Drives Real Results:

An Air Force MRO Case Study� Operating costs: � 20%

� Cycle time: � 46%

� Chargeable hours: � 34%

� Space utilization: � 10%

� Inventory carrying costs: � 60%� Chromium exposure: �

Ogden Air Logistics Center

Hill Air Force Base

Ogden, UT

![Page 23: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/23.jpg)

How Can

Nuclear New Build Benefit?

![Page 24: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/24.jpg)

BIM Best Practices

![Page 25: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/25.jpg)

IPD Best Practices

![Page 26: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/26.jpg)

LEAN Best Practices

Lean Principles and Practices

Empowerment

Alignment of All Activities

Net Benefits for All StakeholdersNet Benefits for All Stakeholders

LEAN is, at its core, a transformative way of thinking, seeing and doing. It is NOT just a set of tools.

![Page 27: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/27.jpg)

Construction PrioritiesThe driving force for a LEAN vision

� Provide an accident-free work environment

� Keep work flowing so that crews are always productive

� Ensure that materials, tools and site are available � Ensure that materials, tools and site are available and ready when needed

� Eliminate waste

� Reduce costs and inventories

� Deliver to spec, on-time and on-budget

![Page 28: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/28.jpg)

Whole-System ApproachAcross the EPCM Value Chain

Concept Design & Engineering Procurement Construction

CommissioningMaintenanceDecommissioningSalvage & Recycle

![Page 29: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/29.jpg)

Waste Elimination/Reduction

Overproduction /Overconsumption

Overprocessing Unnecessary motion/effort

Mistakes /Rework

Waiting

Unnecessary movement of goods

Excess inventory

Unused talent/creativity

![Page 30: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/30.jpg)

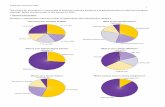

Critical Stakeholder Involvement

![Page 31: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/31.jpg)

A/Es

Labor Owner

Contractor

LEAN

Subs

SuppliersRegulatory

Authorities

Industry

Groups

![Page 32: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/32.jpg)

Team Realignment Engages Workers

![Page 33: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/33.jpg)

Traditional Jobsite OrganizationProject

Schedule

Manager

On-Site

Supervision

Materials and

Equipment

Coordination

Trades are Siloed and Take Orders

![Page 34: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/34.jpg)

LEAN Jobsite Organization

•Increased communication to and between the trades

•Greater control by trades of day-to-day activities

•Increased responsibility and control at the trade level

![Page 35: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/35.jpg)

LEAN Workflow Minimizes Waiting

![Page 36: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/36.jpg)

Traditional Workflow

![Page 37: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/37.jpg)

LEAN Workflow

•PULL as opposed to PUSH

•Modified Kanban

![Page 38: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/38.jpg)

Real-time Error Management

![Page 39: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/39.jpg)

LEAN Drives Real Results:A Large Capital Project

� State-of-the-art ASRS system

� Drawings misinterpreted

� 27’ instead of 9’ concrete footings poured

� Millions of dollars lost / Finger-pointing � Millions of dollars lost / Finger-pointing

� Could have been prevented if those most “in the

know” and closest to the situation (e.g. trades) had

been engaged in a collaborative process

� LEAN deployed to get project back on track and

mitigate further losses

![Page 40: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/40.jpg)

Preventing Errors

Traditional Approach� Limited communication with and between trades

� Limited involvement by those most “in the know”

LEAN ApproachLEAN Approach� Close, real-time, on-site communication among all

key stakeholders when and where necessary

� Close involvement by those most “in the know”

![Page 41: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/41.jpg)

Responding to Errors

Traditional Approach� Top-down accusations

� Infrequent lessons learned to prevent future errors

LEAN ApproachLEAN Approach� On-site response team involving all stakeholders

(including pertinent trades)

� Lessons learned ⇒ prevention of future errors

![Page 42: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/42.jpg)

On-site Visualization Tools

� Kanban Visual Controls

� Ensures all materials and equipment are

manufactured, shipped, received and installed per

requirements

Initiates before operations in the field have started� Initiates before operations in the field have started

� Manages Punchlist, Checkout, Startup, Testing

� Kanban “signals” indicate each stage is completed

![Page 43: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/43.jpg)

Last Planner System

![Page 44: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/44.jpg)

Last Planner System� Internal Customer

� Collaborative schedule/programming

� Make Ready process

� Interdependencies between tasks

� Weekly work planning meetings� Weekly work planning meetings

� Last planners

� Promise cycle

� Percentage of Promises Completed on time (PPC)

� Continuous improvement

![Page 45: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/45.jpg)

Large Capital Projects:

Success Factors / Proven Results

LEAN Conventional

Quality Quality is integral

to process

Quality is

“inspected in”

Cost 20%+improvement to

Excessive waste /

budget overrunsimprovement to

budget

Delivery 30%+ reduction

in project duration

Delays / schedule

overruns

Safety 6S, proper

flow/tools reduce

risk

Clutter, imbalanced

flow increase risk

![Page 46: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/46.jpg)

The Next New Build Cycle:

BIM, IPD and LEAN drive .....

� Design/engineering/construction integration, eliminating “designing while building”

� Stakeholder involvement from the start

� Dealing with critical talent shortage� Dealing with critical talent shortage

� Well-defined scope and good scope control

� Good schedule integration and management

![Page 47: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/47.jpg)

The Next New Build Cycle:

BIM, IPD and LEAN drive .....

� Effective, real-time status reporting

� Agility and adaptability to changes

� Better constructability, maintainability, testabilitytestability

� Budget management and control

� A high degree of accountability across all stakeholders, including labor

![Page 48: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/48.jpg)

The Next New Build Cycle:

BIM, IPD and LEAN drive .....

� Structured problem identification, resolution & documentation

� High degree of owner involvement across the entire projectthe entire project

� Productive communication

� Elimination of organizational silos

� Reduction of risk and uncertainty

![Page 49: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/49.jpg)

Beyond New BuildAcross the Fuel Cycle Value Chain

Enrichment

Fuel Fabrication

On-Site Storage

Reactors

Mining

Conversion to UF6

Used Fuel Recycling

Waste Disposal

![Page 50: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/50.jpg)

LEAN Nuclear/Utility Applications

� Design, Engineering and Construction

� Project Management

� Nuclear Operations and Outage Management

� Supply Chain ManagementSupply Chain Management

� Nuclear Decommissioning

� Licensing/Commissioning (NRC/PUCs)

� Utility Field Operations

![Page 51: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/51.jpg)

Thank YouThank You

![Page 52: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/52.jpg)

Questions?Questions?

![Page 53: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/53.jpg)

Nuclear Construction Summit USA 200926-27 October 2009

Washington, DC

Criterion3535 Piedmont Road NE, Suite 410Atlanta, GA 30305770.333.6389 p 770.333.6391 fwww.criterion-llc.com

Mike Cobb 770.823.5031 [email protected]

![Page 54: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/54.jpg)

Nuclear Construction Summit USA 200926-27 October 2009

Washington, DC

Appendix

![Page 55: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/55.jpg)

LEAN is LEAN is Not

A whole-system

approach

Individual activities

within silos

Across the entire

value chain

Isolated to one part of an

organizationvalue chain organization

About culture and

people, how they think

and interact

About mechanically

applying a set of tools

![Page 56: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/56.jpg)

LEAN is LEAN is Not

Continuous

improvement

A “once and done”

initiative

Fundamentally about

creating opportunities

Fundamentally about

eliminating jobscreating opportunities eliminating jobs

Decentralized decision

making / empowerment

Centralized, top-down

decision making

![Page 57: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/57.jpg)

LEAN is LEAN is Not

Designed and owned by

the whole team

Designed and owned by

management but

implemented by labor

Pulling product and Pushing product and Pulling product and

processes when needed

Pushing product and

processes

Visual communication

and cues

“Flying blind” and

meeting artificial

deadlines

![Page 58: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/58.jpg)

LEAN is LEAN is Not

Based on continuous

flow

Based on batch or poorly

coordinated operations

Conducive to a safer

workplace

In conflict with safety

goalsworkplace goals

![Page 59: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/59.jpg)

LEAN Construction “Traditional” Practice

Workflow-centered

thinking

Activity-centered

thinking

Focus: Interdependencies

between tasks/crews

Focus: Individual

tasks/activitiesbetween tasks/crews tasks/activities

Maximizes performance for

customer at project level

Links product, but not

project, to the customer

![Page 60: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/60.jpg)

LEAN Construction “Traditional” Practice

Designs product and process

concurrently

De-links product

and process

Applies production control

throughout the project and

Control is conceived as

monitoring each throughout the project and

across activities

monitoring each

contract/activity against

schedule and budget

Eliminates waste Conceals much waste

![Page 61: 4.00pm Mike Cobb, Criterion LLC.ppt.ppt [Read-Only]faculty.wiu.edu/K-Hall/344/MCobb-Nuclear-Construction-Summit-2009.pdfLEAN Construction “Traditional” Practice Workflow-centered](https://reader034.fdocuments.in/reader034/viewer/2022043007/5f945000e43a7654e7441eb8/html5/thumbnails/61.jpg)

LEAN Construction “Traditional” Practice

Decentralized, “on the

ground” decision making

Centralized, top-down

decision making

Requires teamwork and

collaboration and

De-emphasizes teamwork

and collaboration and de-collaboration and

emphasizes people issues

and collaboration and de-

emphasizes people issues

Drives a safer work

environment

Treats safety as a monitoring

and control issue