3. Electrically Modulated Transparent Liquid Crystal -Optical Grating Projection

-

Upload

srini-vasan -

Category

Documents

-

view

215 -

download

0

Transcript of 3. Electrically Modulated Transparent Liquid Crystal -Optical Grating Projection

7/27/2019 3. Electrically Modulated Transparent Liquid Crystal -Optical Grating Projection

http://slidepdf.com/reader/full/3-electrically-modulated-transparent-liquid-crystal-optical-grating-projection 1/10

Electrically modulated transparent liquid crystal-optical grating projection

Thomas Buß, Cameron L.C. Smith, and Anders Kristensen*

Department of Micro and Nanotechnology, DTU Nanotech, Technical University of Denmark, Building 345 East,

DK-2800 Kongens Lyngby, Denmark.*[email protected]

Abstract: A transparent, fully integrated electrically modulated projectiontechnique is presented based on light guiding through a thin liquid crystallayer covering sub-wavelength gratings. The reported device operates at 10V with response times of 4.5 ms. Analysis of the liquid crystal alignmentshows that director-reorientation occurs over timescales on the order of 90µs close to the grating surface. The technology is suitable for nextgeneration heads-up-displays and reconfigurable multilayer photonicintegrated circuits.

©2013 Optical Society of America

OCIS codes: (050.0050) Diffraction and gratings; (050.6624) Subwavelength structures;(160.3710) Liquid crystals; (310.2785) “Guided” wave applications; (120.2040) Displays.

References and links

1. J. F. Wager, “Applied physics. Transparent electronics,” Science 300(5623), 1245–1246 (2003).2. Y. Yang, S. Jeong, L. Hu, H. Wu, S. W. Lee, and Y. Cui, “Transparent lithium-ion batteries,” Proc. Natl. Acad.

Sci. U.S.A. 108(32), 13013–13018 (2011).3. L. Xiao, Z. Chen, C. Feng, L. Liu, Z.-Q. Bai, Y. Wang, L. Qian, Y. Zhang, Q. Li, K. Jiang, and S. Fan, “Flexible,

stretchable, transparent carbon nanotube thin film loudspeakers,” Nano Lett. 8(12), 4539–4545 (2008).4. F. Giraud, M. Amberg, B. Lemaire-Semail, and G. Casiez, “Design of a transparent tactile stimulator,” in 2012

IEEE Haptics Symposium (HAPTICS) (IEEE, 2012), pp. 485–489.5. T. S. Kim, J. S. Park, K. S. Son, J. S. Jung, K.-H. Lee, W. J. Maeng, H.-S. Kim, J.-Y. Kwon, B. Koo, and S. Lee,

“Transparent AMOLED display driven by hafnium-indium-zinc oxide thin film transistor array,” Curr. Appl.Phys. 11(5), 1253–1256 (2011).

6. Y.-H. Cheng and G.-D. J. Su, “Waveguide display using polymer-dispersed liquid crystal,” Proc. SPIE 8114,811414, 811414-8 (2011).

7. L. Eisen, M. Meyklyar, M. Golub, A. A. Friesem, I. Gurwich, and V. Weiss, “Planar configuration for image projection,” Appl. Opt. 45(17), 4005–4011 (2006).

8. Z. Yan, W. Li, Y. Zhou, M. Kang, and Z. Zheng, “Virtual display design using waveguide hologram in conicalmounting configuration,” Opt. Eng. 50(9), 094001 (2011).9. D. Rosenblatt, A. Sharon, and A. A. Friesem, “Resonant grating waveguide structures,” IEEE J. Quantum

Electron. 33(11), 2038–2059 (1997).10. T. Buß, C. L. C. Smith, M. Brøkner Christiansen, R. Marie, and A. Kristensen, “Sub-wavelength surface gratings

for light redirection in transparent substrates,” Appl. Phys. Lett. 101(4), 043109 (2012).11. W. Schenck, D.-H. Ko, and E. Samulski, “Liquid crystal alignment on polymer line gratings,” J. Appl. Phys.

109(6), 064301 (2011).12. D.-R. Chiou, L.-J. Chen, and C.-D. Lee, “Pretilt angle of liquid crystals and liquid-crystal alignment on

microgrooved polyimide surfaces fabricated by soft embossing method,” Langmuir 22(22), 9403–9408 (2006).13. R. Lin and J. A. Rogers, “Molecular-scale soft imprint lithography for alignment layers in liquid crystal

devices,” Nano Lett. 7(6), 1613–1621 (2007).14. D. W. Berreman, “Solid surface shape and the alignment of an adjacent nematic liquid crystal,” Phys. Rev. Lett.

28(26), 1683–1686 (1972).15. T. Tamir and S. T. Peng, “Analysis and design of grating couplers,” Appl. Phys. (Berl.) 14(3), 235–254 (1977).16. L. J. Guo, “Nanoimprint lithography: Methods and material requirements,” Adv. Mater. (Deerfield Beach Fla.)

19(4), 495–513 (2007).17. J. P. F. Lagerwall and G. Scalia, “A new era for liquid crystal research: Applications of liquid crystals in soft

matter nano-, bio- and microtechnology,” Curr. Appl. Phys. 12(6), 1387–1412 (2012).18. K. Miyoshi, S. Yamada, S. Miyahara, M. Yamashita, Y. Hashimoto, T. Yukinari, and K. Ishiguro, “Conoscopic

study of liquid crystal after application and removal of the external electric field,” Jpn. J. Appl. Phys. 22(Part 1, No. 12), 1754–1765 (1983).

19. M. Jiao, Z. Ge, Q. Song, and S.-T. Wu, “Alignment layer effects on thin liquid crystal cells,” Appl. Phys. Lett.92(6), 061102 (2008).

#180487 - $15.00 USD Received 23 Nov 2012; revised 6 Jan 2013; accepted 9 Jan 2013; published 16 Jan 2013

(C) 2013 OSA 28 January 2013 / Vol. 21, No. 2 / OPTICS EXPRESS 1820

7/27/2019 3. Electrically Modulated Transparent Liquid Crystal -Optical Grating Projection

http://slidepdf.com/reader/full/3-electrically-modulated-transparent-liquid-crystal-optical-grating-projection 2/10

20. Y. Q. Lin, S. M. Feng, and T. Chen, “Temperature effect on threshold voltage and optical property of twistednematic liquid crystal with applied different voltages,” Optik (Stuttg.) 121(18), 1693–1697 (2010).

21. S. Klinkhammer, N. Heussner, K. Huska, T. Bocksrocker, F. Geislhöringer, C. Vannahme, T. Mappes, and U.Lemmer, “Voltage-controlled tuning of an organic semiconductor distributed feedback laser using liquidcrystals,” Appl. Phys. Lett. 99(2), 023307 (2011).

22. T.-H. Chao, T. T. Lu, S. R. Davis, S. D. Rommel, G. Farca, B. Luey, A. Martin, and M. H. Anderson, “Compactliquid crystal waveguide based Fourier transform spectrometer for in-situ and remote gas and chemical sensing,”Proc. SPIE 6977, 69770P, 69770P-11 (2008).

23. K. Kato, T. Hisaki, and M. Date, “In-plane operation of alignment-controlled holographic polymer-dispersedliquid crystal,” Jpn. J. Appl. Phys. 38(Part 1, No. 3A), 1466–1469 (1999).

24. A. K. Pitilakis, D. C. Zografopoulos, and E. E. Kriezis, “In-line polarization controller based on liquid-crystal photonic crystal fibers,” J. Lightwave Technol. 29(17), 2560–2569 (2011).

25. T. F. Krauss, “Planar photonic crystal waveguide devices for integrated optics,” Phys. Status Solidi A 197(3),688–702 (2003).

26. D. D. John, M. J. R. Heck, J. F. Bauters, R. Moreira, J. S. Barton, J. E. Bowers, and D. J. Blumenthal,“Multilayer platform for ultra-low-loss waveguide applications,” IEEE Photonic. Tech. L. 24(11), 876–878(2012).

27. M. Aljada, K. E. Alameh, Y.-T. Lee, and I.-S. Chung, “High-speed (2.5 Gbps) reconfigurable inter-chip opticalinterconnects using opto-VLSI processors,” Opt. Express 14(15), 6823–6836 (2006).

28. X. Wei and S. M. Weiss, “Guided mode biosensor based on grating coupled porous silicon waveguide,” Opt.Express 19(12), 11330–11339 (2011).

29. S. Dochow, C. Krafft, U. Neugebauer, T. Bocklitz, T. Henkel, G. Mayer, J. Albert, and J. Popp, “Tumour cellidentification by means of Raman spectroscopy in combination with optical traps and microfluidicenvironments,” Lab Chip 11(8), 1484–1490 (2011).

30. B. Landenberger, H. Höfemann, S. Wadle, and A. Rohrbach, “Microfluidic sorting of arbitrary cells withdynamic optical tweezers,” Lab Chip 12(17), 3177–3183 (2012).

31. A. R. Faustov, M. R. Webb, and D. R. Walt, “Note: Toward multiple addressable optical trapping,” Rev. Sci.Instrum. 81(2), 026109 (2010).

1. Introduction

Today’s information-based society has a high demand for display technologies capable of conveying dynamic and interactive data with added functionality. In order to enable a user’sseamless acquisition of desired information, it is preferable to integrate electronics directlyand unobtrusively into transparent surfaces. Displays are a key component of the human– machine interface and transparent displays, combined with transparent electronics [1] and

periphery such as batteries [2], loudspeakers [3] and tactile sensors [4] facilitate fullyintegrated transparent systems for applications that include heads-up-displays (HUDs),automotive driver displays and hand-held electronics. Transparent displays based on organiclight emitting diodes [5] and polymer dispersed liquid crystals [6] have been studied in thisregard, however, a principal challenge in the miniaturization and integration of displays lies

in the fact that the required display area becomes the limiting factor for further reduction of device dimensions. One way to solve this limitation is via the use of projection displays thatoccupy a small area on the device and project information onto a larger screen. Theaforementioned types of transparent displays do not permit projection without additionaloptics that would increase device dimensions and inhibit transparency. Another type, basedon an external display and redirection of the image through a series of gratings in a glass

plate, has also been presented [7,8], but this concept does not provide the advantages of coherent laser projection, e.g. the ability to project onto curved surfaces without focusing.

In this article, a transparent projection display based on sub-wavelength gratings andliquid crystals, without the requirement for polarizers or lenses, is presented. The sub-wavelength gratings are used for light redirection, i.e. the projection of light guided along thedisplay plane outwards from the device onto a screen. Modulation of the outcoupling processis achieved by means of an applied electric field causing molecular reorientation within a thinliquid crystal (LC) layer that is in contact with the optical grating. Basic specifications of thedevice are similar to commercially available products, operating at 10 V with rise and fall-off response times of 0.1 ms and 4.5 ms, respectively. Furthermore, the underlying physics of theliquid crystal director reorientation in close proximity to the grating surface is analyzed,showing that fall-off due to re-alignment occurs on 90 µs timescales under certain conditions,

pointing to the potential for significantly faster device response times. Accordingly, the

#180487 - $15.00 USD Received 23 Nov 2012; revised 6 Jan 2013; accepted 9 Jan 2013; published 16 Jan 2013

(C) 2013 OSA 28 January 2013 / Vol. 21, No. 2 / OPTICS EXPRESS 1821

7/27/2019 3. Electrically Modulated Transparent Liquid Crystal -Optical Grating Projection

http://slidepdf.com/reader/full/3-electrically-modulated-transparent-liquid-crystal-optical-grating-projection 3/10

results denote a key step towards the next generation of projection display technology, wherethe general concept of tunable and selective out-coupling of light from transparent mediacould furthermore be applied to multilayer photonic integrated circuits, addressable chip-to-chip optical interconnects in electronic processors and cell manipulation in lab-on-a-chipsystems.

2. Principle of operation

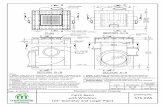

The principle of operation of the device is shown in Fig. 1(a). Light is incident from anexternal laser light source at the side and propagates inside and along the transparent chip. Atspecific locations on the chip, micron-scale rectangular areas, filled with sub-wavelengthgratings, are defined. These gratings act as picture elements (pixels), selectively out-couplinglight at an angle perpendicular to the glass surface, and an entire projected image may thenconsist of many individual pixels. Here the concept is presented by considering three gratings(pixels) of 250 x 250 µm size, arranged in a row. Each grating is covered by a transparentelectrode which is connected to a larger pad at the side to enable local addressing of anapplied voltage.

Fig. 1. (a) Principle of operation for the projection display. Light enters from the side and iscontrollably out-coupled perpendicular to the device plane at specific locations. (b) Detailedside view drawing of the light propagating inside the device and out-coupled by a grating. Theliquid crystal layer enables electrical modulation of individual pixels.

Figure 1(b) illustrates the operating principle and the optical paths in greater detail. Thedevice consists of a substrate (Borofloat glass, n = 1.48, 500 µm thick) and an SU-8 thin film

(n = 1.58, 610 nm thick) with imprinted gratings (corrugation depth 120 nm). These arecovered by a 45 nm indium tin oxide (ITO) transparent electrode on top of each grating. Aliquid crystal layer of 600 nm thickness covers the gratings and finally the device is sealed bya Borofloat glass lid coated on its underside with 45 nm of ITO. Since both the liquid crystallayer and the SU-8 film each have higher refractive indices than the glass substrate, they forma primary optical waveguide for the guided light. However, the spot size of light focused by a10x microscope objective at the sample edge is much larger than the thickness of the thin-films. Accordingly, the entire chip, including substrate and lid, is “flooded” with light that isguided by total internal reflection at the glass/air interfaces. This secondary waveguidecontinuously “refills” the lossy (due to scattering and out-coupling) primary waveguide. Theexact optical response of the waveguide is not trivial due to the numerous material layers andmultimode propagation of guided light. Particularly, distortion of the liquid crystal director causes an anisotropic and inhomogeneous refractive index of the LC layer. However, anapproximation of the direction of incident and guided light, without consideration of

diffraction efficiency or polarization, is given by Eq. (1), which is derived from considerationof the phase differences between grooves and ridges and the requirement of k-vector conservation [9]:

( ) ( )8

sin sin2 2 2

, LC in SU out

n m nθ θ π π π

λ λ ⋅ + = ⋅

Λ(1)

#180487 - $15.00 USD Received 23 Nov 2012; revised 6 Jan 2013; accepted 9 Jan 2013; published 16 Jan 2013

(C) 2013 OSA 28 January 2013 / Vol. 21, No. 2 / OPTICS EXPRESS 1822

7/27/2019 3. Electrically Modulated Transparent Liquid Crystal -Optical Grating Projection

http://slidepdf.com/reader/full/3-electrically-modulated-transparent-liquid-crystal-optical-grating-projection 4/10

Here n LC and nSU8 are the refractive indices of the layers, m the diffraction order, λ the free-

space wavelength of light and Λ the grating period. θ in and θ out are the angles of the in-comingand out-coupled light, respectively (see also Fig. 1(b)), measured from the surface normal. By

using the fixed values m = −1, n LC = 1.5, θ in = 90° (propagation parallel to the device surface)

and θ out = 0° (perpendicular to device surface), the required grating period is determined. Thedevice is designed for operation at 410 nm, 532 nm and 661 nm, accordingly the required

periods are calculated as 274 nm, 355 nm and 441 nm, respectively. The corrugation depthdoes not influence the diffraction angle but only the efficiency. A depth of 120 nm is used,which has not been optimized, but is comparable to previous work in a similar geometry [10]where a diffraction efficiency of about 0.1% is achieved. This low value is sufficient, sinceonly moderate diffraction efficiency is required for each pixel.

By application of a voltage between the lid and the pixels, each pixel may be individuallytuned in terms of the intensity of the out-coupled light. The gratings provide dualfunctionality by facilitating 1) the redirection of light and 2) the uniform alignment of liquidcrystal molecules parallel to the grating lines at zero applied voltage. Alignment of liquidcrystals with surface topography is dependent on the combination of grating dimensions,choice of material and fabrication method [11], with the precise contribution of each stillunder investigation. Previous works comparing lines imprinted in SU-8 and polyimide[12,13], with dimensions on the same order of magnitude as presented here, do however pointtowards a predominance of topographical effects as presented by Berreman [14], i.e. the long-

chained nematic LC molecules minimize their mechanical deformation energy by aligning parallel to surface indentations. Since the nematic LCs also prefer parallel alignment withrespect to each other, the surface grating dictates the orientation of the molecules throughoutthe cell. This ordering may diminish away from the grating (towards the lid of the cell) whereno anchoring method is applied, but this is not an issue because the optical effect is achieved

predominantly in proximity to the grating corrugation. By application of a voltage the LCmolecules tilt from being parallel to the grating lines towards perpendicular orientation. Sincethe nematic LC molecules behave optically like a positive uniaxial crystal, this orientationchange affects the refractive index perceived by the polarized light. Thus the index contrast atthe grating changes, resulting in changes of the diffraction efficiency [15]. If index matching

between the LC and the grating is achieved, then no light is out-coupled aside fromomnidirectional scattering. The intensity contrast of the projected pattern is calculated as the

Michelson contrast /on off on off I I I I − + , where I on and I off are the intensities of the out-coupled

light by a pixel in the on- and off-state, respectively. The optimal value of 1 is achieved if theout-coupling can be completely suppressed and is therefore limited by how well the refractiveindex of the LC layer can be matched to the index of the grating.

3. Fabrication

The devices are fabricated on 10 cm glass wafers by nanoimprint lithography [16], makingcost-effective fabrication of nanostructures in large volumes feasible. To begin, a 610 nmthick layer of SU-8 is spin-coated onto a Borofloat substrate, after which the gratings areformed by nanoimprint using a stamp fabricated by electron beam lithography. Figure 2(a)shows microscope images of gratings with different periods, depicting how narrowwavelength ranges are selectively out-coupled upwards to the objective. These images aretaken from a stamp at an intermediate fabrication stage where the gratings are covered by a 15nm aluminum layer which enhances the color effect.

#180487 - $15.00 USD Received 23 Nov 2012; revised 6 Jan 2013; accepted 9 Jan 2013; published 16 Jan 2013

(C) 2013 OSA 28 January 2013 / Vol. 21, No. 2 / OPTICS EXPRESS 1823

7/27/2019 3. Electrically Modulated Transparent Liquid Crystal -Optical Grating Projection

http://slidepdf.com/reader/full/3-electrically-modulated-transparent-liquid-crystal-optical-grating-projection 5/10

Fig. 2. (a) Optical microscope image of gratings with periods optimized for red, green and blue

light redirection, illuminated with white light from the side. The grating redirects a narrow partof the spectrum upwards through the microscope such that the gratings appear close to thedesigned color. (b) Photograph of an assembled device, filled with liquid crystals. The deviceis essentially transparent, except for the aluminum spacers, which provide electrical connection

between lid and substrate. (c) Scanning electron microscope (SEM) image of the imprintedgratings, covered with an ITO electrode.

After nanoimprint, the pattern of the electrodes on top of the gratings and contact pads atthe edges are defined by photolithography in a layer of AZ5214E photoresist. A 45 nm layer of ITO is sputter-deposited over the surface and a lift-off step in acetone is subsequently

performed to remove the resist layer and the ITO outside the grating regions. The lid is prepared on a separate wafer by defining 600 nm thick spacers of aluminum and a subsequentdeposition of 45 nm ITO. The aluminum spacers define the thickness of the liquid crystallayer and provide electrical contact to the lid. After dicing of individual 20 x 15 mm sizedchips from the wafer, a lid is pressed onto each sample and fixed with epoxy resin. The epoxycontracts during cross-linking such that the contacts of lid and substrate are pressed together to form an electrical connection. In order to fill the cell with LC, the sample is placed on a hot

plate at 60 °C while a drop of nematic liquid crystal (4′-Pentyl-4-biphenylcarbonitrile, 5CB,from Sigma Aldrich) is placed at the edge and fills the cell by capillary forces. When coolingto room temperature, the LC is in nematic phase. Figure 2(b) shows a photograph of the finalsample filled with LC and Fig. 2(c) presents an SEM image of an imprinted grating, covered

by ITO.

4. Measurements

The basic optical operation of the device prior to the addition of LC is shown in Fig. 3(a).Light is focused onto the glass edge from the right, propagating through the glass and then, ateach pixel, projected towards a screen. Since each grating is designed for perpendicular out-coupling at a specific wavelength, one grating cannot be used to project multiple colors. Thisis addressed by using a stack of three replications with different grating periods, as illustrated

in Fig. 3(b). In such a scheme, where the grating with the largest period is at the bottom,gratings on the planes above each level appear transparent due to the sub-wavelength periodand light may pass through the rest of the stack unaffected. In Fig. 3(a) the microscopeobjective is translated to focus onto the corresponding plane for each color. Figure 3(c) showsa CCD camera image of the diffracted light. The vertical divergence, causing an elongated

profile, is a result of focusing by the microscope objective and may be reduced by adequate

#180487 - $15.00 USD Received 23 Nov 2012; revised 6 Jan 2013; accepted 9 Jan 2013; published 16 Jan 2013

(C) 2013 OSA 28 January 2013 / Vol. 21, No. 2 / OPTICS EXPRESS 1824

7/27/2019 3. Electrically Modulated Transparent Liquid Crystal -Optical Grating Projection

http://slidepdf.com/reader/full/3-electrically-modulated-transparent-liquid-crystal-optical-grating-projection 6/10

beam collimation. The horizontal divergence is determined by the grating size; here, a 250µm wide grating results in a line broadening of 740 µm (taken at 1/e2), measured at 20 cmdistance, corresponding to a beam half-angle divergence of 1.23 mrad.

Fig. 3. (a) Three-color operation of the transparent projection display, light is focused onto thesample by the microscope objective from the right side and projected onto a screen at 10 cmdistance. The device shown here consists of three replications stacked on top of each other andglued onto a microscope slide. For each color the objective is translated to focus light onto thecorresponding plane. For this basic demonstration, LC and lid are omitted and a logo is placed

behind the sample just below the out-coupled beam in order to display the transparency. Theinput laser power is 20 mW and the power emitted by each pixel is approximately 2.8 µW,clearly visible in ambient light. Note that only a small fraction of the laser light is incident onthe pixels, thus the diffraction efficiency of a single grating is not measured. (b) Drawing of the stacked device, consisting of three samples with different grating periods. (c) CCD cameraimage of the diffracted light (532 nm).

The operation of samples filled with electrically modulatable LC is investigated in two

ways. In the first experiment, the sample is observed in an optical microscope using a whitelight transmission mode in order to study the physical processes (i.e. not how the displaydevice is intended to operate). The sample is placed between crossed polarizers, serving as

polarizer and analyzer, as shown in Fig. 4(a). Outside the grating area the molecules areordered over short ranges only and disclinations in the orientational order are seen as brightlines. The regions with gratings exhibit less disclinations and the area in general appearsdarker, indicating that the grating dictates some alignment of the molecules. However, thiseffect is only occurring close to the grating and decreases further away (close to the lid) suchthat crystal defects occur and change the polarization of transmitted light, observed as a gray,irregular patterned area. This non-uniform alignment may be improved in future work byapplication of an alignment layer also on the top surface of the cell. Under an applied voltage

between grating and lid, above the threshold for the Frederiks transition [17], the liquidcrystals re-orient towards homeotropic alignment (perpendicular to the surface). With avoltage of 36 V applied (arbitrary high value above the threshold), as shown in the upper rightimage of Fig. 4(a), the molecules align parallel to the electric field such that the light path isalong the optic axis and no birefringence is present. The polarization of transmitted lightremains unaltered during passage through the cell and light is absorbed by the analyzer,causing completely black appearance of the grating.

#180487 - $15.00 USD Received 23 Nov 2012; revised 6 Jan 2013; accepted 9 Jan 2013; published 16 Jan 2013

(C) 2013 OSA 28 January 2013 / Vol. 21, No. 2 / OPTICS EXPRESS 1825

7/27/2019 3. Electrically Modulated Transparent Liquid Crystal -Optical Grating Projection

http://slidepdf.com/reader/full/3-electrically-modulated-transparent-liquid-crystal-optical-grating-projection 7/10

Fig. 4. (a) Characterization of the sample in a transmission optical microscope with crossed polarizers. For the case of zero applied voltage, the grating appears darker than the surrounding but not completely opaque due to topographical LC orientation with the grating. With anapplied voltage, the LC molecules align parallel to the E-field throughout the cell such that thecrossed polarizers block all of the light and the grating area appears completely black. (b)Measurement of the redirected light. The right-most pixel of three is switched between the off-state (left) and the on-state (right) when the applied voltage induces a change in the refractiveindex of the LC, covering the grating. The temporal response is shown below both (a) and (b).

In the second experiment, shown in Fig. 4(b), the samples are characterized in aconfiguration as a projection display, with light being coupled in from the side and a fractionof the light is out-coupled by the gratings. When the voltage is applied, reorientation of theanisotropic LC molecules results in a change in the refractive index perceived by the light,and thereby modifies the diffraction efficiency of the grating. In order to suppress electrolyticeffects, the electrical signal is a bipolar square waveform at 2 kHz, as shown in the lower part

of Fig. 4, together with the response of the transmitted and redirected light.A notable difference between the two configurations is observed in the temporal response

shown in the lower graphs of Fig. 4. For the case of transmitted light, the intensity is constantafter the voltage is switched on, but the redirected light intensity has response times fastenough to partly follow the switchover of the driving voltage with rise and fall times in themicrosecond range. This discrepancy is explained by the different physical processes: duringthe on-switch state the LC molecule orientation is induced by the electric field, while for theoff-switch state the reorientation is due to relaxation caused by the anchoring force at thegrating. This restoring force is larger close to the grating surface and the process occurs onquicker timescales than in the center of the LC layer [18]. In transmission mode the lightintensity is affected by the alignment of LC molecules throughout the entire cell from gratingto lid. For the redirection scheme instead, only the molecules in close proximity to the gratinghave an influence on the diffraction efficiency; hence fast reorientation into the unperturbedstate after switching-off the voltage is possible in this case.

#180487 - $15.00 USD Received 23 Nov 2012; revised 6 Jan 2013; accepted 9 Jan 2013; published 16 Jan 2013

(C) 2013 OSA 28 January 2013 / Vol. 21, No. 2 / OPTICS EXPRESS 1826

7/27/2019 3. Electrically Modulated Transparent Liquid Crystal -Optical Grating Projection

http://slidepdf.com/reader/full/3-electrically-modulated-transparent-liquid-crystal-optical-grating-projection 8/10

Fig. 5. (a) Time-resolved measurement of out-coupled light intensity for TE and TM polarizedlight. With increasing voltage, the molecules tilt from parallel to perpendicular alignment anddepending on the polarization, different refractive indices are perceived by the light. Thisresults in the opposite voltage-intensity relation for TE/TM polarization. (b) Measurement of the response times for TM polarized light as a function of the applied voltage. (c)Measurement of the voltage threshold for TE and TM polarization.

In Fig. 5(a) the optical behavior is analyzed in more detail at a number of applied voltagesand for incident light using both TE and TM polarization. In the case of TE polarization, zeroapplied voltage corresponds to the minimum of out-coupled light. The molecules are aligned

parallel to the grating and as the light wave oscillates along the long (slow) axis of the LCmolecules, the perceived refractive index in the LC is 1.7. When the voltage is increased andthe molecules tilt towards homeotropic orientation, the perceived refractive index isdecreased, reaching 1.5 in the final state. This decrease in perceived LC refractive index

corresponds to an increase in refractive index contrast between the LC and the grating(refractive index of ITO, 2.3), causing an increase in the diffraction efficiency, i.e. increase of the diffracted light intensity. The opposite case is seen when TM polarization is used: at zeroapplied voltage the light polarization is perpendicular to the long axis of the LCs, sensing alow refractive index, i.e. a large index contrast to the grating and high intensity of the out-coupled light. Increasing of the voltage consequently reduces the out-coupled light intensity.

The response times are measured with rise-times well below 1 ms and fall-times of 4.5ms, as shown in Fig. 5(b). Switching times are measured between 5% and 95% light intensityupon switching the 2 kHz signal on/off. An investigation of the threshold voltage is presentedin Fig. 5(c) and the value is measured to be approximately 6 V for both TE and TM

polarization.The measurements with TE/TM polarization verify that the intensity of redirected light is

indeed controlled by adjustments of the refractive index which the light perceives whenimpinging on the grating. Ideally it should be possible to completely suppress the out-coupledlight (apart from scattering) when the refractive index of the grating and the liquid crystal areexactly matched. This could not be achieved with the devices presented here due to the highrefractive index ITO layer which is deposited on top of the grating. Since higher refractiveindex liquid crystal materials are not commonly available, an alternative may be to bury theITO electrodes below the polymer grating. In Fig. 5(a) and 5(c) it is noted that for operation

#180487 - $15.00 USD Received 23 Nov 2012; revised 6 Jan 2013; accepted 9 Jan 2013; published 16 Jan 2013

(C) 2013 OSA 28 January 2013 / Vol. 21, No. 2 / OPTICS EXPRESS 1827

7/27/2019 3. Electrically Modulated Transparent Liquid Crystal -Optical Grating Projection

http://slidepdf.com/reader/full/3-electrically-modulated-transparent-liquid-crystal-optical-grating-projection 9/10

as a projection display, TM polarized light is more suitable because a higher contrast betweenthe bright and dark state is achieved with a value of 0.67. This effect is assumed to originatefrom the complex interplay between the optical mode profile in the waveguide layers and thegrating efficiency, both as function of LC orientation and light polarization. Numericalsimulations of the voltage dependent LC orientation profile, light guiding mechanisms,electric field confinement and grating diffraction efficiency would be required for further investigation. In general, the contrast may be limited by the inhomogeneous liquid crystal

alignment, due to the competing forces of surface alignment and electrically inducedorientation. Even at large voltages, the LC molecules do not fully orient towards normal [19]and thus the achieved performance at applied voltage in terms of redirected intensity andextinction does not reach the values obtained without applied voltage at TE/TM polarization.

5. Discussion

The time-resolved intensity measurements demonstrate switching times of 5 ms, comparableto existing display devices. Additionally, a sub-100 microsecond decay is observed in the

presented device geometry, not only for switching-on, but also for switching-off, which isusually the limiting factor in LC devices. This fast relaxation mode is possibly a surface effectcaused by the polarity in the asymmetric cell. Since the optical effect is localized very closeto the surface, inside the 120 nm thin grating lines, the LC in this vicinity exhibits a major contribution to the redirected signal. This fast µs-scale effect is of modest amplitude, whereadditional experiments, especially with different LC layer thicknesses, would reveal whether this modulation may be used practically.

Due to the strong anchoring on the surface, the threshold voltage of 6 V is larger thantypical LC displays which have a threshold around 2.5 V [20], but still accessible to voltagesused in consumer electronics and significantly below the high voltages reported in some other LC-actuated optical devices [21–24]. It should also be noted that the threshold is rather “soft”,with linear tuning of the light intensity via voltage switching possible from 6 V to 10 V.

For integration of high resolution displays into small devices, the grating size may need to be reduced below the dimensions presented in this work. However, this will correspondinglyincrease the divergence and limit the maximum projection distance, pointing to a designcompromise between resolution and depth of focus to be made. Additional optical elementssuch as microlenses could be applied to the outside of the device to enhance the projectiondistance, although this will come at the cost of distorting the image viewed through theotherwise planar transparent materials. Cross-talk between neighboring pixels may also need

addressing in future work, since pixels located behind others will experience reducedintensities. This may be compensated in two ways: First, the presence of a primary waveguidethat continuously refills the LC waveguide, although more light would be required and muchof it not used. Second, an intelligent controller could adjust the intensity of each pixel basedon the intensity of all other pixels, similar to current LCD TVs where the backlight isdynamically and locally adjusted to increase image contrast.

Until now the article has focused on projection displays, but the aforementioned properties make the device also suitable to a number of other applications. The integration of photonic systems [25] is rapidly advancing and the technique presented here may be used as acoupler in multilayer photonic circuits [26] where light signals may be selectively redirectedfrom one device layer into another. Optical communication links between electronic

processors and external components such as memory or graphics processors may benefit fromthe technology if only a limited number of high-speed links are available and the LC switch isused to reconfigure the connection of these links between selectable components [27].

Transparent lab-on-a-chip (LOC) systems [28] employ optical techniques for purposes suchas spectrographic analysis and cell manipulation, where the technology presented here may bereadily integrated into such LOCs to allow for reconfigurable light patterns generated directlyinside the chip for precise control of localized spectroscopy [29] or optical forces [30,31] atmultiple points. In applications where a tunable light source is available also the wavelength-dependence of the diffraction could be exploited, as the direction of out-coupled light will

#180487 - $15.00 USD Received 23 Nov 2012; revised 6 Jan 2013; accepted 9 Jan 2013; published 16 Jan 2013

(C) 2013 OSA 28 January 2013 / Vol. 21, No. 2 / OPTICS EXPRESS 1828

7/27/2019 3. Electrically Modulated Transparent Liquid Crystal -Optical Grating Projection

http://slidepdf.com/reader/full/3-electrically-modulated-transparent-liquid-crystal-optical-grating-projection 10/10

change if the wavelength is tuned. In this way the emerging beams could be scanned acrossthe target area, e.g. for precise and continuous positioning of optical trapping or sensing

points.

6. Conclusion

To conclude, a transparent and fully integrated electronically modulated projection display isreported based on optical gratings with a thin liquid crystal layer. The feasibility of full color

projection by mixing of primary colors is demonstrated and the device operates at 10 V with afall-off response time of less than 5 ms. The underlying physics of the liquid crystal director reorientation with respect to the grating shows 90 µs response times due to the localization of the optical effect in the proximity of the grating surface. The results denote a key step towardsa new generation of compact and transparent projection display technology, with possibleapplications in head-up displays or other technologies where controlled redirection of guidedlight is required at specific locations from a transparent substrate.

Acknowledgments

This work is supported as part of the EC funded project NaPaNIL (Contract No. 214249).C.L.C. Smith acknowledges financial support from the EU FP7 Marie Curie Fellowship(project number PIIF-GA-2009-254573) and the Danish Research Council for Technologyand Production Sciences (grant number 12-126601).

#180487 - $15.00 USD Received 23 Nov 2012; revised 6 Jan 2013; accepted 9 Jan 2013; published 16 Jan 2013

(C) 2013 OSA 28 January 2013 / Vol. 21, No. 2 / OPTICS EXPRESS 1829