2595532 0077639 59T m - tajhizkala.ir

Transcript of 2595532 0077639 59T m - tajhizkala.ir

m 2595532 0077639 59T m -

ASME-B16.9

ADOPTION NOTICE

ASME-B16.9, "Fittings, Steel Buttwelding, Factory-Made Wrought," was adopted on October 3, 1994 for use by the Department of Defense (DoD). Proposed changes by DoD activities must be submitted to the DoD Adopting Activity: Commanding Officer, Naval Construction Battalion Center, Code 156, 1000 23rd Avenue, Port Hueneme, CA 93043-4301. DoD activities may obtain copies of this standard from the Standardization Document Order Desk, 700 Robbins Avenue, Building 4D, Philadelphia, PA 19111-5094. The private sector and other Government agencies may purchase copies from the American Society of Mechanical Engineers, 345 East 47th Street, New York, NY 10017.

Custodians: Army - ME Navy - YD-1 Air Force - 99

Adopting Activity Navy - YD-1

?

FSC 4730

DISTRIBUTION STATEMENT A. Approved for public release; distribution is unlimited.

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME 826.9 93 0757670 0533520 506 m

AN AMERICAN NATIONAL STANDARD

Factory-Made Wrought Steel

Buttwelding Fittings

ASME B I 6.9-1 993 (REVISION OF ASMVANSI B16.9-1986)

@ The American Society of Mechanical Engineers -

I

I 345 East 47th Street, New York, N.Y. 10017 -

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

Date of Issuance: March 15, 1993

The 1993 edition of this Standard is being issued with an automatic addenda subscription service. The use of an addenda allowqrevisions made in response to public review comments or committee actions t o be published as necessary; revisions published in addenda will become effective 6 months after the Date of Issuance of the addenda. The next edition of this Standard is scheduled for publication in 1998.

ASME issues written replies to inquiries concerning interpretations of technical aspects of this Standard. The interpretations will be included with the above addenda service. Interpretations are not part of the addenda to the Standard.

This code or standard was developed under procedures accredited as meeting the criteria for American National Standards. The Consensus Committee that approved the code or standard was balanced to assure that individuals from competent and concerned interests have had an opportunity to participate. The proposed code or standard was made available for public review and comment which provides an opportunity for additional public input from industry, academia, regulatory agencies, and the public-at-large.

ASME does not "approve," "rate," or "endorse" any item, construction, proprietary device, or activity.

ASME does not take any position with respect to the validity of any patent rights asserted in connection with any items mentioned in this document, and does not undertake to insure anyone utilizing a standard against liability for infringement of any applicable Letters Patent, nor assume any such liability. Users of a code or standard are expressly advised that determination of the validity of any such patent rights, and the risk of infringement of such rights, is entirely their own responsibility.

Participation by federal agency representative(s) or person(s) affiliated with industry is not to be interpreted as government or industry endorsement of this code or standard.

ASME accepts responsibility for only those interpretations issued in accordance with governing ASME procedures and policies which preclude the issuance of interpretations by individual volunteers.

No part of this document may be reproduced in any form, - in an electronic retrieval system or otherwise, without the prior written permission of the publisher.

Copyright O 1993 by THE AMERICAN SOCIETY OF MECHANICAL ENGINEERS

All Rights Reserved Printed in U.S.A.

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME BLb.9 93 m 0759b70 0531522 389 m

FOREWORD

(This Foreword is not part of ASME B1 6.9-1 993.)

In 1921, the American Engineering Standards Committee, later American Standards As- sociation (ASA), organized Sectional Committee B16 to unify and further develop national standards for pipe flanges and fittings (and, later, for valves, gaskets, and valve actuators). Cosponsors of the B16 Committee were the American Society of Mechanical Engineers (ASME), the Heating and Piping Contractors National Association [now the Mechanical Contractors Association of America (MCAA)], and the Manufacturers Standardization Society of the Valve and Fittings Industry (MSS). Cosponsors were later designated as cosecretariat organizations.

Standardization of welding fittings was initiated in 1937 by a subgroup (designated Sub- group 6) of Subcommittee No. 3. After consideration of several drafts, a standard was ap- proved by the Committee, cosponsors, and ASA, and published with the designation ASA

Revisions were made in 1950 and 1955 to add sizes up to NPS 24 and to complete coverage of fittings in some sizes. These revisions were approved and published as ASA B16.9-1951 and ASA B16.9-1958. With the subgroup now designated Subcommittee No. 6 (later Sub- committee F), further revisions were begun to clarify the intent of the standard, to add an- gularity tolerances, and to include fittings of different types (long radius reducing elbows and crosses) and smaller sizes (NPS '/4 and %). This revision was published as ASA B16.9- 1964 after ASA approval.

After reorganization of ASA, first as the United States of America Standards Institute (USASI), then as the American National Standards Institute (ANSI), with the Sectional Committee being redesignated as an American National Standards Committee, another re- vision increasing the size range to NPS 48 and revising the text for clarity was approved and published as ANSI B16.9-1971.

In 1975, Subcommittee F began a major revision to bring the standard up to date with current practice and usage. Common fractions were expressed as decimals (but without in- tending higher precision) and metric dimensional equivalents were added. Provisions for step-wise change of radius for NPS 3/4 long radius elbows and 180 deg. returns were intro- duced. Following Standards Committee, cosecretariat, and ANSI approval, the revision was published as ANSI B16.9-1978. It was updated by a corrective addendum, B16.9a- 1981, issued in February 1982.

In 1982, American National Standards Committee B16 was reorganized as an ASME Committee operating under procedures accredited by ANSI. In this edition, the text has been revised and inch dimensions are established as the standard. Following approval by the Standards Committee and ASME, approval as an American National Standard was given by ANSI on November 12, 1986 with the new designation ASME/ANSI B16.9-1986.

In 1991 the Subcommittee reviewed the document and made a number of revisions. Di- mensions for short pattern lap joints were also added to this 1993 Edition of the Standard.

Requests for interpretation or suggestions for revision should be sent to the Secretary, B16 Committee, The American Society of Mechanical Engineers, United Engineering Cen- ter, 345 East 47th Street, New York, NY 10017.

In 1991 the Subcommittee reviewed the.document and made a number of revisions. Dimensions for short pattern lap joints were also added to this 1993 Edition. This Edition was approved by ASME, and by ANSI on January 22, 1993.

Requests for interpretations or suggestions for revision should be sent to the Secretary, B16 Committee, The American Society of Mechanical Engineers, United Engineering Center, 345 East 47th Street, New York, NY 10017.

B16.9-1940.

iii

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

O

O

O

O

ASME B1 6 COMMITTEE Standardization of Valves, Flanges, Fittings, and Gaskets

(The following is the roster of the Committee at the time of approval of this Standard.)

OFFICERS

W. N. McLean, Chairman R. A. Schmidt, Vice Chairman

J. Yarmush, Secretary

COMMITTEE PERSONNEL

W. L. Ballis, Columbia Gas Distribution Co., Columbus, Ohio J. E. Batey, Union Carbide Corp., South Charleston, West Virginia K. M. Bell, Underwriter’s Laboratory, Inc., Northbrook, Illinois M. L. Blair, U.S. Coast Guard, Washington, D.C. R. R. Brodin, Fisher Controls International, Inc., Marshalltown, Iowa A. Cohen, Copper Development Association, Greenwich, Connecticut W. C. Farrell, Jr., Consultant, Birmingham, Alabama C. E. Floren, Mueller Co., Decatur, Illinois D. R. Frikken, Monsanto Co., St. Louis, Missouri M. W. Garland, Frick Co., Waynesboro, Pennsylvania J. B. Hagen, ABS Americas, New Orleans, Louisiana J. C. Inch, Mueller Brass Co., Hartsville, Tennessee J. S. John, J Square Engineering Co., Houston, Texas G. A. Jolly, Henry Vogt Machine Co., Louisville, Kentucky W. G. Knecht, Anchor/Darling Valve Co., Williamsport, Pennsylvania R. Koester, The William Powell Co., Cincinnati, Ohio J. H. Longacre, Nibco, Inc., Elkhart, Indiana J. H. McCauley, JI., James H. McCauley, Inc., Chicago, Illinois W. N. McLean, Newco Valves, Palos Park, Illinois A. F. Rhodes, Arnco Technology Trust, Houston, Texas F. C. Rosch, Jr., Technicon Enterprises, Inc., Oley, Pennsylvania R. A. Schmidt, Ladish Co., Russellville, Arkansas W. M. Stephan, Flexitallic Inc., Pennsauken, New Jersey T. F. Stroud, Ductile Iron Pipe Research Association, Birmingham, Alabama R. E. White, Repairs, Inc., South Bend, Indiana D. A. Williams, Southern Company Services, Birmingham, Alabama

PERSONNEL OF SUBCOMMITTEE F - STEEL THREADED AND WELDING FITTINGS

G. A. Jolly, Chairman, Henry Vogt Machine Co., Louisville, Kentucky M. A. Weinstock, Secretary, ASME, New York, New York P. R. Benavides. Bonney Forge Corp., Allentown, Pennsylvania D. R. Frikken, Monsanto Co., St. Louis, Missouri R. C. Lafferty, Penna Machine Works, Inc., Chester, Pennsylvania D. H. Monroe, Consultant, Birmingham, Alabama D. W. Muir, Canvil Limited, Simcoe, Ontario, Canada R. A. Schmidt, Ladish Co., Russellville, Arkansas L. H. Schmitt, Capital Manufacturing Co., Columbus, Ohio L. A. Willis, Dow Chemical Co., Freeport, Texas

V

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

CONTENTS

... Foreword ............................................................... 111

Standards Committee Roster .............................................. v

1 2 3 4 5 6 7 8 9

10 11

Scope ............................................................. 1 Pressure Ratings .................................................... 2 Size ............................................................... 2 Marking ........................................................... 2 Material ........................................................... 2 Fittings Dimensions ................................................. 2 Surface Contours ................................................... 3 End Preparation .................................................... 3

ProductionTests .................................................... 3 Tolerances ......................................................... 4

DesignProofTest ................................................... 3

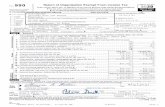

Figures 1 Welding Bevels and Root Face ........................................ 5 2 Maximum Envelope for Welding End Transitions ....................... 6

Tables 1 Tolerances ......................................................... 7 2 Dimensions of Long Radius Elbows ................................... 9 3 Dimensions of Long Radius Reducing Elbows .......................... 10 4 Dimensions of Long Radius Returns ................................... 11 5 Dimensions of Straight Tees and Crosses ............................... 11

7 Dimensions of Lap Joint Stub Ends ................................... 15 8 DimensionsofCaps ................................................. 16 9 Dimensions of Reducers ............................................. 17

6 Dimensions of Reducing Outlet Tees and Reducing Outlet Crosses ......... 12

Annexes A Metric (SI) Tables ................................................... 19 B References ......................................................... 38

vii

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME B1 6.9-1 993

FACTORY-MADE WROUGHT STEEL BUTTWELDING FITTINGS

1 SCOPE

1.1 General

This Standard covers overall dimensions, toler- ances, ratings, testing, and markings for wrought car- bon and alloy steel factory-made buttwelding fittings of NPS Y2 through 48. It covers fittings of any produc- ible wall thickness.

1.2 Exclusions

This Standard does not cover low pressure corro- sion resistant buttwelding fittings. See MSS SP-43, Wrought Stainless Steel Butt-welding Fittings. -

1.3 Partial Compliance Fittings

Fittings may be made to special dimensions, sizes, shapes, tolerances, or of wrought materials other than those covered by this Standard by agreement between the manufacturer and the purchaser. When such fit- tings meet all other stipulations of this Standard, they shall be considered as being in partial compliance therewith, provided they are appropriately marked. (See para. 4.4.)

1.4 Fabricated Fittings

Fabricated laterals and other fittings employing cir- cumferential or intersection welds are considered pipe fabrication, and shall be manufactured in accordance with the applicable section of ASME B31, Code for Pressure Piping.

1.5 Standard Units

The inch is the standard unit for linear dimensions. Values in millimeters are for information and refer- ence only. See Annex A.

O NOTES: (1) Tolerance values shown in Table 1 in decimal inches are com-

mon fractions rounded as follows:

1

0.03 = '/32 0.12 = VI3

0.06 = 0.16 = 5/32

0.09 = 3/32 0.19 = 3/16

0.25 = '/4

0.22 = '/U 0.38 = 3/13

(2) Dimensions in Tables 2 through 9 are common fractions or di- mensions from ANSVASME B36.10M, rounded to two-place decimal fractions.

1.6 References

1.6.1 Referenced Standards. Standards and spec- ifications adopted by reference in this Standard are shown in Annex B, which is part of this Standard. It is not considered practical to identify the specific edition of each standard and specification in the individual references. Instead, the specific edition reference is identified in Annex B. A product made in conform- ance with a prior edition of reference standards and in all other respects conforming to this Standard will be considered to be in conformance.

1.6.2 Codes and Regulations. A fitting used un- der the jurisdiction of the ASME Boiler and Pressure Vessel Code, the ASME Code for Pressure Piping, or a governmental regulation is subject to any limitation of that code or regulation. This includes any maxi- mum temperature limitation, or rule governing the use of a material at low temperature.

1.7 Service Conditions

Criteria for selection of fitting types and materials suitable for particular fluid service are not within the scope of this Standard.

1.8 Welding

Installation welding requirements are outside the scope of this Standard. Installation welding shall be done in accordance with the applicable piping code or regulation covering the piping system into which the fittings are installed.

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME B1 6.9-1 993

2 PRESSURE RATINGS

2.1 Basis of Ratings

The allowable pressure ratings for fittings designed in accordance with this Standard may be calculated as for straight seamless pipe of equivalent material (as shown by comparison of composition and mechanical properties in the respective material specifications) in accordance with the rules established in the applicable sections of ASME B3 1, Code for Pressure Piping. For the calculation, applicable data for the NPS, wall thickness (or schedule number), and material equiva- lent to that of the fitting material shall be used. NPS, wall thickness (or schedule number), and material identity on the fittings are in lieu of pressure rating markings.

2.2 Design of Fittings

The design of fittings shall be established by mathe- matical analyses contained in nationally recognized pressure vessel or piping codes or at the manufactur- er’s option by proof testing in accordance with Section 9 of this Standard. In order to meet design or manu- facturing requirements it is expected that some por- tion of formed fittings may have to be thicker than the pipe wall with which the fitting is intended to be used. The mathematical analyses, if used, may take into ac- count such thicker sections. Records of mathematical analysis and/or successful proof test data shall be available at the manufacturer’s facility for inspection by the purchaser.

3 SIZE

The size of fittings in Tables 1 through 9 is identified by the corresponding nominal pipe size ( W S ) as de- fined in ANSUASME B36.10M.

4 MARKING

4.1 Standard Marking

Each fitting shall be permanently marked to show

(a) manufacturer’s name or trademark; (b) material and product identification (ASTM or

ASME grade symbol). Conformance to this standard is indicated by the prefix “WP” in the grade symbol;

(c) schedule number or nominal wall thickness des- ignation; (d) NPS.

the following:

ASME B L b - S 93 O759670 053L52b T24 m

FACTORY-MADE WROUGHT STEEL BUTTWELDING FITTINGS

4.2 Exceptions

Where the size of the fitting does not permit com- plete marking, the identification marks may be omit- ted in reverse of the order presented above.

4.3 Depth of Stamping

Where steel stamps are used, care shall be taken so that the marking is not deep enough or sharp enough to cause cracks or to reduce the wall thickness of the fitting below the minimum allowed.

4.4 Partial Compliance Fittings

Fittings meeting all requirements of ASTM A 234, A 403, or A 420 except for dimensions, sizes, shapes, or tolerances shall be identified by the marking sym- bol of the specification followed by the applicable Supplementary Requirement number thereof. Fittings in partial compliance with the requirements of the specification shall not use the marking prefix “WP,” and shall be identified as agreed upon between manu- facturer and purchaser.

5 MATERIAL

Wrought fittings covered by this Standard shall be in accordance with ASTM A 234, A403, A420, or the corresponding ASME standard except as provided in para. 1.3. The term wrought denotes fittings made of pipe, tubing, plate, or forgings. Fittings made from block forgings may only be supplied subject to agree- ment between manufacturer and purchaser. Such fit- tings need not meet the requirements of Section 7, Surface Contours.

6 FITTINGS DIMENSIONS

6.1 General

This Standard provides for a fixed position for the welding ends with reference to either the center line of the fittings or the overall dimensions. Dimensional standards for these fittings will be found in Tables 2 through 9 and Tables A2 through A9 of Annex A.

6.2 Special Dimensions

For applications where fatigue loading is a concern, required minimum dimensions shall be furnished by the purchaser.

2

e

O

e

O

e

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME B L b - 9 93 m 0759b70 0533527 960 m

FACTORY-MADE WROUGHT STEEL BUTTWELDING FITTINGS

7 SURFACE CONTOURS

Where adjacent openings in fittings are not in paral- lel planes, they shall be joined by a circular arc on the external surfaces. The arc may be terminated in tangents.

8 END PREPARATION

The standard welding bevels and root face are shown in Fig. l . Transitions from the welding bevel to outside surface of the fitting and from the root face to the inside surface of the fitting lying within the maxi- 0 mum envelope shown in Fig. 2 are at the manufactur- er’s option except as covered in Note ( 5 ) of Fig. 2 or unless otherwise specifically ordered.

9 DESIGN PROOF TEST

9.1 Required Tests

Proof tests shall be made as set forth herein when the manufacturer chooses proof testing to qualify the fitting design. Unless otherwise agreed upon between manufacturer and purchaser, the only required type of proof test is a bursting strength test.

9.2 Test Assembly

9.2.1 Representative Components. Fittings that are representative of production and selected for test shall be identified as to material, grade, and lot, in- cluding heat treatment. They shall be inspected for di- mensional compliance to this Standard.

9.2.2 Other Components. Straight seamless or welded pipe sections whose calculated bursting strength is at least as great as the proof test pressure as calculated in para. 9.3 shall be welded to each end of 0 the fitting to be tested. Any internal misalignment greater than 0.06 in. (1.6 mm) shall be reduced by taper boring at a slope not over 1:3: Length of pipe sections for closures shall be as follows.

(a) Minimum length of pipe shall be one pipe O.D. for NPS 14 and smaller.

(b) Minimum length of pipe shall be one-half pipe O.D. for NPS greater than 14 in.

9.3 Test Procedure

Test fluid shall be water or other liquid used for hy- drostatic testing. Hydrostatic pressure shall be applied to the assembly. The test is successful if the assembly

ASME 616.9-1993

withstands, without rupture, 105% of the computed proof test pressure defined below.

2 st p = - D

where P = computed proof of test pressure S = actual tensile strength of the test fitting, de-

termined on a specimen representative of the test fitting, which shall meet the tensile strength requirements of the applicable ma- terial of para. 5.0

t = nominal pipe wall thickness of the pipe that the fitting marking identifies

D = specified outside diameter of pipe

9.4 Applicability of Test Results

It is not necessary to conduct an individual test of fittings with all combinations of sizes, wall thick- nesses, and materials. A successful proof test on one representative fitting may represent others to the ex- tent described herein.

9.4.1 Size Range. One test fitting may be used to qualify similarly proportioned fittings with an NPS range from one-half to twice that for the tested fitting. The test of a non-reducing fitting qualifies reducing fittings of the same pattern. The test of a reducing fit- ting qualifies reductions to smaller sizes.

9.4.2 Thickness Range. One test fitting may be used to qualify similarly proportioned fittings with t / D ranges from one-half to three times that for the tested fitting.

9.4.3 Material Grades. The pressure retaining ca- ,

pacity of a geometrically identical fitting made of vari- ous grades of steel will be directly proportional to the tensile properties of the various grades. Therefore, it is necessary to test only a single material grade in a rep- resentative fitting to prove the design of the fitting.

1 O PRODUCTION TESTS

Hydrostatic testing of wrought fittings is not re- quired by this Standard. All fittings shall be capable of withstanding, without leakage or impairment of serv- iceability, a hydrostatic test pressure required by the applicable piping code for seamless pipe of material equivalent to the fitting material and of the NPS and wall thickness the fitting marking identifies.

3

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME B1 6.9-1 993 FACTORY-MADE WROUGHT STEEL BUTTWELDING FllTlNGS

11 TOLERANCES

Tolerances for fittings are shown in Tables 1 and Al, and apply to the nominal dimensions given in Ta- bles 2 through 9 and A2 through A9. Where given in the tables, the minimum and maximum dimensions are based on these tolerances. The listings with deci- mals do not imply precision measurement such as use of vernier, micrometer, electronic readout equipment, etc.

4

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

A S I E B L b - S 93 m 0759b70 0533529 733 m

FACTORY-MADE WROUGHT STEEL BUTTWELDING FITTINGS

O ASME 816.9-1993

10 deg. f 1 deg.

37.5 deg. k 2.5 deg.

37.5 deg. f 2.5 deg.

0.06 (1.6) k0.03 (0.81 (Root face)

[Note (1 I I

(a) Plain Bevel (b) Compound Bevel

Nominal Wall Thickness t End Preparation

Less thanx [Note (2)l Cut square or slightly chamfer, at manufacturer's option.

x to 0.88 incl. (22) Plain bevel as in sketch (a) [Note (2)l above.

More than 0.88 (22) Compound bevel as in sketch (b) above.

GENERAL NOTES: (1 Dimensions in parentheses are in millimeters. (2) Other dimensions are in inches.

NOTES: (1) See Section 8 and Fig. 2 for transition contours. (2 ) x = O. 19 (5) for carbon steel or ferritic alloy steel and

O. 1 2 (4) for austenitic alloy steel.

FIG. 1 WELDING BEVELS AND ROOT FACE

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME B1 6.9-1 993

ASME B3b.S '73 0759670 0533530 455 W

FACTORY-MADE WROUGHT STEEL BUTTWELDING FllTlNGS

0.5fmi, l. 5tmi, C I B

Outside "- -

Component or Fitting \ \ \ \ L.

30 deg. max.

Maximum slope 1 ::

Radius 2 0.05tmi,

I / fnom

- T Maximum - Minimum -

[Noie (1)l

NOTES: (1) The value of tmin is whichever of the following is applicable:

(a) the minimum ordered wall thickness of the pipe; (b) 0.875 times the nominal wall thickness of pipe ordered to a pipe schedule wall thickness that has an undertolerance of 12.5%.

(2) The maximum thickness at the end of the component is: (a) the greater of (rmin + 0.16 in.) or 1.1 5tmi, when ordered on a minimum wall basis; (b) the greater of (rm¡,, + 0.1 6 in.) or l . 1 Ofnom when ordered on a nominal wall basis.

(3) Weld bevel shown is for illustration only. (4) The weld reinforcement permitted by applicable code may lie outside the maximum envelope. ( 5 ) Where transitions using maximum slope do not intersect outside surface within the transition region, as shown by phantom outline,

maximum slopes shown shall be used. Alternately, radii lying within the envelope may be used.

FIG. 2 MAXIMUM ENVELOPE FOR WELDING END TRANSITIONS

6

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

Nomi

nal

Outsi

de

Pipe

Di

amete

r a1

Si

ze

Beve

l flM

2 W

’S)

D

Ii2 t

o 2%

-I 3

to 3’1

2

+ 0.0

6 -

0.03

0.06

0.06

0.06

0.06

0.12

0.25

0.25

0.03

4 0.0

6

5 to

a

IOto

18

20

to 24

26

to 30

32

to 48

+0.09

-0

.06

+0.16

-0

.12

+0.25

-0

.19

+0.25

0.1

9

+0.25

0.1

9

All

Fittin

gs Ins

ide

Wall

iam

eter

Thick

- mt

End

ne

ss

(3)

L(3).(

4) t

90

deg.

and

45

deg.

Elbo

ws

and

Tees

Cente

r-to-

En

d Di

mens

ion

AA

CM

Over

all

Over

all

Leng

th

Leng

th

EH

E

Cente

r- Ba

ck-to

- Al

ign-

Outsi

de

Fille

t Ou

tside

to-

Cente

r Fa

ce

ment

of

Diam

eter

Radiu

s Di

amete

r Di

mens

ion

Dlme

nslon

En

ds

of La

p of

Lap

of 0

K u

G R

Barre

l

0.03

0.06

0.06

0.12

0.25

0.25

0.03

0.06

0.06

0.06

0.12

0.25

0.25

0.06

Not

less

than

87.5%

of no

mina

l thi

ckne

ss

0.06

0.06

0.25

0.25

0.25

q.03

0.03

0.12

0.19

0.19

0.19

0.09

0.09

0.12

0.19

0.09

0.09

0.19

0.19

0.25

0.38

0.25

0.06

0.25

0.38

0.25

0.06

0.38

0.38

. . .

. . .

. . .

. .

.

. . .

. . .

TABL

E 1

TOLE

RAN

CES

Redu

cers

and

Lap

Joint

St

ub

Ends

Ca

ps

180

deg.

Retur

ns

Lap

Joint

St

ub

Ends

+o

+o

-0.03

-

0.03

+o

+o

- 0.0

3 -0

.03

+o

+o

- 0.0

3 -0

.06

+o

+o

-0.03

-0

.06

+o

+o

-0.06

-0

.06

+o

+o

- 0.0

6 -

0.06

. . .

. . .

. . .

. . .

See

Table

7

for

limitin

g dim

ensio

ns

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

TABL

E 1

TOLE

RANC

ES

(CON

T’D)

Nomi

nal

Pipe

Si

ze

(NPS

I

Angu

larity

To

l.

Ygrp

F

‘I2

to 4

0.03

0.06

5 to

8 0.0

6 0.1

2 lot

0 12

0.0

9 0.1

9 14

to

16

0.09

0.25

18to

24

0.12

0.38

26

to 30

0.1

9 0.3

8 32

to

42

0.19

0.50

44

to 48

0.1

9 0.7

5

\ K

/

L ‘5 t 1 ==

=z

--

L-

-8z=

-

0

Tees

This

end

flush

’again

st sq

uare

GENE

RAL

NOTE

: Di

mens

ions

are

in inc

hes.

Toler

ance

s ar

e eq

ual

plus

and

minu

s ex

cept

as

noted

.

NOTE

S:

(1)

Out-o

f-rou

nd

is the

su

m of

abso

lute

value

s of

plus

and

minu

s tol

eran

ce.

(2)

This

toler

ance

ma

y be

exc

eede

d in

locali

zed

areas

of

forme

d fitt

ings

wher

e inc

reas

ed

wall

thick

ness

is

requ

ired

to me

et

desig

n re-

qu

ireme

nts

of pa

ra.

2.2.

(3)

The

inside

dia

meter

an

d the

no

mina

l wa

ll thi

ckne

sses

at

ends

ar

e to

be s

pecif

ied

by

the

purch

aser.

(4)

Un

less

other

wise

sp

ecifie

d by

the

pu

rchas

er,

these

tol

eran

ces

apply

to

the

nomi

nal

inside

dia

meter

, wh

ich

equa

ls the

dif

feren

ce

be-

twee

n the

no

mina

l ou

tside

dia

meter

an

d tw

ice

the

nomi

nal

wall

thick

ness

.

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME B1 6.9-1 993

TABLE 2 DIMENSIONS OF LONG RADIUS ELBOWS

Nominal Pipe Size

W S )

2 2'12 3

4 3

5 6 8 10 12

14 16 18 20 22

24 26 28 30 32

34 36 38 40 42

44 46 48

Outside Diameter at Bevel

D

0.84 1 .O5 1.32 1.66 1.90

2.38 2.88 3.50 4.00 4.50

5.56 6.62 8.62 10.75 12.75

14.00 16.00 18.00 20.00 22.00

24.00 26.00 28.00 30.00 32.00

34.00 36.00 38.00 40.00 42.00

44.00 46.00 48.00

Center-to-End

90 deg. Elbows

A

1.50 1.50 1.50 1.88 2.25

3.00 3.75 4.50 5.25 6.00

7.50 9.00 12.00 15.00 18.00

2 1 .o0 24.00 27.00 30.00 33.00

36.00 39.00 42.00 45.00 48.00

51 .O0 54.00 57.00 60.00 63.00

66.00 69.00 72.00

45 deg. Elbows

B

0.62 0.75 0.88 1 .o0 1.12

1.38 1.75 2.00 2.25 2.50

3.12 3.75 5.00 6.25 7.50

8.75 10.00 11.25 12.50 13.50

15.00 16.00 17.25 18.50 19.75

21 .o0 22.25 23.62 24.88 26.00

27.38 28.62 29.88

GENERAL NOTE: Dimensions are in inches.

NOTE: (1) A and B dimensions of 1 .I2 in. and 0.44 in. respectively

may be furnished for NPS 3/4 at the manufacturer's option.

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME B1 6.9-1 993

ASME Blb.9 93 m 0759b70 053l53V O T O m

FACTORY-MADE WROUGHT STEEL BUTTWELDING FITTINGS

O

V A I

L TABLE 3 DIMENSIONS OF LONG RADIUS REDUCING ELBOWS

Nominal Pipe Size

(NPS)

2 x 1 ‘I2

2 x 1% 2 x 1

2’12 x 2 2’12 x 1’12 2% X 1%

3 x 2’12 3 x 2 3 x 1 ’12

3% x 3 3% x 2l/2 3% x 2

4 x 3% 4 x 3 4 x 2’12 4 x 2

5 x 4 5 x 3’12 5 x 3 5 x 2112

6 x 5 6 x 4 6 x 3% 6 x 3

8 x 6 8 x 5 8 x 4

Outside Diameter at Bevel

D

Large End

2.38 2.38 2.38

2.88 2.88 2.88

3.50 3.50 3.50

4.00 4.00 4.00

4.50 4.50 4.50 4.50

5.56 5.56 5.56 5.56

6.62 6.62 6.62 6.62

8.62 8.62 8.62

Small End

1.90 1.66 1.32

2.38 1.90 1.66

2.88 2.38 1.90

3.50 2.88 2.38

4.00 3.50 2.88 2.38

4.50 4.00 3.50 2.88

5.56 4.50 4.00 3.50

6.62 5.56 4.50

Center- to- End A

’ 3.00 3.00 3.00

3.75 3.75 3.75

4.50 4.50 4.50

5.25 5.25 5.25

6.00 6.00 6.00 6.00

7.50 7.50 7.50 7.50

9 .o0 9.00 9.00 9.00

12.00 12.00 12.00

GENERAL NOTE: Dimensions are in inches.

Nominal Pipe Size

(NPS)

10 x 8 10 x 6 10 x 5

12 x 10 12 x 8 12 x 6

14 x 12 14 x 10 14 x 8

16 x 14 16 x 12 16 x 10

18 x 16 18 x 14 18 x 12 18 x 10

20 x 18 20 x 16 20 x 14 20 x 12

20 x 10 24 x 22 24 x 20 24 x 18

24 x 16 24 x 14 24 x 12

I Outside Diameter at Bevel

D

Large End

10.75 10.75 10.75

12.75 12.75 12.75

14.00 14.00 14.00

16.00 16.00 16.00

18.00 18.00 18.00 18.00

20.00 20.00 20.00 20.00

20.00 24.00 24.00 24.00

24.00 24.00 24.00

Small End

8.62 6.62 5.56

1 O. 75 8.62 6.62

12.75 1 O. 75 8.62

14.00 12.75 10.75

16.00 14.00 12.75 10.75

18.00 16.00 14.00 12.75

10.75 22.00 20.00 18.00

16.00 14.00 12.75

:enter- to- End A

15.00 15.00 15.00

18.00 18.00 18.00

2 1 .o0 21.00 2 1 .o0

24.00 24.00 24.00

27.00 27.00 27.00 27.00

30.00 30.00 30.00 30.00

30.00 36.00 36.00 36.00

36.00 36.00 36.00

10

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

FACTORY-MADE WROUGHT STEEL BUTTWELDING FITTINGS ASME B1 6.9-1 993

l " c c c c " l

U

TABLE 4 DIMENSIONS OF LONG TABLE 5 DIMENSIONS OF STRAIGHT RADIUS RETURNS TEES AND CROSSES

T Center-to-End Nominal Pipe Size

(NI'S)

'12

314

1 1 '14 1 'h 2 2 '12 3 3'12 4

5 6 8 10 12

14 16 18 20 22

24 26 28 30 32

34 36 38 40 42

44 46 48

Nominal Pipe

Outside Diameter at Bevel

D

0.84 1 .O5 1.32 1.66 1.90

2.38 2.88 3.50 4.00 4.50

5.56 6.62 8.62 10.75 12.75

14.00 16.00 18.00 20.00 22.00 24.00

Outside Diameter at Bevel

D

0.84 1 .O5 1.32 1.66 1.90

2.38 2.88 3.50 4.00 4.50

5.56 6.62 8.62 10.75 12.75

14.00 16.00 18.00 20.00 22.00

24.00 26.00 28.00 30.00 32.00

34.00 36.00 38.00 40.00 42.00

44.00 46.00 48.00

Cemter-to- Center

O

3.00 3.00 3.00 3.75 4.50

6.00 7.50 9.00 10.50 12.00

5 5.00 18.00 24.00 30.00 36.00

42.00 48.00 54.00 60.00 66.00 72.00

Back-to- Face K

1.88 2.00 2.19 2.75 3.25

4.19 5.19 6.25 7.25 8.25

10.31 12.31 16.31 20.38 24.38

28.00 32.00 36.00 40.00 44.00 48.00

Run C

1 .o0 1.12 1.50 1.88 2.25

2.50 3.00 3.38 3.75 4.1 2

4.88 5.62 7.00 8.50 10.00

1 1 .o0 12.00 13.50 15.00 16.50

17.00 19.50 20.50 22.00 23.50

25.00 26.50 28.00 29.50 30.00

32.00 33.50 35.00

Outlet (1),(2) M

1 .o0 1.12 1.50 1.88 2.25

2.50 3.00 3.38 3.75 4.12

4.88 5.62 7.00 8.50 10.00

1 1 .o0 12.00 13.50 15.00 16.50

17.00 19.50 20.50 22.00 23.50

25.00 26.50 28.00 29.50 28.00

30.00 31.50 33.00

2 2112 3 3 l h

0 5

4

6 8 10 12

14 16 18 20 22 24

O GENERAL NOTE: Dimensions are in inches.

NOTES: (1) See Table 1 for tolerance for alignment of ends, U. (2) Dimension A is equal to one-half of dimension O. (3) O and K dimensions of 2.25 in. and 1.69 in. respectively

may be furnished for NPS 314 at the manufacturer's option.

GENERAL NOTE: Dimensions are in inches.

NOTES: (1 1 Outlet dimension Mfor NPS 26 and larger is recommended

(2) Dimensions applicable to crosses NPS 24 and smaller. but not required.

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME B1 6.9-1 993 FACTORY-MADE WROUGHT STEEL BUTTWELDING FITTINGS

TABLE 6 DIMENSIONS OF REDUCING OUTLET TEES AND REDUCING OUTLET CROSSES

Nominal Pipe Size

(NPS)

’12 X ’h X 310

’h x ’12 x ‘I4

3 1 ~ X 3 1 ~ X ‘12

3/4 X 314 X 310

1 x 1 X % 1 x 1 x ’I2

1% x 1% X 1 1 ‘14 x 1 ’14 x 314

1’14 x 1 ‘14 x ‘12 1’12 x 1‘12 x 1%

1 ‘12 x 1 ’12 X % 1112 x 1‘12 x 1

1‘12 x 1‘12 x ’ h 2 x 2 x 1’12 2 x 2 x 1% 2 X 2 X 1 2 x 2 x % 2’12 x 2’12 x 2 2’12 x 2‘0 x 1 ‘h 2‘12 x 2’12 x 1

3 x 3 x 2’12 3 X 3 X 2 3 x 3 x 1’12 3 x 3 x 1%

3% x 3% x 3 3% x 3% x 2’12 3% x 3’12 X 2 3% x 3% x 1 ’12

4 x 4 x 3% 4 X 4 X 3 4 x 4 x 2’12 4 X 4 X 2 4 x 4 x 1’12

5 X 5 X 4 5 x 5 x 3% 5 X 5 X 3 5 x 5 x 2’12 5 X 5 X 2

2’12 x 2‘12 x 1 ’h

Outside Diameter at Bevel

D i

Run

0.84 0.84 1 .O5 1 .O5

1.32 1.32

1.66 1.66 1.66

1.90 1.90 1.90 1 .go

2.38 2.38 2.38 2.38

2.88 2.88 2.88 2.88

3.50 3.50 3.50 3.50

4.00 4.00 4.00 4.00

4.50 4.50 4.50 4.60 4.50

5.56 5.56 5.56 5.56 5.56

Outlet

0.68 O. 54 0.84 0.68

1 .O5 0.84

1.32 1 .O5 0.84

1.66 1.32 1 .O5 0.84

1.90 1.66 1.32 1 .O5

2.38 1.90 1.66 1.32

2.88 2.38 1.90 1.66

3.50 2.88 2.38 1.90

4.00 3.50 2.88 2.38 1.90

4.50 4.00 3.50 2.88 2.38

Center-to-End

Run C

1 .o0 1 .o0 1.12 1.12

1.50 1.50

1.88 1.88 1.88

2.25 2.25 2.25 2.25

2.50 2.50 2.50 2.50

3.00 3.00 3.00 3.00

3.38 3.38 3.38 3.38

3.75 3.75 3.75 3.75

4.1 2 4.12 4.1 2 4.12 4.1 2

4.88 4.88 4.88 4.88 4.88

lutlet (1 I M

1 .o0 1 .o0 1.12 1.12

1.50 1.50

1.88 1.88 1.88

2.25 2.25 2.25 2.25

2.38 2.25 2 .o0 1.75

2.75 2.62 2.50 2.25

3.25 3.00 2.88 2.75

3.62 3.50 3.25 3.12

4.00 3.88 3.75 3.50 3.38

4.62 4.50 4.38 4.25 4.1 2

(Notes follow at end of table)

12

Nominal Pipe Size

(NPSI

6 x 6 ~ 5 6 x 6 ~ 4 6 x 6 x 3’12 6 x 6 ~ 3 6 x 6 x 2‘12

8 x 8 ~ 6 8 x 8 ~ 5 8 x 8 ~ 4 8 x 8 x 3%

10 x 10 x 8 10 x 10 x 6 10 x 10 x 5 10 x 10 x 4

12 x 12 x 10 12 x 12 x 8 12 x 12 x 6 12 x 12 x 5

14 x 14 x 12 14 x 14 x 10 14 x 14 x 8 14 x 14 x 6

16 x 16 x 14 16 x 16 x 12 16 x 16 x 10 16 x 16 x 8 16 x 16 x 6

18 x 18 x 16 18 x 18 x 14 18 x 18 x 12 18 x 18 x 10 18 x 18 x 8

20 x 20 x 18 20 x 20 x 16 20 x 20 x 14 20 x 20 x 12 20 x 20 x 10 20 x 20 x 8

22 x 22 x 20 22 x 22 x 18

T Outside Diameter at Bevel

D T

Run

6.62 6.62 6.62 6.62 6.62

8.62 8.62 8.62 8.62

10.75 10.75 10.75 10.75

12.75 12.75 12.75 12.75

14.00 14.00 14.00 14.00

16.00 16.00 16.00 16.00 16.00

18.00 18.00 18.00 18.00 1 8 .O0 20.00 20.00 20.00 20.00 20.00 20.00

22.00 22.00

Outlet

5.56 4.50 4.00 3.50 2.88

6.62 5.56 4.50 4.00

8.62 6.62 5.56 4.50

10.75 8.62 6.62 5.56

12.75 10.75 8.62 6.62

14.00 12.75 10.75 8.62 6.62

16.00 14.00 12.75 10.75 8.62

18.00 16.00 14.00 12.75 10.75 8.62

20.00 18.00

Center-to-End

Run C

5.62 5.62 5.62 5.62 5.62

7.00 7.00 7.00 7.00

8.50 8.50 8.50 8.50

10.00 10.00 10.00 10.00

1 1 .o0 1 1 .o0 1 1 .o0 11 .o0

12.00 12.00 12.00 1 2 .o0 12.00

13.50 13.50 13.50 13.50 13.50

15.00 15.00 15.00 15.00 15.00 15.00

16.50 16.50

Outlet (1 ) M

5.38 5.12 5.00 4.88 4.75

6.62 6.38 6.12 6.00

8.00 7.62 7.50 7.25

9.50 9.00 8.62 8.50

10.62 10.12 9.75 9.38

12.00 11.62 11.12 10.75 10.38

13.00 13.00 12.62 12.12 11.75

14.50 14.00 14.00 13.62 13.12 12.75

16.00 1 5.50

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

FACTORY-MADE WROUGHT STEEL BUTTWELDING FITTINGS ASME B16.9-1993

TABLE 6 DIMENSIONS OF REDUCING OUTLET TEES AND REDUCING OUTLET CROSSES (CONT’D)

Nominal Pipe Size

(NPS)

22 x 22 x 16 22 x 22 x 14 22 x 22 x 12 22 x 22 x 10

24 x 24 x 22

2 4 ~ 2 4 x 1 8 24 x 24 x 20

24 x 24 x 16 24 x 24 x 14 24 x 24 x 12 24 x 24 x 10

26 x 26 x 24 26 x 26 x 22 26 x 26 x 20 26 x 26 x 18 26 x 26 x 16 26 x 26 x 14 26 x 26 x 12

28 x 28 x 26

28 x 28 x 20

28 x 28 x 24 28 x 28 x 22

28 x 28 x 18 28 x 28 x 16 28 x 28 x 14 28 x 28 x 12

30 x 30 x 28 30 x 30 X 26 30 x 30 x 24 30 x 30 x 22 30 x 30 x 20 30 x 30 x 18 30 x 30 x 16 30 x 30 X 14

O 30 x 30 x 12 30 x 30 x 10

32 x 32 x 30 32 x 32 x 28 32 x 32 x 26 32 x 32 x 24 32 x 32 x 22 32 x 32 x 20 32 x 32 x 18 32 x 32 x 16 32 x 32 x 14

34 x 34 x 32 34 x 34 x 30 34 x 34 x 28

Outside Diameter at Bevel

D

Run

22.00 22.00 22.00 22.00

24.00 24.00 24.00 24.00 24.00 24.00 24.00

26.00 26.00 26.00 26.00 26.00 26.00 26.00

28.00 28.00 28.00 28.00 28.00 28.00 28.00 28.00

30.00 30.00 30.00 30.00 30.00 30.00 30.00 30.00 30.00 30.00

32.00 32.00 32.00 32.00 32.00 32.00 32.00 32.00 32.00

34.00 34.00 34.00 34.00

Outlet

16.00 14.00 12.75 10.75

22.00 20.00 18.00 16.00 14.00 12.75 10.75

24.00 22.00 20.00 18.00 16.00 14.00 12.75

26.00 24.00 22.00 20.00 18.00 16.00 14.00 12.75

28.00 26.00 24.00 22.00 20.00 18.00 16.00 14.00 12.75 10.75

30.00 28.00 26.00 24.00 22.00 20.00 18.00 16.00 14.00

32.00 30.00 28.00 26.00

Center-to-End

Run C

16.50 16.50 16.50 16.50

17.00 17.00 17.00 17.00 17.00 17.00 17.00

19.50 19.50 19.50 19.50 19.50 19.50 19.50

20.50 20.50 20.50 20.50 20.50 20.50 20.50 20.50

22.00 22.00 22.00 22.00 22.00 22.00 22.00 22.00 22.00 22.00

23.50 23.50 23.50 23.50 23.50 23.50 23.50 23.50 23.50

25.00 25.00 25.00 25.00

Dutlet (1) M

15.00 15.00 14.62 14.12

17.00 17.00 16.50 16.00 16.00 15.62 15.12

19.00 18.50 18.00 17.50 17.00 17.00 16.62

20.50 20.00 19.50 19.00 18.50 18.00 18.00 17.62

21.50 21.50 21 .o0 20.50 20.00 19.50 19.00 19.00 18.62 18.12

23.00 22.50 22.50 22.00 21.50 21 .o0 20.50 20.00 20.00

24.50 24.00 23.50 23.50

Nominal Pipe Size

W S )

34 x 34 x 24 34 x 34 x 22 34 x 34 x 20 34 x 34 x 18 34 x 34 x 16

36 x 36 x 34 36 x 36 x 32 36 x 36 x 30 36 x 36 x 28 36 x 36 x 26 36 x 36 x 24 36 x 36 x 22 36 x 36 x 20 36 x 36 x 18 36 x 36 x 16

38 x 38 x 36 38 x 38 x 34 38 x 38 x 32 38 x 38 x 30 38 x 38 x 28 38 x 38 x 26 38 x 38 x 24 38 x 38 x 22 38 x 38 x 20 38 x 38 x 18

40 x 40 x 38 40 x 40 x 36 40 x 40 x 34 40 x 40 x 32 40 x 40 x 30 40 x 40 x 28 40 x 40 x 26 40 x 40 x 24 40 x 40 x 22 40 x 40 x 20 4 0 x 4 0 ~ 18

42 x 42 x 40 42 x 42 x 38 42 x 42 x 36 42 x 42 x 34 42 x 42 x 32 42 x 42 x 30 42 x 42 x 28 42 x 42 x 26 42 x 42 x 24 42 x 42 x 22 42 x 42 x 20 42 x 42 x 18 42 x 42 x 16

Outside diameter at Bevel

D i- Run

34.00 34.00 34.00 34.00 34.00

36.00 36.00 36.00 36.00 36.00 36.00 36.00 36.00 36.00 36.00

38.00 38.00 38.00 38.00 38.00 38.00 38.00 38.00 38.00 38.00

40.00 40.00 40.00 40.00 40.00 40.00 40.00 40.00 40.00 40.00 40.00

42.00 42.00 42.00 42.00 42.00 42.00 42.00 42.00 42.00 42.00 42.00 42.00 42.00

Outlet

24.00 22.00 20.00 18.00 16.00

34.00 32.00 30.00 28.00 26.00 24.00 22.00 20.00 18.00 16.00

36.00 34.00 32.00 30.00 28.00 26.00 24.00 22.00 20.00 18.00

38.00 36.00 34.00 32.00 30.00 28.00 26.00 24.00 22.00 20.00 18.00

40.00 38.00 36.00 34.00 32.00 30.00 28.00 26.00 24.00 22.00 20.00 18.00 16.00

Center-to-End

Run C

25.00 25.00 25.00 25.00 25.00

26.50 26.50 26.50 26.50 26.50 26.50 26.50 26.50 26.50 26.50

28.00 28.00 28.00 28.00 28.00 28.00 28.00 28.00 28.00 28.00

29.50 29.50 29.50 29.50 29.50 29.50 29.50 29.50 29.50 29.50 29.50

30.00 30.00 30.00 30.00 30.00 30.00 30.00 30.00 30.00 30.00 30.00 30.00 30.00

Outlet (1 ) M

23.00 22.50 22.00 21 -50 21 .o0

26.00 25.50 25.00 24.50 24.50 24.00 23.50 23.00 22.50 22.00

28.00 27.50 27.00 26.50 25.50 25.50 25.00 24.50 24.00 23.50

29.50 29.00 28.50 28.00 27.50 26.50 26.50 26.00 25.50 25.00 24.50

28.00 28.00 28.00 28.00 28.00 28.00 27.50 27.50 26.00 26.00 26.00 25.50 25.00

(Table 6 continues on next page)

13

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME B1 6.9-1 993 FACTORY-MADE WROUGHT STEEL BUTTWELDING FlTllNGS

TABLE 6 DIMENSIONS OF REDUCING OUTLET TEES AND REDUCING OUTLET

CROSSES (CONT’DI

Nominal Pipe Size

(NPSI

44 x 44 x 42 44 x 44 x 40

44 x 44 x 36 44 x 44 x 34 44 x 44 x 32 44 x 44. x 30

44 x 44 x 26 44 x 44 x 24 44 x 44 x 22 44 x 44 x 20

46 x 46 x 44 46 x 46 x 42 46 x 46 x 40 46 x 46 x 38 46 x 46 x 36 46 x 46 x 34 46 x 46 x 32 46 x 46 x 30

46 x 46 x 26 46 x 46 x 24 46 x 46 x 22

44 X 44 X 38

44 x 44 x 28

46 X 46 X 28

48 X 48 X 46 48 X 48 X 44 48 X 48 X 42 48 X 48 X 40 48 x 48 X 38 48 X 48 X 36 48 X 48 X 34 48 X 48 X 32 48 X 48 X 30 48 X 48 X 28 48 X 48 X 26 48 X 48 X 24 48 X 48 X 22

Outside Diameter at Bevel

D

Run

44.00 44.00 44.00 44.00 44.00 44.00 44.00 44.00 44.00 44.00 44.00 44.00

46.00 46.00 46.00 46.00 46.00 46.00 46.00 46.00 46.00 46.00 46.00 46.00

48.00 48.00 48.00 48.00 48.00 48.00 48.00 48.00 48.00 48.00 48.00 48.00 48.00

Outlet

42.00 40.00

36.00 34.00 32.00 30.00

26.00 24.00 22.00 20.00

44.00 42.00 40.00

36.00 34.00 32.00 30.00

26.00 24.00 22.00

46.00 44.00 42.00 40.00

36.00 34.00 32.00 30.00

26.00 24.00 22.00

38.00

28.00

38.00

28.00

38.00

28.00

Center-to-End

Run C

32.00 32.00 32.00 32.00 32.00 32.00 32.00 32.00 32.00 32.00 32.00 32.00

33.50 33.50 33.50 33.50 33.50 33.50 33.50 33.50 33.50 33.50 33.50 33.50

35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00 35.00

GENERAL NOTE: Dimensions are in inches.

3utlet (1 1 M

30.00 29.50 29.00

28.50 28.00 28.00 27.50 27.50 27.50 27.00 27.00

31.50 3 1 .O0 30.50 30.00 30.00 29.50 29.50 29.00 29.00 29.00

28.50

28.50 28.50

33.00 33.00 32.00 32.00 32.00 31 .O0 31 .O0 31 .O0 30.00 30.00 30.00 29.00 29.00

NOTE: (1) Outlet dimension M for run sizes 14 and larger is recom-

mended but not required.

14

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME 836.9 93 H O759670 0533539 682 m

FACTORY-MADE WROUGHT STEEL BUTTWELDING FITTINGS ASME B1 6.9-1 993

Nominal Pipe Size

W S )

'12

3/4 1 1 '14 1 '12

2 2 '12

3 3 '12

4

5 6

10 12

14 16

20 22 24

a

18

[Note

[Note

Note square COI rner

Enlarged section of lap

TABLE 7 DIMENSIONS OF LAP JOINT STUB ENDS

Outside Diameter at Bevel

D

0.84 1 .O5 1.32 1.66 1.90

2.38

3.50 4.00 4.50

5.56 6.62

10.75 12.75

14.00 16.00

20.00 22.00 24.00

2.88

8.62

I 8.00

Long Pattern Length (21,(3),(7)

F

3.00 3.00 4.00 4.00 4.00

6.00 6.00 6.00 6.00 6.00

8.00 a .o0 8.00

10.00 10.00

12.00 12.00 12.00 12.00 12.00 12.00

Short Pattern Length (2),(3),(71

F

2.00 2 .o0 2 .o0 2 .o0 2.00

2.50 2.50 2.50 3.00 3.00

3.00 3.50 4.00 5.00 6.00

6.00 6.00 6.00 6.00 6.00 6.00

Radius of

Fillet (4) R

0.12 0.12 0.12 0.19 0.25

0.31 0.31 0.38 0.38 0.44

0.44 O. 50 O. 50 O. 50 O. 50

O. 50 O. 50 O. 50 O. 50 0.50 O. 50

liameter Diameter of Barrel

Max.

1.38 0.896 1.69

1.376 2.00 1.106

1.716 2.50 2.88 1.965

3.62

6.19 4.096 5.50 3.596 5.00 2.966 4.12 2.456

.4.593

7.31 5.683 8.50

8.743 10.62 6.743

12.75 12.913 15.00 10.913

14.170 16.25

21.00 18.190 23.00 20.240 25.25 22.240 27.25 24.240

18.50 16.180

Min.

0.809

1 .284 1 .o1 9

1.629 1.869

2.344

3.469 3.969 4.469

5.532 6.594

10.719 12.719

13.969 15.969 17.969 19.969 21.969 23.969

2. 844

8.594

GENERAL NOTES: (a) Dimensions are in inches. (bl See Table 1 for tolerances.

NOTES: (1 The lap thickness T shall not be less than nominal pipe wall thickness. (2) When short pattern stub ends are used with larger flanges in Classes 300 and 600, and with most

sizes in Classes 900 and higher, and when long pattern stub ends are used with larger flanges in Classes 1500 and 2500, it may be necessary to increase the length of the stub ends in order to avoid covering the weld with the flange. Such increases in length shall be a matter of agreement between the manufacturer and the purchaser.

(3) When special facings such as tongue and groove, male and female, etc., are employed, additional lap thickness must be provided and such additional thickness shall be in addition to (not included in) the basic length F.

(4) These dimensions conform to the radius established for lap joint flanges in ASME/ANSI 816.5. Pipe Flanges and Flanged Fittings.

(5) This dimension conforms to standard machine facings shown in ASME/ANSI B16.5. The back face of the lap shall be machined to conform to the surface on which it seats. Where ring joint facings are to be applied use dimension Kas given in ASME/ANSI B1 6.5.

(6) Gasket face finish shall be in accordance with ASME/ANSI B16.5 for raised face flanges. (7) The long pattern shall be the standard when not specified by the purchaser. The short pattern

shall be specified by the purchaser.

15

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME Elhm9 9 3 m 0759b70 0533540 3 T 4 m

ASME B I 6.9-1 993

Nominal Pipe Sire

W S )

' I 2

3/4

1 1 '14

1 '12

2 2'12 3 3 'h 4

5 6 8 10 12

14 16 18 20 22

24 26 28 30 32

34 36 38 40 42

44 46 48

FACTORY-MADE WROUGHT STEEL BUTTWELDING FITTINGS

TABLE 8 DIMENSIONS OF CAPS

Outside Diameter at Bevel

D

0.84 1 .O5 1.32 1.66 1.90

2.38 2.88 3.50 4.00 4.50

5.56 6.62 8.62 10.75 12.75

14.00 16.00 18.00 20.00 22.00

24.00 26.00 28.00 30.00 32.00

34.00 36.00 38.00 40.00 42.00

44.00 46.00 48.00

Length (1 I E

1 .o0 1 .o0 1.50 1.50 1.50

1.50 1.50 2.00 2.50 2.50

3.00 3.50 4.00 5 .O0 6.00

6.50 7.00 8.00 9 .o0 10.00

10.50 10.50 10.50 10.50 10.50

10.50 10.50 12.00 12.00 12.00

13.50 13.50 13.50

Limiting Mall Thick- ness for Length E

0.18 0.1 5 0.1 8 0.19 o. 20 0.22 O. 28 0.30 0.32 O. 34

0.38 0.43 O. 50 O. 50 O. 50

O. 50 O. 50 O. 50 O. 50 O. 50

O. 50 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Length (2) €1

1 .o0 1 .o0 1.50 1.50 1.50

1.75 2.00 2.50 3.00 3.00

3.50 4.00 5.00 6.00 7.00

7.50 8.00 9.00 10.00 10.00

12.00 . . . . . . . . . . . . . . . . . . * . . . . . . . . . . . . . . . . .

GENERAL NOTES: (a) Dimensions are in inches. (b) The shape of these caps shall be ellipsoidal and shall con-

form to the shape requirements as given in the ASME Boiler and Pressure Vessel Code.

NOTES: (1 ) Length E applies for thickness not exceeding that given in

column "Limiting Wall Thickness for Length E." (2) Length E, applies for thickness greater than that given in

column "Limiting Wall Thickness" for NPS 24 and smaller. For NPS 26 and larger, length E, shall be by agreement be- tween manufacturer and purchaser.

16

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME B1609 93 m 0759670 0533543 230 m

FACTORY-MADE WROUGHT STEEL BUTTWELDING FllTlNGS ASME B I 6.9-1 993

TABLE 9 DIMENSIONS OF REDUCERS

Outside Diameter at Bevel D

Large End

1 .O5 1 .O5 1.32 1.32

1.66 1.66 1.66

1.90 1.90 1.90 1.90

2.38 2.38 2.38 2.38

2.88 2.88 2.88 2.88

3.50 3.50 3.50 3.50

4.00 4.00 4.00 4.00 4.00

4.50 4.50 4.50 4.50 4.50

5.56 5.56 5.56 5.56 5.56

Small End

0.84 0.68 1 .O5 0.84

1.32 1 .O5 0.84

1.66 1.32 1 .O5 0.84

1.90 1.66 1.32 1 .O5

2.38 1.90 1.66 1.32

2.88 2.38 1.90 1.66

3.50 2.88 2.38 1.90 1.66

4.00 3.50 2.88 2.38 1.90

4.50 4.00 3.50 2.88 2.38

End-to-End H

1.50 1.50 2.00 2.00

2.00 2.00 2.00

2.50 2.50 2.50 2.50

3.00 3.00 3.00 3.00

3.50 3.50 3.50 3.50

3.50 3.50 3.50 3.50

4.00 4.00 4.00 4.00 4.00

4.00 4.00 4.00 4.00 4.00

5.00 5 .O0 5.00 5.00 5.00

Nominal Pipe Size

W S )

6 x 5 6 x 4 6 x 3'12 6 x 3 6 x 2112

8 x 6 8 x 5 8 x 4 8 X 3112

10 x 8 10 x 6 10 x 5 10 x 4

12 x 10 12 x 8 12 x 6 12 x 5

14 x 12 14 x 10 14 x 8 14 x 6

16 x 14 16 x 12 16 x 10 16 x 8

18 x 16 18 x 14 18 x 12 18 x 10

20 x 18 20 x 16 20 x 14 20 x 12

22 x 20 22 x 18 22 x 16 22 x 14

r Outside Diameter at Bevel D

Large End

6.62 6.62 6.62 6.62 6.62

8.62 8.62 8.62 8.62

10.75 10.75 10.75 10.75

12.75 12.75 12.75 12.75

14.00 14.00' 14.00 14.00

16.00 16.00 16.00 16.00

18.00 18.00 18.00 18.00

20.00 20.00 20.00 20.00

22.00 22.00 22.00 22.00

Small End

5.56 4.50 4.00 3.50 2.88

6.62 5.56 4.50 4.00

8.62 6.62 5.56 4.50

10.75 8.62 6.62 5.56

12.75 10.75 8.62 6.62

14.00 12.75 10.75 8.62

16.00 14.00 12.75 10.75

18.00 16.00 14.00 12.75

20.00 18.00 16.00 14.00

r End-to-End

H

5.50 5.50 5.50 5.50 5.50

6.00 6.00 6.00 6.00

7.00 7.00 7.00 7.00

8.00 8.00 8.00 8.00

13.00 13.00 13.00 13.00

14.00 14.00 14.00 14.00

15.00 15.00 15.00 15.00

20.00 20.00 20.00 20.00

20.00 20.00 20.00 20.00

17

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME B3b.S 93 m 0759670 0533542 377 M

ASME B1 6.9-1 993 FACTORY-MADE WROUGHT STEEL BUTTWELDING FITTINGS

TABLE 9 DIMENSIONS OF REDUCERS (CONT'D)

Nominal Pipe Size

(NPS)

24 x 22 24 x 20

24 x 16

26 x 24 26 x 22 26 x 20

24 X 18

26 x 18

28 X 26 28 X 24 28 X 20 28 X 18

30 X 28 30 x 26 30 x 24 30 x 20

32 x 30

32 x 26 32 x 24

34 x 32 34 x 30 34 x 26 34 x 24

36 x 34 36 x 32 36 x 30 36 x 26 36 x 24

32 X 28

i Outside Diameter at Bevel D "

Large End

24.00 24.00 24.00 24.00

26.00 26.00 26.00 26.00

28.00 28.00 28.00 28.00

30.00 30.00 30.00 30.00

32.00 32.00 32.00 32.00

34.00 34.00 34.00 34.00

36.00 36.00 36.00 36.00 36.00

Small End

22.00 20.00 18.00 16.00

24.00 22.00 20.00 18.00

26.00 24.00 20.00 18.00

28.00 26.00 24.00 20.00

30.00 28.00 26.00 24.00

32.00 30.00 26.00 24.00

34.00 32.00 30.00 26.00 24.00

End-to-End H

20.00 20.00 20.00 20.00

24.00 24.00 24.00 24.00

24.00 24.00 24.00 24.00

24.00 24.00 24.00 24.00

24.00 24.00 24.00 24.00

24.00 24.00 24.00 24.00

24.00 24.00 24.00 24.00 24.00

GENERAL NOTE: Dimensions are in inches.

18

Nominal Pipe Size

(NPS)

38 X 36 38 X 34 38 X 32 38 X 30 38 X 28 38 X 26

40 x 38 40 x 36 40 x 34 40 x 32 40 x 30

42 x 40

42 x 36 42 x 34 42 x 32 42 x 30

42 X 38

44 x 42 44 x 40

44 x 36

46 x 44 46 x 42 46 x 40

44 X 38

46 X 38

48 X 46 48 X 44 48 X 42 48 X 40

r Outside Diameter at Bevel D

Large End

38.00 38.00 38.00 38.00 38.00 38.00

40.00 40.00 40.00 40.00 40.00

42.00 42.00 42.00 42.00 42.00 42.00

44.00 44.00 44.00 44.00

46.00 46.00 46.00 46.00

48.00 48.00

48.00 48.00

Small End

36.00 34.00 32.00 30.00

26.00 28.00

38.00 36.00 34.00 32.00 30.00

40.00

36.00 34.00 32.00 30.00

38.00

42.00 40.00

36.00 38.00

44.00 42.00 40.00 38.00

46.00 44.00 42.00 40.00

r End-to-End

H

24.00 24.00 24.00 24.00 24.00 24.00

24.00 24.00 24.00 24.00 24.00

24.00 24.00 24.00 24.00 24.00 24.00

24.00 24.00 24.00 24.00

28.00 28.00 28.00 28.00

28.00 28.00 28.00 28.00

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME BLb.9 93 0759670 0533543 003

FACTORY-MADE WROUGHT STEEL BUTTWELDING FITTINGS

ANNEX A

METRIC (SI) TABLES

(This Annex is an integral part of ASME 816.9-1993 and is placed after the main text for convenience.)

ASME B1 6.9-1 993

O The technique of rounding the metric conversions of the inch dimensions recognized two basic categories of dimensions occurring in this Standard, based upon the function or safety significance of variations in the dimensions.

Where-some slight shift of the absolute value of the minimum and maximum dimensions permitted by the inch dimensions and those provided by the converted metric dimensions do not unacceptably affect the functional or safety characteristics of the fitting, the metric con- versions have been rounded to whole millimeter values in order to facilitate ease of measure- ment by ordinary measuring tapes or rulers with nonmagnified vision. Furthermore, the rounding has not always been made to the nearest whole millimeter. In some cases it has been made to the whole millimeter, which would facilitate tables manifesting logical incre- ments in both the dimensions and their tolerances. It is recognized that the introduction of such variances will create a conflict in the acceptance dimensions or gaging between the inch and metric data. Experience indicates a probability that no serious difficulties will result from this conflict. Hence it is the intent of this Standard that any dimension that is within tolerance by either metric or inch measurement is considered to be in conformance with this Standard.

Where it was considered advisable to limit the variance between the minimum and maxi- mum dimensions permitted by the existing tolerances and those permitted by the converted metric dimensions, closer rounding was utilized.

The metric dimensions shown in Tables Al through A9 are for information and refer- ence. They are not exact equivalents of the dimensions in Tables 1 through 9. If used by agreement between manufacturer and purchaser, complete dimensional interchangeability with standard components cannot be assured. Use of a combination of standard and metric values is contrary to the intent of this Standard.

O

19

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME B3b-9 93 D 0759670 0533544 T 4 T m

ASME B1 6.9-1 993 FACTORY-MADE WROUGHT STEEL BUTWELDING FITTINGS

e

e

e

e

e

rrel(V(Vhl(V(V 1 1 1 1 1 1 1 1 . . 0 0 0 0 0 0 0 0 : : + + + + + + + +

""r(VF((U

1 1 1 1 1 1 1 1 - . 0 0 0 0 0 0 0 0 : : + + + + + + + +

. .

m E c d d, U o O z

o P

S

20

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

TABL

E A

l TO

LER

ANC

ES

(CO

NT’

DI

‘I2 to

4

5 to

8 lot

0 12

14

to 16

16

to24

26

to

30

32

to 42

44

to

48

This

end

flush

’again

st sq

uare

GENE

RAL

NOTE

: Di

mens

ions

are

in mi

llimet

ers

(exce

pt NP

S).

Toler

ance

s ar

e eq

ual

plus

and

minu

s ex

cept

as

noted

.

NOTE

S:

(1)

Out-o

f-rou

nd

is the

su

m of

abso

lute

value

s of

plus

and

minu

s tol

eran

ce.

(2)

This

toler

ance

ma

y be

exc

eede

d in

locali

zed

areas

of

forme

d fitt

ings

wher

e inc

reas

ed

wall

thick

ness

is

requ

ired

to me

et

desig

n re-

qu

ireme

nts

of pa

ra.

2.2

(3)

The

inside

dia

meter

an

d the

no

mina

l wa

ll thi

ckne

sses

at

ends

ar

e to

be

spec

ified

by

the

purch

aser.

(4)

Un

less

other

wise

sp

ecifie

d by

the

pu

rchas

er,

these

tol

eran

ces

apply

to

the

nomi

nal

inside

dia

meter

, wh

ich

equa

ls the

dif

feren

ce

be-

twee

n the

no

mina

l ou

tside

dia

meter

an

d tw

ice

the

nomi

nal

wall

thick

ness

.

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME BLb.9 93 W 0759b70 0533546 832 W

ASME B1 6.9-1 993 FACTORY-MADE WROUGHT STEEL BUTTWEI

TABLE A2 DIMENSIONS OF LONG RADIUS ELBOWS

Nominal Pipe Size

(NPS)

'h (1 1

1 1 1'12

2 2 'I2

3 3% 4

5 6 8

10 12

14 16 18 20 22

24 26 28 30 32

34 36 38 40 42

44 46 48

Outside Diameter

Min.

20 26 32 41 47

59 72 88

1 o1 113

1 40 167 217 270 321

353 403 454 503 554

605 655 706 757 808

859 909 960

101 1 1062

1113 1163 1214

at Bevel D

Nom.

21 27 33 42 48

60 73 89

102 114

141 168 21 9 273 324

356 406 457 508 559

610 660 71 1 762 81 3

864 914 965

1016 1067

1118 1168 1219

r t Max.

22 28 34 43 49

61 74 90

103 116

144 171 22 1 277 328

360 41 O 46 1 514 565

616 667 718 769 820

87 1 921 972

1023 1074

1125 1175 1226

-DING FllTlNGS

Center-to-End

Min.

36 36 36 46 55

74 93

112 131 150

188 227 303 379 454

530 607 683 759 835

91 1 988

1064 1140 1214

1290 1367 1443 1519 1595

1671 1748 1824

90 deg. Elbows A

Nom.

38 38 38 48 57

76 95

114 133 152

190 229 305 38 1 457

533 610 686 762 838

914 99 1

1067 1143 1219

1295 1372 1448 1524 1 600

1676 1753 1829

r Max.

40 40 40 50 59

78 97

116 135 154

192 23 1 307 383 460

536 61 3 689 765 841

91 7 994

1070 1146 1224

1300 1377 1453 1529 1605

1681 1758 1834

45 dag. Elbows

Min.

14 17 20 23 27

33 42 49 55 62

77 93

125 157 187

21 9 251 283 31 5 340

378 403 435 467 497

528 560 595 627 655

690 722 754

B

Nom.

16 19 22 25 29

35 44 51 57 64

79 95

127 159 1 90

222 254 286 318 343

38 1 406 438 470 502

533 565 600 632 660

695 727 759

Max.

18 21 24 27 31

37 46 53 59 66

81 97

129 161 193

225 257 289 32 1 346

384 409 44 1 473 507

538 570 605 637 665

700 732 764

22

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME B3b-9 93 m 0759b70 0533547 759 m

FACTORY-MADE WROUGHT STEEL BUTTWELDING FITTINGS

0 NOTES TO TABLE A2

GENERAL NOTE: Dimensions are in millimeters.

NOTE (1 ) A and &?dimensions for NPS 3/4 may be as shown below at the manufacturer's option.

23

ASME B1 6.9-1 993

Center-to-End

90 deg. Elbows ~~

45 deg. Elbows A B

Min. Nom. Max. Min. Nom. Max. "- 27 29 31 9 11 13

"-

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME B1 6.9-1 993

Nominal Pipe Sire

INPS)

1 1 '14

1 'h 2 2 'I2

3 3 '12

4 5

. 6

8 10 12 14 16

'1 8 20 22 24

i

FACTORY-MADE WROUGHT STEEL BUTTWELDING FITTINGS

L TABLE A3 DIMENSIONS OF LONG RADIUS REDUCINGELBOWS

Outside Diameter at Bevel

D

Min.

32 41 47 59 72

88 1 o1 113 140 167

217 270 32 1 353 403

454 503 554 60 5

Nom.

33 42 48 60 73

89 102 114 141 168

219 273 324 356 406

457 508 559 610

Max.

34 43 49 61 74

90 103 116 144 171

22 1 277 328 360 41 O

46 1 514 565 616

Nominal Pipe Size

(NPS)

2 x 1 'I2

2 x 1 '14

2 x 1

2'12 x 2 2'12 x 1 'h 2'12 X 1 '14

3 x 2'12 3 x 2 3 x 1 'I2

3% X 3 3% x 2'12 3'12 x 2

4 x 3% 4 x 3 4 x 2% 4 x 2

5 x 4 5 x 3% 5 x 3 5 x 2'12

6 x 5 6 x 4 6 x 3% 6 x 3

8 x 6 8 x 5 8 x 4

GENERAL NOTE: Dimensions are in millimeters.

T Center-to-End

Min.

74 . 74

74

93 93 93

112 112 112

131 131 131

150 150 150 150

188 188 188 188

227 227 227 227

303 303 303

24

A

Nom.

76 76 76

95 95 95

114 114 114

133 133 133

152 152 152 152

190 190 190 190

229 229 229 229

305 305 305

Max.

78 78 78

97 97 97

116 116 116

135 135 135

154 154 154 154

192 192 192 192

231 231 231 231

307 307 307

Nominal Pipe Size

(NPS)

10 x 8 10 x 6 10 x 5

12 x 10 12 x 8 12 x 6

14 x 12 14 x 10 14 x 8

16 x 14 16 x 12 16 x 10

18 x 16 18 x 14 18 x 12 18 x 10

20 x 18 20 x 16 20 x 14 20 x 12 20 x 10

24 x 22 24 x 20 24 x 18 24 x 16 24 x 14 24 x 12

Center-to-End

Min.

379 379 379

454 454 454

530 530 530

607 607 607

683 683 683 683

759 759 759 759 759

91 1 91 1 91 1 91 1 91 1 91 1

A

Nom.

38 1 38 1 38 1

457 457 457

533 533 533

610 610 610

686 686 686 686

762 762 762 762 762

914 914 914 91 4 914 914

Max.

383 383 383

460 460 460

536 536 536

61 3 61 3 613

689 689 689 689

765 765 765 765 765

91 7 917 91 7 917 91 7 91 7

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME Blb .9 93 m 0759b70 0531549 521 m

ASME B1 6.9-1 993 FACTORY-MADE WROUGHT STEEL BUTTWELDING FITTINGS

U

TABLE A4 DIMENSIONS OF LONG RADIUS RETURNS

Outside Diameter Back-to-Face Nominal

Pipe Size

(NPS)

(3)

1 ' h

Center-to-Center at Bevel D

Nom.

21 27 33 42 48

60 73 89

102 114

141 168 21 9 273 324

356 406 457 508

559 610

K

Nom.

48 51 56 70 83

106 132 159 184 210

262 313 414 518 61 9

71 1 81 3 914

1016

1118 1219

O

Nom.

76 76 76 95

114

152 191 229 267 305

38 1 457 610 762 914

1067 1219 1372 1524

1676 1829

Max.

55 58 63 77 90

113 139 166 191 21 7

269 320 42 1 525 626

71 8 820 921

1023

1125 1226

Min.

41 44 49 63 76

99 125 152 177 203

255 306 407 51 1 61 2

704 806 907

1 O09

1111 1212

Max.

83 83 83

102 121

159 198 236 274 31 2

388 464 61 7 772 924

1077 1229 1382 1534

1686 1839

Min.

69 69 69 88

107

145 184 222 260 298

374 450 603 752 904

1057 1209 1362 1514

1666 1819

Max.

22 28 34 43 49

61 74 90

103 116

144 171 22 1 277 328

360 41 O 46 1 514

565 61 6

Min.

20 26 32 41 47

59 72 88

101 113

1 40 167 217 270 32 1

353 403 454 503

5 54 605

5 6 8

10 12

14 16 18 20

GENERAL NOTE: Dimensions are in millimeters.

NOTES: (1) See Table A I for tolerance for alignment of ends U. (2) Dimension A is equal to one-half of dimension O. (3) O and K dimensions for size NPS 3/4 may be as shown below at the manufacturer's option.

Center-to-Center Back-to-Face O K

Min. Nom. Max. Min. Nom. Max. "- 50 57 64 36 43 50

"-

25

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

ASME B1b.9 93 0759b70 0533550 243

ASME B16.9-1993 FACTORY-MADE WROUGHT STEEL BUTTWELDING FllTlNGS

TABLE A5 DIMENSIONS OF STRAIGHT TEES AND CROSSES

Nominal Pipe Size

(NPS)

2 2'12 ' 3 3% 4

5 6 8

10 12

14 16 18 20 22

24 26 28 30 32

34 36 38 40 42

44 46 48

Outside Diameter at Bevel

D

l Center-to-End

Run Outlet (11. (2) C M

Min.

20 26 32 41 47

59 72 88

1 o1 113

1 40 167 217 270 32 1

353 403 454 503 554

605 655 706 757 808

859 909 960

101 1 1062

1113 1163 1214

Nom.

21 27 33 42 48

60 73 89

102 114

141 168 219 273 324

356 406 457 508 5 59

610 660 71 1 762 813

864 914 965

1016 1067

1118 1168 1219

Max.

22 28 34 43 49

61 74 90

103 116

144 171 221 277 328

360 410 461 514 565

616 667 718 769 820

871 921 972

1023 1074

1125 1175 1226

Min.

23 27 36 46 55

62 74 84 93

103

122 141 176 214 25 1

276 302 340 378 41 6

429 49 2 518 556 592

630 668 706 744 757

808 846 884

Nom.

25 29 38 48 57

64 76 86 95

105

124 143 178 21 6 254

279 305 343 38 1 41 9

432 495 52 1 559 597

635 673 71 1 749 762

81 3 85 1 889

Max.

27 31 40 50 59

66 78 88 97

107

126 145 180 21 8 257

282 308 346 384 422

435 498 524 562 602

640 678 71 6 754 767

81 8 856 894

~~ ~~~

GENERAL NOTE: Dimensions are in millimeters.

NOTES: (1 1 Outlet dimension M for NPS 26 and larger is recommended but not required. (2) Dimensions applicable to crosses NPS 24 and smaller.

Min.

23 27 36 46 55

62 74 84 93

103

122 141 176 214 25 1

276 302 340 378 41 6

429 492 518 556 592

630 668 706 744 706

757 795 833

Nom. 1 Max.

25

59 57 50 48 40 38 31 29 27

64 66 76 78 86 88 95 97

105 107

124 126 143 145 178 180 21 6 218 254 257

279 282 305 308 343 346 38 1 384 41 9 422

432 435 495 498 52 1 524 559 562 597 602

635 640 673 678 71 1 716 749 7 54 71 1 716

762 800

767

843 838 805

26

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

FACTORY-MADE WROUGHT STEEL BUTTWELDING FITTINGS ASME B I 6.9-1993

TABLE A6 DIMENSIONS OF REDUCING OUTLET TEES AND REDUCING OUTLET CROSSES

a Nominal

Pipe Size

INPSI

T

1 'I2 x 1 'I2 x 1

1'12 x 1'12 x '12

2 x 2 x 1'12 2 x 2 x 11/4

2 X 2 X 1 2 X 2 X 314

1 x 1 '12 x 314

2'12 x 2'12 x 2 2% x 2'/2 x 1112

2% x 2'12 x 1 X 2'h x 1

a 3 x 3 x 2'12 3 X 3 X 2 3 x 3 x 1'12

Outside Diameter of Reducing Tees and Crosses

Min.

20 20 26 26

32 32

41 41 41

47 47 47 47

59 59 59 59

72 72 72 72

88 88 88 88

101 1 o1 1 o1 101

113 113 113 113 113

Run D

Nom.

21 21 27 27

33 33

42 42 42

48 48 48 48

60 60 60 60

73 73 73 73

89 89 89 89

102 102 102 102

114 114 113 114 114

Max.

22 22 28 28

34 34

43 43 43

49 49 49 49

61 61 61 61

74 74 74 74

90 90 90 90

103 103 103 103

116 116 116 116 116

Min.

16 13 20 16

26 20

32 26 20

-41 32 26 20

47 41 32 26

59 47 41 32

72 59 47 41

88 72 59 47

1 o1 88 72 59 47

Outlet D

Nom.

17 14 21 17

27 21

33 27 21

42 33 27 21

48 42 33 27

60 48 42 33

73 60 48 42

89 73 60 48

102 89 73 60 48

a (Notes follow at end of table)

21

Max.

18 15 22 18

28 22

34 28 22

43 34 28 22

49 43 34 28

61 49 43 34

74 61 49 43

90 74 61 49

103 90 74 61 49

-

T Center-to-End Lengths of Tees and Crosses

t Min.

23 23 27 27

36 36

46 46 46