2,6 m /h + 40°C SUBMERGED PUMPS - 3” BOREHOLE 40g/m g1 ...

Transcript of 2,6 m /h + 40°C SUBMERGED PUMPS - 3” BOREHOLE 40g/m g1 ...

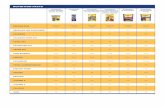

IC 6-8D4 D3

380

300

130

0 2,6 24 130

Hm

Qm3/h

• drawing water from 3” boreholes (DN80), cisterns, wells, tanks, etc.• Providing water supply from mains

• Watering small areas• Feeding fountains • Overpressure

operating limitsFlows rates up to : 2,6 m3/hHead up to : 125 mMax. water temperature: + 40°CMax. sand content: 40g/m3

DN discharge opening : g1”Max. immersion depth: 60 m

appliCations

adVantages• small diameter• easy to install • motor can be rewound • single-phase or three-phase supply • corrosion-proof components • can be installed vertically or horizontally

SUBMERGED PUMPS - 3” BOREHOLE Series D

2 pole - 50 HzStainless steel 304 range

N.T. No 132-5/ENG. - Ed. 1/02-09

• IMMErsON D3 (inox)

• Immerson PAP/H18 ready to install - manometer and 18-litre tank

• ACsonfor

• Immerson PAP/AC ready to install - Acson

ou/or

IMMERSOn D3

1

04

08

01

02

09

03

05

06

07

30

1413

1615

17

182425

2627

28

22

1011

12

20

29

3132

19

333435

3637

21

23

PLAn-CoUPe De PrInCIPedesign• Hydraulic part- centrifugal, multistage with radial impellers.- external housing in stainless steel 304, built-in non-return valve.- Output and suction housing with stainless steel strainer for the D3.

• motor- existing 3-inch motors in single-phase (MP) and in Three-phase (T4). Oil-bath motor resistant to higher temperatures (40°C)speed: 2800 rpmwinding: 1~ 230V 3~ 400Vfrequency: 50Hzinsulation class: 155 (F)protection index : IP 68speed of the coolant flow : 8 cm/s minirestarts each hour : 20 max.

stAnDArD ConstrUCtIonmain parts materialimpellers noryl diffusers polyacetal bearings polyurethane PUr bearing support noryl pump and motor shaft stainless steel

identiFiCation

D3 - 01 - 23 - mP/ PAP / AC t4 H18

Code submerged pump for 3” borehole

Flow rate in m3/h at max. efficiency

stages number

MP : 1~ 230V with permanent capacitorT4 : 3~ 400V

ready to install

Acson or 18-litre tank

1 Cap 2 Valve 3 O-ring 4 Output housing 5 Valve seating 6 Bearing support 7 Bearing 8 screw 9 Grower 10 Pressure washer 11 ring 12 spacer 13 Diffuser disk 14 Diffuser 15 Washer 16 Impeller 17 Diffuser disk 18 Housing 19 screw 20 Cable covering 21 suction housing 22 screw 23 suction strainer 24 shaft 25 spacer 26 Joint 27 washer 28 screw 29 Diffuser disk 30 shims 31 spacer 32 ring 33 Bearing 34 Bearing support 35 spacer 36 Diffuser disk 37 Diffuser

IMMERSOn D3

2

0

10

20

30

40

50

60

70

80

90

100

110

120

130

0,5 1 1,5 2 2,5 3

0,5 1 1,5 2 2,5 3

50

10 8 6 4 2

40 30

6 8 4 2

20 10

0

0

20

40

D3-0145 (45 étages)

D3-0130 (30 étages)

D3-0123 (23 étages)

D3-0115 (15 étages)

m

Qm3/h

Qm3/h

Ql/m

Ql/s

η%

Hm Imp.gpm

N.P

.S.H

.

IMMERSON D3 2 pôles - 50Hz

0,30 à 1 m selon application

Electrode haute

réseau

avec réservoir à vessie

Coffret Yn

ou

Electrode basse (arrêt pompe)

Niveau statique (pompe à l'arrêt)

niveau dynamique (pompe en marche)

Electrode de masse

submergence mini. 1m

H2 H1

1“

74

H

référenceCommande

PuissanceP2

Intensité nominaleIN

Longueur câble section du câble

démarrage direct

H1 H2 Hmasse

sans emballagepompe avec moteur

1~230 V, 50 Hz

3~400 V, 50 Hz

1~230 V, 50 Hz

3~400 V, 50 Hz

1~230 V, 50 Hz

3~400 V, 50 Hz

1~230 V, 50 Hz

3~400 V, 50 Hz

1~230 V, 50 Hz

1~230 V, 50 Hz

3~400 V, 50 Hz

kW A A m m mm2 mm mm mm mm mm kg kgD3 115 0.37 3.75 2.0 1.8 1.8 4 x 1.5 580 377 377 957 957 9.3 9.3D3 123 0.55 4.50 2.1 1.8 1.8 4 x 1.5 780 397 377 1177 1157 10.8 10.5D3 130 0.75 5.85 2.5 1.8 1.8 4 x 1.5 1000 416 397 1416 1397 12.4 12.0D3 145 1.10 – 3.2 – 1.8 4 x 1.5 1380 – 416 – 1796 – 14.4

dimensions

HYDrAULIC FeAtUres installation diagram

orderreference

ratingP2

nominale intensityIN

cable length section of the direct start

cable

H1 H2 H Weight without packaging, with motor

1~230 V, 50 Hz

3~400 V, 50 Hz

1~230 V, 50 Hz

3~400 V, 50 Hz

1~230 V, 50 Hz

3~400 V, 50 Hz

1~230 V, 50 Hz

3~400 V, 50 Hz

1~230 V, 50 Hz

1~230 V, 50 Hz

3~400 V, 50 Hz

stages

stages

stages

stages

2 pole - 50 Hz control box

supply

or

Bladder tank

static level (pump stopped)

0.30 to 1 mDepending on application

Minimum submersion 1m

Earth electrode

Dynamic level (pump running)

Bottom electrode (stop pump)

Top electrode

IMMERSOn D3

3

100 mm

H

120 mm100 mm

H

120 mm

POURQUOI UTILISER UNE JUPE DE REFROIDISSEMENT ?

jupes de refroidissement spécifiques immerson

jupes de refroidissement

FeAtUresa) electricalMP and T4 in 50Hz standard.b) mountingvertically or horizontally (horizontal with coo-ling skirt strongly recommended)

c) Packagingldelivered packed with cable 1.8m long, 4x1,5mm2.

d) maintenanceEquipment exchanged for standard model. Both the hydraulic part and the motor can be repaired.

reCommended aCCessories Yn7112 control box• Voltage switchable from 230 V to 400 V by simply moving the fuse.•Motor overload protection by thermal relay.• Transformer 240 - 400 V/12V, 50/60 Hz• Pump controlled by 2 floats (to avoid rapid hunting when the water-level float is activated).

Low water box (Bme), with:• 2 warning lights on the front: red = water low, green = power on.• Automatic reset adjustable from 30 seconds to 2 minutes.• Operates with a level-detection electrode and 30 m of cable, connected to the box by a plug-in connector.• mains connection via a standard wall socket, 2 pole + earth.

motor cableAcceptable length of cablenature of the motor current motor section of the cable in mm2

(cable with 4 conductors)P2 kW 1,5 2,5 4 6

1~ 230 VDirectstart-up

0,37 78 125 — —0,55 57 95 152 —0,75 45 75 120 174

3~ 400 VDirectstart-up

0,37 — — — —0,55 246 — — —0,75 200 333 — —1,1 146 244 390 —

Weight of cable per m/kg 0,2 0,25 0,3 0,4 0,65

Heat-shrink junctions order reference For cables with section

Jonctiontherm 0 4 X 1,5 mm2 and 4 X 2,5 mm2

Jonctiontherm 1 4 X 4,0 mm2 to 4 X 6 mm2

pap “ready to install”single-phase models (MP) supplied with:• D3 sinle-phase• starter box with thermal protection• 30 m of electric supply cable between pump and box• 30 m of propylene rope to hold the pump• 2 m of supply cable with standard plug• 1 PVC male connector 1”• 1 PVC female connector 1”• depending on the version, a Acson (AC) or pressure booster kit with 18-litre tank (H18).

aCCessories• Isolating valve.• Check valves.• bladder (or galvanised) tanks.• Manometer.• single-core cable for water-level electrodes.• stainless steel cooling skir ts, see technical note cooling skirts. N.T. No300-16/F

FeAtUres oF CooLInG sKIrts

If the diameter of the borehole is too big compared with that of the pump, or to install it in a tank, the speed of the liquid will be inadequate to cool the motor.A cooling skirt then becomes necessary.To check whether a skirt is necessary when installing, see the technical information on cooling skirtsskirt made entirely of stainless steel AIsI 304

For a vertical installation: - 1 motor cooling housing - 1 spacer to centre the motor within the skirt- 3 collars to hold skirts and spacers- 1 joint at the end of the skirt to be positioned between the skirt and the hydraulics

For a horizontal installation: - 1 motor cooling housing - 1 spacer to centre the motor within the skirt- 3 collars to hold skirts and spacers- 1 joint at the end of the skirt to be positioned between the skirt and the hydraulics- set of 2 brackets (motor and hydraulics) to hold the pump stable in the horizontal position

We have kits available for vertical installation which are different from the kits for horizontal installation.

noteFor horizontal installation you need to order the skirt and the fixings kit separately.

composition of the kit H Ø gmm mm mm

stainless steel skirt 500 100spacer to centre the skirt on the motor 75 92,5

joint 20 933 collars1x large bracket (skirt) 112 93 1501x small bracket (hydraulics) 112 71,5 139

Motor cooling housing

Kit of fixings (to be ordered separately)

notasingle-phase motors are intended to operate with a permanent capacitor (MP) supplied in a box with thermal protection (state the type of motor when ordering).In both single-phase and three-phase, you will need a control box and protection against run-ning dry, with water-level electrodes or float.

IMMERSOn D3

4

![Deep Borehole Field Test Laboratory and Borehole Testing ... · The characterization borehole (CB) is the smaller-diameter borehole (i.e., 21.6 cm [8.5”] diameter at total depth),](https://static.fdocuments.in/doc/165x107/5ebe68817151f10bcd35645a/deep-borehole-field-test-laboratory-and-borehole-testing-the-characterization.jpg)