30282 ENVIRONMENTAL PROTECTION · 2019. 6. 10. · the Insulation fiberglass subcategory of the...

Transcript of 30282 ENVIRONMENTAL PROTECTION · 2019. 6. 10. · the Insulation fiberglass subcategory of the...

-

PROPOSED RULES

ENVIRONMENTAL PROTECTIONAGENCY

E 40 CFR Part 4263[FEL 253-5]

PRESSED AND BLOWN GLASS SEGMENTOF GLASS MANUFACTURING POINTSOURCE CATEGORY.

Proposed Effluent Limitations Guidelinesfor Existing Sources and Standards ofPerformance and Pretreatment Stand-ardsNotice is hereby given that effluent

limitations and guidelines for existingsources and standards of performanceand pretreatment standards for newsources set forth in tentative form be-low are proposed by the EnvironmentalProtection -Agency (EPA). On Janu-ary 22, 1974, EPA promulgated a regu-lation adding Part 426 to title 40 of theCode of Federal Regulations (39 FR2564). That regulation with subsequentamendments established effluent limita-tions and guidelines for existing sourcesand standards of performance and pre-treatment standards for new sources forthe Insulation fiberglass subcategory ofthe glass manufacturmg point sourcecategory. The regulation proposed belowwill amend 40 CFR, Part 426-gla s man-ufacturing point source category by add-ing thereto the glass container manu-facturing subcategory (Subpart H), themachine pressed and blown glass manu-facturing subeategory (Subpart I), theglass tubing manufacturing subcategory(Subpart J), the television picture tubeenvelope manufacturing subcategory(Subpart X), the incandescent lamp en-velope manufacturing subcategory (Sub-part L), and the hand pressed and blownglass manufacturing subcategory (Sub-part M), pursuant to sections 301, 304 (b)and (c), 306(b) and 307(c) of the Fed-eral Water Pollution Control Act, asamended (33 U.S.C. 1251, 1311, 1314 (b)and (c), 1316(b) and 1317(c); 86 Stat.816 et seq.; Pub. L. 92-500) (the Act).

(a) Legal authority.-(1) Existingpoint sources. Section 301(b) of the Actrequires the achievement by not laterthan July 1, 1977, of effluent limitationsfor point sources, other than publiclyowned treatment works, which requirethe application of the best practicablecontrol technology currently available asdefined by the Administrator pursuantto section 304(b) of the Act. Section301(b) also requires the achievement bynot later than July 1, 1983, of effluentlimitations for point sources, other thanpublicly owned treatment works, whichrequire the application of best availabletechnology economically achievablewhich will result in reasonable furtherprogress toward the national goal ofeliminating the discharge of all pollut-ants, as determined in accordance withregulations issued by the Administrator-pursuant to section 304(b) of the Act.

Section 304(b) of the Act requires theAdministrator to publish regulationsproviding guidelines for effldient limita-tions setting forth the degree of effluentreduction attainable through the appli-

cation of the best practicable controltechnology currently available-and thedegree- of effluent reduction attainablethrough the application of the best con-trol measures and practices achievableincluding treatment techniques, processand procedural innovations, operatingmethods and other alternatives. Theregulation proposed herein sets forth ef-fluent limitations and guidelines, pursu-ant to sections 301 and 304(b) of the Act,for the glass container manufacturingsubcategory (Subpart H), the machinepressed and blown glass manufacturingsubcategory (Subpart I), the glass tubingmanufacturing subcategory (Subpart J),the television picture tube envelopemanufacturing subcategory (Subpart K),the incandescent lamp envelope manu-facturing subcategory (Subpart L), andthe hand pressed and blown glass manu-facturing subcategory (Subpart 11), ofthe glass manufacturing point sourcecategory.

(2) New sources. Section 306 of the Actrequires the achievement by new sourcesof a Federal standard of performanceproviding for the control of the dischargeof pollutants which reflects the greatestdegree of effluent reduction which theAdministrator determines to be achiev-able through application of the bestavailable demonstrated control technol-ogy, processes, operating methods, orother alternatives, including, where prac-ticabld a standard permitting no dis-charge of pollutants.

Section 306(b) (1) (B) of the Act re-quires the Administrator to propose reg-ulations establishing Federal standardsof performance for categories of newsources included in a list published pur-suant to section 306(b) (1) (A) of theAct. The Administrator published in theFEDERAL REGISTER of January 16, 1973,(38 FR 1624) a list of 27 source cate-gories, including the glass and asbestosmanufacturing category. The regulationsproposed herein set forth the standardsof performancQ applicable to newsources for the glass container manufac-turing Subeategory (Subpart H), the ma-chine pressed and blown glass manufac-turing subcategory (Subpart I), the glasstubing manufacturing subeategory (Sub-part J), the television picture tube envel-ope manufacturing subcategory (Sub-K), the incandescent lamp envelopemanufacturing subcategory (Subpart L),and the hand'pressed and blown glassmanufacturing subcategory (Subpart M),of the glass manufacturing point sourcecategory.

Section 307(c) of the Act requires theAdministrator to promulgate pretreat-ment standards for new sources at thesame time that standards of perform-ance for new sources are promulgatedpursuant to section 306. Sections 426.86,426.96, 426.106, 426.116, 426.126, and426.136, proposed below, provide pre-treatment standards for new sourceswithin the glass container manufactur-ing subcategory (Subpart H), the ma-chine pressed and blown glass manu-facturing subeategory (Subpart I), theglass tubing manufacturing subcategory

(Subpart J), the television picture tubeenvelope manufacturing subcategory(Subpart K), the Incandescent lampenvelope manufacturing subcategory(Subpart L), and the hand pressed andblown glass manufacturing subcategory(Subpart M), of the glass manufacturingpoint source category.

Section 304(c) of the Act requires theAdministrator to Issue to the States andappropriate water pollution controlagencies information on the processes,procedures or operating methods whichresult in the elimination or reduction ofthe discharge of pollutants to implementstandards of performance under Section306 of the Act. The report or "Develop-ment Document" referred to below pro-vides, pursuant to Section 304(c) of theAct, information on such processes, pro-cedures or operating methods.I (b) Summary and basis of proposedeffluent limitations guidelines for existingsources and standards of performanceand pretreatment standards for newsources:

(1) General methodology, The ef-fluent limitations, guidelines and stand-ards of performance proposed hereinwere developed in the following manner.The point source category was firststudied for the purpose of determiningwhether separate limitations and stand-ards are appropriate for different seg-ments within the category. This anal-ysis included a determination of whetherdifferences in raw material used, productproduced, manufacturing process em-ployed, age, size, waste water con-stituents and other factors require de-velopment of separate limitations andstandards for different segments of thepoint source category. The raw wastecharacteristics for each such segmentwere then Identified. This included ananalysis of the source, flow and volumeof water used In the process employed,the sources of waste and waste waters inthe operation, and the constituents of allwaste water. The constituents of thewaste waters which should be subject toeffluent limitations and standards ofperformance were Identified.

The control and treatment technolo-gies eLxsting within each segment, wereidentified. This Included an identifica-tion of each distinct control and treat-ment technology, including both in-plant and end-of-process technologies,which are existent or capable of beingdesigned for each segment. It also in-cluded an Identification of, In terms ofthe amount of constituents and thechemical, physical, and biologicalcharacteristics of pollutants, the effluentlevel resulting from the application ofeach of the technologies. The problems,limitations, and reliability of each treat-ment and control technology were alsoIdentified. In addUtion, the non-waterquality environmental impact, such asthe'effects of the application of suchtechnologies upon other pollution prob-lems, including air, solid waste, noise,and radiation were Identified. The energyrequirements of each control and treat-ment technology were determined as

FEDERAL REGISTER, VOL. 39, NO. 163-WEDNESDAY, AUGUST 21, 1974

30282

-

PROPOSED RULES

well as the cost of the application of suchtechnologies-

The information, as outlined above,was then evaluated in order to deter-mine what levels of technology-consti-tute the "best practicable controltechnology currently available". "bestavailable technology economicallyachievable", and the "best availabledemonstrated control technology, proc-esses, operating methods, or other alter-natives". In identifying such technolo-gies, various factors were considered.These included the total cost of appli-cation of technology in relation to theeffluent reduction benefits to be achievedfrom such application, the age of equip-ment and facilities involved, the processemployed, the engineering aspects of theapplication of various types of controltechniques, process changes, non-waterquality environmental impact (includingenergy requirements) and other factors.

The data upon which the above analy-sis was performed included EPA permitapplications, EPA sampling and inspec-tions, consultant reports, and industrysubmissions.

The pretreatment standards proposedherein are intended to be complementaryto the pretreatjnent standards proposedfor existing sources under 40 CFR Part128. The basis for such standards is setforth in the FEDEALm RErssR of July 19,1973, 38 FR 19236. The provisions ofPart 128 are equally applicable to sourceswhich would constitute "new sources",under section 306 if they were to dis-charge pollutants directly to navigablewaters, except for § 128.133. That sectionprovides a pretreatment standard for"incompatible pollutants" which requiresapplication of the "best practicable con-trol technology currently available", sub-ject to an adjustment for amounts ofpollutants removed by the publicly ownedtreatment works. Since the pretreatmentstandards proposed herein apply to newsources, §§ 426.86,426.96,426.106,426.116426.126, and 426.136 below amend§ 128.133 to specify the application of thestandard of performance for new sourcesrather than the "best practicable" stand-ard applicable to existing sources undersections 301 and 304(b) of the Act

(2) Summary of conclusions with re-spect to the glass container manufac-turing subcategory (Subpart H), themachine pressed and blown glass manu-facturing subcategory (Subpart D, theglass tubing manufacturing subcategory(Subpart J), the television picture tubeenvelope manufacturing subcategory(Subpart 1K), the incandescent lamp en-velope manufacturing subcategory (Sub-

-part L). and the hand pressed and blownglass manufacturing subcategory (Sub-part M), of the pressed and blown glasssegment of the glass manufacturingpoint source category,(i) Categorization. For the purpose

of establishing effluent limitations guide-lines and standards of performance, thepressed and blown glass segment of theglass manufacturing category has beendividedinto six categories:

(1) Subpart H. Glass Container Man-ufacturing Subcategory: This subcate-

gory Includes those plants which meltraw materials at their facility andmechanically process the resultant Classinto glass containers.

(2) Subpart 1. Machine Presed andBlown Glass Manufacturing Subate-gory: This subeategory includes thoseplants which melt raw materials at theirfacility and mechanically process the re-sultant glass into pressed or blown classproducts.

(3) Subpart J. Glass Tubing Manu-facturing Subcategory: This subcategoryincludes those plants which melt rawmaterials at their facility and produceglass tubing as the final product.

(4) Subpart K. Television PictureTiibe Envelope Manufacturing Subcate-gory: This subeategory includes thoseplants which melt raw materials at theirfacility and produce from the resultantglass, television picture tube envelopes asthe final product.

(5) Subpart L. Incandescent LampEnvelope Manufacturing. Subcategory:This subcategory includes those plantswhich melt raw materials at their facil-ity and produce incandescent lamp en-velopes. This subeategory also includesthose plants which frost the envelopes byetching with hydrofluoric acid (HF).

(6) Subpart L. Hand Pressed andBlown Glass Manufacturing Subcate-gory: This subcategory includes thoseplants which melt glass at their facilityand hand process the resultant glass intopressed or blown glass products.

Factors such as raw materials used,age and size of production facilities,principal products and production proc-esses, waste water characteristics, andapplicable treatment methods substanti-ate and verify this subcategorlzation.

(1) Waste charactcristics. The kmownsignificant pollutant properties or con-stituents of waste waters resulting fromthe manufacture of pressed and blownglass include suspended solids, oil, andpH. In addition to these parameters,fluoride may be present to varying de-grees in waste waters associated withthe manufacture of- tdevision picturetube envelopes, incandescent lamp en-velopes, and hand pressed and blownglassware. Lead is slnificant in wastewaters resulting from the production oftelevision picture tube envelopes andcertain hand pressed or blown glassware.Ammbnia is present in sigmilfleant quan-tities in waste waters resulting from thefrosting of incandescent lamp envelopes.Other less significant parameters asso-,elated with waste water resulting fromthe manufacture of preed and blownglass are chemical oxygen demand, dis-solved solids, and heat.

(iii) Origin of waste water PoUutants.Water is used during the manufactureof pressed and blown class for non-con-tat cooling, quenching of cullet, contactcooling of metallic forming or cuttingdevices, batch wetting, abrasive polish-ing, edge grinding, washing, and assortedother uses. A discussion of water usageand the source of pollutant dischargesfollows:

(1) Glass container manufacturingsubcategory. Proes water is used for

cullet quenching, batch wetting, contactcooling of shears, and non-contact cool-ing of batch feeders, melting furnaces,formIng machines, and other auxiliaryequipment. The principal pollutants as-sroated With this subcategory are oil,present In the shear spray or due to lea.-Ing lubricantz; suspended solids, presntin the cullet quenching dischage stream;and pHL

(2) Mach33ine pressed and blown glassmanufacturing subategory. The wateruses and resulting pollutants associatedwith this subcategory are the same asthosz aszcciated with ca- containermanufacturing.

(3) Glass tubing manufacturing sub-category. Prowes water is used for culletquenching and for non-contact coolingof furnace walls and mandrel transrnis-sion. The principal pollutants as-o-ciated with this subcate ory are oil, re-sulting from lubrication leaks; sus-pended solids, present In the culletquench stream; andpH.

(4) Television picture tube envelopemanufacturing subcategory. Water isused for cullet, quenching, batch wetting,contact cooling of she=, non-contaztcooling (of batch feaders, furnaces,presses and miliary equipment), abra-sive polishing, edge grinding, and acidpolishing. The principal pollutants asso-elated With this subcategory are fluoride,contributed by fume scrubbers and acidpolishing rinse waters; lead, present inboth the abrasive and acid polishing dis-charge streanm; susp ded solids, pres-ant in the cullet quench, abrasive polish-

ing, and edge grinding dischargestreara; oil. contributed by s spraydri-ppge, lubrication leaks, and funnelrinse w ater; and PH.

(5) Incandescent lamp envelope man-ufacturing subcategory. Process waters used for non-contact cooling, culletquenching, batch wetting, contact cool-Ing of shers, and rising of frostedbulbs. The principal pollutants 2ssoci-ated with this subsategory are fluoride,contributed by fume scrubbars andfrosted bulb rinse waters; duspendedsolids, present in the cullet quench andfrosting rime water dizchae streams;oil, contributed by shear spray drippazgeand lubrication lea,; ammonia, presentIn the frosting rinse water dischargestream; and pH.

(6) Hand pressed and blown glazsmanufacturing subeatezory. Principalwater usage is that contributed by thevarious flnishing steps asociated withthis subcategory such as cracJ-.off andpolishing, grinding and polishin-, ma-chine cutting, alkali washing, ad-polishing, and acid etching. The usagesvary greatly from plant to plant andfrom day to day. Nealgible quantities ofwater are used for forming and non-contact cooling water Is not required.The principal pollutants associated withthis subcategory are fluoride, con-tributed by the acid polishlng and etch-Ing rinse waters; lead, contributed by theacid treatment of leaded glass; sus-pended solids, present In the dischargewaters of all finishing steps; and pH.

FEDERAL REGISTER, VOL 39, NO. 163--WEDNESDAY, AUGUST 21, 1974

3093-13

-

PROPOSED RULE$

(iv) Treatment and control tech-nology. Waste water treatment and con-trol technologies have been studied foreach subcategory of the industry to de-termine what is (a) the best practicablecontrol technology currently available,(b) .the best available technology eco-nomically achievable, and (c) the bestavailable demonstrated control tech-nology, processes, operating methods orother alternatives. Such technologies ascoagulation, sedimentation, oil separa-tion, lime precipitation, ion-exchange,ammonia stripping, and filtration havebeen considered and recommended asproven methods of control and treatmentof waste waters from the pressed andblown glass segment of the glass manu-facturing category. Many of these tech-nologies are currently practiced withinthe industry; all are readily transferabledue to their wide practice within otherindustrial categories or within the fieldof water treatment.

The following is a discussion of" thecontrol and treatment technologiesrecommended for each subcategory asbest practicable control technology eco-nomically achievable.

(1) Recommended control and treat-ment-glass container manufacturingsubcategory. Both in-plant- techniquesand end-of-pipe methods have been em-ployed by plants of this subcategory to re-duce pollutant discharge. Best practica-ble control technology currently availablewould require that a typical plant using2920 I/metric ton (700 gal/ton) of com-bined process and non-contact coolingwater achieve effluent.levels 9f 24 mg/1for suspended solids and 10 mg/1 for oil.A plant with segregation of process andnoncontact cooling water would be re-quired to attain effluent concentrationlevels of approximately double the afore-mentioned with regard to the processwater stream as this stream accountsfor approximately forty-seven percent ofthe combined flow. These levels are con-sidered to be typical of current operationand are presently achieved by 70 percentof the 40 plants for which effluent data isavailable. These effluent levels are readilyachievable by all plants within this sub-category throfigh normal maintenanceand clean-up operations within the plantand represent the raw waste loadings ex-pected from a glass container plant.Some plants may need to improve house-keeping to achieve the recommendedeffluent levels, while others may elect toprovide end-of-pipe treatment in the'form of some type of sedimentation sys-tem with oil removal capabilities. It isfelt however, that in-plant techniqueswill be a more effective and a consider-ably less expensive means of achievingthe recommended effluent limitations andbest practicable control technology cur-rently available is based on thiscontention.

Best available technology economicallyachievable recommends that the culletquench waste water stream be segregatedfrom the non-contact cooling waterstream, that the cullet quench stream berecirculated through a gravity separator

with treatment of the blowdown by dis-solved air flotation, and that the effluentfrom the dissolved air flotation system befiltered through diatomaceous earth.This will further reduce oil and sus-pended solids in the discharge stream toless than 5 mg/1 and will reduce the con-tact water discharge flow from 1540 1/metric ton (370 gal/ton) to 77 I/metricton- (18.5 gal/ton).

(2) Recommended control and treat-ment-machine pressed and blown glassmanufacturing subcategory. The in-plantcontrol and end-of-pipe treatment meth-ods employed in the machine pressedand blown glas manufacturing subcate-gory are those used in the glass con-tainer manufacturing subcategory. Bestpracticable control technology currentlyavailable would require that a typicalplant using 5630 1/metric ton (1350 gal/ton) of combined process and non-contact cooling water achieve effluentlevels of 25 mg/I for suspended solids and10 mg/1 for oil. A plant with segregationof process and non-contact cooling waterwould be required to attain effluent con-centration levels of approximately doublethe aforementioned with regard- to theprocess water stream as this stream ac-counts for approximately forty-blght per-cent of the combined flow. These effluentlevels are readily achievable by all plantswithin the subcategory with a minimumof in-plant controls or end-of-pipetreatment.

Best available technology economicallyachievable involves the segregation ofcullet quench from noncontact coolingwaters, the recirculation of the culletquench stream through a gravity sepa-rator with treatment of the blowdownby dissolved air flotation, and the diato-maceous earth filtration of the effluentfrom the dissolved air flotation system.This will .further. reduce oil and sus-pended solids in the discharge stream toless than 5 mg/I and will reduce the con-tact water discharge flow from 2920 1/metric ton (700 gal/ton) to 370 I/metricton (88 gal/ton).

(3) Recommendled control and treat-ment--glass tubing manufacturing sub-category. Owing to the high quality er-ratic discharge of cullet quench waterfrom plants within this subcategory, noplants presently employ end-bf-pipetreatment. Best practicable controltechnology currently available would re--quire that a typical plant using 83401/metric ton (2000 gal/ton) of combinedprocess and non-contact cooling waterachieve effluent levels of 27 mg/I forsuspended solids and 10 mg/l for oil. Allfour of the plans for which effluent dataare available presently achieve the rec-ommended levels. These effluent levelsare readily achievable by all plants with-in this subcategory with a minimum ofin-plant control in the form of house-keeping techniques.

Th& best available technology eco-nomically achievable involves the segre-gation of the cullet quench from thenon-contact cooling water stream, therecirculation of the cullet quench waterstream, and treatment of the blowdown

from the cullet quench recIroulatlonsystem by diatomaceous earth filtra-tion. This will further reduce oil and sus-pended solids in the discharge streamto less than 5 mg/I and will reduce thecontact water discharge from 420 I/met-ric ton (100 gal/ton) to 21 1/metrIo ton(5 gal/ton).

(4) Recommended control and treat-ment-televslon picture tube envelopemanufacturing subcategory. Televisionpicture tube envelope plants currentlyemploy in-plant methods of water con-servation and end-of-pipe treatment forfluoride, lead, and suspended solids re-moval. All of the plants for which infor-mation is available treat abrasive andacid polishing waste waters by lime pre-cipitation with the pH being adjustedwhere necessary. It Is this technologyupon which the best practicable controltechnology currently available Is based,A typical plant discharging 4420 1/metrIcton (1060 gal/ton) of finishing wastewater would be required to achieve ef-fluent levels of 15 mg/I of fluoride and1 mg/l of lead for that waste waterstream. The same typical plant whichdischarges 12,500 I/metrIc ton (3000gal/ton) of finishing waste water andcombined cullet quench and non-contactcooling water would be required toachieve effluent levels of 10 mg/i of sus-pended solids and oil, 5.2 mg/l of fluoride,and 0.35 mg/I of lead In the total wastewater stream. All plants within this sub-category are either currently achievingthese levels or can achieve these levels byupgrading the operation of existing treat-ment systems and/or improving house-keeping to minimize pollutant discharge,

Best available technology economt-cally achievable involves the sand filtra-tion of the lime treated effluent to fur-ther remove fluoride and lead precipi-tates, and the passage of the effluentfrom the sand filter through a bed ofactivated alumina, thus further reniov-ing fluoride. This technology will allowthe typical plant to achieve effluent levelsof10 mg/I of oil, 5 mg/I of suspendedsolids; 0.71 mg/I of fluoride, and 0.035mg/1 of lead In the total dischargestream.

(5) Recommended control and treat-ment-incandescent lamp envelope man-ufacturing subategory. The present levelof treatment within the incandescentlamp envelope manufacturing subeate-gory involves oil separation and sedi-mentation applied to the cullet quenchwater stream and lime treatment forfluoride and suspended solids removalfrom frosting waste waters.

Best practicable control technologycurrently available includes the presentstate-of-the-art for treatment of wastewaters within the subategory and theaddition of steam stripping for ammonlaremoval and a recarbonatlon system forpH adjustment of the frosting wastewater discharge stream. A typical plantusing 4500 l/metle ton (1080 gal/ton) ofcombined noncontact cooling and oulletquench water would be required toachieve effluent levels of 25 mg/I of oiland suspended solids In this waste water

FEDERAL REGISTER, VOL, 39, NO. 163-VWEDNESDAY, AUGUST 21, 1974

30284

-

PROPOSED RULES

stream. The typical plant also discharges3420 /metric ton (820 gal/ton) of frost-ing waste water; effluent levels of 25 mag/Iof suspended solids, 20 mg/1 of fluoride,and 30 mg/1 of ammonia are readilyattainable after treatment of this wastestream. Plants not currently achievingthese effluent levels can add. to theirpresent treatment system an ammoniaremoval system and a recarbonation sys-tem and can upgrade their present sys-tems to optimize suspended solids re-moval by better controlling flocculation,adding polyelectrolyte or other coagu-lant aids recirculating sludge, or reduc-ing weir overflow rates.

Best available technology economicallyachievable includes the sand filtrationof the effluent from the lime precipita-tion system, activated alumina filtrationof the effluent from the sand filters, anddiatomaceous earth filtration of the cul-let quench waste water stream. Thistechnology will allow a typical plant toachieve effluent levels of 5 mg/1 for sus-pended solids and oil in the cullet quenchwaste water stream, and 5 mg/1 of sus-pended solids and 2 mg/I of fluoride inthe frosting waste water stream. Thesetechnologies are not current industrypractice but have been employed formany years in the field of watertreatment.

(6) Recommended control and treat-nent-hand pressed and blown glass

manufacturing subcategory. Very limiteddata are available on the hand pressedand blown industry with regard to efflu-ent discharge. Owing to the low wastewater volumes, the lack of sufficientquantities of cooling water that couldbe used for dilution, and the very limiteddata available, achievable effluent levelsin the hand pressed and blown glasssubcategory are expressed in terms ofconcentrations (mg/I). Waste waterconstituents requiring control are sus-pended solids, fluoride, and lead.

Best practicable control technologycurrently available requires that effluentconcentrations of 25 mg/I for suspendedsolids, 15 mg/1 for fluoride, and 1.0 mg/1for lead be attained. Most plants donot make leaded glass and for theseplants, lead is not a problem. Manyplants do not acid etch or polish glassand therefore, do not have a fluorideproblem. Methods of achieving-the bestpracticable control technology currentlyavailable include sedimentation, clarifi-cation, land disposal, improved house-keeping techniques, and batch limeprecipitation.

Best available technology economicallyachievable requires that effluent levels of5 mg/1 for suspended solids, 2 mg/Ifor fluoride, and 0.1 mg/i for lead beattained. This involves sand filtration inall cases, and the use of activated alu-mina to further remove fluorides in thosecases where hydrofluoric acid is usedto etch or polish glassware.

Solid waste control. The applicationof these technologies requires that solidwaste control be considered. Best practi-cable control technology and best avail-able control technology as they are

known today, require disposal of thepollutants removed from waste watersproduced within this industry segmentin the form of solid wastes or liquid con-centrates. In most cases these are non-hazardous substances requiring onlyminimal custodial care. However, someconstituents may be hazardous and mayrequire special consideration. In orderto ensure long-term protection of theenvironment from any hazardous orharmful constituents, special considera-tion of disposal sites must be made. Alllandfill sites where such hazardouswastes are disposed should be selected soas to prevent horizontal and verticalmigration of these contaminants toground or surface waters.

In cases where geologic conditionsmay not reasonably ensure this, ade-quate legal and mechanical precautions(e.g., impervious liners) should be takento ensure long term protection to theenvironment from hazardous materials.Where appropriate, the location of solidhazardous materials disposal sitesshould be permanently recorded in theappropriate office of legal jurisdiction.It should be noted that there Is no evi-dence that the application of the recom-mended control and treatment tech-nologies will result in any unusual solidwaste disposal problems.

(v) Cost estimates for control ofwaste water pollutants. The capital andtotal yearly costs to the pressed andblown glass segment of the glass manu-facturing category to achieve the pro-posed best practicable control tech-nology currently available effluent limi-tations guidelines are estimated to be$2.67 million and $0.966 million respec-tively. This estimate is based on theassumption that only surface ds-chargers are affected by the proposedguidelines. There are: (a) 55 knownglass container, (b) 23 known machinepressed and blown glass, (c) 9 knownglass tubing, (d) 4 known television pic-ture tube envelope, (e) 3 known incan-descent lamp envelope, and (1) 13known hand pressed and blown glassmanufacturing surface dischargers. Thisestimate of surface dischargers is basedon RAPP applications, industry supplieddata, and a survey of the pressed andblown glass segment The Agency Is re-questing additional information with re-gard to surface dischargers at this time.

The capital and total yearly costs tothe pressed and blown glass segment ofthe glass manufacturing category toachieve the proposed best availabletechnology economically achievable ef-fluent limitations guidelines are esti-mated to be $27.7 and $0.59 millionrespectively. This estimate is based onthe assumption that only surface dis-chargers are affected by the proposedguidelines with no credit given for thosefacilities which currently employ all ora portion of the best available tech-nology economically achievable. Thisestimate also includes those costs assocl-ated with best practicable control tech-nology currently available.

3O285

(vi) Energy requirements and ron-water quality environmental impacts. Itis estimated that the equivalent ofeighteen million and thirty-one millionilowatt hours of electricity are required

to achieve the best practicable controltechnology currently available and thebest available technology economicallyachievable, respectively. This amounts toa less than one percent Increase in anIndividual plant's current energy re-quirement In all subcategories with theexception of the incandescent lamp en-velope manufacturing subcategory. Thesteun stripping of ammonia, on whichbest practicable control technology cur-rently available for that subcategory isbased, is a high energy user and resultsn an eight percent increase over current

energy requirements. The 650 mag/1 rawwaste discharges of ammonia necessitateIts removal to ensure environmentalprotection.

With the exception of ammonia re-moval, required for the incandescentlamp envelope subcategory, there is noevidence that application of the proposedefiluent limitations guidelines will resultIn any unusual air or solid waste disposalproblems. The ammonia stripped fromIncandescent lamp envelope frostingwaste water. will be discharged to theatmosphere but methods are availableto reduce the concentrations to below thethreshold of odor.

(vii) Economic impact analsis. Apreliminary assessment of the effects ofBPOTCA, BATEA, and NSPS costs forthe industry indicated that only two ofthe si: subcategorie-machine pressedand blown glass manufacturing and handprezsed and blown glass manufacturing-could face potential impacts under theproposed guidelines. Hence, detailed eco-nomic analysis was carried out only forthose two sectors.

Adverse economic impacts as the resultof BPCTCA efiluent limitations guide-lines are expected to occur only in thehand prezzed and blown glass manufac-turing subcategory. Between 3 and 5closures are anticipated primarily be-cause of the inabijity of some firms inthis subcategory to raise the capital nec-esary to purchase Pollution controlsystems for treatment of hydrofluoricacid etching wastes. However, only 46percent of the hand pressed and blonglass manufacturing subcategory per-forms acid etching. The plants which donot acid etch will be able to meet theguidelines with a substantially lowercapital Investment.

The threatened plants represent be-tween 10 and 15 percent of segment ca-pacity and about '700 to 1,000 employees.In addition, some regional effects mayarise due to the fact that hand pressedand blown glass manufacturing plantsare concentrated in the Ohio-West Vir-ginia area. Price increases necessary torecover annual BPCTCA costs (includ-ing depreciation and cost of capital)should be modest-approximateiy Ipercent for those plants with acid etchingand about 0.9 percent for those plantswithout acid etching.

FEDERAL REGISTER, VOL 39, NO. 163-WEDNESDAY, AUGUST 21, 1974

-

30286

Plants in the incandescent lamp enve-lope manufacturing subcategory willhave to make significant expendituresto achieve BPCTCA effluent limitationsguidelines, but no adverse effects are ex-pected. The estimated price increase isabout 1.0 percent.

None of the remaining four subcate-gories-machine pressed and blown glassmanufacturing, glass container manu-facturing, television picture tube enve-lope manufacturing and glass tubingmanufacturing-should face any signifi-cant impacts under the proposedBPCTCA guidelines. This is based on theassumption that plants in these subcate-gories will be able to meet the proposedBPCTCA limitations without new in-vestment. Some industry comments statethat a few plants may, in fact, requiremodification in order to tomply withproposed BPCTCA limitations. TheAgency is requesting additional cost in-formation for such plants, and in theevent significant plant modification costsare identified, the impact analysis will bereevaluated..The proposed BATEA effluent limita-

tions guidelines should not cause anysignificant economic impacts. Price in-creases necessary to maintain currentprofit levels should be less than 2.4 per-cent, and no further plant closures havebeen projected.

The proposed effluent limitationsguidelines are not expected to have anynoticeable effect on balance of paymentsor overall industry growth, althoughgrowth in the machine pressed andblown glass manufacturing subcategorymay be hindered due to the diversion ofcapital into pollution control equipment.

The report entitled "DevelopmentDocument for Proposed Effluent Limita-tions Guidelines and New Source Per-formance Standards for the Pressed andBlown Glass Segment of the Glass lanu-facturing Point Source Category" detailsthe analysis undertaken in support ofthe regulation being proposed herein andis available for inspection in the EPAInformation Center, Room 227, WestTower, Waterside Mall, Washington,D.C., at all EPA regional offices, and atState water pollution control offices. Asupplementary analysis prepared forEPA of the possible economic effects ofthe proposed regulation is also avail-able for inspection at these locations.Copies of both of these documents arebeing sent to persons or institutionsaffected by the proposed regulation, orwho have placed themselves on a mailinglist for this purpose (see EPA's AdvanceNotice of Public Review Procedures, 38R 21202, August 6, 1973). An additional

limited number of copies of both reportsare available. Persons wishing to obtaina copy may write the EPA InformationCenter_ Environmental ProtectionAgency, Washington, D.C. 20460, Atten-tion: Mr. Philip B. Wisman.

On June 14, 1973, the Agency pub-lished procedures designed to ensure that,when certain major standards, regula-tions, and guidelines are proposed, an ex-planation of their basis, purpose and en-

PROPOSED RULES

vironmental effects is made available to charts, diagrams, and tablc3, It is clearlythe public (38 FR 15653). The procedures impracticable to publish the materialare applicable to major standards, regu- contained in these documents In thelations, and guidelines which are pro- FEDER.L REGISrln. To the extent poslible,posed on or after December 31, 1973, and significant aspects of the material havewhich prescribe national standards of been presented in summary form in fore-environmental quality or require national going portions of this preamble, Addi-emission, effluent, or performance stand- tional dis~ussion Is contained in the fol-ards and limitations. lowing analysis of comments received

-The Agency determined to implement and the Agency's response to them. Asthese procedures in order to insure that has been indicated, both documents arethe public was apprised of the environ- available for inspection at the Agency'smental effects of its major standards Washington, D.C. and regional officessetting actions and was provided with and at State water pollution controldetailed background information to as- agency offices. Copies of each have beensist it in commenting on the merits of distributed to persons and institutionsa proposed action. In brief, the proce- affected by the proposed regulations ordures call for the Agency to make public who have placed themselves on a mailingthe information available to it delineat- list for this purpose. Finally, so long asing the major nonenvironmental factors the supply remains available, additionalaffecting the decision, and to explain the copies may be obtained from the Agencyviable options available to It and the as described above.reasons for the option selected. When this regulation Is promulgated,

The procedures contemplate publica- revised copies of the Development Dou-tion of this information in the FDmuA ment will be available from the Super-RE isTER, where this is practicable. They intendent of Dbcuments, Governmentprovide, however, that where, because of Printing Office, Washington, D.C. 20402.the length of these materials, such pub- Copies of the Economic Analysis will belication is impracticable, the material available through the National Tech-may be made available in an alternate nical Information Service, Springfield,format. Virginia 22151.- The report entitled "Development (c) Summary of Vublic participation.Document for Proposed Effluent Limita- Prior to this publication, the agenciestions Guidelines and New Source Per- and groups listed below were consultedformance Standards for the Pressed and and given an opportunity to participate.Blown Glass Segment of the Glass Manu- in the development of effluent ltmita-facturing Point Source Category" con- tions, guidelines, and standards proposedtains information available to the Agency for the pressed and blown glass segmentconcerning the major environmental ef- of the glass manufacturing category. Allfects of the regulation proposed below, participating agencies have been in-including: formed of project developments. An

(1) The pollutants presently dis- initial draft of the Development Docu-charged into the Nation's waterways by ment was sent to all participants andmanufacturers of pressed and blown comments were solicited on that report.glass and the degree of pollution reduc- The following are the principal agenciestion attainable from implementation of and groups consulted: (1) Effluentthe proposed guidelines and standards Standards and Water Quality Informa-(see particularly sections IV, V, VI, IX, tion Advisory Committee (establishedX, and XI); under section 515 of the Act); (2.) all

(2) The anticipated effects of the pro- State and U.S. Territory Pollution Con-posed-regulation on other aspects of the trol Agencies; (3) Ohio River Valleyenvironment including air, solid waste Sanitation Commission; (4) Now B ng-disposal and land use, and noise (see land Interstate Water Pollution Controlparticularly section VIII); and Commission; (5) Delaware River Basin

(3) Options available to the Agency Commission; (6) Hudson River Sloopin developing the proposed regulatory Restoration, Inc.; (7) Conservationsystem and the reasons for its selecting Foundation; (8) Environmental Defensethe particular levels of effluent reduction Fund; (9) Natural Resources Defensewhich ai'e proposed (see particularly sec- Council; (10) The American Society oftions VI, VII, and VIII). Civil Engineers; (11) Water Pollution

The supplementary report entitled Control Federation; (12) National Wild-"Economic Analysis of Proposed Effluent life Federation; (13) The American So-Guidelines for the Pressed and Blown ciety of Mechanical Engineers; (14) U.S.Glass Industry" contains an estimate of Department of Commerce; (15) U.S. Do-the cost of pollution control require- partment of the nterior; (16) Glaments and an analysis of the possible Container .anufacturers Institute; (17)effects of the proposed regulation on Consolidated Gas Supply Corporation,prices, production levels, employment, (18) Glass Containers Corporation; (19)communities in which pressed and blown West Virginia Glass Specialty Company;glass manufacturing plants are located, (20) Viking Glass Company; (21) Louloand international trade. In addition, the Glass Company; (22) Pilgrim GlassDevelopment Document describes, in see- Corporation; (23) Colonial Glas Com-tion VIII, the cost and energy consump- pany; (24) Kopp Glass Inc.; (25)ion implications of the proposed regu- Owens-Illinois; (26) Fenton Art Glass

lations. Company; (27) Westlnghouso ElectrloThe two reports described above in the Company; (28) Federal Glass Company;

aggregate exceed 200 pages in length (29) Thatcher Glass Manufacturingand contain a substantial number of Company; (30) Fostoria Glass Corn-

FEDERAL REGISTER, VOL. 39, NO. 163-VIEDNESDAY, AUGUST 21, 1974

-

PROPOSED RULES

pany; (31) Minners Glass Company;(32) Gillender Brothers, Inc.; (33)Coming Glass Works; (34) GeneralElectric Company; and (35) Ball Cor-poration.

The following responded with com-ments: U.S. Water Resources Council;Delaware River Basin Commission; Min-nesota Pollution Control Agency; Owens-Illinois; Glass Container ManufacturersInstitute; State of Michigan, Departmentof Natural Resources; General ElectricCompany; and North Carolina Depart-ment of Natural & Economic Resources.

The primary issues raised in the de-velopment of the proposed effluent limita-tions guidelines and standards of per-formance and the treatment of theseissues herein are as follows:

(1) A common criticism was that pre-treatment standards were omitted fromthe draft development document. It wasstated that both pretreatment standardsand effluent limitations guidelines werenecessary in order that the pressed andblown glass industry can make firm en-gineering and economic commitments.

It has been Agency policy to proposepretreatment standards at the time ofpromulgation of effluent limitationsguidelines. However, the Agency wouldwelcome, at this time, data or suggestionspertaining to pretreatment standards forthe pressed and blown glass segment ofthe glass manufacturing category.

(2) The comment was received thatthe data base on whichIthe guidelines arebased is inadequate and that the Agencyshould extensively sample the pressedand blown glass segment to develop amore thorough and reliable data base.

All available data pertaining to thepressed and blown glass segment hasbeen analyzed and engineering judg-ments made based upon this data. TheAgency feels that the data base is ade-quate but does solicit any additional datawhich supports or contradicts the find-ings expressed in the draft developmentdocument.

(3) The comment was made that theage of a facility should be a factor withregard to the suboategorization of thepressed and blown glass segment with-therecommendation that a range of valuesbe specified which would reflect the ageof an individual facility.

The available data does not supportthis contention. However, the Agency so-licits information which substantiatesthis clain Information showing the re-lationship of investment required to at-tain effluent limitations guidelines, wa-ter usage, or waste loadings to age of afacility would be particularly useful insupporting the hypothesis that age is animportant factor affecting subcategori-zation of the industry segment.

(4) An objection was made to the in-clusion of noncontact cooling water flowin the characterization of the typicaIplant on which the BPCTCA guidelinesfor the glass container, machine pressedand blown, television picture tube en-velope, and glass tubing manufacturingsubcategories are based. It was statedthat while on a weight basis the recom-

mended guidelines are achievable inmost cases, industry feels that concentra-tion limits will be violated when wastestreams are segregated and recirculationsystems are employed during the interimperiod between 1977 and 1983 in orderthat BATEA limitations be attained.

Effluent limitations guidelines will beapplied consistent with a schedule ofcompliance leading to achievement oflevels of abatement required by the Act.Such limitations as are required by efflu-ent limitations guidelines will be statedin quantitative terms, i.e., unit of weightper unit of time (kg/day) for each pol-lutant limited. Qualitative limitations(i.e., concentration) set at a fixed levelare not consistent with fixed quantitativelimitations in a variable or reducing flowcontext, but may be required by State au-thority preserved under Section 510 ofthe Act. In such a situation, the morestringent effective limitation would beobserved.

(5) The comment was made that the20 mg/l level for fluoride which the draftdevelopment document states that thetypical incandescent lamp envelope man-ufacturing plant can achieve is toostringent and inconsistent with anNPDES permit which Is now being writ-ten. The commenter recommended thatthe 32 mg/l level which their plant is nowachieving is a more realistic level.

The development document presentsfindings, of an extensive survey of theentire subcategory rather than of a sin-gle plant. The available data supportsthe proposed effluent limitations guide-lines.

(6) The comment was made that be-cause no plants in the incandescent lampenvelope manufacturing subcategory arecurrently treating the 650 mg/1 concen-trations of ammonia discharged by thetypical plant, ammonia removal tech-niques are not best practicable controltechnology currently available and untilmore research is done, do not even qual-ify as best available technolo3y econom-ically achievable.

The high levels of ammonia whichoccur in waste waters associated withthe incandescent lamp envelope manu-facturing subcategory are capable ofproducing adverse biological effects. Thepresent degree of treatment-within thissubcategory has been Judged to be In-adequate with regard to ammonia re-moval. Many ammonia removal tech-niques exist and the deficiency of plantswithin this subcategory with regard totreatment of ammonia necessitates atransfer of technology from other pointsource categories. Waste waters fromplants within this subcategory are cur-rently treated to remove fluorides by theaddition of lime to a PH of 11 causingthe precipitation of calcium fluoride.This high pH makes the air or steamstripping of ammonia a rather attractivemethod of treatment. The technique onwhich effluent limitations guidelines arebased Is steam stripping which Is well-demonstrated in the fertilizer, petroleumand petrochemical and steel industries.

30-987

(7) The comment was made that theproposed recommendations for BATEAwill result In essentially zero dischargeof pollutants and the need for the opti-mistic technology transfer predictionsand the extremely low effluent levelsrecommended was not understood.

The Act declares that the national goalIs the elimination of discharge of pol-lutants by 1985. The proposed effluentlimitations guidelines fulfin the require-ment of progress toward this nationalgoal. The technoloaes on which BATEAeffluent limitation guidelines are basedare well demonstrated by their applica-tion to treatment of waste waters asso-elated with other industrial categoriesor application in the field of watertreatment.

(8) The comment was made that thecosts presented in the draft developmentdocument for typical plants are not rep-rezentative of all the plants Witlhn thevarious subcategories.

The technologies currently employedby plants within these various subcate-gorles of the pressed and blown glasssegment are considered acceptable asBPCTCA. There Is therefore, no expectedsignificant increase in capital invest-ment, the only requirement being thatplants operate existing pollution controland treatment equipment properly or im-prove houseLzeeping techniques to con-trol raw waste loadings. The Agency does,however, solicit data which support orcontradict this contention. The fact thatthe recommended levels are achievableIs demonstrated by the high percentageof plants for which data Is available thatcurrently meet the BPCTCA require-ments.

Interested persons may participate inthis rulemaking by submitting writtencomments in triplicate to the EPA Infer-mation Center, Environmental Protec-tion Agency, W-1hington, D.C. 20460.Attention: mr. Philip B. visman. Com-ments on all aspects of the proposedregulation are solicited. In the eventcomments are in the nature of criticismsas to the adequacy of data which areavailable, or which may be relied uponby the Agency, comments should iden-tify and, it possible, provide any addi-tional data which may be available andshould indicate why such data are essen-tial to the development of the regula-tions. In the event comments address theapproach taLen by the Agency in estab-lsbhing an effluent limitations guidelineor standard of performance, EPA solicitssuggestions as to what alternative ap-proach should be taken and why andhow this alternative better satisfies thedetailed requirements of sections 301,304(b), 306, and 307 of the Act.

A copy of all public comments will beavailable for inspection and copying atthe EPA Information Center, R3oom 227,West Tower, Waterside M , 401 MStreet SW., Washington, D.C. A copy ofprelimiary draft contractor reports, theDevelopment Document, and economiastudy referred to above, and certain sup-Plementary materials supporting thestudy of the industry concerned will also

FEDERAL REGISTER. VOL 39, NO. 163-WEDNESDAY, AUGUST 21, 1974

-

PROPOSED RULES

be maintained at this location for publicreview- and copying. The EPA informa-tion regulation, 40 CFR Part 2, providesthat a reasonable fee may be charged forcopying.

All comments received on or beforeSeptember 20, 1974, will be considered.Steps previously taken by the Environ-mental Protection Agency to facilitatepublic response within this time periodare outlined In the advance notice con-cerning public review procedures pub-lished on August 6, 1973 (38 FR 21202).

Dated: August 13,1974.JoM-T QUARLES,

Acting Administrator.PART 426-EFFLUENT LIMITATIONS AND

GUIDELINES FOR EXISTING SOURCESAND STANDARDS OF PERFORMANCEAND PRETREATMENT STANDARDS FORNEW SOURCES FOR THE GLASS CON-TAINER MANUFACTURING POINTSOURCE CATEGORYSubpart H-Glass Container Manufacturing

SubcategorySec.426.80 Applicability; description of the

glass container manufacturingsubcategory.

426.81 Specialized definitions.426.82 Effluent limitations guidelines rep-

resenting the degree of effluentreduction attainable by the ap-plication of the best practica-ble control technology currentlyavailable.

426.83 Effluent limitations guidelines rep-resenting the degree of effluentreduction attainable by the appli-cation of the best available tech-nology economically achievable.

426.84 [Reserved]426.85 Standards of performance for new

sources.426.86 Pretrcatment standards for new

sources.Subpart I-Machine Pressed and BlownrGlass

Manufacturing Subcategory426.90 Applicability;, description of the

machine pressed and blown glassmanufacturing subcategory.

426.91 Specialized definitions.426.92 Effluent limitations guidelines rep-

resenting the degree of effluentreduction attainable by the appli-cation of the best practicablecontrol technology currentlyavailable.

426.93 Effluent limitations guidelines rep-resenting the degree of effluentreduction attainable by the ap-plication of the best availabletechnology economically achieva-ble.

426.94 [Reserved]426.95 Standards of performance for new

sources.426.90 Pretreatment standards for new

sources.Subpart J-Glass Tubing Manufacturing

Subcatcgory426.100 Applicability, description of the

glass tubing manufacturing sub-category.

426.101 Specialized definitions.426.102 Effluent limitations guidelines rep-

resenting the degree of effluentreduction attainable by the appli-cation of the best practicablecontrol technology currentlyavailable.

Se.0426.103

426.104426.105

426.106

Effluent limitations guidelines rep-resenting the degree of effluentreduction attainable by the appli-cation of the best available tech-nology economically achievable.

[Reserved]Standards of performance for new

sources.Pretreatment standards for new

sources.Subpart K-Television Picture Tube Envelope

Manjfacturing Subcategory

426.110 Applicability; description of thetelevision picture tube envelopemanufacturing subcategory.

426.111 Specialized definitions.426.112 Effluent limitations guidelines rep-

resenting the degree of effluentreduction attainable by the ap-plication of the best practicablecontrol technology currentlyavailable.

426.113 Effluent limitations guidelines rep-resenting the degree of effluentreduction attainable by the ap-plication- of the best availabletechnology economically acbiev-able.

426.114 IReserved]426.115 Standards of performance for new

sources.426.116 Pretreatment standards for new

sources.

Subpart L--Incandescent Lamp EnvelopeManufacturing Subcategory

426.120 Applicability; description of theincandescent lamp envelopemanufacturing subcategory.

426.121 Specialized definitions.426.122 Effluent limitations guidelines

representing the degree of efflu-ent reduction attainable by theapplication of the best practi-cable control technology cur-rently available.

426.123 Effluent limitations guidelinesrepresenting the degree of efflu-ent reduction attainable by theapplication of the best availabletechnology economically Achiev-able.

426.124: [Reserved]426.125 Standards of performance for new

sources.426.126 Pretreatment standards for new

sources.

Subpart M-Hand Pressed and Blovifl GlassManufacturing Subcategory

426.130 Applicability;, description" of thehand pressed and blown glassmanufacturing subcategory.

426.131 Specialized definitions.426.132 Effluent limitations guidelines

representing the degree of efflu-ent reduction attainable by theapplication of the best practi-cable control technology cur-rently available.

426.133 Effluent limitations guidelinesrepresenting the degree of efflu-ent reduction attainable by theapplication of the best Availabletechnology economically achiev-able.

426.134 lneserved]426.135 Standards of Performance for new

sources.

426.136 Pretreatment standards for newsources.

Au=011=: Sees. 301, 304(b)- and (c),306(b) and 307(c), Federal Water PollutionControl Act, As amended (33 U.S.C. 1251,1311, 1314 (b) and (c)- 1316(b) and 1317(c);86 Stat. et seq.; Pub L. 92-500) (the Act)

Subpart H-Glhtss ContainerManufacturing Subctegory

§426.80 Applicability: description ofthe glass container mnufacttringsubcategory.

The provisions of this subpart are ap-plicable to discharges resulting from theprocess by which raw materials aremelted in a furnace and mechanicallyprocessed into glass containers.§ 426.81 Specialized definitions.

For the purpose of this subpart:(a) Except as provided below, the (ex-

cept for definitions, abbreviations andmethods of analysis set forth in Part 401of this chapter shall apply to this sub-part.

(b) The term "furnace pull" shallmean that amount of glass drawn fromthe glass furnace or furnaces.

(c) The term "oil" shall mean thosecomponents of a waste water amenableto measurement by the methoddescribed In "Mlethods for ChemicalAnalysis of Water and Wastes", 1971,Environmental Protection Agency, Ana-lytical Quality Control Laboratory, page217.

§ 426.82 Effluent limitations guidelhcirepresenting the degree of effluentreduction attainable by the applica.tion of the best practicable controltechmology currently available.

In establishing the limitations set forthin this section, EPA took into account allInformation it was able to collect, developand solicit with respect to factors (suchas age and size of plant, rpw materials,manufacturing processes, products pro-duced, treatment technology available,energy requirements and costs) whichcan affect the industry subcategorIzatonand effluent levels established. It Is, how-ever, possible that data which would af-fect these limitations have not beenavailable and, as a result, these limita-tions should be adjusted for certainplants in this industry. An individualdischarger or other interested personmay submit evidence to the RegionalAdministrator (or to the State, If theState has the authority to issue NPDESpermits) that factors relating to theequipment or facilities involved, theprocess applied, or other such factors re-lated to such discharger aro fundamen-tally different from the factors consid-ered in the establishment of theguidelines. On the basis of such evidenceor other available information, the Re-gional Administrator (or the State) willmake a written finding that such factorbare or are not fundamentally differentfor that facility compared to those specl-fled in the Development Document. ifsuch fundamentally different factors arefound to exist, the Regional Administra-tor or the State shall establish for thedischarger effluent limitations in theNPDES permit either more or less strin-gent than the limitations establishedherein, to the extent dictated by suchfundamentally different factors. Suchlimitations must be approved by the Ad-ministrator of the Environmental Pro-

FEDERAL REGISTERl, VOL 39, NO. 163-WEDNESDAY, AUGUST 21, 1974

30288

-

I PROPOSED RULES

tection Agency. The Administrator mayapprove or disapprove such limitations,specify other limitations, or initiate pro-ceedings to revise these regulations. Thefollowing limitations establish the quan-tity or quality of pollutants or pollutantproperties, controlled by this section,which may be discharged by a pointsource subject to the provisions of thissubpart after application of the bestpracticable control technology currentlyavailable:

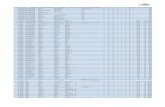

Effluent limitations

Effluent Average of dailycharacteristc axum for values for thirty

any one day consecutlve daysshall not exceed

(Metric units) g/kkg of furnace pull

O l_. 60.0 .........TSS =--:- 140.0 ..........

. Within the -...range .0 to9.0.

(English units) Ibh1000 lb of furnnce

OIL . 0.05 --------TSS..-...-.-. 0.14- ..........p -_-_._z ........ Within the ----

range 0.0 to9.0.

§ 426.33 Effluent limitations -qrepresenting the degree ofreduction attainable by thetion of the best available teeconomically achievable.

The following limitations estaquantity or quality of pollutantslutant properties, controlled bytion, which may be discharged b3source subject to the provisionssubpart after application of tavailable technology econachievable:

Effluentflinltatf

Effluent .Averecharacteristic Maximum for value,

any one day causesshnl:

(Metric units) g/kkg of furnace pu

OIL_ . ;_ -0.8 .........-.

pH....... ... -Within the =.....range 6.0 to9.0.

(English units) lbJ1000 lb of furnace

Off 0.003-. _z=_T5B..S..a ..... 0.003... -pM ----....-----. . Within the -.-.---

range 0.0 to9.0.

§ 426.84 [Reserved]§ 426.85 Standards of perform

new sources.

The following standards of pance establish the quantity or qu

3,3.070.0

pollutants or pollutant properties, con-trolled by this section, which may be dis-charged by a new source subject to theprovisions of this subpart:

Eilucat 111tt'ezs

Emftuent Av fdlalchnrcttcrsio Maximum far rai far thirty

any ono day cs-rz :u o dayrElal net ftxc T

(metrfo units) rpklu of furnan aull

OIL ............. 0.4TSS -------------. .8 ............. .4pL ..............- W--- tahora, ..................

00 to 9.0.

(English unit,) Ibhq 10 lb of farnz- run

OIL----.... 0.008-- ... "I.TS&_. O8.X43 . 0m.. .p _ -.......-------- Wlthnthorago ..................

0.0 to 9.0.

----------§ 426.86 Pretreatment standards fornew sources.

The pretreatment standards undersection 307(c) of the Act for a sourcewithin the glass cQntalner manufactur-

.07 ing subcategory, which is a user of a............ publicly owned treatment works (and

which would be a new source subJect tosection 306 of the Act, if it were to dis-charge pollutants to the navigable

udelines waters), shall be the standard set fortheffluent in Part 128 of this chapter, except that,applica- for the purpose of this section, § 128.133lmology of this chapter, shall be amended to

read as follows: "In addition to the pro-ish the hibitions set forth in § 128.131 of thisor pol- chapter, the pretreatment standard for

this see- incompatible pollutants introduced intoa point a publicly owned treatment works shallof this be the standard of performance for new

,he best sources specified in § 426.85; Provided,omically That, if the publicly owned treatment

works which receives the pollutants iscommitted, in its NPDES permit, to re-move a specified percentage of any in-compatible pollutant, the pretreatment

e of daily' standard applicable to users of such.for thirty1tlve dayas treatment works shall, except in the

not exceed case of standards providing for no dis-charge of pollutants, be correspondingly

I reduced in stringency for that pol-lutant."

0.4 Subpart I-Machine Pressed and BlownGlass Manufacturing Subcategory

§426.90 Applicability; description ofthe machine pressed and blown glnos

pu manufacturing subcntegory.

The provisions of this subpart are ap-.o01 plicable to discharges resulting from the.134 process by which raw materials are- ------ zmelted in a furnace and mechanically

processed into pressed or blown glass-ware.§ 426.91 Specialized definitions.

ance for For the purpose of this subpart:(a) Except as provided below, the

erform- general definitions, abbreviations anduality of methods of analysis set forth In part 401

of this chapter shall apply to thissubpart.

(b) The term "furnace pull" shallmean that amount of glass drawn fromthe rlass furnace or furnaces.

(c) The term "oil" shall mean thosecomponents of a waste water amenableto measurement by the method de-scribed in "M.ethods for Chemical Analy-sis of Water and Wastes", 1971, Environ-mental Protection Agency, AnalyticalQuality Control Laboratory, page 217.§ 426.92 Effluent limitations guidelines

representing the degree of effluentreduction attainable by the applica-tion of the best practicable controltechnology currently available.

In establishing the limitations setforth in this section. EPA took into ac-count all information it was able to col-lcer, develop and solicit with respect tofactors (such as age and size of plant,raw materials, manufacturing processes,products produced, treatment technolo.-yavailable, energy requirements andcozts) which can affect the industry sub-categorization and efiluent levels estab-lished. It is, however, possible that datawhich w ould affect these limitations havenot baen available and, as a result, theselimitations should be adjusted for certainplants in this industry. An Individualdischarger or other interested personmay submit evidence to the RezionalAdministrator (or to the State, if theState has the authority to Issue NPDESpermits) that factors relating to theequipment or facilities involved, theprocess applied, or other such factorsrelated to such discharger are fundamen-tally different from the factors consid-ered in the establishment of the guide-lines. On the basis of such evidence orother available information, the RegionalAdministrator (or the State) will make awritten finding that such factors are orare not fundamentally different for thatfacility compared to those specified inthe Development Document. If suchfundamentally different factors arefound to exist, the Regional Adminis-trator or the State shall establish forthe discharger effluent limitations in theNPDES permit either more or less strin-gent than the limitations establishedherein, to the extent dictated by suchfundamentally different factors. Suchlimitations must be approved by theAdminlstrafor of the EnvironmentalProtection Agency. The Administratormay approve or disapprove such limita-tions, specify other limitations, or initi-ate proceedings to revise these regula-tions. The following limitations estab-lish the quantity or quality of pollut-ants or pollutant properle;, controlledby this section, which may he dischargedby a point source subject to the pro-visions of this subpart after applicationof the best practicable control technol-ozy currently available:

FEDERAL REGISTER, VOL. 39, NO. 163-VWEDNESDAY, AUGUST 21, 1974No. 163-1t. Ir-2

30289

-

PROPOSED RULES

Effluent limitations

Effluent Average of dailycharacteristic Maximum for values for thirty

any one day consecutive days,hall not exceed

(Metric units) g/kkg of furnace pull

Oil ............. . - -6.0Tss --------.. k 09 --- 140.0pH- ---------------- Within the ----------

range 6.0 to9.0.

(English units) 1I1000 lb of furnace pull

Oil --------------- 0.112 ----........ .056TSS --- 0.2------------ .14pH ...... - Within the

range 6,0 to9.0.

§ 426.93 Effluent limitations guidelinesrepresenting the degree of efflhentreduction attainable by the applica-tion of the best available technologyeconomically achievable.

The following limitations establish thequantity or quality of pollutants or pol-lutant properties, controlled by this sec-tion, which may be discharged by a pointsource subject to the provisions of thissubpart after application of the bestavailable technology economicallyachievable:

Effluent limitations

Effluent Average of dailycharacteristic Maximum for values for thirty

any one day consecutive daysshall not exceed

(Metric units) gfcktg of furnace pull

Oil --------------- ------...3.0 ....-- L8TSs --------------- 3.6 --------------- L8PH ----.-.---------..Withintho the ...........

range 0.0 to9.0.

(English units) lblO00 lb of farnaeo pul

Oil --------------- 0.0036 .----..... . 0018TSS -- _---------- .003r ........... .0018P

T - - - - - - - - - - - - -- Within the ...... ........

range 6.0 to9.0.

§ 426.94 [Reserved]§ 426.95 Standards of performance for

new sources.

The following standards of perform-ance establish the quantity or quality ofpollutants or pollutant properties, con-trolled by this section, which may be dis-charged by a new source subject to theprovisions of this subpart:

Efiluent limitations

Effluent Average of dailycharacteristic Maximum for values for thirty

nay ono day consecutive daysshall not exceed

(Metric units) gfkkg of furnace pull

O i- 3.6 --.-.-------- 1.8T S .--------------.. 3.6 .............. 1, 8pH ----------------- W ithin the ...................

range 6.0 to9.0.

(English units) lb100 lb of furnace pull

Oil --------------- 0.00M0 ............ 0018TSS -------------- 0.0030 ---. 0018pH - - - - - - - - - - - - - - Within the ...........

range 6.0 to9.0.

§ 426.96 Pretreatment standards fornew sources.

The pretreatment standards undersection 307(c) of the Act for a sourcewithin the machine pressed and blownglass manufacturing gubeategory, whichis a user of a publicly owned treatmentworks (and which would be a new sourcesubject to section 306 of the Act, if itwere to discharge pollutants to the navi-gable waters), shall be the standard setforth in Part 128 of this Chapter, exceptthat, for the purpose of this section,§ 128.133 of this Chapter shall beamended to read as follows: "In addi-tion to the prohibitions set forth in§ 128.131 of this Chapter, the pre-treatment standard for incompatiblepollutants introduced into a publiclyowned treatment works shall be thestandard of performance for-new sourcesspecified in § 426.95: Provided, That, ifthe publicly owned treatment workswhich receives the pollutants is com-mitted, in its NPDES permit, to remove aspecified percentage of any incompatiblepollutant, the pretreatment standard ap-plicable to users of such treatment worksshall, except in the case of standardsproviding for no discharge of pollutants,be correspondingly reduced in stringencyfor that pollutant."

Subpart J--Glass Tubing Manufacturing§ 426.100 Applicability; description of

the glass tubing manufacturing sub-category.

The provisions of this subpart are ap-plicable to discharges resulting from theprocess by which raw materials aremelted in a furnace and mechanicallyprocessed into glass tubing as a finalproduct.

§ 426.101 Specialized defiition.For the purpose of this subpart:(a) Except as provided below, the gen-

eral definitions, abbreviations and meth-ods of analysis set forth In Part 401 ofthis Chapter shall apply to this subpart.

(b) The term "furnace pull" shallmean that amount of glass drawn fromthe glass furnace or furnaces.

(c) The term "oil" shall mean thosecomponents of a waste water amenableto measurement by the method describedin "Methods for Chemical Analysis ofWater and Wastes," 1971, EnvIronmentalProtection Agency, Analytical QualityControl Laboratory, page "17.§426.102 Effluent linitaton-4 gtiuidc'li

representing the degree of ellluentreduction attainable by the applict-tion of the be4,t praclicable controltechnology currently available.

In establishing the limitations setforth in this section, EPA took into ac-count all information It was able tocollect, develop and solicit with respectto factors (such as age and size of plant,raw materials, manufacturing proceses,products produced, treatment technologyavailable, energy requirements and costs)which can affect the Indus-try subcatc-gorization and effluent levels established.It is, however, possible that data whichwould affect these limitations have notbeen available and, as a result, thesolimitations should be adjusted for cer-tain plants in this industry. An Individ-ual discharger or other interested per-son may submit evidence to the RegionalAdministrator (or to the State, If theState has the authority to Issue NPDEpermits) that factors relating to theequipment or facilities involved, theprocess applied, or other such factorsrelated to such discharger are funda-mentally different from the factors con-sidered In the establishment of theguidelines. On the basis of such evidenceor other available information, theRegional Administrator (or the State)will make a written finding that suchfactors are or are not fundamentallydifferent for that facility compared tothese specified in the Development Docu-ment. If such fundamentally difterentfactors are found to exist, the RegionalAdministrator or the State shall estab-lish for the discharge effluent limita-tions in the NPDES permit either moreor less stringent than the limitationsestablished herein, to the extent dictatedby such fundamentally different factors,Such limitations must be approved by theAdministrator of the Environmental

FEDEPAL REGISTER, VOL. 39, NO. 163-WEDNESDAY, AUGUST 21, 1974

30290

-

PROPOSED RULES

Protection Agency. The Administratormay approve or disapprove such limitx-tions, specify other limitations, or ili-tiate proceeding to revise these regula-tions. The following limitations estab-lish the quantity or quality of pollutantsor pollutant properties, controlled bythis section, which may be discharged bya point source subject to the provisionsof this subpart after application of thebest practicable control technology cur-rently available:

Effluent nitations

Effuent Average of dallycharacteristic Mn hamn for values for thirty

any one day cose utlvo daysanlnot ercead

(Metric unts) gflkk of furnaca pul

Oil ..-- - --- 170.0 -----.. _- 0TSS ...... 4.0-7..... 23.0pH* .... -. ' Within the

range 6.0th9.0.

(Engish uhit) IhJ10 0 lb off Urn- pul

Oil- ....------- 0.17 .5TSS _ 0.46-.... .23pH ___ Within the

range 0.0 to9.0.

§ 426.103 Effluent Ifmitations guidelinesrepresenting the degree of effluentreduction attainable by the applica-tion of the best available teelmologyeconomically achievable.

The following limitations establish thequantity or quality of pollutants or pol-lutant properties, controlled by this sec-tion, which may be discharged by a pointsource subject to the provisions of-this subpart after application of thebest available technology economicallyachievable:

:Effluent linitatlons

Effluent Ave rage of dailycharacteristic Itasimum for values for thirty

any one day consecutive daysshall not excee

(Metric units) gfkkg of furnace pul

OiL - ..---------- 0.2 -...........- 01TSS --..-.-------- 0.2 ------------.-pH. W----------- ithin the- -------------

rane 6.0 to

(English units) Ib/10N) Ib of furnace pull

S --------- 00002 ---.- O31'rss - ----0.0092)----.O3pH ------------- Within the

rane 6.0 to

§ 426.104 [Reservedl

§ 426.105 Standardslofperformance fornew sources.

The following standards of perform-ance establish the quantity-or qualityof pollutants or pollutant properties,controlled by this section, which may bedischarged by a new source subject to theprovisions of this subpart:

.eal t ,ls TLmnm fir vVal= f= tlflt7ay ono day eivdg

fl io unlt ) 1lb 0 farnra pl r

OL_. __: . . .. . . 0. 1"T5 . .. 0.2. . . .1pHL.--..... Withi U:th . .

run,0(.0to 0.

(Enllsh unit) lbJ1 MW lb of fImz= pull

OIL --- O. 0.0M .1

Tss-kn50.00M .0.W2pH .. ..... Wthin tba ............ .ranaco.0to 9.

§426.106 Prctreatment standards fornew sources.

The pretreatment standards undersection 307(0) of the Act for a, sourcewithin the glass tubing manufacturingsubcategory, which is a user of a pub-licLy owned treatment works (and whichwould be a new source subject to section306 of the Act, if It were to dischargepollutants to the navigable waters), shallbe the standard set forth in part 128 ofthis chapter, except that, for the pur-pose of this section, § 123.133 of thischapter shal be amended to read as fol-lows: "In addition to the prohibitions setforth In § 128.131 of this chapter, thepretreatment standard for incompatiblepollutants introduced Into a publiclyowned treatment works shal be thestandard of performance for new sourcesspecified In § 426.105; Prorldcd, That,if the publicLy owned treatment worlmwhich receives the pollutants I- com-mitted, in its NPDES permit, to re-move a specified percentage of any In-compatible pollutant, the pretreatmentstandard applicable to users of suchtreatment worl shall, except in the caweof standards providing for no dischargeof pollutants, be correzpondingly reducedin stringency for that pollutant."

Subpart K-Teleuislon Plcture TubaEnvelope M'anufacturing Subcategory

§ 426.110 Applicability; description ofdte television picture tube cnvelopemanufacturing subcategory.

The provisions of this subpart are ap-plicable to discharges resulting from theprocess by which raw materials aremelted in a furnace and procused intotelevision picture tube envelopes.§ 426.111 Specialized definition.

For the purpose of this subpart:(a) Except as provided helow, the gen-

eral definitions, abbreviations and meth-ods of analysis set forth In Part 401 ofthis chapter shall -apply to this subpart.

(b) The term "furnace pull" shallmean that amount of glazs drawn fromthe glass furnace or fumaces.

(c The term "oil" shall mean thosecomponents of a waste vater ahenableto measurement by the methcd descrited

-in '%ethods for Chemical Analysis ofWater and Wastes," 1971, EnvironmentalProtection Agency, Analytical QualityControl Laboratory, page 217.

§ 426.112 Effl untlh itationsguidelinesreprenting the degree of effluentreduction attainable by the applica-tion of the best practicable controlt MnoIo -currcntly ava ilaIe.-