3DCS AAO - Advanced Analyzer & Optimizer - CENIT AG AAO - Advanced Analyzer & Optimizer Save time...

Transcript of 3DCS AAO - Advanced Analyzer & Optimizer - CENIT AG AAO - Advanced Analyzer & Optimizer Save time...

3DCS AAO - Advanced Analyzer & OptimizerSave time and resources with easy to use tools

All the Tools You Need to Test and Optimize Your Products

3DCS AAO is an Add-on Module for 3DCS Suite of products. As a package of advanced tools, AAO gives engineers the tools they need to analyze variation results quickly, to make engineering decisions earlier, and at lower cost, in the challening task of quality risk management.

Advanced Tools to Make Modeling Easier - The What

3DCS AAO is a set of Analyzers and Optimizers that can be used to quickly optimize designs based on set criteria, to analyze the relationships between parts and do it all in an isolated environment, creating a ‘test lab’ for design changes.

Optimizers and Analyzers - The How

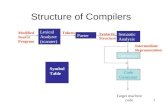

3DCS AAO consists of four primary components: Advanced Analyzer, Critical Tolerance Identi�er, Optimizer and Locator Sensitiviy Analyzer. The Advanced Analyzer creates a matrix of Geofactors and tolerances, showing a global view of the model and the relationship between the model’s parts. The Optimizer optimizes tolerances based on quality criteria with the push of a button, while the Locator Sensitivity Analyzer tests locator strategies and moves.

Save Time and Get New Insight Into Your Design - The Why

Using AAO’s analyzers, engineers can work more e�ciently on large models, quickly honing in on key areas, and testing di�erent ‘what if’ scenarios in an isolated environment to �nd the best one before updating the model. With the Optimizer, engineers have the power to optimize for cost or quality with the push of a button, making it easier to reduce costs on non-critical areas. All of these tools combine to make engineers more e�cient and e�ective.

+248-269-9777 | [email protected] | www.3DCS.com

Four Tools in One -Advanced Analyzer, Critical Tolerance Identi�er, Locator Sensitivity Analyzer and Cost and Quality Optimizer.

What-If Studies – Test design changes using simulation to reduce the need for prototypes.

Quickly Identify Contributors– Find the true source of your problem to root cause build issues and non-conformance with the Critical Tolerance Identi�er.

Global View of Model – View all of your model tolerances and Geofactors in a single matrix. Quickly see and change multiple tolerances on large models.

Real Time Analysis – Modify tolerances and make changes in the Analyzer Matrix and see your results instantly, no need to run additional analyses.

Use as a Design Test Lab – Update the model when you’re ready, not before. Make changes, see the results, and then start over without a�ecting your model.

Find Geometric Relationships - See the Geofactors related to your parts, the Geometric relationships between components that determine

Key Product Highlights:

DCS has been supporting quality management in industries including automotive, aerospace, medical device, electronics and industrial machinery for over 20

years. DCS solutions are used daily by companies like Airbus, BMW, GM, LG, Nissan, Phillips, Sony, Textron Aviation and VW. By applying DCS's 3D Model Based

environment for Predictive Variation Analysis and Responsive SPC, manufacturers have reduced quality costs related to yield, scrap, rework and warranty issues.

Create a Matrix to Get a Global ViewView all of the products tolerances and Geofactors in a single color coded matrix based on given speci�cations. Change the speci�cations with a drag bar to instantly identify trouble areas. Use to view and change many tolerances quickly on large models.

Optimize for Cost or QualityChoose cost or quality goals and have AAO optimize your model for you. Look through the changes and keep the ones you like, updating the model only when you’re ready.

Determine Geofactors to Find Sensitive AreasFind Geofactors and view them in the Matrix. These show the Geometric relationship, the multiplying e�ect of tolerances on one another so that you can isolate your most sensitive parts that have the greatest quality impact.

Validate Moves and Locator StrategiesUse Locator Sensitivty Analyzer (LSA) to determine the e�ect of di�erent locators on a part. Discover optimal assembly conditions, check the di�erence between di�erent strategies and validate your move and assembly processes.

Make Changes and See the ResultsChange tolerances, assembly processes or design characteristics and determine the outcome. Find issues and test solutions before building expensive prototypes or beginning production. See the results of your changes in the Matrix right away, without having to run additional analyses or simulations.

+248-269-9777 | [email protected] | www.3DCS.com

3DCS Advanced Analyzer & OptimizerPowerful tool set to make modeling faster and more e�cient

Quickly Validate and Test Your Model

Advanced Analyzer Matrix shows Geofactor results and global tolerances

Critical Tolerance Identi�er quanti�es the e�ect of each tolerance on the total product

Locator Sensitivity Analyzer tests Locators and Assembly Moves