29 May 2002

description

Transcript of 29 May 2002

LW155LW155

29 May 2002

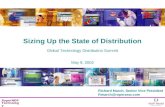

Advanced Planning Briefing to Industry

Mr. Jim Shields

DPM, LW155

2

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

Towed Artillery Towed Artillery DigitizationDigitization

(TAD)(TAD)

Improved AccuracyImproved Accuracy

More ResponsiveMore Responsive

Dispersed – Flexible OperationsDispersed – Flexible Operations

No SurveyNo Survey

RadioAntenna

Mission Computer, Battery & Power Supply

Gunner’s Display

Radio & GPS Receiver

Inertial NavigationUnit (INU)

Assistant Gunner’s Display

Vehicle Motion Sensor

Section Chief Control & Display Unit

(SCCDU)

Lightweight High-Strength TitaniumLightweight High-Strength Titanium

Improved Strategic DeploymentImproved Strategic Deployment

Improved Ground MobilityImproved Ground Mobility

Improved SurvivabilityImproved Survivability

XM777 HowitzerXM777 Howitzer

LW155 System LW155 System XM777 and TADXM777 and TAD

Harder to Find, Harder to Hit, Harder to Kill!!

3

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

Joint Requirements for Joint Requirements for XM777 & TADXM777 & TAD

XM777E1XM777E1 9500 - 10,500 Lbs. - Deployable and Mobile Emplace in 3 Min* Displace in 2 Min* All USAF (2 per C130, LW155 & FMTV in C141) Rate of Fire 4-8 RPM, Sustained 2 RPM Max Range 30km with Rocket Assist Bold Shift in 3 Min Primer Feed Mechanism 800 to 900 Rds Between Systems Abort

Towed Artillery Digitization (TAD)Towed Artillery Digitization (TAD) Digital Indirect Fire Control Inertial Navigation with GPS Backup 1-Mil Pointing Accuracy Advanced Direct Fire Sight TAD Weight: 200-500 Pounds

4

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

Program EvolutionProgram Evolution

19961996

LW155 Shoot-offLW155 Shoot-off

19971997

2001200120022002

Contract Award & EMD Gun Design (8 Guns)Contract Award & EMD Gun Design (8 Guns)

Extensive Developmental TestingExtensive Developmental TestingFinal Developmental TestingFinal Developmental Testing

20052005

USMC IOCUSMC IOC20022002

OA & MS COA & MS C

20062006

US Army TAD IOCUS Army TAD IOC

First Prototype FiredFirst Prototype FiredUSMC & US Army Field EvaluationUSMC & US Army Field Evaluation

Accuracy DemonstrationsAccuracy Demonstrations19891989

199019901994-951994-95

19981998

Textron NovationTextron Novation

20042004

OT & Full Rate Production Dec.OT & Full Rate Production Dec.

5

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

Engineering and ManufacturingEngineering and Manufacturing Development Development

Applied Shoot-Off Lessons Learned

Maximize Safety, RAM and HFE

Comprehensive Evaluation of EMD Prototypes

Joint Marine & Army Live Fire Tests

Detailed Logistics & Fielding Plans

Production Preparation & Decision

6

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

Allied Involvement Allied Involvement in LW155in LW155

Italy and United Kingdom

Trilateral EMD MOU, March 99

Both Provided Supplemental Funding

Production MOU Under Negotiation

7

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

Digital Fire ControlGeneral Dynamics

Burlington, VT

8

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

Operational Operational AssessmentAssessment

VideoVideo

9

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

Production ReadinessProduction Readiness

All EMD Weapons Manufactured by BAE SYSTEMS in the UK

Corporate Decision to Produce >70% in the US (Excluding GFE)

EMD Contract Modified to Incorporate Pilot Production

BAE Selected US Partners

Production will Introduce Over 30 Castings

Pilot Production Gun Tested Prior to Milestone C

LRIP Insertion Lowers Production Risk

GUN and DFCS Efforts Combined

Pursuing Multi-Year Procurement Strategy for USMC LRIP

Pursuing Joint Multi-Year Strategy for FRP (FY05 – FY09)

10

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

Elevating Mass Elevating Mass CastingsCastings

Buffer Yoke(Howmet )

Front Bridge (P.C.C.)

Breech Bridge(Howmet)

Axle Caps (P.C.T.)

Axle Housings (Howmet)

Balancer Eye (P.C.T.)

Trunnion Caps (P.C.T.) Elevating Yoke

(Howmet )

11

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

Elevating Mass Elevating Mass CastingsCastings

Front BridgeFront Bridge

Axle CapAxle Cap

Buffer YokeBuffer Yoke Elevation YokeElevation Yoke

Trunnion CapTrunnion Cap

Axle HousingAxle HousingBreech BridgeBreech Bridge

Balancer EyeBalancer Eye

12

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

Lower Lower Carriage CastingsCarriage Castings

Trail Casting R.H. (P.C.C.)

Trail Casting L.H. (P.C.C.)

Saddle BaseCasting (P.C.C.)

Stabiliser L.H. (P.C.C.)

Stabiliser R.H. (P.C.C.)

Saddle Arm L.H. (P.C.T.)

Saddle Arm R.H. (P.C.T.)

13

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

Lower Carriage CastingsLower Carriage Castings

++ ++ ==

SaddleSaddle

StabilizerStabilizer TrailsTrails

Body LugsBody Lugs

BaseBase RH ArmRH Arm LH ArmLH Arm

14

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

Saddle Base FabricationSaddle Base Fabrication

Comprising 75 Pre - Prepared Component Parts.

416 Manhours Complex Fixturing Required. Complex Purging. Skilled Fabrication Resource. High Risk Of Re-Work, Due To Shrinkage

& Distortion Problems

All Eliminated All Eliminated by One Castingby One Casting

15

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

TAD/XM777TAD/XM777 Integration Status Integration Status

Axel ModsAxel Mods Stabilizer ModsStabilizer Mods

Cradle ModificationsCradle Modifications

• TALIN 4000 Selected as INU

• Mounting Locations On Gun 1008

• Incorporating Excalibur Platform

Integration Kit (PIK) Interface

• Successful PDR Held Apr 9th

16

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

XM777E1 ScheduleXM777E1 Schedule

APS+ DFCSAPS+ DFCSDevelopmentDevelopment

XM777E1 SystemXM777E1 SystemIntegration & TestIntegration & Test

XM777E1XM777E1LRIP & OTELRIP & OTE

XM777 GunXM777 GunDevelopmentDevelopment

TAD Objective Software,TAD Objective Software,Direct Fire Sight & MVS P3IDirect Fire Sight & MVS P3I

XM777E1XM777E1MSIIIaMS C

XM777E1XM777E1MSIIIbFRPD

DesignDesignIntegrationIntegration

Block 1

Block 2 XM777E2XM777E2P3I P3I Mat’l Mat’l ReleaseRelease

XM777XM777MSIIIaMS C

XM777XM777MSIIIbFRPD

XM777 GunXM777 GunLRIP & OTELRIP & OTE

M777 GunM777 GunProductionProduction

ObjectiveObjectiveM777A2M777A2SystemSystem

(M777 with(M777 withFull TAD)Full TAD)

M777A1M777A1ProdProd

FY02FY02 FY03FY03 FY04FY04 FY05FY05 FY06FY06 FY07FY07

M777A1M777A1IOCIOC

17

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

• Improved Position and Azimuth Determining System (IPADS)-- New start, successor to PADS

• Gun Laying and Positioning System (GLPS)-- In final stages of fielding

• M198: 155mm Howitzer (Medium Towed Artillery) -- Fielded, sustainment initiatives

• M119: 105mm Howitzer (Light Towed Artillery) -- Fielded, sustainment initiatives

Newly Chartered Life Cycle / Management Oversight-- Result of AMC – ASA(ALT) Reorganization

-- Management / Execution based out of Rock Island, IL

JPMO LW155JPMO LW155Recent Program AdditionsRecent Program Additions

18

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

SummarySummary

Completing OA

Incorporate Changes from OA Onto PPG

Complete Test of Pilot Production Gun

Complete MS C Documentation

Facilitization and Readiness of Value Chain for Production

Continue DFCS Development and Integration Efforts

Near Term FocusNear Term Focus

Program on Track for for MS C

19

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

Back-UpsBack-Ups

20

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

TDP StatusTDP Status

OA Build standard 2062 Drawings 100 % complete

Pilot Production build standard 107 planned changes from OA standard

59 incorporated in TDP 28 in progress 9 accelerated for PP2 build standard 11 deferred to LRIP

Process in place to incorporate any additional producibility changes from supply chain during PP build

Joint Lightweight 155mm Howitzer (LW 155) Funding

FY02 Fiscal and Congressional Information

SEN Robert Torricelli (D)SEN Jon Corzine (D)REP Rodney Frelinghuysen (R-11th) (HAC)Government City (Dist) MajorComp FY02$ FY03- FY07$

1. New Jersey

SEN Patrick J. Leahy (D) (SAC)SEN James M. Jeffords (I at large)REP Bernard Sanders (I at large)

GDAS Burlington TAD 10.0M 140.4M

Government City (Dist) Major Comp FY02$ FY03-FY07$

SEN Mike DeWine (R) (SAC)SEN George Voinovich (R )REP James A. Traficant, Jr. (D-17th)

Contractor City (Dist) Major Comp FY02$ FY03-FY07$RTI International Metals Niles Titanium 80.3M

ARDEC Picatinny Engineering 5.0M 20.0M

SEN Charles Schumer (D)SEN Hillary Rodham Clinton (D)REP Michael R. McNulty (R-21st)

Watervliet Arsenal Watervliet Barrel Assy 3.4M 106.6M

Contractor City (Dist) Major Comp FY02$ FY03-FY07$

SEN Thad Cochran (R) (SAC)SEN Trent Lott (R) REP Gene Taylor (D-5th) (HASC)Contractor City (Dist) Major Comp FY02$ FY03-FY07$

SEN Dianne Feinstein (D) (SAC)SEN Barbara Boxer (D) REP Howard P. (Buck) McKeon (R-25th) (HASC)Contractor City (Dist) Major Comp FY02$ FY03-FY07$

United Defense Hattiesburg Final Int/Assy $51.5M

Hydro-Mill Chatsworth Body 74.2M*

SEN Mitch McConnell (R ) (SAC) SEN Jim Bunning (R) (SASC)REP Ken Lucas (D-4th)Contractor City (Dist) Major Comp FY02$ FY03-FY07$

Rotek, Inc Florence Traverse Rack 20.5M

SEN John Warner (R) (SASC)SEN George Allen (R) REP Virgil Goode (I-5th) (HAC)REP Bob Goodlatte (R-6th)Contractor City (Dist) Major Comp FY02$ FY03-FY07$

Wegmann Lynchburg Elevation Assy 15.5M

SEN Gordon Smith (R)SEN Ron Wyden (D) REP David Wu (D-1st)Contractor City (Dist) Major Comp FY02$ FY03-FY07$

Precision Castparts Corp Portland Castings 37.1M

SEN Gordon Smith (R)SEN Ron Wyden (D) REP Peter DeFazio (D-4th)REP Darlene Hooley (D-5th)Contractor City (Dist) Major Comp FY02$ FY03-FY07$

Pacific Cast Technologies Albany Castings 37.1M

SEN Richard G. Lugar (R)SEN Evan Bayh (D) REP Julia M. Carson (D-10th)

Major Tools & Machine Inc. Indianapolis Spades/Trails 37.1M Contractor City (Dist) Major Comp FY02$ FY03-FY07$

2. Vermont

3. New York

4. Ohio

5. Indiana

7. Mississippi

8. California

9. Kentucky

10. Virginia

11. Oregon

12. Oregon

SEN Carl Levin (D) (SASC)SEN Debbie Stebenow (D) REP William Clay, Jr. (D-1st)Contractor City (Dist) Major Comp FY02$ FY03-FY07$

Howmet Castings Whitehall Castings 49.4M

13. Michigan

SEN Christopher Bond (D) (SAC)SEN Jean Carnahan (D) (SASC)REP Peter Hoekstra (R-2nd)Contractor City (Dist) Major Comp FY02$ FY03-FY07$

Seiler Instrument & Mfg St Louis Optical Fire Control 0.9M19.4M

14. Missouri

1

32

456

157

8 9

10

11, 12

14

13

SEN Richard J. Durbin (D) (SAC)SEN Peter G. Fitzgerald (R) REP Lane Evans (D-17th) (HASC)

Gov/Contractor City (Dist) Major Comp FY02$ FY03-FY07$Rock Island Arsenal Rock Island B.O.L.T.S. 21.1M

6. IllinoisSEN Thad Cochran (R) (SAC)SEN Trent Lott (R) REP Gene Taylor (D-5th) (HASC)Contractor City (Dist) Major Comp FY02$ FY03-FY07$Camp Shelby Hattiesburg Acceptance Testing 2.2M

15. Mississippi

22

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

LW155 TeamLW155 Team

Program Management JPMO LW155, Picatinny Arsenal, NJ

Prime Contractor & Developer, Cradle Assy BAE SYSTEMS, Barrow-in-Furness, UK

Titanium RTI International Metals, Niles, OH

Spades & Stabilizers Major Tool & Machine Inc., Indianapolis, IN

Digital Fire Control General Dynamics, Burlington, VT

Body Assembly Hydro-Mill, Chatsworth, CA

Breech Operating & Loading Tray System RIA, Rock Island, IL

Cannon Assembly Watervliet Arsenal, Watervliet, NY

US Integrator Final Assembly United Defense, Hattiesburg, MS

Traverse Rack Rotek Inc., Florence, KY

Elevation Assembly Wegmann, Lynchburg, VA

Titanium Castings Pacific Castparts Corp, Portland, OR Pacific Cast Technologies, Albany, OR Howmet Castings, Whitehall, MI

Optical Fire Control Seiler Instrument & Mfg, St Louis, MO

CRADLE ASSEMBLY

BUFFER ASSEMBLY

ACCUMULATORASSEMBLY

BUFFER YOKE ASSEMBLY

BALANCERASSEMBLY

SCAVENGING ASSEMBLY

LOADING SYSTEMASSEMBLY

FULLY ASSEMBLEDELEVATING MASS

MUZZLE BRAKEASSEMBLYBASIC

ORDNANCE

BREECHASSEMBLY

COMPLETEEQUIPMENT

FULLY ASSEMBLEDCARRIAGE

INTEGRATED BODY ANDSADDLE WITH ASSEMBLEDELEVATING GEAR

ELEVATION ASSEMBLY

HANDWHEELASSEMBLIES

SUSPENSION AND WHEEL ASSEMBLY ON BODY

STABILISERASSEMBLY

SPADEASSEMBLY

DAMPERASSEMBLY

TRAVERSERACK ASSEMBLY

BODYASSEMBLY

The GunThe GunELEVATING MASS TEAM

UPPER CARRIAGE TEAM

LOWER CARRIAGE TEAM

INTEGRATION TEAM

SADDLE ASSEMBLY WITHBALANCING POST ASSEMBLIES

TRUNNION GEARBOXASSEMBLY

24

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

Producibility Mods for Pilot Producibility Mods for Pilot ProductionProduction

8 EMD guns manufactured using manual TIG 3200 lbs of titanium per gun 6000 welding hours per gun Early distortion issues

21 Castings introduced for gun 1009 (PP1) Reduces welding hours by @ 50% Reduces Ti structures part count by 51% Reduces manufacturing variability Allow for ‘targeted’ strengthening of structures

New Jigs and process controls Greatly reduced distortion and variability of fabrications

25

The Future of Towed Cannon ArtilleryThe Future of Towed Cannon Artillery

April GAO Brief

Casting vs. Fabrication Casting vs. Fabrication Part CountPart Count

Titanium Structure Fabrication CastingCradle 324 172 Body 215 166Saddle 116 9Stabilisers 70 2Spades 120 120 Trails 98 8 Elevating Yoke 19 1Buffer Yoke 11 1

Total Part Count 973 479

51% Part Count Reduction for Ti Structures51% Part Count Reduction for Ti Structures

TAD Block 2 - Delta Development (SW, Direct Fire, & Objective MVS)

Legend:Legend:Block 1 Development Task

XM777 Development Task

XM777E1 Integration Task

TFT Event “Test-Fix-Test” Event

Program Milestone

LLIPR

XM777 EMD

2 5

First Production XM777 Deliveries

W I P

IF Design

IF Eval

Howitzer/DFCS Interface Design Review

E1 PDR

E1 DDR

XM777E1 Integration

J F M A M J J A S O N D

2002 2003 20042001

PDR DDR

FY04FY03FY02 FY05

2005

O N D

OA Systems IAT&C & Safety Release

IF Prototype

TAD IF & Mass Mock Up Production

Development

Fire Control HW Bench Integration

Testing

LOG DEM

DFCS / M777E1 IAT&C

APS+ Bench DVT

FQT Complete

JOINT DVT (12mo)

OA Training

FQT Start

LUT

FY06

1 Oct 01 Assumed Start of Focused

APS+ Development

OTE

PQT/FAT

MS FRPDMS C

PP1 M/F

PP2 M/F

1008 (TAD I/F)

OA REPORT

PP2 TESTPP2 TESTPP1 TEST

EUA

Report / MS Prep

MS C

XM777E1 LRIP

2006

OTE Systems IAT&C

OTE Report / MS Prep

MS FRPD

M777E1

IOC

EUA

TAD Block 1 Development

XM777 Development

TFT Event 1: Interfaces &

Environments Validated

TFT Event 2: Components

Qualified

TFT Event 3: Integration Evaluated

Functionally Verified APS+Qualified APS+

Components

Procure/Fab & Qualification

Validated Interface Environments

TFT Event 4: Integrated Technical

Test

RQMTS

DESIGN SW CODE & TEST

INTEGRATION

VERIF / FQT

HW FAB/PROCURE

CONF TEST

OTE Report / MS Prep

OTE Systems IAT&C & Safety

Release OA Training

Block 2 P3I Task

Material Release

FY07

Land Warrior Assess.

J F M A M J J A S O N D J F M A M J J A S O N D J F M A M J J A S O N D J F M A M J J A S O N D

ScheduleSchedule