30” Stand-On Aerator Wheel Drive Axlefls.ixfr.com › 144 › 136 ›...

Transcript of 30” Stand-On Aerator Wheel Drive Axlefls.ixfr.com › 144 › 136 ›...

TORO RESIDENTIAL PRODUCTS Turf Renovation # 3 November 14, 2012

30” Stand-On Aerator Wheel Drive Axle

PRODUCT: 2012, 30” Stand-On Aerator UNITS AFFECTED: Model Number(s): Serial Number(s): 33518 312000101-312000112 SITUATION: We have received field reports of the wheel drive axle failing. The

reports received cover three unique issues. The first being a missing cotter pin on the castle nut behind the hub, the second the result of the outer torque nut coming loose, and the third being the axle shaft snapping where the shaft is threaded for the castle nut.

CORRECTION: To check the cotter pin you will need to remove the tires on each side to

verify that the cotter pin (#8) securing the castle nut (#7) is installed and bent open enough to prevent it from falling out.

The torque on this castle nut securing the tapered bearings is less than 10 ft. lbs. so the cotter pin is critical in preventing the castle nut from loosening. The proper torque procedure on the castle nut is to initially tighten it to 60 ft. lbs. while turning the hub, loosen it, retorque to 10 ft. lbs. and then loosen the nut to the first available slot that allows the cotter pin to be inserted and then bent open. When retorquing the wheel drive hub nut (not shown) to this axle we recommend a torque of 225 – 235 ft. lbs. and checking it after the first 20 – 25 hours.

-OVER –

Routing Svc Mgr Tech 1 Tech 2 Tech 3 Tech 4 Tech 5 Parts Mgr Sales Mgr Warranty Mgr

Initials

SERVICE BULLETIN

TORO RESIDENTIAL PRODUCTS Turf Renovation # 3 (November 14, 2012) Page 2

The parts manual only lists the part number of the axle and bearing assembly. In most cases you will only need the bare axle P/N 116-6721 and will not need to replace the entire assembly.

Attached is the instruction sheet with the step by step procedure to remove and replace the axle sub assembly. The operators manual will be updated with information stating chains should be checked and adjusted twice weekly and lubricated each time checked or adjusted. Grease all fittings weekly or more in heavier use conditions. Failure to adjust chains will lead to premature failure of chains and sprockets.

WARRANTY: Normal warranty applies. This is NOT a mandatory repair; "Fix as Fail"

only. Out of warranty failures require Distributor Service Manager/Toro Solutions Team prior approval.

Labor Allowance: 0.4 hour - Cotter pin check and nut retorque. 1.0 hour - Wheel axle replacement. SRT # 677-BX-01 Cotter pin check and nut retorque. SRT # 677-BX-02 Wheel axle replacement. Damage Code: 80 PARTS: 3272-13 Pin Cotter 116-6721 Axle Only 116-7645 Axle & Bearing Assembly

AXLE BEARING ASSEMBLY INSTRUCTIONS

1Service Instruction Sheet

1. Blow the dirt and debris off the unit and check the area in and around the tines on the side you are removing for packed in dirt and grass. Remove the debris in the tine area if need be.

2. Position the unit in the work area, raise and secure the back of the unit as high as possible using two jack stands to support the unit (Fig. 02).

Fig. 02 IMG-1044

3. Remove the drive tire on the side you are working on.

4. Remove the lock nut securing the hub to the axle shaft (Fig. 03). Remove the hub.

Fig. 03 IMG-1045

NOTE:

This service instruction sheet was written expressly for Toro servicing dealers and assumes the reader has basic mechanical knowledge and skills. This instruction sheet is electronically “linked” to models that utilize the components or systems covered.

The Toro Company has made every effort to ensure the information is complete and correct and reserves the right to change product specifications or this service instruction sheet without notice.

30” Stand On Aerator Axle Sub Assembly Replacement

Axle Bearing Assembly Removal

Tools Required: Floor jack Jack stands (2) Impact 1/2” drive Sockets: 1-1/2”, 1-1/8”, 13/16”, 9/16” Breaker bar 1/2” Ratchet wrenches: 9/16”, 3/4” Short end wrench 9/16” Small screwdriver Hub puller

Fig. 01 IMG-1064a

AXLE BEARING ASSEMBLY INSTRUCTIONS

2 Service Instruction Sheet

7. Remove two tines from the outside spider that are in-line to each other (Fig. 06). It is not necessary to remove the connector link from the chain if it is not being replaced. Work the chain off the sprocket and let it drop down.

Fig. 04 IMG-1048

Fig. 06 IMG-10566. On the underside of the unit, loosen the nut for the

chain tensioner and slide the tensioner to the top of the slot (Fig. 05).

Fig. 05 IMG-1052

8. Slide the axle sub assembly outward (it will be necessary to cock the unit at an angle to get the rear-tine stub shaft hooked behind the sprocket). As you rotate the shaft counterclockwise using one of the tines on the next set of tines, the unit can be removed (Fig. 07).

Fig. 07 IMG-1059

5. Remove the four nuts securing the axle sub assembly to the frame (Fig. 04).

AXLE BEARING ASSEMBLY INSTRUCTIONS

3Service Instruction Sheet

Axle Bearing Assembly Installation

1. If installing an axle and bearing assembly, proceed to step 3. Replacing a damaged wheel axle first remove it from the wheel bearing mount. Check to make sure the grease seals are not damaged. You will notice the grease seals are installed backwards to allow grease to be purged when greasing the unit. If either of these are damaged it will need to be replaced. Mount a spacer, the bearing mount, another spacer, and then install the castle nut and cotter pin using the instructions in the next step (Fig. 08).

3. Slide the axle assembly inward (it will be necessary to cock the unit at an angle to get the rear tine stub shaft hooked behind the sprocket). As you rotate the tines clockwise to install the unit (Fig. 09).

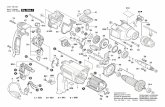

A. Sheel bearing mount E. ScrewB. Tapered roller bearing F. Wheel axleC. Spacer G. Castle nutD. Grease seal H. Cotter pin

Fig. 08 IMG-1000a

Fig. 09 IMG-1059

2. Install the castle nut and tighten it to 60 ft-lbs. while turning the hub, loosen it, then re-torque to 10 ft-lbs. Loosen the castle nut to the first available slot that allows the cotter pin to be inserted and bent open.

4. Reinstall the chain onto the sprocket and replace the two tines that were previously removed (Fig. 10).

Fig. 10 IMG-1056a

AEF

H

BDGC

AXLE BEARING ASSEMBLY INSTRUCTIONS

4 Service Instruction Sheet

5. Install the four screws securing the axle assembly back in position, install the four nuts and tighten securely (Fig 11).

7. Re-install the wheel hub to the axle and torque the lock nut to 225-235 ft-lbs. (Fig 13).

Fig. 11 IMG-1048 Fig. 13 IMG-1045

6. Slide the chain tensioner onto the top of the chain and re-tighten with very little play in the chain. (Fig 12).

8. Install the tire and torque the lug nuts to 90-95 ft-lbs.

9. Lower the unit to the ground, test drive and re-check the chain tension.

Fig. 12 IMG-1052a