20320140501001 2

-

date post

19-Oct-2014 -

Category

Technology

-

view

264 -

download

1

description

Transcript of 20320140501001 2

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 – 6308

(Print), ISSN 0976 – 6316(Online) Volume 5, Issue 1, January (2014), © IAEME

1

STRUCTURAL HEALTH MONITORING OF CONCRETE STRUCTURES

EVALUATING ELASTIC CONSTANTS AND STRESS-STRAIN

PARAMETERS BY X-RAY DIFFRACTION TECHNIQUE

Prof. N. K. DHAPEKAR

(Research Scholar, K.L.University Vijayawada, Andra Pradesh, India.

Assistant Professor, Head of Civil Engineering Department, K.I.T.E Raipur, Chhattisgarh India)

ABSTRACT

This research paper highlights the applicability of X-ray diffraction method to evaluate the

true and effective modulii of concrete ie; Young’s modulus of elasticity, Bulk modulus of elasticity

and modulus of Rigidity at different temperatures along with compressive strength or compressive

stress and strain. The aim of this study is to explore the possibilities of structural health monitoring

of concrete structures in different temperate regions through X-ray diffraction technique as compared

to the normal Non-Destructive methods like Rebound Hammer, Ultrasonic pulse velocity tests or de-

structive lab methods used in practice today. This paper consolidates the variation in true and effec-

tive modulii along with compressive strength and strain at very low temperate regions (upto 5 degree

Celsius), moderate temperate regions (up to 25 degree Celsius) to high temperate regions (upto 50

degree Celsius).

Key-Words: Structural Health Monitoring, Non-Destructive Method, X-Ray Diffraction,

Modulii of Elasticity, Stress, Strain.

1. INTRODUCTION

Normal laboratory tests (Destructive) are employed on concrete cubes or cylinders for

determining modulus of elasticity and compressive strength. For existing concrete structures as a part

of structural health monitoring of concrete structures various non-destructive tests are employed such

as Rebound hammer, Ultrasonic pulse velocity tests etc; This paper focuses on the study of

behaviour of concrete subjected to prolonged loading at different temperatures which has special im-

portance in structural health monitoring of concrete structures as concrete is not truly elastic material

since it possess the ability to creep during and after the application of load. Modulii of concrete and

it’s corresponding compressive strength are required in the design calculations of concrete

INTERNATIONAL JOURNAL OF CIVIL ENGINEERING AND

TECHNOLOGY (IJCIET)

ISSN 0976 – 6308 (Print)

ISSN 0976 – 6316(Online)

Volume 5, Issue 1, January (2014), pp. 01-12

© IAEME: www.iaeme.com/ijciet.asp

Journal Impact Factor (2013): 5.3277 (Calculated by GISI)

www.jifactor.com

IJCIET

©IAEME

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 – 6308

(Print), ISSN 0976 – 6316(Online) Volume 5, Issue 1, January (2014), © IAEME

2

structures. In the field of structural health monitoring of reinforced concrete structures it is extensive-

ly used in the form of modular ratio. There is an agreement on the increasing modulii of elasticity

with the increase in compressive strength of concrete. The equations published highlights the true

modulii and effective modulii at different temperatures. These equations predicts the compressive

strength and strain in concrete which are the key parameters for making decisions about it’s life dura-

tion. These equations enables to monitor the structural health of concrete structures in cold countries

(upto 5 degree Celsius) to high temperate regions (upto 50 degree Celsius). In this paper 5 grams of

two powder samples of 15cm x 15cm x 15cm cubes in unstressed condition (cube not subjected to

failure load in compressive testing machine) and stressed condition (cube subjected to failure load in

compressive testing machine) are taken and X-ray diffraction is carried out for M-20 grade normal

concrete.

2. X-RAY DIFFRACTION GRAPH AND PEAK LIST

2.1 M.20 Unstressed sample

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 – 6308

(Print), ISSN 0976 – 6316(Online) Volume 5, Issue 1, January (2014), © IAEME

3

2.2 Graphics M.20 unstressed sample

2.3 Peak List

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 – 6308

(Print), ISSN 0976 – 6316(Online) Volume 5, Issue 1, January (2014), © IAEME

4

2.4 Graphics M.20 stressed sample

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 – 6308

(Print), ISSN 0976 – 6316(Online) Volume 5, Issue 1, January (2014), © IAEME

5

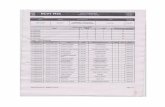

3. MIX DESIGN CALCULATIONS (M-20 GRADE)

3.1. Cement Cement Type/Brand/Make : OPC 43 Grade.IS:8112 Ultratech Cement Limited.

Specific Surface Area of Cement : 287 Kg./m2 as per IS8112:1989.

Standard Consistency : 28.00 as per IS 456:2000.

Initial Setting : 145 .Min-30 Minutes.

Final Setting: 240 . Maximum-600 Minutes.

Compressive strength in MPa- a. 3 Days – 38.5 N/mm

2 ( 23 min.-IS8112-2013 )

b. 7 Days – 50.5 N/mm2 ( 33 min. – IS8112-2013 )

c. 28 Days – 57.5 N/mm2 (43 min. – 58 Mpa max.)-IS8112-2013.

(CaO-0.70SO3)- 0.80 – 0.66 min- IS8112-1989

(2.8SiO2+1.2Al2O3+0.65Fe2O3)- 0.80 – 1.02 max.-IS8112-1989.

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 – 6308

(Print), ISSN 0976 – 6316(Online) Volume 5, Issue 1, January (2014), © IAEME

6

Chemical Requirements Insoluble residue(%by mass)-2.53 (3 - min.-IS8112-1989).

Magnesia(% by mass) – 2.20 ( 6.0 – min.-IS8112-1989)

Sulphuric anhydride(% by mass) – 1.85 (3.0-max.-IS8112-1989)

Total loss of ignition(% by mass) – 1.85 (5.0 max.-IS8112-1989)

Total Chloride(% by mass) – 0.01 (0.10 max.-IS8112-1989)

Soundness – Le-Chat Expansion(mm) – 1.00 (10 max-IS8112-1989)

Auto-Clave Expansion(%) – 0.140 ( 0.80 max.-IS8112-1989)

3.2 Fine and Coarse aggregates

3.2.1. Data on ingredients

OPC/PPC/PSC/RHC/HAC/SRC/LHC – Ultratech OPC-43 Grade (Hirmi Cement Works) –

Sp.Gravity – 3.13 – Mix Design Quantity – 350kg/Cum.

Fine Aggregate-I (Natural Sand) – Source Mahanadi – Sp.Gr. 2.63 – Water absorption 2.55-

Mix Design 791 Kg/Cu m.

Coarse Aggregate-III(20mm) – Mandir Hasaud/Khapri – Sp.Gr.2.79 – Water Absorption 1.05-

Mix Design 744Kg/Cu m.

Coarse Aggregate-IV(12.5mm)-Mandir Hausad/Khapri-Mix Design 0Kg/Cu m.

Coarse Aggregate-IV(10mm)-Mandir Hausad/Khapri-Sp.Gr. 2.78-Water Absorption-1.55-Mix

Design 399 Kg/Cum.

Water-Source is Borewell-Sp.Gravity 1.00 –Mix Design 175 Kg/Cu m.

Density of concrete per cubic meter is 2460.2 Kg/m3.

3.2.2 Mix Code

Characteristic strength at 28 days(N/mm2)-20

Standard Deviation(N/mm2)-5.0(As per IS456 2000)

Value of ‘ t ‘ – 1.65 (As per IS456 2000)

Target mean strength at 28 days(N/mm2)-28.25

Workability in terms of slump(mm)-100+/-15

Exposure condition – moderate.

Min.Cementetious content(Kg/Cum)-350.

Max.water cement ratio-0.50

Nominal max.size of aggregates(mm)-20

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 – 6308

(Print), ISSN 0976 – 6316(Online) Volume 5, Issue 1, January (2014), © IAEME

7

3.3 Strength Analysis

No.of Days Wt.in

grams.

Load in

KN.

Compressive Strength

(N/mm2)

3 Days

8105 473 21.02

8165 468 20.80

8180 469 20.84

7 Days

8135 543 24.13

8255 549 24.40

8200 542 24.09

28 Days

8220 657 29.20

8180 645 28.70

28 days results as on 08.09.2013

4. TRUE MODULII OF ELASTICITY

4.1 Low temperate regions (up to 5 degree Celsius) β Cos θ = ( K . λ ) / D where

β = FWHM (⁰ 2 Th.) = 0.0836 (Refer 2.3)

2θ = Pos. (⁰ 2 Th.) = 26.5668 (Refer 2.3)

θ = 13.28⁰

λ = 1.54 K-Alpha 2 [A⁰] (Refer 2.1) K = 0.90

D = (K . λ ) / (β Cos θ )

D = (0.90 x 1.54) / ( 0.0836 x Cos 13.28)

D = 17.00 A⁰ = Particle size in A

⁰.

For true modulus of elasticity ( E ) ,

β Cosθ =(K λ / D)+{4Sinθ[2CPtµ3]0.5

}/E0.5

CP = Enthalpy

t =Temperature in⁰ Kelvin=273+5=278

⁰K

µ = Poisson’s ratio = 0.18

0.0836 Cos13.28 = ( 0.90 x 1.54 / 17.0) + {4Sin13.28[2 x 879 x 278 x 0.183]0.5

}/ E0.5

0.0813=0.0815+{0.9188[53.387]}/ E0.5

-2 x 10-4

= 49.051 / E

0.5

E true = 6.015 x 1010

N/m2

where

E = 2G ( 1+µ ) = 3K (1-2µ )

G = Modulus of rigidity.

K = Bulk modulus of elasticity.

Gtrue = ( 6.015 x 1010

) / 2 ( 1+ 0.18)

Gtrue = 2.548 x 1010

N/m2

Ktrue = 6.015 x 1010

/ 3(1 - 2µ )

Ktrue = 3.132 x 1010

N/m2

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 – 6308

(Print), ISSN 0976 – 6316(Online) Volume 5, Issue 1, January (2014), © IAEME

8

4.2 Moderate temperate regions (up to 25 degree Celsius) D = (K . λ) / (β Cos θ )

D = (0.90 x 1.54) / (0.0836 x Cos 13.28)

D = 17.00 A⁰ = Particle size in A

⁰.

For true modulus of elasticity,

β Cosθ =(K λ / D)+{4Sinθ[2CPtµ3]0.5

}/E0.5

CP = Enthalpy

t =Temperature in⁰ Kelvin=273+25=298

⁰K

µ = Poisson’s ratio = 0.18

0.0836 Cos13.28 = (0.90 x 1.54 / 17.0) + {4Sin13.28[2 x 879 x 298 x 0.183]

0.5}/ E

0.5

0.0813=0.0815+{0.9188[55.274]}/ E0.5

-2 x 10-4

= 50.785 / E

0.5

E true = 6.447 x 1010

N/m2

where

E = 2G (1+µ) = 3K (1-2µ )

G = Modulus of rigidity.

K = Bulk modulus of elasticity.

Gtrue = 2.731 x 1010

N/m2

Ktrue = 3.357 x 1010

N/m2

4.3 High temperate regions (up to 50 degree Celsius) D = (K . λ) / (β Cos θ)

D = (0.90 x 1.54) / (0.0836 x Cos 13.28)

D = 17.00 A⁰ = Particle size in A

⁰.

For true modulus of elasticity (E),

β Cosθ =(K λ / D)+{4Sinθ[2CPtµ3]0.5

}/E0.5

CP = Enthalpy

t =Temperature in⁰ Kelvin=273+50=323

⁰K

µ = Poisson’s ratio = 0.18

0.0836 Cos13.28 = (0.90 x 1.54 / 17.0) + {4Sin13.28[2 x 879 x 323 x 0.183]

0.5}/ E

0.5

0.0813=0.0815+{0.9188[57.546]}/ E0.5

-2 x 10-4

= 52.873 / E

0.5

E true = 6.988 x 1010

N/m2

where

E = 2G ( 1+µ ) = 3K (1-2µ )

G = Modulus of rigidity.

K = Bulk modulus of elasticity.

Gtrue = 2.961 x 1010

N/m2

Ktrue = 3.639 x 1010

N/m2

5. EFFECTIVE MODULII OF ELASTICITY

5.1 Low temperate regions (up to 5 degree Celsius) β Cos θ = ( K . λ ) / D where

β = FWHM (⁰ 2 Th.) = 0.0669 (Refer 2.4)

2θ = Pos. (⁰ 2 Th.) = 26.7827 (Refer 2.4)

θ = 13.39⁰

λ = 1.54 K-Alpha 2 [A⁰] (Refer 2.4)

K = 0.90 ( )

D = ( K . λ ) / (β Cos θ )

D = ( 0.90 x 1.54 ) / ( 0.0669 x Cos 13.39)

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 – 6308

(Print), ISSN 0976 – 6316(Online) Volume 5, Issue 1, January (2014), © IAEME

9

D = 21.2 A⁰ = Particle size in A

⁰.

For effective modulus of elasticity,

β Cosθ =(K λ / D)+{4Sinθ[2CPtµ3]0.5

}/E0.5

CP = Enthalpy

t =Temperature in⁰ Kelvin=273+5=278

⁰K

µ = Poisson’s ratio = 0.18

0.0669 Cos13.39 = (0.90 x 1.54 / 21.2) + {4Sin13.39[2 x 879 x 278 x 0.183]

0.5}/ E

0.5

0.0650=0.0653+{0.9263[53.387]}/E0.5

-3.000 x 10-4

= 49.452 / E

0.5

E effective = 2.717 x 1010

N/m2

where

E = 2G ( 1+µ ) = 3K (1-2µ )

G = Modulus of rigidity.

K = Bulk modulus of elasticity.

Geffective = 1.151 x 1010

N/m2

Keffective = 1.415 x 1010

N/m2

5.2 Moderate temperate regions (up to 25 degree Celsius) D = (K . λ ) / (β Cos θ )

D = (0.90 x 1.54) / (0.0669 x Cos 13.39)

D = 21.20 A⁰ = Particle size in A

⁰.

For effective modulus of elasticity,

β Cosθ =(K λ / D)+{4Sinθ[2CPtµ3]0.5

}/E0.5

CP = Enthalpy

t =Temperature in⁰ Kelvin=273+25=298

⁰K

µ = Poisson’s ratio = 0.18

0.0669 Cos13.39 = ( 0.90 x 1.54 / 21.2) + {4Sin13.39[2 x 879 x 298 x 0.183]0.5

}/ E0.5

0.0650=0.0653+{0.9263[55.274]}/E0.5

-3 x 10-4

= 51.200 / E

0.5

E effective = 2.912 x 1010

N/m2

where

E = 2G ( 1+µ ) = 3K (1-2µ )

G = Modulus of rigidity.

K = Bulk modulus of elasticity.

Geffective = 1.234 x 1010

N/m2

Keffective = 1.517 x 1010

N/m2

5.3 High temperate regions (up to 50 degree Celsius) D = (K . λ ) / (β Cos θ )

D = (0.90 x 1.54) / (0.0669 x Cos 13.39)

D = 21.20 A⁰ = Particle size in A

⁰.

For true modulus of elasticity (E),

β Cosθ =(K λ / D)+{4Sinθ[2CPtµ3]0.5

}/E0.5

CP = Enthalpy

t =Temperature in⁰ Kelvin=273+50=323

⁰K

µ = Poisson’s ratio = 0.18

0.0669 Cos13.39 = (0.90 x 1.54 / 21.2) + 4Sin13.39[2 x 879 x 323 x 0.183]0.5

}/ E0.5

0.0650=0.0653+{0.9263[57.546]}/E0.5

-3.00 x 10-4

= 53.304 / E

0.5

E effective = 3.157 x 1010

N/m2

where

E = 2G ( 1+µ ) = 3K (1-2µ )

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 – 6308

(Print), ISSN 0976 – 6316(Online) Volume 5, Issue 1, January (2014), © IAEME

10

G = Modulus of rigidity.

K = Bulk modulus of elasticity.

Geffective = 1.337 x 1010

N/m2

Keffective = 1.644 x 1010

N/m2

5.4 M.20 grade concrete

5.5 Stress calculations Only particular set of grains contributes to particular hkl reflection.

d = 1.03246 A⁰ @ 2θ = 96.5044⁰

do = 1.03468 A⁰ @ 2θ = 96.2292⁰

Strain = (d – do) / d0

€ = (1.03246- 1.03468) / 1.03468

€ = -2.145 x 10-3

Stress = € x Keff.

Stress= (-2.145 x 10-3

) x (1.415 x 1010

)

Stress= -30.351 x 106 N/m

2

Stress= -30.351 N/mm2 @ 5 degree Celsius

Stress = € x Keff.

Stress=( -2.145 x 10-3

) x (1.517 x 1010

)

Stress= -30.351 x 106 N/m

2

Stress= -32.539 N/mm2

@ 25 degree Celsius

Stress = € x Keff.

Stress=(-2.145 x 10-3

) x (1.644 x 1010

)

Stress= -35.263 x 106 N/m

2

Stress= -35.263 N/mm2 @ 50 degree Celsius

Sr

No.

Temp

True modulii of concrete

E ( N/m2 ) G ( N/m

2 ) K ( N/m

2 )

1 5⁰ C 6.015 x 10

10 2.548 x 10

10 3.132 x 10

10

2 25⁰ C 6.447 x 10

10 2.731 x 10

10 3.357 x 10

10

3 50⁰ C 6.988 x 10

10 2.961 x 10

10 3.639 x 10

10

Effective modulii of concrete

E ( N/m2 ) G ( N/m

2 ) K ( N/m

2 )

4 5⁰ C 2.717 x 10

10 1.151 x 10

10 1.415 x 10

10

5 25⁰ C 2.912 x 10

10 1.234 x 10

10 1.517 x 10

10

6 50⁰ C 3.157 x 10

10 1.337 x 10

10 1.644 x 10

10

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 – 6308

(Print), ISSN 0976 – 6316(Online) Volume 5, Issue 1, January (2014), © IAEME

11

Negative sign is only because atomic spacing (d) is less in stressed condition as compared to

do ie; atomic spacing in A⁰ in unstressed condition. These stresses may also be called as compressive

strength after 28 days. So finally compressive strength after 28 days is tabulated below.

5.5 CONCLUSION

True and effective modulii of elasticity can be determined through X-ray diffraction

technique at different temperatures. The observed increase of elastic constants with increase in

temperature reflects strengthening of interatomic bonding. Larger values of true modulii of concrete

composition is due to large elastic energy as compared to effective modulii. Compressive strength

computed by X-ray diffraction technique is matching with the average compressive strength deter-

mined by Compressive testing machine (CTM).X-ray diffraction method can be implemented as a

alternative method for determining the compressive strength of concrete.

5.6 ACKNOWLEDGEMENTS

The authors would like to acknowledge the support of Indian Institute of Technology

Bombay for the X ray diffraction report of M.20 grade concrete powder.

5.7 REFERENCES

1. Elements of X-ray diffraction (Second edition) by B.D.Cullity, department of metallurgical

engg. and material science, university of Notre Dame.

2. Hand book of analytical techniques in concrete science and technology. Principles, technique

and applications by V.S.Ramachandran and James.J.Beaudoin. Institute for research in

construction. National research council Canada Ottawa, Ontario, Canada.

Stresses / Compressive strength after 28 days of curing by

X-Ray Diffraction Method

01. Temperature 5⁰ C 25⁰ C 50⁰ C

02. Stresses / Compressive Strength

in Mpa. By XRD method.

30.351 32.539 35.263

Stresses / Compressive strength after 28 days of curing by

Compression testing machine in lab

( Refer table 3.3)

01. Temperature 5⁰ C 25⁰ C 50⁰ C

02. Stresses / Compressive Strength

in Mpa.

- 28.95

(Average

strength.)

-

International Journal of Civil Engineering and Technology (IJCIET), ISSN 0976 – 6308

(Print), ISSN 0976 – 6316(Online) Volume 5, Issue 1, January (2014), © IAEME

12

3. Svinning,K, Bremseth,S.K and Justnes, H.x-Ray diffraction studies on variations in micro-

structures in Portland clinker correlated to variations in production conditions in the Kiln,

Proc.18th

international cement micros. page 382-403(1996).

4. Abbas S. Al-Ameeri, K.A.Al- Hussain and M.S Essa, “Constructing a Mathematical Models

to Predict Compressive Strength of Concrete from Non-Destructive Testing”, International

Journal of Civil Engineering & Technology (IJCIET), Volume 4, Issue 4, 2013, pp. 1 - 20,

ISSN Print: 0976 – 6308, ISSN Online: 0976 – 6316.

5. Current applications of X-ray diffraction residual stress measurement by Paul.S.Prevey,

Lambda research in ASM international ,materials park, OH,1996, pp 103-110.

6. Comparative study of residual stress measurement methods on CVD diamond films by

J.G.Kim and Jin Yu. Advanced institute of science and technology, department of materials

science and engg. P.O.Box 305-701, Kusung-Dong 373-1, Taejon, Korea.

7. Dr. K.V.Ramana Reddy, “Non- Destructive Evaluation of In-Situ Strength of High Strength

Concrete Structures”, International Journal of Civil Engineering & Technology (IJCIET),

Volume 4, Issue 4, 2013, pp. 21 - 28, ISSN Print: 0976 – 6308, ISSN Online: 0976 – 6316.

8. X-ray diffraction study of the single crystal elastic modulii of Fe up to 30GPa by Sebastein

Merkel, Jinflu Shu, Philippe Gillet in journal of geophysical research published on 13 May

2005.

9. Adil M. Abdullatif and Tareq S. Al-Attar, “Structural Behavior of Reed: Evaluation of Tensile

Strength, Elasticity and Stress-Strain Relationships”, International Journal of Advanced

Research in Engineering & Technology (IJARET), Volume 4, Issue 1, 2013, pp. 105 - 113,

ISSN Print: 0976-6480, ISSN Online: 0976-6499.

10. M.E Hilley, Ed. residual stress measurement by X-ray diffraction, SAE J784a, society of

automotive engineers, Warrendak, PA, 1971, p.21-24.

11. Atomistic calculation of size effects on elastic coefficients in nanometer sized tungsten layers

and wires by P.Villain, P.Beauchamp, K.F.Badwai, P.Goudeau, P.O.Renaut in January-2004.

![[XLS] · Web view1 2 2 2 3 2 4 2 5 2 6 2 7 2 8 2 9 2 10 2 11 2 12 2 13 2 14 2 15 2 16 2 17 2 18 2 19 2 20 2 21 2 22 2 23 2 24 2 25 2 26 2 27 2 28 2 29 2 30 2 31 2 32 2 33 2 34 2 35](https://static.fdocuments.in/doc/165x107/5aa4dcf07f8b9a1d728c67ae/xls-view1-2-2-2-3-2-4-2-5-2-6-2-7-2-8-2-9-2-10-2-11-2-12-2-13-2-14-2-15-2-16-2.jpg)

![[XLS] · Web view1 2 2 2 3 2 4 2 5 2 6 2 7 8 2 9 2 10 11 12 2 13 2 14 2 15 2 16 2 17 2 18 2 19 2 20 2 21 2 22 2 23 2 24 2 25 2 26 2 27 28 2 29 2 30 2 31 2 32 2 33 2 34 2 35 2 36 2](https://static.fdocuments.in/doc/165x107/5ae0cb6a7f8b9a97518daca8/xls-view1-2-2-2-3-2-4-2-5-2-6-2-7-8-2-9-2-10-11-12-2-13-2-14-2-15-2-16-2-17-2.jpg)