25

Transcript of 25

1

BRIGHT NIGHTBright Night is an easily brandable wrist torch. Whether used for the late night walk home or for raving, it is the perfect handsfree accessory.

Adam Coleberd (1021564)

ContentsBriefThe ProblemFirst Initial SolutionsExisting ProductsThe UseMarket researchResearch based ideasHuman FactorsElectronicsDevelopment Protomold AnalysisMaterial ChoicePrintingManufacturing MethodsManufacturing SystemsFinal ProductBPMA ProposalConcept BoardManufacture & costingGeneral Arrangement DrawingReferences

3456789

1012141819

2021

222425262728

3

BriefProduce a new innovative promotional product which can be manufactured for £2.50 or under suitable for manufacture of 10,000 to 100,000 units.

4

The ProblemOn the way home from a night out I was walking along the street, which in West Dorset is usually a dark, fairly quiet street. I made it to my door and stood there thumbling with my keys. The challenge was finding the keyhole and getting the right key in to be able to unlock the door. This has happened many times to myself, although the dark streets isn’t always an issue, often finding the keyhole and the right key is. After discussing this issue with my parents and other family members, it was clear it wasn’t just myself that suffered this problem. When talking about the issue with my sisters, they highlighted the fact that sometimes they feel a little uneasy when walking along dark streets alone.I suggested the idea of them carrying a little torch in their handbag. The main argument against carrying a torch was that it would take up space and also mean the effort of looking through their bag to find it and another thing to just have the hassle of, particularly when intoxicated.I asked were they against perhaps using a torch if it wasn’t as much effort to have on them.They said yes, as long as it wasn’t a restricting object.

Updated Brief- Produce a torch which is unrestricting.- Practical.- Low hassle.

5

First Initial SolutionsSketches of first ideas were from traditional torches to lights which attached to an ear or finger.

6

Existing Products

All of the products pictured are sold for no more than £3. They are predominantly little torches with extra functions, making them more desirable as a product. These products show that there is not only an obvious market for handy torches, but also that they can be manufactured under our brief unit price of £2.50.

Charity wrist bands have taken off in a big way and have been very popular for several years now. Cheap to produce and easily branded. They have developed into other items such as usb wristbands as shown below which are already given away as promotional products by some companies.

Rebel Patents Wristband Torch.This seemed to be the only vaguely similar torch i could find to my initial ideas. It is very bulky, but also includes extra features such as flashing amber lights. It uses 3 x AAA batteries.

7

The Use

8

Yes

No

Yes

No

Yes

No

Yes

No

Do you already or are you happy to wear something on your wrist?

Have you ever needed a torch but haven’t had one on you?

Do you struggle to find your keys or your door lock in the dark?

If you are ever on a night out or at a festival, do you ever hold or wrap glowstocks around your wrists?

Market Research2011 Sales by Product Category

2010 figures in brackets.

Above is the estimated figures of promotional products distributor sales by category for 2011 collated by PPAI. This market was worth:

$17.72 BillionAn estimated 29.64% was made up of wearable products, such as t-shirts, neck wear, head and wrist bands. To be able to have a product within this kind of size market would be a significant boost.Other markets this product could have the potential to hit are: Personal and Electronic.These 3 markets have a combined market share of

34.52% equals an estimated $6.12 Billion.

Knowing the potential market size of the product, some more in depth market research was done. This is all shown above. It shows that most people are happy to wear something on their wrist and that the majority have also needed a torch when they haven’t had one. This gives a clear indication that their is potential for this product. It is shown that the majority of people asked in this survey have worn or held glowsticks, and have at some point struggled to find keys or the door lock when it is dark. This immediately confirms that the potential market for clients to use this product as a promotion of their company extends into other areas which have been previously highlighted.

9

This shows the movement from initial solutions to the ideas developed from the market research. A wrist torch, realised into an idea. Using photoshop and a quick CAD model to show a better representation of the potential product.

Research Based Ideas

10

Human FactorsThe product needs to fit peoples wrists, because of similar items such as charity wristbands, it makes sense to base the dimensions on those of the bands.

Additional anthropometric data was collected. Pictured below is the data of:1% women (smallest) to 99% men (biggest). Its shows a hand width range of 69mm to 99mm.Wrist width of 51mm to 76mm.

The band needs to be able to get over the hand whilst also being able to be relatively tight on the wrist to stay on. Most charities focus predominantly on the adult wrist bands as this size would then fit all although maybe loose on some.Looking at www.gowristbands.co.uk, a leading wristband manufacturer, they produce the following sizes for adults: 202mm - Adults 192mm - mostly Women and Young Adults.

Go wristbands also only produce two widths of wristbands which are 12mm and 25mm. This is a good guide for the width of the band of the product. These sizes are both comfortable and sustain everyday wear. The torch block on one part of the band will need to be wider than the rest of the band. Knowing 25mm has a sustained market as a wristband shows that having a part of the product as wide as that on the wrist is acceptable. Although comparitive products such as watches can be much larger in size.

11

Bright Night will guide you home

12

ElectronicsThe product needs to fit peoples wrists. because of similar items such as charity, it makes sense to base the dimensions on those of the bands.

Below shows the break of the main electronic components in this multi function camping torch. The electronics is more complex than needed for my product as it contains an LED on each end, which both have separate functions. All controlled from the single button with multiple presses. I have pictured the main electronics including the space for the cell batteries on my wrist, to show size.

Above shows a couple demonstrations of 3 and 2 LED circuits. The 3 LEDs shown needed 7.5V to light them. The 2 LEDs needed only 5V. There will be limited space in the cavity for the cells which will power the LEDs. If the LEDs were in parallel, the Voltage required would be reduced.

Below shows the use of a small button in the 2 LED series circuit. A button will be placed below the top edge of the cavity. As the material of the main body is flexible, when the top is pressed it will press the button switching on/off the light.

After talks with an electrical engineer, the circuit was discussed and the LEDs were put into parallel, this meant using 3volt LEDs that 2 or 3 could be run off one 3volt cell. The engineer also noted that the use of a 150 ohm resistor in series with each 3volt LED would reduce the chance of failure. This is due to the resistor reducing the current flow sufficiently. The engineer gave prices for LEDs which would be under £0.05 each and that a PCB would cost for this application £0.08, and the flow soldering would be around £0.10. The suppliers RS components and Rapid components were suggested for the other items.

In order to make a PCB first you must make a schematic diagram of the circuit you wish to have printed, it is then transferred on computer software such as Easy Peasy. The file is then sent to print which prints the desired circuit on the board. Hence why it is called a printed circuit board. The PCB would then have the required components placed in position on it, the legs of the components would then be bent over to avoid risk of the components falling out. The boards would then be placed on a conveyor in a flow soldering machine. This takes the board and as shown overleaf, sprays flux on the components legs and track, it then undergoes heating. This process helps the solder flow along the required paths. Molten solder which is pulsated to cause a wave, touches the tracks and flows where required soldering the components in place. This is a very time saving manufacturing process. Ideal for the manufacture of a 100,000 units. Manual soldering would be very time consuming and labour cost would be increased.

13

Component

LED

Switch

PCB

Cell

Manufacture

Cost

£0.05

£0.14

£0.08

£0.25

£0.10

Quantity

2

1

1

1

TOTAL

Total

£0.10

£0.14

£0.08

£0.25

£0.67

ElectronicsA prototype of the intended circuit was made to test the theory of components would work.

The total from the values found and the suggested values by the engineer come to £0.67 per unit.When looking at the product on the previous page. This was bought for £1.00.

Bearing in mind that a product at market has usually over a 50% profit margin. Then taking into account shipping and handling. The product which also had some injection moulded parts, would have cost a lot less than the full costing opposite. Although it is that costing which will be taken forward as the guide for the product. With the information here in mind.

The circuit was made using a push to make switch. For the actual product a on/off switch would be used

The image above demonstrates a single LED torch which was bought powered by 3 small button cells. This demonstrates that the proposed 2 LED torch would be bright enough to make a difference.

14

Development Protomold AnalysisThe initial CAD model was sent for quotation to Protomold. They sent back a full quotation along with a full analysis of the components. They highlight the issues with the model and explain the changes needed to be able to carry out a better quality moulding.

Below shows the initial model which was sent for analysis. This shows how a draft angle is needed for easier removal from the mould giving a better quality end result.

The image shows the modification made to the strap giving a small draft angle from the centre split line out. Allowing an easier realise from the mould.

Draft angles were added where highlighted by protomold.

15

Protomold highlighted the issue of an undercut on the model, which wouldn’t be able to be moulded.

The product was re-modelled without the undercuts. Shown below.

Another potential issue highlighted by Protomold was that the parts in dark blue were thicker than nominal. With the new model, the thickness was decreased with a larger wider internal cavity which minimises the thicker areas. Also allowing a better space for the electronic components.

16

Development Protomold Analysis continuedInjection Moulding is the process Protomold use. However, they do not mould silicone. The pieces were still analysed for their costing evaluation and analysis of the components themselves as shown previously.

Protomold Costing

Main Body

Tooling price: £1,627.00

Based on the use of: ABS, Clear (Polylac PA-758)Quantity based unit price: 1,000 £1.76 10,000 £1.15 100,000 £1.10

Lens

Tooling price: £959.00

Based on the use of: Acrylic (PMMA), Clear (Plexiglas 6N)Quantity based unit price: 1,000 £1.45 10,000 £0.86 100,000 £0.83

Add £333.00 setup charge to each lot of production parts.

Due to Protomold not having the desired material, using the settings in SolidWorks, the density was changed to that of Silicone 2329Kg/m . Using this the programme worked out the weight of the main body allowing a calculation of cost for silicone using the cost per tonne price.

Main Body

Cost per tonne = £2100.00 Kg = £2.10 g = £0.0021 x 29.20 = £0.06132Based on the use of: Silicone

Although this cost is considerably less than Protomold, it doesn’t include labour costs. A cost for silicone moulding was unavailable as most suppliers wouldn’t take my proposed concept seriously I believe due to asking for the numbers I needed.

The lens had no major issues that needed looking at from the protomold analysis. The only potential issue was the thickness highlighted in blue. But it is something, that is only a worry. More than likely would be fine. It is something that after an initial batch could be looked at should sinking be an issue.

The lens could be glued into position by hand using a silicone adhesive. Once the electronics would be in place. Talking to a Modelling specialist, it would be a minimal amount to adhere the two components. A suitable sealant is about £4.50 for a large tube.

17

Another potential process which could be used for the manufacture of the main body and lens of the product is compression moulding. Although slightly different processes would be used for the

This is when an excess amount of rubber is placed into one half of the mould and then is compressed using the other half of the mould along with being heated. The excess amount of material gives a thorough and even distribution around the mould. When the pressure and heat is removed the product is released from the mould.

When using rubber it is a slower process than using plastics. Rubber would have an expected 10 minute cycle time compared to 2 minutes for plastics.

Costing for compression moulding is roughly 3-4 times the material cost. With what is described as moderate tooling costs. Injection moulding would generally have a higher tooling cost although does depend on cavities. Injection moulding would generally have a better surface finish.

18

Material Choice

Material

Polypropylene

LDPE

Silicone

Natural Rubber

Cost/Tonne

£620

£1017

£2100

£1980

Density (Kg/m )

905

920

2329

1100

Flexible

Semi

Semi

Yes

Yes

The material selection for the main body of the product is based upon products which already exist. All four materials listed are ones which can be manufactured using common mass manufacturing processes. The main ones to produce the intended product would be: - Injection moulding - Compression moulding - Blow moulding

Material

Polypropylene

HDPE

Acrylic

PET

Cost/Tonne

£620

£1097

£985

£560

Density (Kg/m )

905

960

1150

1455

Flexible

Semi

Semi

Semi

Semi

The selection of material for the lens is a little more complex as there are a few materials capable of producing the component desired. PET is often for bottles whilst, HDPE is mainly for use for similar purposes but also chopping boards and such like.Glass although a very good material for lenses, it isn’t in this case the best material for the job. Without additional processes, it is a very brittle material. This isn’t suitable for a product which may be thrown out to people in crowds.

Main Body/ Strap

Lens

Final Choice MaterialSiliconeThe product most similar to the intended main body is the charity bands previously looked at. These are made from silicone. Although the most expensive material highlighted, it is fully flexible unlike the two cheapest materials. The full flexibility would allow the product to easily be taken on and off the wrist without a potentially expensive connector. Being able to keep the part as one piece, minimises processes. For these reasons Silicone will be used to make the main component of this product.

AcrylicThe lens will be made from acrylic, it gives a great finish when injection moulded. Although not the cheapest material, the costing from protomold is acceptable. Knowing a increased lead time could also bring this cost down. Acrylic is also the most common material mentioned used for lenses, which makes it the superior choice.

19

Product Data Sheet

Sylub Inks for Silicone Rubber

The Products These inks are available for the screen or pad printing of silicone rubber. They are supplied as a 2 pack consisting of Sylub Ink and Sylub Catalyst.

Special Features High Gloss Good colour strength Cures to give excellent adhesion to silicone rubber High lightfastness

Printing Information Mix 10 parts of ink to 1 – 1.5 parts of catalyst by weight. The silicone rubber surface should be clean and degreased by wiping with iso-propyl alcohol and allowed to dry completely. The rubber may now be printed in the normal way with the prepared mixed ink. Care should be taken not to handle the rubber surface or allow any grease, oils or contaminants to come into contact with it. Mixed ink and catalyst should be printed and cured within 4 hours of mixing. Duration of cure will depend on the system of heating used but could be 20 minutes at 200C. Adhesion could if necessary be further improved by extending the curing time. Store unmixed ink and catalyst below 27C for maximum shelf life.

After Printing Information Rub resistance Yes Water resistance Yes Elasticity Yes

Popular Basic Colours Product Codes Pack Size Sylub Black 80-SD153 1 Kilo Sylub White 80-SD154 1 Kilo Sylub Catalyst 80-SD116 150 mls Other colours can be supplied to match individual requirements

The above information on this Product Data Sheet is given as a guide only and it is recommended that the inks are tested under the user’s normal conditions to ensure that they are satisfactory for the purpose intended.

Silicone Inks Ltd. Tel/Fax +44 (0)1732 364564. www.siliconeinks.com 23 Cranford Road, Tonbridge, Kent, United Kingdom, TN10 4HL

Printing

The choice of material for the main body of the product was silicone. Because of its properties, it requires special inks. Contact was made with a company called Silicone Inks Ltd. The following information was recieved about the inks they can supply. Including a possible printing process.

Mixing Preparation (2 component ink) The required mix ratio is ten parts by weight of ink to one part by weight of hardener. When machine mixing, avoid prolonged high speeds. Placing the material in a closed container in a cool (below 50°F) environment will extend the mixed pot life. The separate components may be stored in closed containers up to one year at room temperature (72°F). Adhesion improves with increased post curing. Because pigments can settle during storage is suggested that the Silicone Ink be stirred before use. Add the hardener to the ink to assure complete dispersion. Mixing may be done by hand with a spatula or by machine. Avoid stirring in an excessive amount of air. Thinner: If the mixed viscosity is too thick for a specific application, SI Solvent is available to custom design the viscosity for a specific application. Ink Solvent is environmentally friendly. It has zero VOC and will not adversely affect the adhesion of the system. Attention: the use of any solvents or retarders other than those in SI series may adversely affect printing and adhesion. Drying: Silicone Ink must be dried at 204°C (400°F) for 2 – 6 minutes. Caution: contact with some materials will inhibit the drying of Silicone Ink. These include: silicone RTV containing organo-tin catalysts, sulfur- containing compounds, amines, some urethanes, and organic acids. A small-scale compatibility test is always recommended.

This is another process for the mixing of ink suitable for use on silicone. This was found on www.inkcups.com. The process states a drying time could be as little as 2 minutes in the right conditions. This would dramatically reduce the manufacture time. The process would be screen printing the silicone body of the product.

Product on a revolving holder.

Stencil

Squeegee

Ink

The above image is a very simplified demonstration of the screen printing process which is repeated with each colour ink and different stencils to make up the image intended. Even though for mass manufacture, screen printing is still seen a quite manual process due to the need for control and movement of components. Depending on the print, it would cost roughly £0.10.

With reference to www.dowcorning.com, screen printing is potentially one of the best ways to print silicone,

20

Manufacturing MethodsThe decision was made for the use of injection moulding to make the main body of the product. The reason for the decision was that it is a process which gives a very high quality finish. It has a low wastage and is a common process.As shown in the image the process is explained.

The difference between the two components, the main body and lens is the material used. The intended design of the parts will also not require the pictured top action core. As both parts can be simply moulded using only a two part mould.

The material is loaded into the Hopper above a heated driven corkscrew. The material then is released into the corkscrew, which moves the material to the nozzle end. Material is then injected into the mould filling the cavity. The two part mould will be cooled, the gate at the end of the corkscrew will be closed and the mould will be pulled apart and the new moulded part released.

Although the tooling may cost more than other methods, it gives a superior finish than methods such as compression moulding.

Overall Costing

Main Body ElectronicsLensPrintingTOTAL UNIT:

TOTAL 100,000:

£0.06132£0.67£0.83£0.10£1.66132

x 100,000

= £166,132.00

Tooling

TOTAL:

TOTAL 100,000:

£959.00£1627.00

£2586.00

+£166,132.00

£168,718.00

This costing is not fully accurate as it has been hard to get contact with suppliers which deal with silicone. Even after e-mailing and follow up calls. Getting the figures required was difficult.

21

Manufacturing SystemsJust In Time is a manufacturing system in which materials are purchased and units are produced only as needed to meet actual customer demand.In a just in time manufacturing system back stock is reduced to the minimum and in some cases are zero. JIT approach can be used in both manufacturing and merchandising companies. It has big effects, however, on the operations of manufacturing companies which maintain three class ofback stock -raw material, work in process, and finished goods. Traditionally, manufacturing companies have maintained large amounts of all three types of inventories to act as buffers so that operations can proceed smoothly even if there are unanticipated disruptions. Raw materials inventories provide insurance in case suppliers are late with deliveries. Work in process inventories are maintained in case a work station is unable to operate due to a breakdown or other reason. Finished goods inventories are maintained to accommodate unanticipated fluctuations in demand. While these inventories provide buffers against unforeseen events, they have a cost. In addition to the money tied up in the inventories, experts believe that the presence of back stock encourages inefficient and sloppy work, results in too many defects, and dramatically increase the amount of time required to complete a product.Just-In-Time Concept:Under ideal conditions a company operating a JIT manufacturing system would purchase only enough materials each day to meet that days needs. Moreover, the company would have no goods still in process at the end of the day, and all goods completed during the day would have been shipped immediately to customers. As this sequence suggests, "just-in-time" means that raw materials are received just in time to go into production, manufacturing parts are completed just in time to be assembled into products, and products are completed just in time to be shipped to customers.Although few companies have been able to reach this ideal, many companies have been able to reduce back stock only to a fraction of their previous level. The result has been a substantial reduction in ordering and warehousing costs, and much more efficient and effective operations. In a just in time environment, the flow of goods is controlled by a pull approach. The pull approach can be explained as follows. At the final assembly stage a signal is sent to the

preceding work station as to the exact amount of parts and materials that would be needed over the next few hours to assemble products to fill customer orders, and only that amount of materials and parts is provided. The same signal is sent back to each preceding workstation so a smooth flow of parts and materials is maintained with no appreciable inventory buildup at any point. Thus all workstations respond to the pull exerted by the final assembly stage, which in turn respond to customer orders. The pull approach described above can be contrasted to the push approach used in conventional manufacturing system. In conventional system, when a workstation completes its work, the partially completed goods are pushed forward to the next work station regardless of whether that workstation is ready to receive them. The result is an unintentional stockpiling of partially completed goods that may not be completed for days or even weeks. This ties up funds and also results in operating inefficiencies. For one thing, it becomes very difficult to keep track of where every thing is when so much is scattered all over the factory floor.An other characteristics of conventional manufacturing system is an emphasize on "keeping every one busy" as an end on itself. This inevitably leads to excess inventories particularly work in process inventories. In Just in time manufacturing, the traditional emphasize of keeping everyone busy is abandoned in favor of producing only what customers actually want. Even if that means some workers are sat doing nothing.

Advantages:

Investments that were tied up in back stock can be used elsewhere.

Areas previously used, to warehouse components and products can be used for other more productive uses.

Defect rates are reduced, resulting in less waste and greater customer satisfaction.

As a result of advantages such as those cited above, more companies are embracing just in time manufacturing system each year. Most companies find, however, that simply reducing back stock is not enough. To remain competitive in an ever changing and ever competitive business environment, must push for continuous improvement.

22

Final ProductStrengths

- Clear advertising space.- Able to be relatively simply re-sized.- Large potential client base.- Practical and fun product.- Large amount of opportunities.- Intuitive switching on/off.

Opportunities

- Could be modified with different colour LEDs.- Larger and smaller versions could be made.- Additional features could be added such as flashing lights.- Apart of a campaign for safety.- Different colours could be used for different companies.- Ultra-Violet light could be used.- Possibility for replacing cells.

Weaknesses

- Battery life will limit life time.- Silicone can tear under excessive strain.- Limited light output.- The sizing could mean it is loose or tight for some.

Threats

- The use of small torches.- Consumers may not use the product.- The limited battery life.- Companies may feel it is not appropriate or useful.- Cheaper bands without the torch. (Plain bands)-

24

BPMA Proposal

Concept Board

Manufacture & Costing

General Arrangement Drawing

BRIGHT NIGHTBright Night is an easily brandable wrist torch. Whether used for the late night walk home or for raving, it is the perfect handsfree accessory.

26

Manufacturing MethodsThe decision was made for the use of injection moulding to make the main body of the product. The reason for the decision was that it is a process which gives a very high quality finish. It has a low wastage and is a common process.As shown in the image the process is explained.

The difference between the two components, the main body and lens is the material used. The intended design of the parts will also not require the pictured top action core. As both parts can be simply moulded using only a two part mould.

The material is loaded into the Hopper above a heated driven corkscrew. The material then is released into the corkscrew, which moves the material to the nozzle end. Material is then injected into the mould filling the cavity. The two part mould will be cooled, the gate at the end of the corkscrew will be closed and the mould will be pulled apart and the new moulded part released.

Although the tooling may cost more than other methods, it gives a superior finish than methods such as compression moulding.

Overall Costing

Main Body ElectronicsLensPrintingTOTAL UNIT:

TOTAL 100,000:

£0.06132£0.67£0.86£0.10£1.69132

x 10,000

= £16,913.20

Price per unit based upon 10,000 units is:

£1.69132

This cost doesn’t include a silicone manufacture process, only the material due to being unable to get contact with the required people.

With the two main components injection moulded and the PCB made and soldered using flow soldering. The main body can go for printing. The electronics and lens can be slotted into place and glued. The product is then ready. Press the top and the torch should work.

27

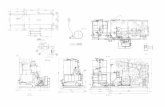

General Arrangement Drawing

24

73

A

A

30

SECTION A-A SCALE 1 : 1

12 3

ITEM NO. PART NAME Material QTY.1 Main Body Silicone 12 Lens Acrylic 1

1WEIGHT:

A3

SHEET 1 OF 1SCALE:1:1

DWG NO.

TITLE: Bright NightREVISIONDO NOT SCALE DRAWING

MATERIAL: Refer to parts listDATESIGNATURENAME

DEBUR AND BREAK SHARP EDGES

FINISH: Refer to parts list.

UNLESS OTHERWISE SPECIFIED:DIMENSIONS ARE IN MILLIMETERSSURFACE FINISH: Refer to Part list.TOLERANCES: LINEAR: 0.1 ANGULAR: 0.5

DRAWN

3 Electronics PCB and components

Finish

Tool marks removed.Tool marks removed.

o+-

Adam Coleberd

28

ReferencesAutism [2013] Charity bands [image online] Available at: http://cdn.shopify.com/s/files/1/0211/3764/products/538485_414920468522892_1409970916_n_1024x1024.jpg?141 [Accessed: 6th April 2013]Oempromo [2013] USB Wristband [image online] Available at: http://photo.oempromo.com/Prod_119/1-Gb-USB-Wristband-200-Series_92735739.jpg [Accessed: 6th April 2013]N/A [2013] Clubbing [image online] Available at: http://www.wallpapers-place.com/images/wallpapers/clubbing_2_hd_widescreen_wallpapers_1440x900.jpeg [Accessed: 6th April 2013]Rebel Patents [2013] Wristband Torch [image online] Available at: http://ecx.images-amazon.com/images/I/510GvXEmkRL._SL500_AA300_.jpg [Accessed: 7th April 2013]N/A [2013] Camping Tent [image online] Available at: http://6yearsinaraincape.com/wp-content/uploads/2011/07/tent-camping.jpg [Accessed:7th April 2013]N/A [2013] Dark Street [image online] Available at: http://4.bp.blogspot.com/-Nbb3w7UB5jM/TdD2Bx2N0zI/AAAAAAAAACA/_4ClKaj2THA/s1600/dark_street.jpg [Accessed: 20th April 2013]PPAI [2012] 2011 Sales [image online] Available at: http://www.ppai.org/inside-ppai/research/Documents/2011%20SalesVolume%20Sheet.pdf [Accessed: 8th April 2013]N/A [2013] Trekking [image online] Available at: http://3.bp.blogspot.com/-Xoqh75cTmM0/TsQAECWYkzI/AAAAAAAAAB0/1AeruXs3K0M/s1600/trekking.jpg [Accessed: 16th April 2013]Amnesia [2013] Amnesia Logo [image online] Available at: http://asklogo.com/images/A/download%20amnesia%20ibiza%20vector%20logo.jpg [Accessed: 22nd April 2013]Go Outdoors [2013] Go Outdoors Logo [image online] Available at: http://www.nationalfishingmonth.com/userfiles/Image/GO%20Outdoors%20Logo%20as%20Photoshop%20Vectors%20CMYK%20SMALL.jpg [Accessed: 22nd April 2013]N/A [2010] Garden Scene [image online] Available at: http://asleeptodream.files.wordpress.com/2010/06/kings-path.jpg [Accessed: 19th April 2013]N/A [2012] Arm [image online] Available at; http://25.media.tumblr.com/tumblr_mdxc843kMn1qg4o1do1_1280.jpg [Accessed: 19th April 2013]N/A [2011] Woman in street [image online] Available at: http://fannytrangczech.files.wordpress.com/2011/06/walking_at_night.jpg [Accessed: 24th April 2013]N/A [2013] Promo Products [image online] Available at: http://lonestarpromotional.com/promotional(collage).jpg [Accessed: 24th April 2013]N/A [2013] Wave Soldering [image online] Available at: http://www.ami.ac.uk/courses/topics/0225_wave/ [Accessed: 20th April 2013]

Henry Dreyfuss Associates [1981] Humanscale Hands and Feet [images] Thames and Hudson [2007] Manufacturing Processes for Design Professionals [images and text]

Go Wristbands [2013] Sizing [text online] Available at: http://www.gowristbands.co.uk/faq.php [Accessed: 7th April 2013]Engineering Toolbox [2013] Material Properties [text online] Available at: http://www.engineeringtoolbox.com/density-solids-d_1265.html [Accessed: 11th April 2013]Index Mundi {2013] Material Pricing [text online] Available at: http://www.indexmundi.com/commodities/?commodity=rubber¤cy=gbp [Accessed: 11th April 2013]Silicone Inks Ltd [2013] Silicone Ink [text online] http://www.siliconeinks.com/index.htm [Accessed: 17th April 2013]Dow Corning [2013] Printing [text online] http://www.dowcorning.com/content/design/designmaterial/screen-printing_silicone.aspx [Accessed: 17th April 2013]N/A [2013] Just in time [text online] http://accounting4management.com/just_in_time.htm [Accessed: 23rd April 2013]