35223389-EFC-3044196-3062322.pdf

Click here to load reader

-

Upload

chmubasher-maqsoodalam -

Category

Documents

-

view

212 -

download

0

Transcript of 35223389-EFC-3044196-3062322.pdf

8/9/2019 35223389-EFC-3044196-3062322.pdf

http://slidepdf.com/reader/full/35223389-efc-3044196-3062322pdf 1/4

م ي ح ر ن ا ح ر م ا سد ح اا ن ي س ر ا ي و ف ا ر ش م ع ا س ا ة و ص ا و ن ي ب ا : ر

ت ت و ر ح م و ر ي م و ع س ا

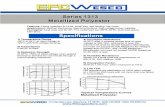

Cummins Speed ControllerEFC 3044196 / EFC 3062322

Function:3044196 Speed Controller is a fully electronic closed loop control design; itis used for fast transient load changesFast and accurate response to control engine speed, when connected tothe match the EFC series actuator and magnetic speed electronictransmissionCUMMINS Sensor signals can be perfectly controlled CUMMINS engine.

By design, it can be pre-installed simple adjustments, including adjustmentof work rate and idle, to help for more than one machine or a specialSpecial use of the input, and to prevent reverse battery voltage,instantaneous pulse voltage, short circuit actuator failures and the loss ofspeed.

8/9/2019 35223389-EFC-3044196-3062322.pdf

http://slidepdf.com/reader/full/35223389-efc-3044196-3062322pdf 2/4

Sensor signal or power supply in case of security protection.3062322 is the power plus large, can drive the engine of 500KW or more)

Technical Specifications:Speed Stability: Better Than ± 0.25% Speed Range: 1 KHz ~ 6.5 KHz Thermal Stability: ± 0.7% maximum Regulation: 260 ± 20Hz IDLE 85% of Rated Speed DROOP Adjustment : Minimum Position for the 15Hz ± 6Hz / per Ampere of LoadCurrent ChangesMaximum position: 400Hz ± 75Hz /Per Ampere of Load Current ChangesExternal Speed Adjustment: ± 200Hz (external 1K Ω )

AUX input sensitivity: 148Hz / 1V ± 10Hz. Impedance: 1MΩ

Environment:

Operating temperature range: -40~85°COperating humidity range: Max 95% RHStorage temperature: -55~92°CShock: 20~100Hz 500mm/Sec

Input Power:Supply voltage 12V and 24V DC battery systems, Ground Negative polarity, Powerconsumption 40mA

Actuator continuous current minimum 1A; maximum 4.5A (3062322 maximum currentup to 8A)Speed sensor signal: 2 ~120V RMS

Note:The performance parameters are measured at the working frequency of 3800Hz

8/9/2019 35223389-EFC-3044196-3062322.pdf

http://slidepdf.com/reader/full/35223389-efc-3044196-3062322pdf 3/4

Installation:Step 1 - 3044196 installation:

1. According to the following data in the appropriate position openings, it is proposed toinstall anti-slip self-locking screw four mounting holes : 135mm×102mm 5.5mm Placecenter of a circle distance: 135mm × 102mm, 5.5mm diameter holes installed2. In accordance with the following wiring connections can be one to one:

1- + Positive Power supply2- - Negative Power Supply3-4 Output For Actuators5-6 Input From MPU (Speed Sensor)7-8-9 External Speed Tuning10- Idle Speed Switch11- Public Side

Step 2 - 3044196 debug:In the power off, generators do not run the case; adjust the trim to its original position:The IDLE SPEED (idle speed) adjustment to the midpoint (20 laps fine-tuning, the firstcounter-clockwise in the end, then clockwise Acupuncture can be rotate 10 laps).Will RUN ( running speed) adjustment to the midpoint (20 laps fine-tuning, the first

counter-clockwise in the end, then clockwise Acupuncture can be rotate 10 laps).

The GAIN (gain) adjusted to 20% to 50% (fine-tuning of a circle).Will DROOP (speed droop rate) adjusted to 0.DROOP operation: regulating DROOP to load to full load value between thedates required, to adjust clockwiseDROOP will increase.Start the engine:

Adjust potentiometer to control the speed of the engine is operating at a predeterminedrotating speed Clockwise to increaseEngine speed. GAIN if the speed controls system instability that is slightly lower GAINsettings.GAIN: When the engine is a no-load, GAIN adjustment is as follows:The GAIN adjustment clockwise until the engine speed slowly began to swing.Then slowly rotate counter-clockwise to reduce the GAIN value until the speed ofadjustment stable.

8/9/2019 35223389-EFC-3044196-3062322.pdf

http://slidepdf.com/reader/full/35223389-efc-3044196-3062322pdf 4/4

Synchronous operation (ISOCHRONOUS) should pay attention when:To use synchronized operation, they have to DROOP in the end turned the knob andthen it started.Speed droop rate of operation is controlled by the DROOP button; clockwise rotation

will increase its rate of speed droop;To set the speed droop rate value, must be made light of MPU and the throttle actuatorfrequency axis in No load to full load under the rotation. For example, when MPUaccess frequency of 4260Hz and the throttle actuator axis Rotation between the no-loadto full load is about 30 degrees, it will DROOP button can be set in the 10 clock positionProvide about 4% set by the air speed to full speed pulse droop rate; and lowerelectromagnetic pulse frequency or speed Smaller axis of rotation will make the system

speed droop even lower.

ں ا ش و ي ل غ و ر ف ت ن و س ر ق

م س د ت و ق ص ر ط ر ئ ي ج ا

د ل آ ص ل ي و ا ی د ر ي ر ک ئ س ن ا و