206

-

Upload

duaa-gadoraa -

Category

Documents

-

view

213 -

download

0

description

Transcript of 206

Why studying of materials engineering?

• Understanding of the basics of materials and their applications will not only make you a better engineer, but will help you during the design process.

• In order to be a good designer, you must learn what materials will be appropriate to use in different applications.

• You need to be capable of choosing the right material for your application based on its properties.

• And you must recognize how and why these properties might change over time and due to processing.

• Materials science and engineering (MSE) is an interdisciplinary field of science and engineering that studies and manipulates the composition and structure of materials.

• The term “processing” means how materials are shaped into useful components to cause changes in the properties of different materials.

• The structure of materials has a deep influence on many properties of materials, even if the overall composition does not change! For example, if you take a pure copper wire and bend it repeatedly, the wire not only becomes harder but also becomes increasingly brittle! Eventually, the pure copper wire becomes so hard and brittle that it will break. The electrical resistivity of the wire will also increase as we bend it repeatedly.

• The changes in the material’s properties are due to a change in its internal structure. If you look at the wire after bending, it will look the same as before; however, its structure has been changed at the microscopic scale. The structure at the microscopic scale is known as the microstructure. If we can understand what has changed microscopically, we can begin to discover ways to control the material’s properties.

• Materials scientists would examine steel at a microscopic level to determine if its properties can be altered to meet all of these requirements.

• For example in a car chassis production, Engineers consider the cost of processing this steel along with other considerations. How can we shape such steel into a car chassis in a cost-effective way? Will the shaping process itself affect the mechanical properties of the steel? What kind of coatings can be developed to make the steel corrosion resistant? In some applications, we need to know if these steels could be welded easily.

• Usually the selection of materials involves trade-offs between many properties.

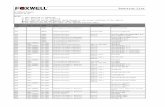

Classification of MaterialsExamples Examples of Applications Properties

Metals and Alloys

Copper Electrical conductor

wire High electrical conductivity, good formability

Gray cast iron Automobile engine blocks Castable, machinable, vibration-damping

Alloy steels Wrenches, automobile chassis, They are particularly useful for structural or load-bearing applications.

Significantly strengthened byheat treatment

Ceramics and Glasses

SiO2–Na2O–CaO Window glass Optically transparent, thermally insulating

Al2O3, MgO, SiO2 Refractories (i.e., heat-resistant lining of furnaces) for containing molten metal

Thermally insulating, withstand high temperatures, relatively inert to molten metal

Barium tianate Capacitors for microelectronics High ability to store charge

Silica Optical fibers for information technology

Refractive index, low optical losses

Polymers

Polyethylene Food packaging Easily formed into thin, flexible, airtight film

Epoxy Encapsulation of integrated circuits Electrically insulating andmoisture-resistant

Phenolics Adhesives for joining plies in plywood

Strong, moisture resistant

Semiconductors

Silicon Transistors and integrated circuits Unique electrical behavior

GaAs Optoelectronic systems Converts electrical signals to ight, lasers, laser diodes, etc.

Composites

Graphite-epoxy Aircraft components High strength-to-weight ratio

Tungsten carbide-cobalt (WC-Co)

Carbide cutting tools for machining High hardness, yet good shock resistance

Titanium-clad steel Reactor vessels Low cost and high strength of steel with the corrosionresistance of titanium

• In general, metals have good electrical and thermal conductivity. Metals and alloys have relatively high strength, high stiffness, ductility or formability, and shock resistance.

• Ceramics have exceptional strength under compression. Ceramics are strong and hard, but also very brittle. They have a high heat resistance. Advanced ceramics are used in the making of computer chips, sensors, capacitors, wireless communications, spark plugs, inductors, and electrical insulation. Some ceramics are used as barrier coatings to protect metallic substrates in turbine engines. Ceramics are also used for industrial applications such as the tiles for the space shuttle, a catalyst support, and the oxygen sensors used in cars.

• Polymers are typically organic materials. Polymeric materials include rubber (elastomers) and many types of adhesives. Polymers typically are good electrical and thermal insulators although there are exceptions such as the semiconducting polymers. They are typically not suitable for use at high temperatures. Many polymers have very good resistance to corrosive chemicals. Polymers have thousands of applications ranging from bulletproof vests, compact disks (CDs), ropes, and liquid crystal displays (LCDs) to clothes and coffee cups. Thermoplastic polymers have good ductility and formability; thermosetting polymers are stronger but more brittle.

• Semiconductors: Silicon, germanium, and gallium arsenide-based semiconductors such as those used in computers and electronics are part of a broader class of materials known as electronic materials. The electrical conductivity of semiconducting materials is between that of ceramic insulators and metallic conductors.

• Composite Materials: The main idea in developing composites is to blend the properties of different materials. These are formed from two or more materials, producing properties not found in any single material. Concrete, plywood, fiberglass and carbon fibers are examples of composite materials.

• The structure-property relationships in materials are often influenced by the surroundings to which the material is subjected during use. This can include exposure to high or low temperatures, cyclical stresses, sudden impact, corrosion, or oxidation. These effects must be accounted for in design to ensure that components do not fail unexpectedly.

• Temperature: Metals and alloys that have been strengthened by certain heat treatments or forming techniques may suddenly lose their strength when heated. (see figure)

• Corrosion: Most metals and polymers react with oxygen or other gases, particularly at elevated temperatures. Materials also are attacked by corrosive liquids, leading to failure. The engineer faces the challenge of selecting materials or coatings that prevent these reactions and permit operation in extreme environments.

• Fatigue: In many applications, components must be designed such that the load on the material may not be enough to cause permanent deformation. When we load and unload the material thousands of times, even at low loads, small cracks may begin to develop, and materials fail as these cracks grow. This is known as fatigue failure.

• Strain Rate: In many applications, the level and rate of strain have to be considered. a silicone-(not silicon-) based plastic (Silicone is a man-made substance derived from silicon and other chemicals, and it may

be a liquid or a rubber-like plastic polymer.), can be stretched significantly if we pull it slowly (small rate of strain). If you pull it fast (higher rate of strain), it snaps. A similar behavior can occur with many metallic materials.