30RH 040-240 “B” - תדיראן – Tadiran 040 - 240... · 30RH 040-240 “B” Nominal...

Transcript of 30RH 040-240 “B” - תדיראן – Tadiran 040 - 240... · 30RH 040-240 “B” Nominal...

30RH 040-240 “B”

Nominal cooling capacity 38-210 kW

Nominal heating capacity 38-229 kW

Air-to-Water Heat Pumps with Integrated Hydronic Module

The 30RH Aquasnap heat pumps feature the latest techno -logical innovations: ozone-friendly refrigerant HFC-407C, scroll compressors, low-noise fans made of a composite material and microprocessor control. The refrigerant circuit with its patented receiver/heat exchan ger, and the auto-adaptive Pro-Dialog control system guarantee reliable and economical operation in all climates from -10°C to 45°C. Aquasnap includes a complete hydronic module as standard, simplifying the installation to straight-forward operations like connection of the power supply and the water supply and return piping.

Features

■ Integrated hydronic module for fast installation, incorporat- ing all hydronic components: removable screen fi lter, water pump with high available pressure, expansion tank, water fl ow switch, safety valve, pressure gauges, and purge valve. A throttle valve allows adjustment of the water fl ow in accordance with the characteristics of the installation. All components are protected against frost down to -20°C.

■ Low-volume water loop: the auto-adaptive algorithm controls the water temperature and eliminates any risk of excessive compressor cycling. In the majority of comfort air conditioning applications a buffer tank is unnecessary. The low water volume reduces the energy consumption during changeover from heating to cooling during in-between seasons.

■ Ecological refrigerant HFC-407C: no effect on the ozone layer, replaces R-22 in air conditioning applications with small and medium capacities. Extensively tested by Carrier for several years, it offers the same performance and reliability guarantees as R-22.

■ The receiver/heat exchanger (Carrier patent) enhances reliability and performance of the 30RH heat pump. In the heating mode the refrigerant is condensed in the receiver at the plate heat exchanger outlet. This device compensat-es for large differences in volume between the coil and the water heat exchanger (plate heat exchanger). It ensures an ideal refrigerant charge in heating and cooling mode and perfect control of subcooling or superheating. Compressor life is increased (no risk of refrigerant migration into the compressor), and the use of the heat exchangers is maximised.

■ The revolutionary, low-noise, two-speed Flying Bird II fan is made of composite recyclable material and employs a multi-blade design and a rotating shroud, as used in the aeronautical industry. It is exceptionally quiet, and does not generate the low-frequency noise, irritating to the human ear. At part load or low outdoor temperatures the fan automatically switches to the low speed. To reduce the operating noise even further, the fan is not fi xed to the top unit panel, but supported by an extremely rigid tower chassis.

AQUASNAP

■ Defrost is optimised by the auto-adaptive algorithm. This and the new coil design reduce the defrost cycle duration by an average of 50%. For increased safety an electric heater prevents accumulation of ice on the air heat exchanger base.

■ Quiet, vibration-free scroll compressors, durable and maintenance-free. The use of several compressors per circuit (from size 30RH 050) reduces the start-up current and the power consumption at part load.

■ The refrigerant circuit is completely leak-proof for life. All pipes and refrigeration components are welded. Pressure sensors, mounted directly on the pipes, take the place of the pressure switches and their capillary tubes, a source of leaks in the past.

■ From size 30RH 090 upwards, two independent refrigerant circuits ensure partial cooling/heating capacity in all circumstances.

■ Electrical connections are simplifi ed, and the standard Aquasnap equipment includes a main disconnect switch, and a single entry point of the three-phase without neutral power supply to the whole unit.

■ Large removable panels and the hinged door of the control box ensure perfect accessibility and permit easy access to all components. Furthermore an opening allows adjustments to be made without interrupting the operation of the unit. For the most important maintenance opera-tions the unit top cover is easily removed, and total access from above is possible, with the fan remaining in place.

■ The electric resistance heater control module (accessory) permits control of up to four stages of electric heat for supplementary heating at low outdoor temperatures.

■ The evaporator is a welded, stainless steel plate heat exchanger, maximising the thermodynamic properties of HFC-407C and offering considerably increased perfor-mances as well as low water-side pressure drops. From size 30RA 090 upwards the units are equipped with a twin-circuit interlaced heat exchanger for safe operation at part load. When the unit is shut down, the heat exchanger is protected against freeze-up by a trace heater.

PRO-DIALOG Plus control

PRO-DIALOG Plus is an advanced numeric control system that combines complex intelligence with great operating simplicity. PRO-DIALOG Plus constantly monitors all machine parameters, optimising the operation of compressors, fans, cycle reversing valve and water pump.

A powerful control system

■ The Pro-Dialog Plus control is auto-adaptive and guarantees total protection of the compressors. The system permanently checks the operating parameters and responds to avoid excessive cycling and maintain the ideal operating range for the compressor (temperatures and pressures out of range etc.). By taking corrective action before the fault occurs, the auto-adaptive control frequently prevents a shutdown of the heat pump due to a fault condition.

■ To optimise power consumption, PRO-DIALOG Plus automatically resets the chilled water temperature set-point in accordance with the outdoor air temperature or the return water temperature or uses a second set-point (example occupied/unoccupied) and ensures automatic heating/cooling changeover.

■ The system also controls the start-up of a boiler relay or manages a supplementary electric heater (accessory).

Clear and easy-to-use control system

■ The operator interface is clear and user-friendly: LEDs and two numeric displays ensure immediate verifi cation of all unit operating data.

■ Buttons conveniently positioned on a synoptic heat pump diagram offer immediate display of the operating para-meters: temperatures, pressures, set point, run times etc.

■ 10 menus offer direct access to all machine controls, including a history of possible faults, for rapid and complete heat pump fault diagnosis.

Extended communications capabilities

■ PRO-DIALOG Plus allows remote control. Volt-free contacts regulate: start/stop, cooling/heating mode selection, power demand limit or selection of the second set point. The system permits remote signalling of any possible anomaly for each refrigerant circuit.

■ The internal clock permits programming of: - Heat pump start/stop - operation at the second set-point (e.g. unoccupied room) - operation of the heat pump with the fan at low speed to

reduce the noise level.■ Master/slave control of two heat pumps operating in

parallel with operating time equalisation.■ RS 485 serial port for remote heat pump control via

communications bus.

PRO-DIALOG Plus operator interface

Options and accessories

Option Accessory

Fan with available pressure for discharge ducting (30RH 090-240) x

Unit with very low noise level x

Condenser anti-corrosion pre-treatment for marine applications x

Electronic compressor starter for reduction of start-up current (30RH 040-080) x

Unit without hydronic module x

Hydronic module with dual pump x

Supplementary electric resistance heater control board (3 stages + 1 emergency stage) x

Communications board with JBus or Bacnet or LonTalk protocol x

3

6

7

2

1

24

23

16

14

9

21

20

8

4

22

5

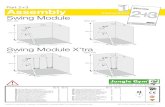

Hydronic module (040 to 160)

1

2

3

4

5

6

75

8

10

11

9

18

15

1714

1417

15

16

13

19

13

12

Typical hydronic circuit diagram

Legend

Components of unit and hydronic module

1 Victaulic screen filter

2 Expansion tank

3 Safety valve

4 Available pressure pump

5 Purge valve and pressure tap (see Installation Manual)

6 Pressure gauge to measure the plate heat exchanger pressure drop (to

be isolated with valve No. 5 if not used)

7 System air vent

8 Flow switch

9 Flow control valve

10 Plate heat exchanger

11 Evaporator defrost heater

Installation components

12 Air vent

13 Thermometer sleeve

14 Flexible connection

15 Check valve

16 System water drain plug (on connection pipe supplied in the unit)

17 Pressure gauge

18 Freeze-up protection bypass valve (when valves No. 15 are closed

during winter)

19 Charge valve

20 Plate heat exchanger outlet

21 Plate heat exchanger inlet

22 Water inlet

23 Water outlet

24 Customer connection sleeves for welded or screw connection

(supplied)

--- Hydronic module (units with hydronic module)

Note: Units without hydronic module (option) are equipped with a flow switch

and an internal piping heater.

Physical data

30RH 040 050 060 070 080 090 100 120 140 160 200 240

Nominal cooling capacity* kW 38.3 43.6 54.0 66.0 71.0 83.0 92.0 106.0 132.0 142.0 179.0 210.0

Nominal heating capacity** kW 38.4 44.6 57.0 65.0 78.0 85.0 96.0 116.0 130.0 153.0 194.0 229.0

Seasonal energy efficiency (ESEER) kW/kW 3.01 2.58 2.85 3.58 3.21 3.72 3.47 3.71 3.64 3.34 3.20 3.09

Operating weight, with hydronic module kg

Single pump 566 624 647 661 691 1183 1196 1238 1312 1368 2233 2405

Dual pump 646 704 727 741 768 1260 1273 1338 1412 1468 2321 2493

Unit without hydronic module 542 600 623 637 665 1152 1165 1200 1274 1330 2086 2258

Refrigerant charge kg R-407C

Circuit A 10.9 11.5 15.1 16.7 19.5 11.4 11.8 15.6 17.4 20.3 22.5 29.5

Circuit B - - - - - 12.0 15.6 15.6 17.4 20.3 29.5 29.5

Compressors Hermetic scroll compressor, 48.3 r/s

Quantity, circuit A 1 2 2 2 2 1 1 2 2 2 2 3

Quantity, circuit B - - - - - 2 2 2 2 2 3 3

No. of capacity steps 1 2 2 2 2 3 3 4 4 4 5 6

Minimum capacity % 100 46 42 50 50 25 25 21 25 25 20 16.5

Control type PRO-DIALOG Plus

Air heat exchangers Grooved copper tubes, aluminium fins

Fans Axial Flying Bird II fans with rotating shroud

Quantity 1 1 1 1 1 2 2 2 2 2 4 4

Total air flow (high speed) l/s 3870 3660 4080 5600 5600 7350 7950 8160 11200 11200 17343 20908

Speed (high/low speed) r/s 11.5/5.8 11.5/5.8 11.5/5.8 15.6/7.8 15.6/7.8 11.5/5.8 11.5/5.8 11.5/5.8 15.6/7.8 15.6/7.8 11.5/5.8 15.6/7.8

Water heat exchangers Direct-expansion welded plate heat exchanger

Water volume l 3.6 4.6 5.9 6.5 7.6 7.2 8.2 9.8 11.4 13.0 26.8 26.8

Max. water-side operating pressure kPa

Option without hydronic module 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000 1000

Unit with hydronic module 300 300 300 300 300 300 300 300 300 300 400 400

Hydronic module

Pump (single centrifugal, 48.3 r/s) Monocell composite pump Monocell pump

Quantity 1 1 1 1 1 1 1 1 1 1 1 1

Expansion tank volume l 12 12 12 12 12 35 35 35 35 35 50 50

Expansion tank pressure kPa 100 100 100 100 100 150 150 150 150 150 150 150

Water connections

(with and without hydronic module)

Victaulic (sleeves for welding or screw connections supplied) Threaded male

gas connections

Diameter in 2 2 2 2 2 2 2 2-1/2 2-1/2 2-1/2 3 3

Outside tube diameter mm 60.3 60.3 60.3 60.3 60.3 60.3 60.3 76.1 76.1 76.1 88.9 88.9

Legend

* Nominal conditions: water heat exchanger entering/leaving temperature 12°C/7°C, outdoor air temperature 35°C.

** Nominal conditions: air heat exchanger entering/leaving temperature 40°C/45°C, outdoor air dry bulb temperature 7°C.

Sound levels

30RH 040 050 060 070 080 090 100 120 140 160 200 240

Sound power, dB(A) 10-12 W 82 82 82 86 87 85 85 85 89 90 91 92

According to Eurovent 8/1 (derived from ISO standard 3744 or ISO 9614-1).

Electrical data

30RH (without hydronic module) 040 050 060 070 080 090 100 120 140 160 200 240

Power circuit

Nominal power supply V-ph-Hz 400-3-50

Voltage range V 360-440

Control circuit supply The control circuit is supplied via the unit-mounted transformer

Maximum unit power input* kW 20.3 24.6 30.1 35.2 40.0 44.2 49.6 60.5 70.7 79.7 104.3 124.9

Nominal unit current draw** A 28.0 34.7 41.2 47.0 54.3 62.7 69.1 82.3 94.1 108.6 140.3 168.7

Maximum unit current draw at 360 V*** A 37.0 45.7 54.9 62.7 72.4 82.6 91.9 109.8 125.4 144.8 185.4 222.9

Maximum unit current draw at 400 V**** A 33.6 41.4 49.7 57.0 65.7 75.1 83.4 99.5 113.9 131.3 168.7 202.8

Maximum start-up current

Standard unit� A 158.4 151.0 168.9 176.1 190.4 199.8 208.1 218.6 233.0 256.1 293.4 327.6

With electronic starter control� A 99.0 101.0 113.0 120.0 132.0 - - - - - -

Holding current for three-phase short circuits kA 6 6 6 6 6 10 10 10 10 10 19 19

* Power input of the compressor(s) + fan(s) at maximum unit operating conditions: entering/leaving water temperature = 15°C/10°C, maximum condensing temperature of 67.8°C and 400 V

nominal voltage (values given on the unit name plate).

** Nominal unit operating current draw at the following conditions: evaporator entering/leaving water temperature 12°C/7°C, outdoor air temperature 35°C. The current values are given at 400 V

nominal voltage.

*** Maximum unit operating current at maximum unit power input and 360 V nominal voltage.

**** Maximum unit operating current at maximum unit power input and 400 V nominal voltage (values given on the unit name plate).

� Maximum instantaneous starting current at 400 V nominal voltage and with compressor in across-the-line-start (maximum operating current of the smallest compressor(s) + fan current + locked

rotor current of the largest compressor).

� Maximum instantaneous starting current at 400 V nominal voltage and with compressor with electronic starter (maximum operating current of the smallest compressor(s) + fan current + reduced

start-up current of the largest compressor).

Hydronic module 040 050 060 070 080 090 100 120 140 160 200 240

Single pump

Shaft power kW 0.75 0.75 0.75 0.75 1.1 1.1 1.1 1.85 1.85 1.85 5.5 5.5

Power input* kW 1.1 1.1 1.1 1.1 1.4 1.4 1.4 2.5 2.5 2.5 6.6 6.6

Maximum current draw at 400 V** A 2.1 2.1 2.1 2.1 3.1 3.1 3.1 5.0 5.0 5.0 10.6 10.6

Dual pump

Shaft power kW 2.2 2.2 2.2 2.2 2.2 2.2 2.2 3.0 3.0 3.0 5.5 5.5

Power input* kW 2.7 2.7 2.7 2.7 2.7 2.7 2.7 4.0 4.0 4.0 6.6 6.6

Maximum current draw at 400 V** A 4.7 4.7 4.7 4.7 4.7 4.7 4.7 6.6 6.6 6.6 10.6 10.6

Note: The water pump power input values are given for guidance only.

* To obtain the maximum power input for a unit with hydronic module add the maximum unit power input from the top table to the pump power input (*) from the table above.

** To obtain the maximum unit operating current draw for a unit with hydronic module add the maximum unit current draw from the top table to the pump current draw from the table above.

Electrical data notes:

� 30RH 040-240 units have a single power connection point located at the main switch.

� The control box includes the following standard features:

- a main disconnect switch, starter and motor protection devices for each compressor, the

fan, the optional pumps

- the control devices

� Field connections:

All connections to the system and the electrical installations must be in full accordance with

all applicable local codes.

� The Carrier 30RH units are designed and built to ensure conformance with these codes.

The recommendations of European standard EN 60204-1 (corresponds to IEC 60204-1)

(machine safety - electrical machine components - part 1: general regulations) are

specifically taken into account, when designing the electrical equipment.

NOTES:

� Generally the recommendations of IEC 60364 are accepted as compliance with the

requirements of the installation directives. Conformance with EN 60204-1 is the best

means of ensuring compliance with the Machines Directive § 1.5.1.

� Annex B of EN 60204-1 describes the electrical characteristics used for the operation of

the machines.

1. The operating environment for the 30RH units is specified below:

a. Environment* - Environment as classified in EN 60721 (corresponds to IEC 60721):

- outdoor installation*

- ambient temperature range: -10°C to +45°C ± 1 K, class 4K3*

- altitude: ≤ 2000 m

- presence of hard solids, class 4S2 (no significant dust present)

- presence of corrosive and polluting substances, class 4C2 (negligible)

- vibration and shock, class 4M2

b. Competence of personnel, class BA4* (trained personnel - IEC 60364)

2. Power supply frequency variation: ± 2 Hz.

3. The neutral (N) conductor must not be connected directly to the unit (if necessary use

transformers)

4. Over-current protection of the power supply conductors is not provided with the unit.

5. The factory-installed disconnect switches/circuit breakers are of a type that is suitable to

interrupt the power in accordance with EN60947-3 (corresponds to IEC 60947-3).

6. The units are designed for connection to TN networks (IEC 60364). For IT networks the

earth connection must not be at the network earth. Provide a local earth, consult competent

local organisations to complete the electrical installation.

NOTE:

If particular aspects of an actual installation do not conform to the conditions

described above, or if there are other conditions which should be considered,

always contact your local Carrier representative.

* The required protection level for this class is IP43BW (according to reference document

IEC 60529). All 30RH units are protected to IP44CW and fulfil this protection condition.

Operating limits

Evaporator water flow rate, l/s

30RH Min. water flow Max. water flow* Max. water flow**

Single pump Dual pump

040 1.0 3.5 4.4 3.7

050 1.1 4.0 5.2 4.6

060 1.4 4.4 6.0 5.8

070 1.5 4.6 6.4 6.4

080 1.7 5.5 6.8 7.3

090 2.3 5.6 6.9 7.6

100 2.6 5.8 7.4 8.8

120 3.1 8.5 10.5 10.8

140 3.5 8.8 11.4 12.7

160 4.2 9.1 11.9 14.4

200 5.3 23.4 23.4 24.2

240 6.3 23.4 23.4 24.2

30RH Heating mode

040-240Entering water temperature at

start-up, °C

Entering water temperature at

shut-down, °C

Leaving water temperature

during operation

Entering air temperature, °C

Minimum� Maximum Minimum Maximum Minimum� Maximum Minimum Maximum

10 45 3 60 20 50 -10 40

30RH Cooling mode

040-240Entering water temperature at

start-up, °C

Entering water temperature Leaving water temperature at

shut-down, °C

Entering air temperature, °C

during operation

Minimum� Maximum Maximum Minimum� Maximum Minimum Maximum

7.8 30 60 5 15 -10 46

Notes:

* Maximum flow rate for an available pressure of 50 kPa (unit with hydronic module)

** Maximum flow rate for a pressure drop of 100 kPa (unit without hydronic module)

� For applications requiring operation below 7.8°C contact Carrier

� For applications requiring operation below 5°C anti-freeze must be used

Operating range in cooling mode Operating range in heating mode

Leaving water temperature

En

teri

ng

air

te

mp

era

ture

ûC

20

15

10

5

0

-5

-10

20 25 30 35 40 45 50 ûC

25

30

35

�

40

Leaving water temperature

En

teri

ng

air

te

mp

era

ture

Notes:

1. Water heat exchanger Δt = 5 K

2. The water heat exchanger and the hydronic module are protected against frost down to -20°C.

Operating range with required anti-freeze solution and special Pro-Dialog control configuration

Available static system pressureSingle pump

50

75

100

125

150

175

200

225

250

0 2 4 6 8 10 12 14 16 18 20 22 24 26

1

2 3

4

5

6 7

8

9 10

Av

aila

ble

sta

tic

pre

ss

ure

, k

Pa

Water flow rate, l/s

Legend

1 30RH 040 6 30RH 100

2 30RH 050 7 30RH 120

3 30RH 060 8 30RH 140

4 30RH 070 9 30RH 160

5 30RH 080-090 10 30RH 200-240

Dual pump

50

75

100

125

150

175

200

225

250

0 2 4 6 8 10 12 14 16 18 20 22 24 26

1

2

3

4

5

6

7

8

9 10 11

Water flow rate, l/s

Av

aila

ble

sta

tic

pre

ss

ure

, k

Pa

Legend

1 30RH 040 7 30RH 100

2 30RH 050 8 30RH 120

3 30RH 060 9 30RH 140

4 30RH 070 10 30RH 160

5 30RH 080 11 30RH 200-240

6 30RH 090

Water loop volumeMinimum water loop volume

Volume = CAP (kW) x N* = litres, where CAP is the nominal cooling capacity at nominal operating conditions.

Air conditioning application N*

30RH 040 3.5

30RH 050 to 240 2.5

Industrial process cooling

30RH 040 to 240 See note

NOTE:

For industrial process cooling applications, where high stability of the water temperature

must be achieved, the values above must be increased.

Maximum water loop volume

Units with hydronic module incorporate an expansion tank that limits the water loop volume. The table below gives the maximum loop volume for pure water or ethylene glycol with various concentrations.

30RH

040-080

30RH

090-160

30RH

200-240

(in litres) (in litres) (in litres)

Pure water 600 1500 2000

10% ethylene glycol 450 1200 1600

20% ethylene glycol 400 1000 1400

35% ethylene glycol 300 800 1000

Dimensions/clearances30RH 040-080

1081

1329

2071

1000

1000

1

2

1

2

1000

1000

Legend:

All dimensions are given in mm.

Control box

Required clearances for air entry

Required clearances for maintenance

Water inlet

Water outlet

Power cable entry

Air outlet, do not obstruct

NOTE: Drawings are not contractually binding.

Before designing an installation, consult the

certified dimensional drawings, available on

request.

Dimensions/clearances30RH 090-160

20712278

1329

1000

1000

1000

1000

2

1

1

1

1

2

30RH 200-240

2279 3351

1674

2

1

1

1

1

2

1000

1000

1000

2

2

1000

Legend:

All dimensions are given in mm.

Control box

Required clearances for air entry

Required clearances for maintenance

Water inlet

Water outlet

Power cable entry

Air outlet, do not obstruct

NOTE: Drawings are not contractually binding.

Before designing an installation, consult the

certified dimensional drawings, available on

request.

Heating capacities, single and dual pumps

30

RH

En

terin

g a

ir t

em

pe

ra

ture

, °C

LW

T-1

0-5

07

10

CA

PC

OM

PU

NIT

CO

ND

PR

ES

PR

ES

CA

PC

OM

PU

NIT

CO

ND

PR

ES

PR

ES

CA

PC

OM

PU

NIT

CO

ND

PR

ES

PR

ES

CA

PC

OM

PU

NIT

CO

ND

PR

ES

PR

ES

CA

PC

OM

PU

NIT

CO

ND

PR

ES

PR

ES

(1

)(2

)(1

)(2

)

(1

)(2

)

(1

)(2

)

(1

)(2

)

°C

kW

kW

kW

l/s

kP

ak

Pa

kP

ak

Wk

Wk

Wl/

sk

Pa

kP

ak

Pa

kW

kW

kW

l/s

kP

ak

Pa

kP

ak

Wk

Wk

Wl/

sk

Pa

kP

ak

Pa

kW

kW

kW

l/s

kP

ak

Pa

kP

a

04

03

02

2.3

8.9

71

0.2

1.0

69

16

22

08

25

.49

.03

10

.21

.21

12

15

92

05

30

.49

.41

10

.61

.45

17

15

42

01

41

.31

0.4

11

.61

.97

32

13

71

86

44

.71

0.5

11

.72

.14

38

13

01

81

05

02

6.1

12

.31

3.5

1.2

58

16

32

09

29

.81

2.4

13

.61

.42

10

16

02

07

35

.61

2.9

14

.11

.71

51

55

20

35

11

3.7

14

.92

.45

31

13

21

85

55

13

.91

5.1

2.6

13

51

26

18

0

06

03

31

3.7

14

.91

.58

81

62

20

93

7.7

13

.81

51

.81

11

58

20

64

51

4.3

15

.52

.15

15

15

12

01

61

15

.11

6.3

2.9

22

81

27

18

56

61

5.3

16

.53

.14

32

11

81

79

07

03

7.7

15

17

.51

.89

16

02

08

43

15

.21

7.7

2.0

61

11

55

20

55

11

5.8

18

.32

.46

16

14

51

98

68

17

.21

9.7

3.2

62

81

18

18

17

41

7.5

20

3.5

33

31

06

17

3

08

0

45

.11

8.3

20

.82

.16

10

20

02

06

52

18

.52

12

.46

13

19

32

02

62

19

.22

1.7

2.9

41

81

78

19

38

32

0.3

22

.83

.97

33

13

81

68

89

20

.62

3.1

4.2

63

81

24

16

0

09

04

9.5

20

.52

2.9

2.3

61

21

95

20

35

62

0.6

23

2.7

16

18

51

97

67

21

.52

3.9

3.2

22

21

68

18

79

52

3.1

25

.54

.52

41

11

21

52

10

22

3.5

25

.94

.85

47

94

14

1

10

0

56

22

.72

5.1

2.6

61

21

90

20

16

32

2.8

25

.23

.03

15

17

91

95

76

23

.72

6.1

3.6

22

11

59

18

41

03

25

.42

7.8

4.9

23

71

01

14

91

11

25

.82

8.2

5.3

14

28

11

37

12

06

72

7.4

29

.83

.22

12

21

71

96

77

27

.63

03

.67

15

21

01

92

92

28

.63

14

.38

21

19

71

85

12

53

0.2

32

.65

.96

36

15

41

63

13

43

0.6

33

6.4

41

13

91

56

14

07

53

0.1

35

.13

.61

12

15

19

68

63

0.3

35

.34

.11

14

20

61

92

10

33

1.6

36

.64

.91

19

19

01

85

13

73

4.4

39

.46

.53

32

14

41

63

14

83

54

07

.07

37

12

61

54

16

08

93

6.3

41

.34

.23

12

20

71

94

10

13

6.6

41

.64

.83

15

19

51

89

12

13

8.1

43

.15

.77

21

17

31

79

16

34

0.1

45

.17

.78

36

10

61

49

17

54

0.7

45

.78

.36

41

82

13

8

20

0

11

54

6.5

54

5.4

87

23

02

28

13

84

7.6

55

6.5

71

02

25

22

31

63

49

.35

77

.81

32

19

21

62

04

47

.25

59

.74

20

20

52

02

21

64

7.6

55

10

.32

32

00

19

7

24

01

38

60

70

6.5

91

02

25

22

31

57

60

70

7.5

21

32

20

21

81

88

63

73

8.9

81

72

11

20

82

48

57

68

11

.92

91

86

18

22

67

58

68

12

.73

31

77

17

3

04

0

35

21

.99

.87

11

.11

.05

91

62

20

82

5.1

9.9

41

1.1

1.2

12

16

02

06

30

10

.31

1.5

1.4

41

71

54

20

14

01

1.4

12

.61

.91

30

14

01

88

43

.51

1.6

12

.82

.08

36

13

31

83

05

02

5.7

13

.51

4.7

1.2

38

16

32

09

29

.41

3.6

14

.81

.41

01

61

20

73

5.2

14

.11

5.3

1.6

81

51

55

20

34

8.7

15

.21

6.4

2.3

22

81

37

18

95

21

5.4

16

.62

.48

32

13

11

84

06

03

2.5

15

16

.21

.55

81

62

20

93

7.2

15

.11

6.3

1.7

81

01

59

20

74

4.5

15

.61

6.8

2.1

31

51

51

20

15

91

6.8

18

2.8

42

61

30

18

76

41

71

8.2

3.0

53

01

21

18

1

07

0

37

.11

6.6

19

.11

.77

81

60

20

84

2.4

16

.71

9.2

2.0

31

11

56

20

55

11

7.4

19

.92

.43

16

14

61

99

67

19

21

.53

.21

28

12

01

82

73

19

.32

1.8

3.4

83

21

09

17

5

08

0

44

.52

0.2

22

.72

.12

92

01

20

65

12

0.3

22

.82

.43

12

19

32

02

61

21

.12

3.6

2.9

11

81

79

19

48

12

2.6

25

.13

.85

31

14

31

72

87

22

.92

5.4

4.1

43

61

30

16

3

09

04

8.7

22

.52

4.9

2.3

31

21

95

20

35

62

2.7

25

.12

.66

15

18

61

98

67

23

.52

5.9

3.1

92

11

69

18

89

12

5.6

28

4.3

33

81

21

15

89

82

62

8.4

4.6

64

41

04

14

8

10

05

52

4.9

27

.32

.62

11

19

12

02

63

25

27

.42

.99

15

18

01

96

75

25

.92

8.3

3.5

82

01

60

18

51

00

28

.23

0.6

4.7

83

51

08

15

41

08

28

.63

15

.16

40

88

14

1

12

06

63

03

2.4

3.1

71

12

18

19

67

63

0.2

32

.63

.62

14

21

11

93

91

31

.33

3.7

4.3

42

01

98

18

61

21

33

.63

65

.79

34

15

91

66

13

03

4.1

36

.56

.23

39

14

51

59

14

07

43

3.2

38

.23

.55

10

21

61

96

85

33

.43

8.4

4.0

61

32

07

19

31

02

34

.73

9.7

4.8

61

91

91

18

51

34

38

.14

3.1

6.4

23

11

48

16

51

46

38

.64

3.6

6.9

63

61

30

15

6

16

08

74

04

54

.16

11

20

81

94

10

04

0.3

45

.34

.76

14

19

71

89

11

94

1.8

46

.85

.72

01

74

18

01

58

44

.74

9.7

7.5

53

41

15

15

31

70

45

.35

08

.12

38

92

14

3

20

01

13

51

59

5.4

72

30

22

81

36

53

60

6.4

91

02

26

22

31

62

54

62

7.7

21

32

19

21

72

00

52

60

9.5

42

02

07

20

42

12

53

60

10

.12

22

02

19

9

24

01

36

65

75

6.4

91

02

26

22

31

55

66

76

7.4

21

22

21

21

81

86

68

78

8.8

81

72

11

20

92

41

63

74

11

.52

81

90

18

62

59

64

74

12

.43

21

81

17

7

04

04

02

1.3

10

.91

2.1

1.0

29

16

32

08

24

.51

11

2.2

1.1

71

11

60

20

62

9.4

11

.41

2.6

1.4

11

61

55

20

23

9.1

12

.61

3.8

1.8

72

91

41

19

04

2.5

12

.81

42

.03

34

13

51

84

05

02

51

51

6.2

1.2

71

64

21

02

8.7

15

.11

6.3

1.3

71

01

61

20

83

4.5

15

.61

6.8

1.6

51

41

56

20

34

6.4

16

.91

8.1

2.2

22

51

41

19

14

9.7

17

.11

8.3

2.3

82

91

35

18

7

06

03

1.6

16

.61

7.8

1.5

17

16

32

10

36

.31

6.7

17

.91

.73

10

15

92

07

43

.61

7.2

18

.42

.08

14

15

22

02

58

18

.71

9.9

2.7

72

51

32

18

86

21

8.9

20

.12

.98

29

12

41

83

07

03

6.1

18

.52

11

.73

81

61

20

94

1.4

18

.62

1.1

1.9

81

11

57

20

64

9.8

19

.22

1.7

2.3

81

51

48

20

06

62

1.1

23

.63

.15

27

12

21

84

72

21

.42

3.9

3.4

23

11

11

17

7

08

04

3.2

22

.42

4.9

2.0

79

20

22

07

49

.62

2.5

25

2.3

71

21

95

20

36

02

3.3

25

.82

.85

17

18

11

95

79

25

.22

7.7

3.7

63

01

47

17

48

52

5.5

28

4.0

63

41

33

16

6

09

04

7.4

24

.92

7.3

2.2

61

11

97

20

45

42

5.1

27

.52

.61

51

88

19

96

52

5.9

28

.33

.12

21

17

21

89

87

28

.43

0.8

4.1

83

61

29

16

39

42

8.8

31

.24

.51

41

11

31

53

10

05

32

7.5

29

.92

.55

11

19

32

03

61

27

.73

0.1

2.9

21

41

82

19

77

32

8.6

31

3.5

12

01

63

18

69

83

1.3

33

.74

.66

33

11

41

57

10

63

1.7

34

.15

.05

39

95

14

5

12

06

43

3.1

35

.53

.08

11

21

91

97

74

33

.33

5.7

3.5

41

42

13

19

38

93

4.4

36

.84

.25

19

19

91

87

11

83

7.4

39

.85

.65

33

16

41

68

12

73

7.8

40

.26

.09

38

15

01

61

14

07

23

6.9

41

.93

.45

10

21

71

97

83

37

.14

2.1

3.9

61

32

09

19

31

00

38

.44

3.4

4.7

61

81

93

18

61

32

42

.24

7.2

6.3

13

01

52

16

61

43

42

.74

7.7

6.8

53

51

34

15

8

16

08

54

4.3

49

.34

.05

11

21

01

95

97

44

.64

9.6

4.6

51

41

99

19

01

17

46

.15

15

.59

19

17

71

81

15

54

9.9

55

7.3

83

21

21

15

61

67

50

55

7.9

63

79

91

46

20

01

11

57

65

5.3

17

23

12

29

13

45

86

66

.49

22

62

24

16

06

06

77

.63

13

22

02

17

19

65

86

69

.38

19

20

82

05

20

85

96

69

.96

21

20

32

00

24

01

32

72

82

6.3

19

22

62

24

15

27

28

27

.24

12

22

22

20

18

27

48

48

.71

16

21

32

10

23

57

08

01

1.2

26

19

21

89

25

37

18

11

2.1

30

18

41

80

30

RH

En

terin

g a

ir t

em

pe

ra

ture

, °C

LW

T-1

0-5

07

10

CA

PC

OM

PU

NIT

CO

ND

PR

ES

PR

ES

CA

PC

OM

PU

NIT

CO

ND

PR

ES

PR

ES

CA

PC

OM

PU

NIT

CO

ND

PR

ES

PR

ES

CA

PC

OM

PU

NIT

CO

ND

PR

ES

PR

ES

CA

PC

OM

PU

NIT

CO

ND

PR

ES

PR

ES

(1

)(2

)(1

)(2

)

(1

)(2

)

(1

)(2

)

(1

)(2

)

°C

kW

kW

kW

l/s

kP

ak

Pa

kP

ak

Wk

Wk

Wl/

sk

Pa

kP

ak

Pa

kW

kW

kW

l/s

kP

ak

Pa

kP

ak

Wk

Wk

Wl/

sk

Pa

kP

ak

Pa

kW

kW

kW

l/s

kP

ak

Pa

kP

a

04

04

52

3.6

12

.21

3.4

1.1

31

01

61

20

72

8.6

12

.61

3.8

1.3

71

51

56

20

23

8.4

13

.91

5.1

1.8

42

81

42

19

14

1.9

14

.11

5.3

23

31

36

18

5

05

02

7.7

16

.71

7.9

1.3

29

16

22

08

33

.51

7.2

18

.41

.61

31

57

20

44

4.6

18

.71

9.9

2.1

32

31

43

19

44

7.9

18

.92

0.1

2.2

92

71

38

19

0

06

03

51

8.4

19

.61

.67

91

60

20

84

2.4

19

20

.22

.02

13

15

42

03

57

20

.82

22

.71

24

13

41

90

61

21

22

.22

.93

28

12

61

84

07

04

02

0.7

23

.21

.91

10

15

82

07

48

.42

1.3

23

.82

.31

14

14

92

01

65

23

.32

5.8

3.1

26

12

41

85

70

23

.62

6.1

3.3

73

01

14

17

8

08

04

7.9

25

27

.52

.29

11

19

72

04

58

25

.82

8.3

2.7

71

61

84

19

77

82

8.1

30

.63

.72

29

14

91

75

84

28

.43

0.9

4.0

13

41

36

16

7

09

05

22

7.8

30

.22

.51

14

19

12

00

63

28

.73

1.1

3.0

32

01

75

19

18

53

1.4

33

.84

.05

34

13

41

66

92

31

.83

4.2

4.3

83

91

19

15

7

10

05

93

0.7

33

.12

.82

13

18

51

99

71

31

.63

43

.41

19

16

61

88

96

34

.73

7.1

4.5

73

21

18

16

01

04

35

.13

7.5

4.9

63

79

91

48

12

07

13

6.9

39

.33

.41

13

21

51

94

86

38

40

.44

.13

18

20

21

88

11

64

1.5

43

.95

.53

32

16

71

70

12

54

24

4.4

5.9

73

61

54

16

3

14

08

04

1.4

46

.43

.82

12

21

11

94

97

42

.74

7.7

4.6

21

71

96

18

71

30

46

.75

26

.19

29

15

51

68

14

14

7.3

52

6.7

33

41

38

16

0

16

09

44

9.6

55

4.4

91

32

02

19

21

14

51

56

5.4

31

81

81

18

31

53

56

61

7.3

32

12

41

57

16

55

66

17

.87

36

10

21

47

20

01

32

65

72

6.3

92

27

22

41

58

66

74

7.5

31

32

20

21

81

94

65

73

9.2

81

92

09

20

62

06

65

73

9.8

62

12

04

20

1

24

01

46

79

89

6.9

91

12

23

22

11

77

81

91

8.4

61

62

14

21

22

29

78

88

11

25

19

51

91

24

87

98

91

1.8

29

18

71

83

04

05

02

7.5

14

15

.21

.31

14

15

72

04

38

.11

5.4

16

.61

.82

27

14

31

91

41

.51

5.6

16

.81

.98

32

13

71

86

05

03

2.2

19

20

.21

.54

12

15

82

05

43

.22

0.6

21

.82

.06

22

14

61

95

46

.52

0.9

22

.12

.22

25

14

01

91

06

04

0.7

21

22

.21

.95

12

15

52

04

56

23

24

.22

.67

23

13

61

91

60

23

.22

4.4

2.8

82

71

28

18

6

07

04

6.5

23

.72

6.2

2.2

21

31

51

20

26

42

5.8

28

.33

.04

25

12

71

86

69

26

.12

8.6

3.3

12

91

16

18

0

08

05

62

8.7

31

.22

.66

15

18

71

98

78

31

.33

3.8

3.7

22

91

49

17

58

43

1.6

34

.14

.01

34

13

61

67

09

06

13

1.8

34

.22

.92

18

17

81

93

83

34

.73

7.1

3.9

73

21

38

16

99

03

5.1

37

.54

.33

81

23

15

9

10

0

69

35

37

.43

.28

17

17

11

91

94

38

.54

0.9

4.5

13

11

21

16

11

02

38

.94

1.3

4.8

93

71

02

15

0

12

08

34

24

4.4

3.9

71

72

05

18

91

14

46

48

.45

.44

31

17

01

71

12

34

6.5

48

.95

.88

35

15

71

65

14

09

34

7.5

52

4.4

41

62

00

18

91

27

52

57

6.0

72

81

59

17

01

38

52

57

6.6

13

31

42

16

2

16

01

09

57

62

5.2

21

71

86

18

51

52

62

67

7.2

93

21

25

15

71

65

63

68

7.8

63

61

03

14

8

20

01

55

74

81

7.4

21

22

21

21

81

93

73

80

9.2

31

82

09

20

62

05

73

80

9.8

12

12

04

20

2

24

01

70

89

10

08

.13

15

21

62

14

22

58

69

71

0.8

24

19

71

93

24

38

79

71

1.6

28

18

91

85

Heating capacities, single and dual pumps (continued)

Le

ge

nd

:

LW

T

Le

av

ing

wa

ter

tem

pe

ratu

re

CA

P k

W

In

sta

nta

ne

ou

s h

ea

tin

g c

ap

ac

ity

CO

MP

kW

C

om

pre

ss

or

po

we

r in

pu

t

UN

IT k

W

Un

it p

ow

er

inp

ut,

(c

om

pre

ss

ors

, fa

ns

an

d c

on

tro

l c

irc

uit

)

CO

ND

l/s

C

on

de

ns

er

wa

ter

flo

w r

ate

CO

ND

kP

a

Co

nd

en

se

r p

res

su

re d

rop

PR

ES

kP

a (

1)

Av

aila

ble

pre

ss

ure

at

the

un

it o

utl

et

(un

it w

ith

sin

gle

-pu

mp

hy

dro

nic

mo

du

le)

PR

ES

kP

a (

2)

Av

aila

ble

pre

ss

ure

at

the

un

it o

utl

et

(un

it w

ith

du

al-

pu

mp

hy

dro

nic

mo

du

le)

Ap

pli

ca

tio

n d

ata

:

Sta

nd

ard

un

its

Re

frig

era

nt:

R-4

07

C

Co

nd

en

se

r te

mp

era

ture

ris

e:

5 K

Co

nd

en

se

r fl

uid

: w

ate

r

Fo

ulin

g f

ac

tor:

0.4

4 x

10

-4 (

m2 K

)/W

Pe

rfo

rma

nc

es

in

ac

co

rda

nc

e w

ith

EN

14

51

1.

He

ati

ng

ca

pa

cit

y a

t lo

w o

utd

oo

r t

em

pe

ra

ture

Th

e p

ub

lis

he

d h

ea

tin

g c

ap

ac

itie

s a

re in

sta

nta

ne

ou

s c

ap

ac

itie

s.

Th

ey

do

no

t ta

ke

ac

co

un

t o

f th

e d

ec

rea

se

of

the

he

ati

ng

ca

pa

cit

y,

res

ult

ing

fro

m t

he

fo

rma

tio

n o

f fr

os

t o

n t

he

co

il a

nd

th

e e

ffe

ct

of

the

de

fro

st

cy

cle

s.

Th

e in

teg

rate

d h

ea

tin

g c

ap

ac

ity

ta

ke

s t

he

se

eff

ec

ts in

to a

cc

ou

nt.

Th

ey

de

pe

nd

on

th

e t

em

pe

ratu

re a

nd

th

e

rela

tiv

e h

um

idit

y (

rh)

of

the

ou

tdo

or

air

.

Co

rre

cti

on

fa

cto

r t

o o

bta

in i

nte

gra

ted

he

ati

ng

ca

pa

cit

ies

Le

av

ing

wa

ter

tem

p.

°C

Ou

tdo

or

tem

pe

ratu

re °

C (

87

% r

h)

-10

-50

71

0

30

0.8

80

.85

0.8

71

1

35

0.8

70

.85

0.8

71

1

40

0.8

80

.85

0.8

71

1

45

0.8

90

.86

0.8

81

1

50

0.9

10

.89

0.9

11

1

No

te:

Th

e C

arr

ier

ele

ctr

on

ic s

ele

cti

on

pro

gra

m p

erm

its

ca

lcu

lati

ng

th

e in

teg

rate

d h

ea

tin

g c

ap

ac

ity

as

a f

un

cti

on

of

the

ac

tua

l h

um

idit

y c

on

dit

ion

s a

t th

e in

sta

lla

tio

n s

ite

. C

on

tac

t C

arr

ier

for

yo

ur

pe

rso

na

lis

ed

he

at

pu

mp

Cooling capacities, single and dual pumps

30

RH

Co

nd

en

se

r e

nte

rin

g a

ir t

em

pe

ra

ture

, °C

LW

T2

53

03

54

04

5

CA

PC

OM

PU

NIT

CO

OL

CO

OL

PR

ES

PR

ES

CA

PC

OM

PU

NIT

CO

OL

CO

OL

PR

ES

PR

ES

CA

PC

OM

PU

NIT

CO

OL

CO

OL

PR

ES

PR

ES

CA

PC

OM

PU

NIT

CO

OL

CO

OL

PR

ES

PR

ES

CA

PC

OM

PU

NIT

CO

OL

CO

OL

PR

ES

PR

ES

(1

)(2

)(1

)(2

)

(1

)(2

)

(1

)(2

)

(1

)(2

)

°C

kW

kW

kW

l/s

kP

ak

Pa

kP

ak

Wk

Wk

Wl/

sk

Pa

kP

ak

Pa

kW

kW

kW

l/s

kP

ak

Pa

kP

ak

Wk

Wk

Wl/

sk

Pa

kP

ak

Pa

kW

kW

kW

l/s

kP

ak

Pa

kP

a

04

05

40

.11

0.7

11

.91

.91

30

14

01

88

37

.91

1.8

13

1.8

12

71

43

19

13

5.7

13

14

.21

.71

24

14

71

94

33

.61

4.3

15

.51

.61

21

15

01

97

31

.61

5.7

16

.91

.51

19

15

31

99

05

04

5.8

14

.41

5.6

2.1

92

51

41

19

24

3.3

16

17

.22

.07

22

14

51

95

40

.81

7.8

19

1.9

52

01

49

19

83

8.3

19

.62

0.8

1.8

31

71

52

20

03

5.7

21

.52

2.7

1.7

11

51

55

20

2

06

05

71

6.3

17

.52

.72

41

34

19

05

41

81

9.2

2.5

62

11

39

19

35

11

9.9

21

.12

.41

19

14

41

96

47

.52

1.8

23

2.2

71

71

48

19

94

4.5

23

.92

5.1

2.1

31

51

51

20

1

07

06

91

8.8

21

.33

.28

29

11

71

80

65

20

.72

3.2

3.1

22

61

24

18

46

22

2.8

25

.32

.95

23

13

01

88

58

24

.92

7.4

2.7

82

11

36

19

25

52

7.3

29

.82

.61

81

41

19

6

08

0

75

23

.42

5.9

3.5

82

71

54

17

97

12

5.9

28

.43

.39

24

16

21

84

67

28

.53

13

.19

21

16

91

88

63

31

.33

3.8

2.9

91

91

76

19

25

83

4.3

36

.82

.79

16

18

31

96

09

08

72

4.1

26

.54

.15

35

13

01

64

82

26

.82

9.2

3.9

23

21

40

17

07

72

9.6

32

3.7

28

15

01

76

73

32

.63

53

.47

25

15

91

82

68

35

.83

8.2

3.2

52

21

67

18

7

10

0

97

27

29

.44

.62

33

11

61

58

91

29

.83

2.2

4.3

73

01

28

16

68

63

2.9

35

.34

.12

27

13

91

72

81

36

.13

8.5

3.8

82

41

49

17

87

63

9.6

42

3.6

32

11

58

18

4

12

01

11

32

.63

55

.32

91

74

17

31

05

36

.13

8.5

5.0

22

61

81

17

79

93

9.8

42

.24

.73

24

18

91

81

93

43

.64

64

.45

21

19

51

84

87

47

.85

04

.17

19

20

11

87

14

01

37

37

.74

2.7

6.5

73

31

43

16

21

30

41

.44

6.4

6.2

33

01

54

16

81

23

45

.55

15

.92

71

64

17

21

16

49

.95

55

.56

24

17

41

77

10

95

56

05

.21

21

18

31

81

16

01

50

46

.45

17

.16

31

12

91

59

14

25

15

66

.77

28

14

21

65

13

35

66

16

.38

25

15

51

71

12

56

26

75

.98

22

16

71

76

11

76

87

35

.58

19

17

71

81

20

0

18

75

46

18

.95

17

21

12

08

17

75

96

78

.47

16

21

42

12

16

76

57

37

.99

14

21

72

15

15

77

27

97

.52

13

22

02

18

14

87

98

67

.05

11

22

32

21

24

02

21

65

75

10

.62

41

98

19

52

09

72

82

9.9

92

12

03

20

01

97

79

89

9.4

21

92

07

20

51

85

87

97

8.8

51

72

12

20

91

73

96

10

68

.27

15

21

62

13

04

0

64

1.5

10

.81

21

.98

32

13

71

86

39

.21

1.9

13

.11

.87

29

14

11

90

37

13

.21

4.4

1.7

72

61

45

19

33

4.8

14

.51

5.7

1.6

62

31

48

19

63

2.7

15

.81

71

.56

20

15

11

98

05

04

7.3

14

.61

5.8

2.2

62

61

39

19

04

4.7

16

.21

7.4

2.1

42

41

43

19

34

2.2

18

19

.22

.02

21

14

71

96

39

.61

9.8

21

1.8

91

81

50

19

93

72

1.7

22

.91

.77

16

15

32

01

06

05

81

6.5

17

.72

.79

25

13

11

88

55

18

.31

9.5

2.6

42

31

36

19

15

22

0.1

21

.32

.52

01

41

19

44

9.1

22

.12

3.3

2.3

51

81

45

19

74

6.1

24

.12

5.3

2.2

16

14

92

00

07

0

71

19

.12

1.6

3.3

93

11

13

17

76

72

12

3.5

3.2

22

81

20

18

26

42

32

5.5

3.0

52

51

26

18

66

02

5.2

27

.72

.87

22

13

31

90

56

27

.53

02

.72

01

38

19

4

08

0

77

23

.72

6.2

3.7

29

15

01

76

73

26

.22

8.7

3.4

92

51

58

18

16

92

8.8

31

.33

.29

23

16

61

86

65

31

.73

4.2

3.0

92

01

73

19

06

03

4.7

37

.22

.89

17

18

01

94

09

09

02

4.5

26

.94

.29

37

12

31

60

85

27

.12

9.5

4.0

53

41

34

16

68

02

9.9

32

.33

.82

30

14

41

73

75

32

.93

5.3

3.6

27

15

41

79

71

36

.13

8.5

3.3

72

41

63

18

4

10

01

00

27

.32

9.7

4.7

73

51

08

15

49

53

0.2

32

.64

.52

31

12

11

61

89

33

.33

5.7

4.2

62

81

32

16

88

43

6.5

38

.94

.01

25

14

31

75

79

40

42

.43

.76

22

15

31

81

12

01

15

33

35

.45

.47

31

16

91

71

10

83

6.5

38

.95

.18

28

17

71

75

10

24

0.2

42

.64

.89

25

18

51

79

96

44

.14

6.5

4.6

23

19

21

83

90

48

.35

14

.31

20

19

81

86

14

01

42

38

.14

3.1

6.7

93

51

36

15

91

35

41

.94

6.9

6.4

53

11

47

16

41

28

46

51

6.1

28

15

81

70

12

05

05

55

.75

25

16

81

74

11

35

56

05

.39

23

17

81

79

16

01

55

47

52

7.3

93

21

21

15

61

46

52

57

6.9

92

91

35

16

21

38

57

62

6.5

82

61

48

16

81

29

63

68

6.1

82

31

61

17

41

21

69

74

5.7

72

11

72

17

9

20

01

94

55

62

9.2

61

82

09

20

61

83

60

68

8.7

61

72

12

21

01

73

66

74

8.2

71

52

16

21

31

63

73

80

7.7

91

32

19

21

61

53

80

87

7.3

11

22

21

21

9

24

02

28

66

76

10

.92

51

95

19

22

16

73

83

10

.32

32

00

19

72

04

80

90

9.7

42

02

05

20

21

91

88

98

9.1

51

82

10

20

71

79

97

10

78

.56

16

21

42

11

04

07

42

.91

11

2.2

2.0

53

41

34

18

44

0.6

12

.11

3.3

1.9

43

11

39

18

73

8.3

13

.31

4.5

1.8

32

71

43

19

13

6.1

14

.61

5.8

1.7

22

41

46

19

43

3.9

16

17

.21

.62

22

14

91

97

05

04

8.7

14

.81

62

.33

28

13

71

88

46

.21

6.4

17

.62

.21

25

14

11

92

43

.61

8.2

19

.42

.08

22

14

51

95

41

20

21

.21

.96

20

14

81

97

38

.42

1.9

23

.11

.83

17

15

22

00

06

06

01

6.7

17

.92

.88

27

12

81

86

57

18

.51

9.7

2.7

32

41

34

18

95

42

0.3

21

.52

.58

22

13

91

93

51

22

.32

3.5

2.4

31

91

43

19

64

7.6

24

.42

5.6

2.2

81

71

47

19

9

07

07

31

9.3

21

.83

.53

31

08

17

47

02

1.2

23

.73

.33

30

11

51

79

66

23

.32

5.8

3.1

52

71

22

18

46

22

5.5

28

2.9

72

41

29

18

85

82

7.8

30

.32

.79

21

13

51

92

08

08

02

4.1

26

.63

.81

30

14

51

73

75

26

.52

93

.62

71

53

17

87

12

9.2

31

.73

.42

41

62

18

36

73

23

4.5

3.1

92

11

69

18

86

23

53

7.5

2.9

81

91

77

19

3

09

09

32

4.8

27

.24

.42

40

11

71

55

88

27

.42

9.8

4.1

93

61

28

16

38

33

0.3

32

.73

.95

32

13

91

69

78

33

.33

5.7

3.7

22

91

49

17

57

33

6.4

38

.83

.49

25

15

81

81

10

01

03

27

.73

0.1

4.9

33

71

01

14

99

83

0.6

33

4.6

73

31

14

15

79

23

3.6

36

4.4

13

01

26

16

48

73

6.9

39

.34

.15

27

13

71

71

81

40

.44

2.8

3.8

92

41

48

17

8

12

01

18

33

.43

5.8

5.6

53

31

64

16

81

12

36

.93

9.3

5.3

53

01

72

17

31

06

40

.74

3.1

5.0

52

71

81

17

71

00

44

.64

74

.76

24

18

81

81

93

48

.85

14

.46

21

19

51

84

14

01

47

38

.64

3.6

7.0

13

71

28

15

51

39

42

.44

7.4

6.6

63

31

40

16

11

32

46

.55

26

.33

01

52

16

71

24

51

56

5.9

42

71

63

17

21

17

56

61

5.5

72

41

73

17

7

16

01

59

47

.65

37

.62

34

11

21

52

15

15

35

87

.21

31

12

81

59

14

25

86

36

.79

28

14

21

65

13

46

36

86

.38

25

15

51

71

12

56

97

45

.96

22

16

71

76

20

02

00

55

63

9.5

72

02

06

20

31

90

61

68

9.0

61

82

10

20

71

79

67

75

8.5

51

62

14

21

11

69

74

81

8.0

61

42

17

21

51

59

81

88

7.5

71

32

20

21

8

24

02

35

67

77

11

.32

71

92

18

92

23

74

84

10

.72

41

98

19

42

10

81

91

10

.12

22

03

20

01

98

89

99

9.4

51

92

07

20

41

85

98

10

88

.85

17

21

22

09

30

RH

Co

nd

en

se

r e

nte

rin

g a

ir t

em

pe

ra

ture

, °C

LW

T2

53

03

54

04

5

CA

PC

OM

PU

NIT

CO

OL

CO

OL

PR

ES

PR

ES

CA

PC

OM

PU

NIT

CO

OL

CO

OL

PR

ES

PR

ES

CA

PC

OM

PU

NIT

CO

OL

CO

OL

PR

ES

PR

ES

CA

PC

OM

PU

NIT

CO

OL

CO

OL

PR

ES

PR

ES

CA

PC

OM

PU

NIT

CO

OL

CO

OL

PR

ES

PR

ES

(1

)(2

)(1

)(2

)

(1

)(2

)

(1

)(2

)

(1

)(2

)

°C

kW

kW

kW

l/s

kP

ak

Pa

kP

ak

Wk

Wk

Wl/

sk

Pa

kP

ak

Pa

kW

kW

kW

l/s

kP

ak

Pa

kP

ak

Wk

Wk

Wl/

sk

Pa

kP

ak

Pa

kW

kW

kW

l/s

kP

ak

Pa

kP

a

04

08

44

.31

1.1

12

.32

.12

37

13

11

81

41

.91

2.2

13

.42

33

13

61

85

39

.61

3.4

14

.61

.89