2016-2017 PUMP STATIONS & EQUIPMENT · 2016-03-02 · Corken Bypass Valve #B166-75 Internal Valve...

Transcript of 2016-2017 PUMP STATIONS & EQUIPMENT · 2016-03-02 · Corken Bypass Valve #B166-75 Internal Valve...

WWW.TARANTIN.COM • 800-922-0724

PUMPSTATIONS

2016-2017

& EQUIPMENT

WWW.TARANTIN.COM | 800-922-0724

“From our one location in 1983, we have grown to a top-notch company with six locations serving the Eastern US. These achievements could not have been possible without the support of our customers, vendors and employees. As we move forward, we remain steadfast in our commitment to excellence in customer service.”

BackordersItems not shipped with your original order will be kept on order and shipped as soon as possible unless otherwise specified.

FreightWe ship UPS, FED-EX, and common carrier. Orders are shipped in the most economical manner. If you have a shipping preference, please indicate when placing your order. Freight terms are FOB origin unless otherwise agreed upon.

QualityWe adhere to strict quality control. Thus, Tarantin guarantees all items to be free of damage upon shipping. Freight damages must be addressed by the appropriate company handling your delivery.

Pump Stations, Autogas, and Accessories 1Pumps 10Emergency Shut-off Valves 14

1 43

1 2 Meters 15Compressors 17Cylinders and Storage Cabinets 18Tank Anchoring 22Cathodic Protection 23Tools and Accessories 25MOSCAP Gauges 29Hose Assemblies and Accessories 30Signs and Decals 32

PUMP STATIONS, AUTOGAS, AND ACCESSORIES

1800-922-0724 | WWW.TARANTIN.COM

Tank Stand #TS

Tank Relief ValveRegO #8685GT

Chek-Lok ValveRegO #7590UT

Stainer#N260-10

Hydro Relief 3127U

5/8” O.D.“K” Tubing

3/8” O.D.“L” Tubing

Corken Bypass Valve #B166-75

Internal Valve w/ Thermal Latch

#A3209DT080 + A3209TL

2” Pipe RunnerOptional

#RUNNERS 40/15 GALV

Flex Connector#FLX1-1/4-12

Pump Plate#TPMP

Corken Pump#C12FD2A-SM30

Quick Action ValveRegO #7901TB

Filling Coupling

RegO #7193D-10

Excess Flow ValveRegO

#3272GPullaway Valve

RegO #A2141A6or #A2141A6L

Hydro ReliefRegO #3127U

Liqua-Tech Flowmeter

#090534-100

1 1/2”x 1 1/4”Bushing

GENERAL INFORMATION FOR PUMPING STATION DESIGN

• Choose the proper size tank for the operation, with a 1,000 gallon tank for a large industrial motor fueling or a 500 gallon tank for a small 20 lb. refilling.

• Always use a tank with a bottom withdrawal, preferably a new one. If a used tank is to be used, remove as many heavy ends as possible.

• Size the pump to the operation. Try to consider future expansion. If a meter is to be used, be sure to use a large enough pump, such as a Corken C12 or large C13.

• Couple the pump to an external by-pass, DO NOT rely on an internal by-pass on the pump.

• If a meter is to be used be sure it is designed for the operation. Use Liqua-Tech LPM102 or Liquid Controls MA4.

• Piping should be the same size as your pumps and meters, never smaller. Schedule 80 pipe and Type K copper tubing is required.

• Safety is a major consideration. Be sure a fire extinguisher and proper warnings and decals are used.

PUMP STATIONS, AUTOGAS, AND ACCESSORIES

WWW.TARANTIN.COM | 800-922-0724 2

Skid

Credit Card Processor & Fuel Managment System

Components Package

Dispenser

Hose & Nozzle Package

1000+ Gallon Tank

Retail PumpApplications: • Small Fleets• Single Location• Multiple Vehicles• No Data Collected or

Management SystemFeatures:• Display Total Gallons

Dispensed• Custom Graphics (free of

charge)• Stainless Steel Panels• Test Pumped & Calibrated Prior to

Shipment• Hose Retractor with Hose Support

Applications:• Very Large Fleets/Retail• Multiple Locations• Multiple Vehicles• Accepts Credit Cards• Remote Management of Users,

Vehicles, Dispensers and Tanks

(WiFi enabled, see Software section for more information on capabilities)

Features• Display Total Gallons & Price of

Gallons Dispensed

• Accepts MiFare Tags & Swipe Cards

• Pump Authorization• Custom Graphics (free of

charge)• Receipt Printer• Remote Management

Commercial PumpApplications:• Medium to Large Fleets• Multiple Locations/Fleets• Multiple Vehicles• Remote Management of Users,

Vehicles,• Dispensers, and Tanks• No Internal WiFi or

Credit Card CapabilitiesFeatures:• Display Total Gallons Dispensed• Custom Graphics (free of charge)• Stainless Steel Panels• Test Pumped & Calibrated Prior to Shipment• Hose Retractor with Hose Support

Autogas Dispensing Pump Station

PUMP STATIONS, AUTOGAS, AND ACCESSORIES

3800-922-0724 | WWW.TARANTIN.COM

Aluminum Fully Assembled Pump Station Cabinet*D2A-KIT-ALUM

Components Include:• Cabinet• Tank Stands (not pictured)• Corken C12 Pump with Switch• Bypass Valve• Liqua-Tech Meter

• Scale (Do not install wheels if placed in cabinet)• Piping Kit (Internal Valve 1¼”, Hydrostatic

Relief Valve, Angle Valve ¾”, Excess Flow Valve ¾”, Y Strainer, Flex Connector, Forged Steel Fittings, Schedule 80 Nipples, ¾” Breakaway Coupling)

*Corken pump shown. Also available with a Smith Pump.

PUMP STATIONS, AUTOGAS, AND ACCESSORIES

WWW.TARANTIN.COM | 800-922-0724 4

Aluminum Assembled Pump Station Cabinet*D1-KIT-ALUM

Components Include:• Cabinet• Tank Stands (not pictured)• Corken C12 Pump with Switch• Bypass Valve• Liqua-Tech Meter

• Piping Kit (Internal Valve 1¼”, Hydrostatic Relief Valve, Angle Valve ¾”, Excess Flow Valve ¾”, Y Strainer, Flex Connector, Forged Steel Fittings, Schedule 80 Nipples)

*This compact Pump Station does not include Scale.

Corken pump shown. Also available with a Smith Pump.

CLOSED VIEW

PUMP STATIONS, AUTOGAS, AND ACCESSORIES

5800-922-0724 | WWW.TARANTIN.COM

Aluminum Assembled Autogas - Small FleetD1-KIT-ALUM-AUTOGAS-FILTER

Aluminum Assembled Autogas - Medium FleetD3-MINI-SKID-KIT-AUTOGAS

• Aluminum D3 Cabinet• Corken FF075 High Differential Pump

& Bypass with 7.5hp 3ph Motor• Flange Kit• Liquid Controls MA5 Meter with ATC

• Veeder Root Mechanical Printing Register Head

• Blue Moon AutoGas Filter

• LG1E Dispensing Nozzle

• Hose Retractor and Hose Bunn with 3/4” Hose

• Auxillary 1/2” Cylinder Fill Hose

• Side View

CLOSED VIEW

CLOSED VIEW

SIDE VIEW

Optional:Hose Retractor with HoseBunn #6102-1078P and #PB-1394

Blue Moon Autogas Filter #FST-634

Nozzle Boot #NBGG

Smith Bypass #WW-340

Smith Autogas Pump #GC-1LZ-M

Liqua-Tech 1” Mechanical Meter w/ATC #090028-105

Diamond Plate Alumnimun Cabinet

#D-1-ALUM

PUMP STATIONS, AUTOGAS, AND ACCESSORIES

WWW.TARANTIN.COM | 800-922-0724 6

Aluminum Assembled AutogasD2A-KIT-ALUM-AUTOGAS-FILTER

CLOSED VIEW

Components Include:• Smith GC AutoGas Series pump

and bypass valve• Blue Moon Filter• 3/4” x 18 ft. Hose with Gas Guard

Autogas Nozzle• Cabinet• Tank Stands (not pictured)• Corken C12 Pump with Switch

• Bypass Valve• Liqua-Tech Meter• Piping Kit (Internal Valve 1¼”,

Hydrostatic Relief Valve, Angle Valve ¾”, Excess Flow Valve ¾”, Y Strainer, Flex Connector, Forged Steel Fittings, Schedule 80 Nipples)

PUMP STATIONS, AUTOGAS, AND ACCESSORIES

7800-922-0724 | WWW.TARANTIN.COM

Hose Retractor with Bunn6102-1078PRetractor Kit, vertical 78 inches Includes box, post, bracket, foot, and hardwarePB-1394Hose Clamp 1-1/8” outside diameter3/4” inside diameterFST-634Blue Moon Autogas Filter

NB-GGGas Guard Nozzle Boot

Tank StandsTSTank Stand Pair with Meter Plate

TS-1Tank Stand Pair (no meter plate)

TS-HDTank Stand Pair Heavy Duty 1800-1900

TPMPPump Plate

TST-1Step

Detecto Portable Platform Scales854F100PHeight: 45”Width: 24”Depth: 35”Platform height: 19”Platform width: 28”Wheels: Large 5” diameter, Heavy Duty RuboleneShipping Weight: 132lbs.Max Capactiy: 1000lbs.Front of Beam: 100lbs. x 0.5lbs.(Do not install wheels if placed in cabinet)

TPMP

TS-1

TS-HD

TST-1

TS

PUMP STATIONS, AUTOGAS, AND ACCESSORIES

WWW.TARANTIN.COM | 800-922-0724 8

Pump Station Hose

Rego Hose End Connectors7193L-10AFor filling forklift cylinders.

7193U-10For DOT cylinder filling hoses1/4” M.NPT inlet connectionFQCC outlet connection

7193D-10For filling DOT cylinders1/4” M.NPT inlet connectionM.POL CGA 510 outlet connection

POL AdaptersME393HDHeavy duty forgingAllows quick connection from QCC fill adapter to M.POL fill connector.Convenient hex for secure connection15/16” M.ACME x SN swivel POL connection

MSCP-901HF.POL x 1 3/4” ACME adapter

Rego Quick-Acting Valves

Fill Adapter for Gasmate II & Quick Disconnect Valve

Rego Adapter

PS-HOSECompleted, assembled, and ready to useDispenser hose 1/2” x 18 ft. with RegO Snap Valve and POL Fill Adapter.

7901TBFor cylinder filling hoses 1/2” F.NPT inlet connection1/4” F.NPT outlet connection

F2763297193T-10For filling DOT cylindersF.POL CGA 510 inlet connectionType 1 15/16” F.ACME outlet connection

PUMP STATIONS, AUTOGAS, AND ACCESSORIES

9800-922-0724 | WWW.TARANTIN.COM

Service: A flexible, heavy duty, and high pressure hose for the transfer of liquid or vapor propane or butane, in heater, torch, filling, delivery, and unloading applications.

Part Number I.D. (in.) Braid O.D.

(in.)Approx.Wt. Per 100 Ft.

Max Recom. WP (PSI)

Ferrule Part #

LPH-1/4INDB 1/4 2 5/8 16 350 7327

LPH-3/8INDB 3/8 2 3/4 22 350 7332

LPH-1/2IN 1/2 2 15/16 31 350

LPH-3/4IN 3/4 2 1 ¼ 49 350

LPH-1IN 1 2 1 ½ 61 350

LPH-1 1/4IN 1 ¼ 2 1 7/8 100 350

LPH-1 1/2IN 1 ½ 3 2 5/32 110 350

LPH-2IN 2 3 2 ¾ 157 350

Part Number Hose ID

Thread Size

HC-4231 ¼” 1/8”

HC-4232 ¼” ¼”

HC-4233 ¼” 3/8”

HC-4252 3/8” ¼”

HC-4253 3/8” 3/8”

BG30 FE 3/8” ½”

Part Number

Hose ID

Thread Size

HC-4835 ¼” 3/8” OD

HC-4855 3/8” 3/8” OD

HC-4857 3/8” ½” OD

Part Number

Hose ID

Thread Size

HC-4335 ¼” 3/8” OD

HC-4355 3/8” 3/8” OD

HC-4357 3/8” ½” OD

Part Number

Hose ID

Thread Size

HC-4631 ¼” 1/8”

HC-5632 ¼” ¼”

BG-32EC ¼” 3/8”

BG-32CE 3/8” ¼”

BG-32EE 3/8” 3/8”

HC-4654 3/8” ½”

Part Number Hose ID

HC-5232¼” Male Pipe Thread x

¼” Hose Barb

HC-52333/8” Male Pipe Thread x

¼” Hose Barb

Part Number Description

HC-53353/8” Female Flare Adapter

x ¼” ID Hose Barb

HC-5333¼” Female Flare Adapter x

¼” ID Hose Barb

MALE PIPE MPT X HOSE BARB

MALE FLAREby Hose Barb

FEMALE NPTby Hose Barb

FEMALE FLARE SWIVELby Hose Barb

FEMALE FLARE SWIVEL X HOSE BARBHigh Pressure Fittings

MALE PIPEby Hose Barb High Pressure Fit-tings

Parker L.P. Gas Hose

WWW.TARANTIN.COM | 800-922-0724 10

PUMPS

Corken Autogas PumpPump OnlyDesigned for high-pressure propane motor fueling. Three mounting options available. Direct drive with coupling, belt drive, and direct-mounted with C-face motor.• FF060 runs with a single phase electric power• FF075 & FF150 runs with a three phase power source

Part Number Flow Rate Inlet Outlet

FF060* up to 22 GPM & 150 PSIG 1 1/2” ANSI 300# 1” ANSI 300#

FF075* up to 40 GPM & 200 PSIG 1 1/2” ANSI 300# 1” ANSI 300#

FF150* up to 58 GPM & 250 PSIG 1 1/2” ANSI 300# 1” ANSI 300#

*Flanges required for installation. Contact us with your specific requirements.

Pump & MotorDesigned for high-pressure propane motor fueling. Three mounting options available. Direct drive with coupling, belt drive, and direct-mounted with C-face motor.

• HDPFF-060 runs with a single phase electric power

• FF075 & FF150 runs with a three phase power source

Part Number Flow Rate Inlet Outlet

HDPFF060* up to 22 GPM & 150 PSIG 1 1/2" ANSI 300# 1" ANSI 300#

HDPFF075* up to 40 GPM & 200 PSIG 1 1/2" ANSI 300# 1" ANSI 300#

HDPFF150* up to 58 GPM & 250 PSIG 1 1/2" ANSI 300# 1" ANSI 300#

*Flanges required for installation. Contact us with your specific requirements.

Variable Frequency Drive (VFD)A Variable Frequency Drive (VFD) converts the single phase of the FF060 & HDPFF-060 to a three phase power.

Part Number Size

4204 15 hp

4204-1 10 hp

4204-2 20 hp

PUMPS

11800-922-0724 | WWW.TARANTIN.COM

Corken C-Series PumpComplete with Pump, Motor, & SwitchC10 is ideal for single scale cylinder filling operations. Fill 20lb. cylinders in 30-45 seconds and a 100lb. cylinder in 2 1/2-3 minutes. The flow rate is 6.5 gallons per minute at 50PSID. C12 is ideal for faster filling operations including motor fuels. Rated at 15 gallons per minute at 50 PSI.

Part Number HP PH Volt Inlet Outlet GPM@50 PSI

C10-SM-30 1 1 115/230 1 1/4” 1” 6.5

C12FD2A-SM30 2 1 115/230 1 1/2” 1” 15

*C-12 used for general filling 20lb. - 42lb. cylinders and motor fuel cylinders Recommend using C-12 with meter application

Repair Kits

Pump Seal Assembly Impeller Seal

HousingMotor Only

Heaters Internal Switch

For Switch

C9 113-CXA* 1003-09 1004-1X

C10/F10 113-CXA* 1003-0 1004-1X 2555 2275 (600-T0X5) P28

C12/F12 113-CXA* 1003-2 1004-1X 2556**2275**

(600-T0X5)P32**

C13/F13 113-CXA* 1003-3 1004-1X 4261 P35

C14/F14 113-CXA* 1003-4 1004-1X 2557

*Includes Case O-Ring (2-246A) and Case Clearance Shims (1014/1014-1)**with 1 1/2 hp motor

Model GPM Max PSID

C10 12* 80

C12 19* 85

C13 36* 110

C14 38* 125

*20 PSID @ 3450 RPM

Basic Valve & Nipple KitsPK-BKIncludes safety internal valve, strainer, flex, nipples, pipe fittings, adapters and hoses to complete your pump station.

Meter Piping KitsLCMK-01All the extra valves and fittings to install a meter in your pump station system.

WWW.TARANTIN.COM | 800-922-0724 12

PUMPS

Part Number Description

DW-1Z Pump 10 GPM, 3/4”

EG-1Z Pump 10 GPM, 3/4”

EC-HZ Pump 15 GPM, 1”

GC-1LZ Pump 13 GPM, 3/4”

EM1-3B Motor 1 HP, 3600 RPM

EM-5B Motor 1.5 HP, 3600 RPM

GC-1LZ-Mwith an EM-5B Motor

DW-1Z-Mwith an EM1-3B Motor

EG-1Z-Mwith an EM1-3B Motor

• Gear set easy to maintain without disturbing the mechanical shaft• No service ball bearing with no load design• Balanced gear configuration minimizes gear tooth contact• Superseal Mechanical shaft seal assembly, built as a kit onto the

pump shaft

GC-1LZ-M

with foot mount

GC-1LZwith foot mount

ASK ABOUT OUR SMITH PUMP AUTOGAS PACKAGE

PUMPS

13800-922-0724 | WWW.TARANTIN.COM

Corken Z3200 The Z-Series Coro-Valve® truck pumps are a new generation of truck pumps specifically designed to comply with the pumping requirements demanded by the LPG industry.

Pump Speed

Differential Pressure

Approximate Delivery on Propane

Break HP Required

Pump Torque Required

RPM PSI (KPA) GPM (LPM) BHP (KW) Ft Lbs (KG/M)

750 50 (345) 112 (424) 6.2 (4.6) 43.4 (58.9)

750 100 (689) 99 (375) 9.9 (7.4) 69.3 (94.0)

650 50 (345) 95 (360) 5.2 (3.9) 42.0 (57.0)

650 100 (689) 84 (318) 8.2 (6.1) 66.3 (89.9)

600 50 (345) 86 (326) 5.0 (3.7) 41.3 (56.0)

600 100 (689) 76 (288) 7.8 (5.9) 64.8 (87.9)

500 50 (345) 70 (265) 3.8 (2.8) 39.9 (54.1)

500 100 (689) 62 (235) 5.8 (4.3) 60.9 (82.6)

The Z4500 is a 4 inch stationary pump designed for transport loading and multiple bobtail loading applications. Rated up to 800 RPM.

Pump Speed

Differential Pressure

Approximate Delivery on Propane

Break HP Required

Pump Torque Required

RPM PSI (BAR) GPM (LPM) BHP (KW) Ft Lbs (KG/M)

800 50 (3.4) 400 (1511) 13.3 (9.1) 88 (12.0)

800 100 (6.9) 360 (1360) 26.7 (19.7) 176 (24.3)

650 50 (3.4) 326 (1209) 10.8 (8.0) 87 (12.0)

650 100 (6.9) 283 (1070) 21.7 (16.1) 175 (24.2)

500 50 (3.4) 235 (888) 8.3 (6.2) 87 (12.0)

500 100 (6.9) 200 (756) 16.7 (12.4) 175 (24.2)

The Z3500 is a 3 inch foot mount pump designed for stationary applications. Rated up to 800 RPM. Direct replacement for 3 inch Blackmer Pump.

Pump Speed

Differential Pressure

Approximate Delivery on Propane

Break HP Required

Pump Torque Required

RPM PSI (BAR) GPM (LPM) BHP (KW) Ft Lbs (KG/M)

800 50 (3.4) 121 (460) 6.6 (4.9) 43.4 (6.0)

800 100 (6.9) 110 (420) 10.6 (7.9) 69.3 (9.6)

650 50 (3.4) 98 (371) 5.2 (3.9) 42 (5.8)

650 100 (6.9) 88 (333) 8.2 (6.1) 66.3 (9.2)

500 50 (3.4) 73 (276) 3.8 (2.8) 39.9 (5.5)

500 100 (6.9) 63 (238) 5.8 (4.3) 60.9 (8.4)

Z4500

Z3500

WWW.TARANTIN.COM | 800-922-0724 14

EMERGENCY SHUT-OFF VALVES

Rego Emergency Shut-off ValvesEspecially designed for installation in liquid or vapor transfer lines at LP-gas bulk plants to provide for quick shut off of liquid or vapor flow in the event of an accidental pull-away or hose rupture.

Part Number

Exclusively For Use

With

Inlet and Outlet

Connections

Liquid Flow Capacity At

10 PSIG Pressure Drop (GPM)

A6010 LP-gas 1 1/4” F./NPT -

A6016 LP-gas 2” F.NPT 475 (LP-gas)

A6024 LP-gas 3” F.NPT -

ESV Pneumatic ControlsPart Number Description

6016-60DCylinder assembly kit to convert 6016

ESVs to pneumatic shutdown.

6016-60CPneumatic remote for 6016.

Open/close actuator

7605PN-50

Pneumatic remote shutdown system kit, complete with 100’ of tubing, fittings, 1 charging valve assembly, and 1 remote

shutdown assembly.

7605APN-8A Extra shutdown valve assembly.

7605AP-16 1/4” tubing tee w/ nuts.

7605AP-151/8” NPT x 1/4” tubing,

straight connector.

METERS

15800-922-0724 | WWW.TARANTIN.COM

14

31 2

Designed for retail sales dispensing units, the Liqua-Tech Model LPM-102 offers the widest flow range (3-18gpm) available in a meter this size and contains all required accessories including vapor eliminator, strainer and differential valve. ATC available.

1” Meter 090534-100090534-102Rate of Flow:• 3.0 to 18.0 gpmWorking Pressure:• 350 psi

(24 bar) max. (24.6 Kg/cm2)

Connections:• Standard assembly has inlet at

left and outlet to right with 3/4” and 1” female pipe threads available.

Register:• Veeder-Root, print or non-print• Temperature Compensator:• Compensates to 60°F (15°C)

Range:• -10°F to 125°F• -23°C to 52°C

LPM - 102 w/rest register (w/o temp comp) complete

090534-100

1 Main case housing 400027-00

2 Cover, main case 087173-710

3 Cover, vapor eliminator 087193-710

4 Flanges, inlet/outlet 087180-710

5 Flange, differential valve 087179-710

6 Flange, strainer 400025-001

7 Gasket, main case 004861-016

8 O-Ring, vapor eliminator flange 100139-012

9 O-Ring, inlet/outlet flange 100139-007

10 Bolt, Hex Head 7/16 x 1-1/4 Drilled 040237-005

Undrilled 040237-004

11 Bolt, Hex Head 3/8 NC x 1 100067-027

12 Bolt, Hex Head 5/16 NC x 1 100063-26

13 Loackwasher, split 5/16 100121-010

14 Measuring chamber 042075-101

15 Seal pin 042792-000

16 Roller, control 042086-010

17 Diaphragm 042791-000

18 Vapor return valve 087190-000

19 Float 087189-001

20 Gear Train, 43.5 ratio, US Gal 080905-017

21 Strainer 120 Mesh 101738-001

22 O-Ring strainer end caps 100139-006

23 Tube assembly, vapor release 087196-001

24 Nut, flared 087198-000

25 Male connector 1/8 NPT x 1/4 Tube 084826-100

26 900 Elbow, 1/8 NPT x 1/4 Tube 087195-000

27 Thermowell 086666-702

28 Cover, thermowell 083732-000

29 Register adapter tower 886150-000

30 Sockethead screws, 10-32 x 3/8 088524-010

31 Lock Washers, split #10 041211-000

32 Star Drive, with set screw 082976-001

33VRA-101-Register gear plate adapter (w/o Tem-perature comp)

886101-001

34 Cap screws, 1/4-28 x 5/8Drilled 100061-101

Undrilled 100061-100

35 Lock Washers, ext 1/4 100123-100

36 Register complete, Veeder Root(non printing) 788700-102

WWW.TARANTIN.COM | 800-922-0724 16

METERS14

31 2

Liqua-Tech Mid-Com MeterLiqua-Tech’s LPM-102 equipped with Mid:Com’s intrinsically safe E:Count LT Counter for established reliability, accuracy, and safety. This meter is also equipped with Liqua-Tech’s Patented Trac-Bearing measuring chamber, for improved accuracy, reliability and lower maintenance. The Trac-Bearing design controls and stabilizes piston rotation more efficiently than standard control rollers, resulting in greater sustained linear accuracy with less wear.With ATC: 090028-706

Lectrocount LCR-IILiquid Controls produces among the most reliable and accurate metering systems available, worldwide. For truck-mounted or fixed-site custody transfer applications requiring Weights & Measures approved accuracy, LC products deliver consistent, error-free, dependable service. Liquid Controlls family of

LectroCount electronic registers provide:

Liquid Control MeterLC Meters are known worldwide for exceptional accuracy, reliability, and longevity in a broad range of applications including truck applications meter-ing refined petroluem products and LPG.

• Improved efficiency relative to mechanical systems

• Electronic temperature compensation

• Weights & Measures approvals• Ruggedness and reliability

• Simplicity of Operation• Compatability with mobile

computing solutionsOptional Air Eliminator + Optional Vapor Eliminator MA-7-GY-10-LCR II

FEATURES AND BENEFITS OF ELECTRONIC REG-ISTRATION• Muti-point calibration to

improve the accuracy over a wide flow range

• Electronic Temperature Volume Compensation (ETVC) to reduce lost volume

• Increased security

• Future expansion and modularity with RS232/485 communication

• Greater control and accuracy of the delivery system through use of two stage valves, optical air eliminators with a LectroCount

• Register as a central control unit

• Lower total cost of ownership through fewer moving parts, solid state electronics and longer MTBF (Mean Time Between Failure).

Meter Registers Veeder Root Registers Neptune Registers

Part Number Description

788700-002 Veeder Root Register Only

789002-002*V.R. Register Printer-Face Up Ticket – Right

Hand**

100498-009 3/4” Neptune 631 (Code AEAAD)

100498-016 1” Neptune 631 (Code AAAAD)

880030-000 1 1/4-2” Neptune 833 (Code O)

*Factory rebuilt register available. Core return required.**Left hand register available–special order. Part Number: 7809022-701

788700-002600 SERIES

800 SERIES789002-002

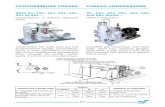

COMPRESSORS

17800-922-0724 | WWW.TARANTIN.COM

Krug Portable Compressor

Uses include on-site upgrading or downgrading size of storage in the field and emptying cylinders or tanks in need of repair.Compressor with LP engine H50LPHCompressor with gasoline engine H50GH Compressor only (no engine) 16771

Also available in natural gas and electric models. Repair parts available as well.

Compressors are extremely versatile as they can be used to transfer liquids between tanks, off-load liquids, recover residual vapor and

evacuate vapors for cylinder maintenance.

PK-C Includes...Part

Number Qty Description

LPH-1/2” 2 18ft. 1/2” hoses w/ends

LPH-3/4” 1 40ft. 3/4” hose w/ends

3171A 2 1 1/4” F.ACME x 1/2” MPT

7572C-14A 1 Check Loc Adapter 3/4”

3175 2 1 3/4” F.ACME x 3/4” MPT

7550P 1 Transfer Valve 3/4”

5765D 1 1 3/4” M.ACME x 3/4”

600120 1 Coupling SCH 80 3/4”

A7705P 1 Globe Valve 3/4” FPT

A7704P 2 Globe Valve 1/2” FPT

3175B 1 Coupling, 1 3/4” F.ACME x 1/2”

31270 1 Vent top 8” Q Series Vaporizer

75900 1 Riser Fusion 1 1/4” IPS x 1 1/4” MPT

Corken CompressorsAdd 107 to the model number to include the following: complete gas compressor bulk plant unit with pressure gauges, steel base plate, liquid trap, 4-way valve, strainer, interconnecting piping, adjustable driver slide base, V-belt drive and enclosed belt guard - ready to receive an electric motor driver. Relief valve not included. Corken suggests a 250 PSI relief. Comes in various vertical & horizontal models.*Maximum flow is based on 825 RPM or max-imum HP, 30 PSID. Capabilities are based on 100°F and will vary depending on piping and conditions.

Model Size

Specifications 91 291 491 691

Number of Stages 1 1 1 1

Number of Cylinders 1 2 2 2

Bore of Cylinders, Inches (cm)

3 (76.2) 3 (76.2) 4 (101.6)4 ½

(114.3)

Stroke, Inches (cm)2 ½

(63.5)2 ½

(63.5)3 (76.2) 4 (101.6)

Min at 400 RPM4

(113)8

(227)17 (481) 29 (821)

Max at 825 RPM8

(227)16 (453)

36 (1020)

60 (1699)

Max Discharge Pres. PSIG (bars)

335 (23.1)

335 (23.1)

335 (23.1)

335 (23.1)

Continuous Duty 5 5 5 5

Intermittent Duty 7 7 7 7

Maximum Allowable Driver Size, HP

7 ½ 15 15 30

Maximum Flow - Propane Flow - Propane GPM (m3/hr)*

50 (11.4)101

(22.9)215

(48.8)361

(82.0)

WWW.TARANTIN.COM | 800-922-0724 18

CYLINDERS AND STORAGE CABINETS

20 LB. White Cylinder10518VWZOPD/QCCZinc Metalized SteelRust Resistant

10 LB. Aluminum Vertical & Horizontal9058TC.2 (vertical)

9059TC.1 (horizontal)OPD/QCC

30 LB. White Cylinder1170VWZOPD/QCCZinc Metalized Steel Rust Resistant

40 LB. White Cylinder*1270VWZOPD/QCCZinc Metalized Steel Rust Resistant

100 LB. Gray Cylinder1836VGZMultivalveZinc Metalized SteelRust Resistant

CYLINDERS AND STORAGE CABINETS

19800-922-0724 | WWW.TARANTIN.COM

100 LB. ASME Cylinder68143Vacuum PurgedPlastic Lids

420 LB. ASME Cylinder6762.8Vacuum PurgedPlastic Lids

100 LB. Manchester Cylinder1428SteelPOL Adapter

33 LB. Steel Forklift Cylinder5580Liquid with gaugeQuick Fill ValveQuick coupler installer

33 LB. Aluminum9315.52Liquid with fill valvewith gaugeQuick coupler installed

33 LB. Aluminum*9367Mower cylinderVapor withdrawalFuel efficient & Green

*Other Sizes Available

WWW.TARANTIN.COM | 800-922-0724 20

CYLINDERS AND STORAGE CABINETS

20 LB. White Cylinder10518VWZOPD/QCCZinc Metalized SteelRust Resistant

33 LB. Steel Cylinder5580Forklift cylinderGauge and fill valve 7141MCode 12

These heavy duty Gas Cylinder Cabinets are designed for outdoor storage using heavy gauge construction. If you’re looking to keep your gas cylinders safe, choose either the X or M Series cabinets to store your tanks.Features:• Lockable T-handle plus hasp for padlock• Tapered front shelf for easy cylinder placement• Heavy duty tubular hinge welded to frame and door

Construction:• All welded construction. No nuts and bolts to come

loose.• 1 ½” angle frame• 1” angle shelves• 16 gauge steel roof• 16 gauge expanded metal sides and doors

Part Number

*Low Profile Depth Width Height

X-12 12 27” 43” 50”

X-16 16 27” 60” 50”

X-18 18 27” 43” 72”

X-24 24 27” 60” 72”

X-24L 24* 27” 85” 50”

X-36 36 39” 50” 72”

*Low Profile

Part Number

Number of Cylinders Depth Width Height

M-4 4 37” 30” 40”

M-6 6 37” 30” 55”

M-8 8 37” 30” 70”

M-12 12 37” 43” 70”

M-16 16 37” 60” 70”

M-24 24 37” 85” 70”

20 LB. Cylinder Storage CabinetsPowder coated white. Other colors

available. Includes 3 safety decals and a place for a safety placard (placard not included).

33 LB. Cylinder Storage Cabinets

Painted safety yellow - rust inhibitor and includes 3 safety decals.

Have You Visited Our New Website?

Recently we combined our Tarantin.com and our Tarantin.net websites into one clean, easy to use website. From here on forward www.Tarantin.com will be the place to sign up for training, catch up on our videos and blogs, download our catalogs, and do your online purchasing. Check it out today, and if you haven’t signed up for an online purchasing account, click the “Login or Register” link in the upper left corner and then click “Don’t Have an Account” link. Fill out the form and we’ll set you up today. See you online!

Are You Getting Our Monthly Newsletter?Keep up on what’s new a Tarantin when you sign up for our monthly newsletter. New products, new videos, new blogs, and what’s on clearance. Sign up at www.Tarantin.com/tarantin-news

WWW.TARANTIN.COM • 800-922-0724

Follow Us On Social Media

Follow us on your preferred social media outlet and keep up on everything that is happening in the world of propane. We share important information from the various Propane Gas Associa-tions.

WWW.TARANTIN.COM | 800-922-0724 22

TANK ANCHORING

Tank Cradles*120 gal. to 350 gal. tanks need 1 strap and 2 anchors. 351 gal. tanks to 1500 gal. tanks require 2 straps and 4 anchors.

Aluminum Tank Cradles

TC-1-A

Part Number Description Use

1346 36” Earth Anchor w/4” & 6” Disks Dense / Normal Soil

159336” Earth Anchor w/4” & 6” Disks &

StabilizerDense / Medium Soil

1284 50” Earth Anchor w/Double 4” Disks Loose to Medium Soil

1284G50” Earth Anchor Galvanized w/Double

4” DisksLoose to Medium Soil

2391Dry Concrete Anchor w/Bolt Expansion

SleeveConcrete - Dry

2010-MINUTE Split Bolt and Nut All Anchors

2365Stainless Steel Sling w/Sheathed Strap

& SealsFor Vertical Cylinders

2375 Stainless Steel Strap 100 ft. Roll Cylinders

2382 Strap Sheathing - 150 feet Cylinders

2730 Minute Man Drive Machine Cylinders

2741 Minute Man Anchor Adapter Cylinders

2375

Underground anchoring equipment for 500 and 1,000 gallon tanks. These are specifically designed to secure both 500 and 1,000 gallon Underground Tanks to a cement pad.

Minuteman Tank Anchoring System for Floodplain Tiedown

1284G1346

2010-Minute

23912741

Underground Tank KitUG-KitContains:(2) 1/2” x 15’ cables(4) 1/2” x 6’ turnbuckles(6) 1/2” cable clips(4) 1/2” x 9” x 15” anchors

*For the safe transportation of propane tanks.

CATHODIC PROTECTION

23800-922-0724 | WWW.TARANTIN.COM

Magnesium Anode Bag5, 9, and 17 lb. anode with 10 ft. X #12 gauge electrical lead attached. Bagged and boxed for shipping protection.Part Numbers:MG-5LB, MG-9LB, MG-17LB

Anode Test KitATK-2The anode test kit meets the requirements of NF-PA58’s new standard for Cathodic Protection. Anode test includes: meter, instructions, half-cell, 12-foot lead with hippo clip, set of red & black adapters, and case.

Riser Pipe ClampRetrofit anode connection for existing or new underground tanks.Part Number:RPC.1

Download Cathodic Protection Record Sheet at tarantin.com/downloads/Cathodic-Protection-Recording-Sheet.pdf

Bracket Mounting AdapterOptional accessory item for the anode test kit (ATK-2). For use with telescoping extension pole (16281).

16285

Telescoping Extention PoleOptional accessory item for the anode test kit (16285).

16281

Copper Sulfate Crystals 12 oz.16906Optional accessory item for the anode test kit.

Copper Sulfate Crystals 1 lb. 3 oz.T&R50300Optional accessory item for the anode test kit.

Copper Sulfate Anti-Freeze17105Optional accessory item for the anode test kit.

WWW.TARANTIN.COM | 800-922-0724 24

CATHODIC PROTECTION

WHY TANKS CORRODE Underground steel tanks corrode due to an electro- chemical reaction between the tank and the surrounding soil. The process of corrosion occurs due to small voltage differences on the steel surface that result in the flow of DC current from one location to another. Where current flows from the tank into the soil corrosion occurs. This location is called the anode in a corrosion circuit. Where current flows from the soil to the tank, no corrosion occurs. The progress of corrosion is determined by the amount of current flowing between the anode and the cathode and whether the locations of the anode/cathode remain constant over time. Corrosion rates are generally higher in wet soil environments since the conductivity of the soil promotes the flow of DC current in the corrosion circuit.

Corrosion generally exhibits itself on underground tanks in either a general overall rusting or more commonly, a pitting attack. Pit locations may result from metal- lurgical conditions of the steel surface or soil variations such as rocks, salts, fertilizer, moisture concentration, ox-ygen concentration, etc.PREVENTING CORROSIONProtecting underground tanks from corrosion is easily achieved by the use of two commonly applied protection methods: external coating and cathodic protection. These two methods are complementary and should be used in conjunction with the other. An effective external protective coating insulates the steel from the soil environment, thus preventing the flow of corrosion current from the anode to the cathode. An effective external coating can protect over 99% of the tank surface area. However, no coating is perfect. Damage from construction or soil stresses create tiny defects, which may result in accelerated corrosion at the defect.

Cathodic protection prevents corrosion at those defects by applying DC current from an external source, forcing the tank to become cathode. Application of sufficient DC current to the tank will prevent any corrosion from occurring. The two general types of cathodic protection systems are sacrificial and impressed current. Sacrificial systems are used when the amount of current required for the protection is small, such as in underground propane tanks. Impressed current systems are more commonly used for large structures such as large diameter pipelines. Electrical isolation of the tank from metallic piping systems and electrical grounds is critical for the cathodic protection system’s effectiveness.HOW SACRIFICIAL CATHODIC PROTECTION WORKSSacrificial systems work by creating a galvanic connection between two different metals. The most common anode material is magnesium, which when coupled to steel re-sults in DC current flow from the magnesium to the steel. The open circuit potential of steel is about -0.50 volts

referenced to a copper sulfate electrode. The open circuit potential of magnesium is about -1.55V to -1.80V. By connecting the two metals together, the difference of 1 to 1.25V volts results in current flow to the tank that overcomes the natural corrosion cells that exist on the tank. With this current available to the tank, no corrosion occurs.MAGNESIUM ANODESThere are a variety of anode sizes and alloys used for cathodic protection. The two primary alloys are designed as H-1 (or AZ63) and High Potential. The H-1 alloy is produced from recycled magnesium and has an open circuit potential of approximately – 1.55V. This alloy is well suited for protection of underground propane tanks. The High Potential alloy is 99% pure magnesium having an open circuit potential up to -1.8V. This alloy should be used for soil applications over 10,000 ohm-cm resistivity.

The two most common anode sizes used for underground propane tanks are 9 lb. and 17lb. The size designation relates to the metal weight. 10’ of #12 TW insulated wire is attached to the anodes. Anodes are then backfilled in a mixture of gypsum, bentonite, and sodium sulfate to lower the electrical resistance of the anode to soil. The mixture is a low cost, nonhazardous, electrically conductive backfill. The anode and backfill is then packaged in a cotton bag and either a cardboard box or paper bag. Actual shipping weight of these anodes with backfill is 27 lb. and 45 lb.APPLICATION RECOMMENDATIONSMagnesium anodes can protect underground tanks in most soil conditions. The H-1 alloy is generally very effective. The following chart provides size and quantity recommendations for various size tanks based on conservative design assumptions. This chart covers soil conditions up to 10,000 ohm-centimeter resistivity.

Resistivities higher than 10,000 ohm-centimeter generally represent very dry soils. Verification of soil resistivity can be performed through soil analysis. Contact us for design recommendations in locations where soil resistivities exceed 10,000 ohm-cm, or if there is no effective external coating on the tank.

The propane service line from the tank to the house also must be considered in the cathodic protection design, unless the service line is plastic. All underground steel pipe should be externally coated with a corrosion resistant material. The service line should be electrically isolated at the house with an insulating fitting or union. If service pipe is less than 50’ in length, the tank anodes will pro-vide sufficient current to protect both tank and pipe. For longer lengths of pipe, an additional anode may be required at the house connections.

If another metallic material such as copper is used for service piping, the pipe should be electrically isolated from the tank at the fill pipe connection. Copper and steel create a galvanic couple that will accelerate corrosion of the steel tank when directly connected to copper.

TOOLS AND ACCESSORIES

25800-922-0724 | WWW.TARANTIN.COM

Presto-Tap Gauges6800300 PSI Gauge

6800-B90300 PSI Gauge with Bleeder Valve

PT-30LP30 PSI Gauge with Bleeder Valve 90Patented, liquid filled or dry 30 PSI/ ambient temperature gauge. The inner red dial is the temperature reading that should closely correspond to the pressure reading (outer black dial) if liquid is in tank. Quick adapter provides access to the Presto-Tap valve without tools. Cloth belt-loop holster is inclluded. Also available with 10” hose to easily accomodate underground tanks.

PT9102 Series Service ValvesPT9102RT11.1PT9102RT11.7For vapor withdrawal service on DOT and ASME containers. They have an integral pressure relief valve and may only be used as an accessory valve on containers that have an independant pressure relief valve sufficient for that container’s capacity.• 3/4” M. NPT• Service Connection F. POL CGA 510• Fixed Liquid Level Vent Valve: Yes• Approx. Filling Rate Liquid Flow GPM: Pressure

drop across valve• 10 PSIG: 7.6 | 25 PSIG: 11.7 | 50 PSIG: 15.2 | 100

PSIG: 20.6

Test AdapterMSCP-TRVUL listed 1/8” M. NPT Regulator Valve for tank pressure and regulator tap location. Tank pressure, first stage and 11” w.c. locations. MSCP-TRV provides access for test instruments, either attached or by means of a hose barb.

PT7556R MultivalvePT7556RS12.0Suited for vapor withdrawal of ASME containers where compact groups of components are necessary. Separate filler valves and pressure relief valves are required.

Pigtails with Presto-TapPT912JS1212” POL 1/4” M. NPT

PT912JS2020” POL x 1/4” MPT

Presto Tap Universal Service Tech KitUniversal Service-Tech-KitThis diagnostic and leak tech kit includes a 6800 kg gauge, a PT-30 kg gauge, PT-5 kg gauge, PT-OZ, MHA-Straight, univer-sal flex hose, 3/16 allen key, RV, and bag.

Pressure Tap with BlockMSCP-TRV-BLOCKM.POL x F.POL high pressure test block (between tank and regulator).

WWW.TARANTIN.COM | 800-922-0724 26

TOOLS AND ACCESSORIES

Breakaway Locks500BRKHidden breakaway feature allows fire department or emergency response personnel access to valves, plant gates, etc. Lock shackle breaks away when struck with a hammer or chisel. Keyed alike.

Steel-Guard PaintB54W151-1GTank, solar white, 1 Gal.B54W151-5GTank, solar white, 5 Gal.

B50W24-1G Kem bond white primer, 1 Gal.B50W24-5GKem bond white primer, 5 Gal.

B71S200-1GBondplex, 1 Gal.B71S200-5GBondplex, 5 Gal.8538-1GSilver gray, 1 Gal.8538-5GSilver gray, 5 Gal.

353-8-1GTarlon Mastic bottom guard for cylinders, 1 Gal.

Ideal for use with pressurized gas systems. Ultra-sensitive to low pressure, minute leaks. Retains bubbles; bubble size indicates leak rate. Safe for use on polyethylene pipe fittings as outlined in ASTM test D-1693. Service temperature range: -10 ° F to 160 ° F. Wettable: fluid stays on metal longer, it can be used on vertical surfaces.

Sherlock 5-Second Leak Detector

LocksThe easy to install 510 Saf-T-Lok securely locks POL service valves to prevent unauthorized hookups, reduce pilferage, and secures tanks after “out of gas” calls. Provides an effective credit control.

Part Number Description

510 POL-LOCK

510-K POL-LOCK KEYB531G & B827P-A0

POL Lock complete with lock and plug for LP outlet valve keyed alike (key not included)

S502K-C-BLUEKey (when ordered with lock order) cut uniquely with coe for

each company

S533G-LLVC-A01 3/4" ACME valve cap lock with brass cap and slip ring with

lock keyed alike (key not included)

510

510-KB531G

B827P-A0S502K-C-BLUES533G-LLVC-A0

pictured in order of listing

NO. 11-1GThinner for use with 1 Gal. of masticFor use on underground tanks. 1 Gal. will coat an entire 1,000 Gal. tank

Roskote R28 UG Tank Coating/MasticR28-11 Gal.

R28-55 Gal.

Bucket GridBG-1For 5 gallon pail

The Original Saf-T-Lok510 Lock

510-KKey

1 key per box of 12 locks. Key can be sold separately.

300-L321 Pint Empty Bursh Top

800-LS31 Pint Empty Spray Bottle

800-LS51 Gallon Low Temp Jug

Locking CapsMSCP-MLC-12 1/4” inside diameter, 1 1/2” bottom opening, 1 1/8” height, filler valve type

MSCP-MLC-S42 1/2” diameter, 1 3/8” bottom opening, 1” height, 100lb. valve type: Encloses ACME thread or handwheel on valve to prevent tampering.

TOOLS AND ACCESSORIES

27800-922-0724 | WWW.TARANTIN.COM

Edmont Raised Finish Monkey Grip Glove23-173Raised finishProvides excellent grip for easier, safer handling of wet and dry materials. Tough vinyl coating resists chemicals and abrasion. Comfortable non-woven lining to keep wetness on the outside and dryness on the inside.

Halt! Dog RepellentHalt-Case12 - 1 1/2 oz. cans per caseComplete with belt clip.

Bee BopperBeebop-CaseWasp and Hornet spray 12 - 14 oz. cans per case

Luther’s Tank Wash103504 - 1 Gal. jugs per caseConcentrate is formulated to clean and shine paint on steel, fiberglass , and plastic tanks. Dilution rate of 4 to 1.

Wood Safety Plugs

Safety Treads/Ice Cleats

WP3/4X123/4” x 12”

WP1-1/2X121 1/2” x 12”

WP2-1/2X122 1/2” x 12”

WP3-1/2X243 1/2” x 24”

WP4-1/2X244 1/2” x 24”

WP HOLDERFor 3/4” - 1 1/2” & 2 1/2” - Truck

SGT-1Size 8-11 Spiked

SGT-2Size 11-13 Spiked

SS-2XLSize 13+ All Purpose

SGC-1MSize 5-9 Coiled

SGC-2LSize 9-12 Coiled

SGC-3XLSize 12+ Coiled

Strap onto your work boot for sure footing on any surface. Easy-on tough rubber materal.

Leather Palm GloveNO.1Packed 12 pairs per caseGeneral duty protective leather glove. Tuff stretch design. One size fits all.

23-173

SGC pictured

Hydrex Gloves11-435-09 & 11-435-10Stay Cool in any work environment with Hydrex® nitrile exam gloves. Hydrex® inner coating helps absorb moisture and keeps you cool during extended wear. These gloves give you cut protection and are suit-able in work environments where there is possible contact with bodily fluids, microorganisms, and chemicals.

Winter Tuf-Duk GloveFoam insulated fit and flexibility for non-slip handling of cylinders and for driving.

31-791T-M Medium

In the event of a valve being sheared off, hammering in a wood safety plug will allow you to remove the tank to safe area.

WWW.TARANTIN.COM | 800-922-0724 28

TOOLS AND ACCESSORIES

Emergency Response KitERK-1A complete package in a special toolbox that improves your ability to respond to propane emergencies. It is recommended for placement with key personnel in your company so that emergency response time can be kept to a minimum.

High Pressure Test Block2962Test block M. POL x F. POL0-300 PSI gauge and bleeder.

Low Pressure Test KitMSCP-LPTKIncludes pressure gauge, case, and 30” rubber tubing with bell end.

Teflon TapeZT13520” x 3/4” RollStandard Density

Yellow TapeYT71520” x 1/2” Roll

YT75520” x 1” Roll

High Pressure Test AssemblyFor air testing of piping systems includes brass test block, ½” Female pipe, air valve, and cap and a high pressure gauge

test assembly block

Part Number Range Gauge

MSCP-HPTA-5 0-5 PSI

MSCP-HPTA-30 0-30 PSI

MSCP-HPTA-60 0-60 PSI

MSCP-HPTA-100 0-100 PSI

High Pressure Test KitHPTK-2Provides for easy and accurate high pressure tests that conforms with gas check procedures.

29800-922-0724 | WWW.TARANTIN.COM

back mount

Steel Case Pressure Gauges 4 1/4”Standard single scale dial with PSI ranges, steel black case, phosphor or bronze bourdon tubeTest Assembly Block

Part Number Range Gauge

MSCP-SG4.5-300 0-300 PSI

MSCP-SG4.5-400 0-400 PSI

bottom mount

Steel Case Pressure Gauges2” industry standard single scale dial PSI ranges, steel painted black enamel bezel and case, clear glass lens, brass movement, phosphor or bronze bourdon tube

1/8” NPT ConnectionPart Number Range Gauge

MSCP-SG2-15 1/8 0-15 PSI

Bottom Mounted 2” x 1/4” Bottom Connection

Part Number Range Gauge

MSCP-SG2-15 0-15 PSI

MSCP-SG2-30 0-30 PSI

MSCP-SG2-60 0-60 PSI

MSCP-SG2-100 0-100 PSI

MSCP-SG2-200 0-200 PSI

MSCP-SG2-300 0-300 PSI

MSCP-SG2-400 0-400 PSI

Back Mounted2” x 1/4” Back Connection

Part Number Range Gauge

MSCP-SGC2-15 0-15 PSI

MSCP-SGC2-30 0-30 PSI

MSCP-SGC2-60 0-60 PSI

MSCP-SGC2-100 0-100 PSI

MSCP-SGC2-200 0-200 PSI

MSCP-SGC2-300 0-300 PSI

MSCP-SGC2-400 0-400 PSI

Brass Case Pressure Gauges2” single scale dial, PSI Ranges, glossy brass case with screw-on bezel, clear glass lens, brass move-ment, phosphor or bronze bourdon tube

1/8” NPT Con-nection

Part Number Range Gauge

MSCP-BG2-300 1/8

0-300 PSI

Bottom Mounted 2” x 1/4” Bottom Connection

Part Number Range Gauge

MSCP-BG2-15 0-15 PSI

MSCP-BG2-30 0-30 PSI

MSCP-BG2-60 0-60 PSI

MSCP-BG2-100 0-100 PSI

MSCP-BG2-300 0-300 PSI

MSCP-BG2-400 0-400 PSI

Back Mounted2” x 1/4” Back Connection

Part Number Range Gauge

MSCP-BGC2-15 0-15 PSI

MSCP-BGC2-30 0-30 PSI

MSCP-BGC2-60 0-60 PSI

MSCP-BGC2-100 0-100 PSI

MSCP-BGC2-300 0-300 PSI

MSCP-BGC2-400 0-400 PSI

Ammonia Pressure GaugesAmmonia Pressure Gauges by Mos-cap Engineering are designed to last. Built with Stainless steel tubes and sockets, Moscap’s ammonia pressure gauges are white with black scales. With an accuracy of Grade B (±3-2-3%) ASME B40.1, you can gauge your ammonia levels accurately. 2 ½” dial range with ¼” NPT

Bottom Mounted 2 1/2” x 1/4” Bottom Connection

Part Number Range Gauge

MSCP-AG2.5-60 0-60 PSI

MSCP-AG2.5-150 0-150 PSI

MSCP-AG2.5-160 0-160 PSI

MSCP-AG2.5-400 0-400 PSI

Liquid Filled Gauges

Glycerin liquid filled, stainless steel case, industry standard PSI/

KPA dual scale readings, 2 ½” dial range

Bottom Mounted 2 1/2” x 1/4” Bottom Connection

Part Number Range Gauge

MSCP-SGL2.5-30 0-30 PSI

MSCP-SGL2.5-300 0-300 PSI

MSCP-SGL2.5-400 0-400 PSI

Back Mounted 2 1/2” x 1/4” Back Connection

Part Number Range Gauge

MSCP-SGCL2.5-300 0-300 PSI

MSCP-SGCL2.5-400 0-400 PSI

HOSE ASSEMBLIES AND ACCESSORIES

WWW.TARANTIN.COM | 800-922-0724 30

Adapter HosesThe 40407 adapter hose has a safe, convenient, and user friendly design that makes it ideal for hooking up portable and high pressure appliances such as camp stoves, lanterns, and table top grills to large cylinders.

Hose Assemblies

Part Number Length Connection Max PSI Capacity

(BTU/hr.)

556#1791 12 feet 1/2” F. Flare 1/2 PSI (vapor only) 80,000

556#1793 12 feet 3/8” F. Flare 1/2 PSI (vapor only) 80,000

Part Number Length Connection Width

42413-120 120” 3/8” F. Flare x 3/8” F. Flare 1/4”

42610-48 48” 3/8” M. MPT x 3/8” F. Flare 3/8”

42613-60 60” 3/8” F. Flare x 3/8” F. Flare 3/8”

42613-120 120” 3/8” F. Flare x 3/8” F. Flare 3/8”

Part Number Length Connection Width

40407-48 48” 1”-20m x POL 1/4”

40407-60 60” 1”-20m x POL 1/4”

40402-24 24” 1/4” INVFL x POL 1/4”

40402-48 48” 1/4” INVFL x POL 1/4”

Replacement Hose and RegulatorsPart Number Length Connection

150-I5LTC24GRQC 24” 3/8” F. Flare x FQCC

150-I5LTC36GRQC 36” 3/8” F. Flare x FQCC

150-ISLTC60GRQC 60” 3/8” F. Flare x FQCC

UL and CSA Listed Hose AssembliesThermoplastic hose assemblies are available in 1/4” and 3/8” ID sizes only. The hose has a working pressure of 350 PSI with a 1750 PSI burst rating. All assemblies up to 60 inches in length are dual (UL and CSA) listed.

HOSE ASSEMBLIES AND ACCESSORIES

31800-922-0724 | WWW.TARANTIN.COM

Rego Quick Acting, Minimum Loss Hose End Valves for Bobtail Delivery Trucks and Dispensing Stations

Loss at disconnect is now less than 2CCDesigned to vastly reduce the amount of product vented when disconnecting bobtail delivery trucks, dispensing systems, and ahydrous ammonia nurse tanks.

Part Number

Inlet Connection

(F. NPT)

Outlet Connection (F. ACME)

Locking Handle

Flow at 1 PSIG (CV) Pressire Drop* (GPM/Propane)

A7793A 3/4” 1 3/4” yes 16.0

A7797A 1” 1 3/4” yes 16.0

Hose End SwivelsPart Number Inlet-Outlet Description Make

JO-1 1” M. NPT Swivel connector Full Circle

Bobtail Hoses• Textured Covered and tested• MPT EndsLPH-1NX125P-T – 1 inch x 125 feetLPH-1NX150P-T – 1 inch x 150 feet

SIGNS AND DECALS

WWW.TARANTIN.COM | 800-922-0724 32

Sign FramesSF-1 2’ x 4’, Frame ground style

M-97A-D 2’ x 4’, Frame floor style comes with hardware

DOT Cylinder Label Warning

CS33 2 1/2” x 5 1/2”, White vinyl printed in Red, Blue, and BlackCS-33-GHS 2 1/2” x 5 1/2”Custom printed with customer’s name, address, and phone number

Propane FillM-97A 2’ x 4’, Single FaceM-97A-D 2’ x 4’, Double Face M-97B 3’ x 6’, Single Face M-97-BD 3’ x 6’, Double Face

No Smoking

V-23BB 22” x 4” , Printed Red

Propane

V-28BB 14” x 4” , Printed Red

NFPA Hazard Rating HZ-1162 1/2” x 5”, Printed blue, yellow, black, and red

Recommended Procedures for FillingV-206 14” x 21 1/4” White printed RedP-20614” x 21 1/4” Blue printed Red

White Vinyl Bilingual Warning

AA-16-BI Printed red and blackMinimum order of 100

White Vinyl Warning

White Vinyl Custom Company Name

A-16 Printed red and black, Minimum order of 3,500

LP Gas VinylV-1075

Propane Exchange Single FaceM-93AX 2’ x 4’

No Smoking V-26B 12” x 18”, Printed RedM-26B 12” x 18”, Metal printed Red

Metal Gate SignM632 27” x 5”, Printed Red

AA-16 Printed red and black, Min. order of 100

New changes to OSHA’s Hazard Communication Standard are bringing the United States into alignment with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), further improving safety and health protections for America’s workers. The GHS is expected to prevent injuries and illnesses, save lives and improve trade conditions for chemical manufacturers. The Hazard Communication Standard in 1983 gave the workers the ‘right to know,’ but the new Globally Harmonized System gives workers the ‘right to understand.’Benefits: The modification is expected to prevent over 500 workplace injuries and illnesses and 43 fatalities annually. Once fully implemented it will also:• Improve the quality and consistency of hazard information in the workplace, making it safer for workers to

do their jobs and easier for employers to stay competitive;• Enhance worker comprehension of hazards, especially for low and limited-literacy workers, reduce confusion

in the workplace, facilitate safety training, and result in safer handling and use of chemicals;• Provide workers quicker and more efficient access to information on the safety data sheets;• Result in cost savings to American businesses of more than $475 million in productivity improvements, fewer

safety data sheet and label updates and simpler new hazard communication training: and• Reduce trade barriers by harmonizing with systems around the world.Major changes to the Hazard Communication Standard:• Hazard classification: Chemical manufacturers and importers are required to determine the hazards of the

chemicals they produce or import. Hazard classification under the new, updated standard provides specific criteria to address health and physical hazards as well as classification of chemical mixtures.

• Labels: Chemical manufacturers and importers must provide a label that includes a signal word, pictogram, hazard statement, and precautionary statement for each hazard class and category.

• Safety Data Sheets: The new format requires 16 specific sections, ensuring consistency in presentation of important protection information.

• Information and training: To facilitate understanding of the new system, the new standard requires that workers be trained by December 1, 2013 on the new label elements and safety data sheet format, in addition to the current training requirements.

What you need to do and when:• Chemical users: Continue to update safety data sheets when new ones become available, provide training on

the new label elements and update hazard communication programs if new hazards are identified.• Chemical Producers: Review hazard information for all chemicals produced or imported, classify chemicals

according to the new classification criteria, and update labels and safety data sheets.

Effective Completion Date

Requirement(s) Who

December 1, 2013 Train employees on the new label elements and SDS format. Employers

June 1, 2015*

December 1, 2015

Comply with all modified provisions of this final rule, except:

Distributors may ship products labeled by manufacturers under the old system until December 1, 2015.

Chemical manufacturers, importers, distributors and employers

June 1, 2016 Update alternative workplace labeling and hazard communication program as necessary, and provide additional employee training for newly identified physical or health hazards.

Employers

Transition Period Comply with either 29 CFR 1910.1200 (this final standard), or the current standard, or both.

All chemical manufacturers, importers, distributors and employers

2NH

6

FL

5

AL

4VA

3PA 1 NJ

1

2

3

4

5

6

CORPORATE HEADQUARTERSTarantin Industries86 Vanderveer RoadFreehold, NJ 07728Toll Free: 800 922 0724Fx: 732 780 5173

BRANCH LOCATIONSTarantin Industries20 Commercial DriveBrentwood, NH 03833Toll Free: 800 922 0724Fx: 603 679 4605

Tarantin Industries30 Industrial RoadElizabethtown, PA 17022Toll Free: 800 922 0724Fx: 717 361 0370

Tarantin Industries9733 Coach RoadRichmond, VA 23237Toll Free: 800 922 0724Fx: 804 279 0206

Tarantin Industries240 Oxmoor Court, Suite 268Birmingham, AL 35209Toll Free: 800 922 0724Fx: 877 769 1222

Tarantin Industries5050 State Road 206 WestElkton, FL 32033Toll Free: 800 922 0724Fx: 904 692 1068

WWW.TARANTIN.COM • 800-922-0724