2G HTS Coils - SuperPower IncFact+Sheet_2014_v1.pdf · 2G HTS Coils Industry leaders rely on...

Transcript of 2G HTS Coils - SuperPower IncFact+Sheet_2014_v1.pdf · 2G HTS Coils Industry leaders rely on...

2G HTS Coils

Industry leaders rely on SuperPower’s second-generation high temperature superconducting (2G HTS) wire to enable significant advances in physics, biology and chemistry research, medical technology and green energy applications.

SuperPower supplies long lengths of high-performance 2G HTS wire to fabricate coils for advanced devices such as HTS magnets, motors, generators, transformers and SMES. 2G HTS wire, as compared with conventional copper, results in more compact coil geometries that allow for greater design flexibility (high field solenoids, race track, etc.) Coils fabricated with SuperPower 2G HTS wire have enormous benefits for research, NMR spectroscopy, high field magnets and energy applications.

SuperPower® 2G HTS Wire delivers performance advantages for your demanding coil applications – enhanced by our expert engineering and design services.

SuperPower® 2G HTS Wire is uniquely suited for coil applications:

• Compact – high engineering current density and half the thickness of most other 1G and 2G conductors

• High-Performance – high strain and strength tolerance compared with most high field LTS, 1G and other 2G wires

• Reliable – superior wire stability and mechanical properties

• Powerful – excellent performance in magnetic fields (high current/energy density)

• Flexible – Suitable for both pancake and layer wound coil types

SuperPower’d expertise, excellence and experience for the advancement of high field magnets:

• 2012 – Brookhaven National Laboratory has advanced superconducting technology to a level that HTS magnets are now being considered seriously in the upgrade of current accelerators, for use in future accelerators and in muon colliders.

• 2012 – a joint research team from the National High Magnetic Field Laboratory, the University of Colorado, and the National Institute of Standards and Technology has successfully demonstrated the world’s first multi-layer electromagnet that was wound from a high-temperature superconducting cable at a field of 20.0 tesla. They also demonstrated a record winding current of 4100 amperes in a single-turn magnet at a background field of 19.81 tesla.

• 2011 – NHMFL successfully tests a superconducting electromagnet to a field of 35.4 Tesla. The new record was achieved with a layer-wound insert magnet constructed with a single piece of SuperPower 2G HTS wire approximately 100 meters in length and nested in a 31 T background magnet.

• 2009 – a coil fabricated and wound by SuperPower and tested at the National High Magnetic Field Laboratory (NHMFL) at Florida State University (FSU), achieved a world record of 27.4 Tesla at 4.2K in a 19.89 Tesla background field

• 2008 – a coil fabricated and tested by NHMFL at 4.2K in a background field of 31 Tesla achieved a world record of 33.8 Tesla at an average winding current density of 459 A/mm2

• 2007 – previous record of 26.8 Tesla in 19 Tesla background was achieved in a coil fabricated by SuperPower

SuperPower Inc. is a subsidiary of Furukawa Electric Co., Ltd.SuperPower® is a registered trademark of SuperPower Inc.

Inc.

450 Duane Ave. Schenectady, NY 12304 USATel: 518-346-1414 Fax: 518-346-6080

E-mail: [email protected] Website: www.superpower-inc.com2G Marketing/Marketing Collateral/PDF Sheets/2014/SP_Coil Spec Sheet_2014_v1.pdf

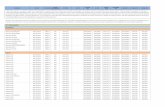

Specifications SCS4050 (4 mm wide)

SCS12050 (12 mm wide) Comments

Total thickness 0.1 mm 0.1 mm

Copper stabilizer thickness (total) 0.04 mm 0.04 mm Surround stabilizer with rounded corners

Substrate thickness 0.05 mm 0.05 mm Hastelloy® C-276Critical tensile stress > 550 MPa > 550 MPa At 77KCritical bend diameter in tension 11 mm 11 mm At room temperatureCritical bend diameter in compression 11 mm 11 mm At room temperatureCritical axial tensile strain 0.45% 0.45% At 77K

Substrate resistance 125 micro-ohm cm 125 micro-ohm cm Higher resistance leads to lower eddy current ac loss

Substrate magnetic properties Non-magnetic Non-magnetic Leads to lower ferro-magnetic ac lossJoint resistance < 20 nΩcm2

Critical bend diameter of joint 25 mmStandard critcal current (minimum) 100A and higher 300A and higher At 77K, self field

Wire Specifications:SuperPower is producing long lengths of high-performance 2G HTS wire to fabricate coils for devices such as HTS motors, generators, transformers, SMES and high field magnets. Properties uniquely suited for coils include:

• Ic uniformity in long lengths; standard deviation less than 10%• Long, single piece lengths of robust and high performing 2G HTS wire are available• Wire is half the thickness of 1G wire and other brands of 2G wire, offering

– High engineering current density, 77K, 0 Tesla:• Standard Wire (Je) = 250 A/mm2

• Premium Wire (Je) = 275 to 325 A/mm2

– Superior mechanical properties particularly suited for coil applications• Wire exhibits excellent performance in magnetic field (data available on request)• Different configurations are available, including widths down to 2 mm• Suitable for both pancake and layer wound coils• Superior wire stability

Images shown are just examples of the types of coils SuperPower has designed, constructed and/or wound. Contact us today to discuss your unique coil application.