2009 Fall Gazette

-

Upload

griffin-greenhouse-supplies -

Category

Documents

-

view

226 -

download

0

description

Transcript of 2009 Fall Gazette

New Toll Free Numbers

Toll Free Order Line:1-800-659-4346

Griffin General Inquires:1-800-888-0054

Griffin Locations:Cheshire, CTBall Ground, GATewksbury, MAGray, MEBridgeton, NJEwing, NJ

Auburn, NYBrookhaven, NYSchenectady, NYMorgantown, PAKnoxville, TNRichmond, VA

Griffi n announces new toll free numbers, and improvements to the way we handle your call. Our goal is to provide you immediate attention by answering your call as quickly and as effi ciently as possible. Often the limited staff at some of our smaller Branch locations hinders our ability to accomplish this goal, especially during peak times of the year. To remedy this problem we created a core customer service group to answer your calls and questions.

Our Customer Service Representatives are here to provide you the highest level of service. Our computer system has access to all locations so they see everything that an employee at your local Branch sees. The Customer Service Rep who answers your call can assist you when placing an order, inquiring about product availability or pricing, or answer questions about your delivery. They can also contact all Griffi n employeesto forward a message to a specifi c employee per your request.

In addition to the new toll free order line and fax line, we are also pleased to announce a new way to email us your order. To place an order:

• Toll free Order Line number: 1-800-659-4346• Email your order to: orders@griffi nmail.com• Fax your order to: 1-877-636-3623

To call a specifi c location or for all other inquiresyou can call us toll free at: 1-800-888-0054This number will give you access to all of thedepartments listed below.

• Press 1 Customer Service• Press 2 Plant Department• Press 3 Construction Department• Press 4 Technical Services• Press 5 Accounting Department• Press 6 Local Branch Location• Press 7 Corporate Directory• Press 0 Speak with our Receptionist

New

New

New

2

All articles and material featured in this Gazette cannot be duplicated without written permission. Copyright © 2009 by Griffin Greenhouse & Nursery Supplies

G R I F F I N G A Z E T T E F A L L 2 0 0 9 I S S U E

GGSPro Brings Technical Support to Growers

www.ggspro.com1-888-GGSPRO-1 ggspro@griffi nmail.com

Presentation Library15 technical grower related presentations. New presentations added monthly.

PublicationsPacked with in-depth technical articles focusing on the issues that affect your business.

DVD’sWe offer a series of instructional DVD’s in an array of areas.

Poster SetsInsect and disease quick reference posters with pesticide recommendations, mode of action, mixing rates and conversion tables to solve your insect and disease problems. Posters available in 11”x17” and 18”x24”.

Package # 1 Presentation Library & 4 Publications (1 year)$115.00

Package # 2 Presentation Library/4 Publications/Posters (1 year)$135.00

Package # 3 3 DVD’s & 4 Publications $99.00

Package # 4 4 DVD’s & 4 Publications$125.00

Package # 5 4 DVD’s/4 Publications/Posters $150.00

Posters Size in Packages # 2 & #5 are 11” by 17”All Packages have a $6.95 shipping fee added.Offers good through December 31, 2009

GGSPro Special Packages

W W W . G R I F F I N S . C O M 3

2009 Griffi n MA & PA Grower Expos

This year’s installments of the MA and PA Griffi n Grower Expos were held on August 26 in Springfi eld, MA and September 23 in Lancaster, PA. For those searching for a sign that industry health is returning, these two events, as well as the GA Expo held in June, made a decisive statement in the affi rmative.

The MA Expo was supported by over 100 vendors and drew 567 growers during the day long event. The PA Expo included over 70 vendors and drew an attendance of 675 growers. Each day was jam packed with vendor specials on products, plant material options from an impressive list of plant producers, great food and refreshment, and Griffi n’s outstanding educational seminar program.

This year’s educational program included presentations on new plant varieties for 2010, insect and mite control by Rick Yates, and a panel discussion dealing with marketing ideas of multi generational family operations. The two panelists were David Volante and Tal White, well known growers from Massachusetts and Virginia, respectively. Dave and Tal shared histories of their family run operations and visions of where they are leading them in the years ahead to keep them healthy and relevant. Raffl e prizes were also part of each Expo with MA Expo attendees receiving a Dosatron injector, Blue Ray disc player, and Ipod. PA Expo attendees received a Dosatron injector, portable generator, and 18 volt cordless tool set. In addition, the Myers group is giving away a trip to Disney World or the Atlantis Resort in the Bahamas at each Expo location.

Congratulations to all of the Grower Expo Prize Winners!

Massachusetts Prize Winners

1st Prize: Dosatron Injector Vaiuso Farm, Brandford, CT

2nd Prize: Blue Ray Disc PlayerRemington Greenhouse, Suffi eld, CT

3rd Prize: I-Pod Robins Flower Pot, Farmington, ME

Pennsylvania Prize Winners 1st Prize: Dosatron Injector Houck Homes, Shoemakersville, PA2nd Prize: Portable Generator Mahlon Zimmerman, East Earl, PA3rd Prize: 18 Volt Cordless Tool Set The Flower Wagon, Lititz, PA

3333333

By Peter Konjoian

4 G R I F F I N G A Z E T T E F A L L 2 0 0 9 I S S U E

Centralized Customer ServiceGROWER to GROWER

A change has been implemented in Griffin’s customer service that is helping to streamline how customer telephone calls are processed. You may already be aware that our traditional, branch-centric system has been expanded and modernized into a corporate wide centralized system.

This upgrade will result in shorter response time for customers calling any branch in the Griffin system. It will also allow for near instantaneous

order information, more efficient servicing of customers, and quicker response time in directing calls to the appropriate department.

When you’re busy, we are as wellOver the years I’ve enjoyed stating during internal Griffin meetings that as we growers go…so goes Griffin. Running a greenhouse business during the spring rush is arguably one of the most hectic jobs in agriculture. When the busy season arrives growers have twenty four hour days to accomplish 36 hours worth of work. So too does Griffin feel the challenge of keeping greenhouse supplies and equipment flowing through the distribution pipeline during the busy season. As Griffin has grown over the years the intensity of crunch time has also increased as local branches meet the challenge of servicing customers quickly and efficiently. Some who are reading this article remember days of old when the Tewksbury, Massachusetts branch and corporate home was the only branch in the company. In those days Griffin was a one branch show and able to comfortably keep pace with local demands of the growers in the area.

Some are reading this article from their greenhouses in Georgia and only know that the Ball Ground branch is the newest in the Griffin system. Others in Knoxville, Tennessee have been Griffin customers for a bit longer but still only a handful of years. And between Georgia and Massachusetts Griffin branches dot the landscape servicing growers for any number of years bracketed by the bookend branches mentioned. Literally, from Maine to Georgia and out to the Pennsylvania-Ohio border growers have become comfortable conducting their greenhouse business with Griffin. Reciprocally, Griffin has become comfortable working with the growers throughout this expansive territory. So, when I say that as we growers go…so goes Griffin, what I’m trying to say is when you’re busy, Griffin is as well. And when you’re very busy telephone call volume at any given branch can overpower customer service capacity. While this isn’t your direct concern, in-branch customer service personnel are charged with covering counter sales and unloading transfer trucks that operate between branches as well as manning the telephone lines. A natural efficiency to be achieved with the new centralized customer service system takes advantage of the fact that crunch time doesn’t occur at the same time at all of the branches. The spring rush for southern growers occurs before that of northern growers. This means that some customer service capacity will be available, in reciprocal fashion, as the

spring season wave spreads from south to north. Some northern reps will be available to help southern customers during their peak time which will be followed by some southern reps being available to help northern customers as their peak approaches.

Your job…let us know who you areWith the new centralized system, every customer service representative company wide from Maine to Georgia can take a call and service an order. The only required information from the customer is telling us who you are. No big deal, just a new routine. Once a customer identifies himself any customer service rep can access his orders, open quotes, track deliveries, and most anything else that’s needed. With each passing month more of us become comfortable doing business on the web. When dealing with companies regularly we often establish passwords to identify ourselves in order to access past activity, place a new order, you get the picture. Similarly, if a customer service rep at a distant branch is assisting during a telephone call all he or she needs…no…what he or she needs is to know who’s on the other end of the phone line. Many of Griffin’s customer service reps are people growers are already familiar with and have found on the other end of the telephone for years. We encourage you to ask for them at various Griffin functions such as Grower Expos, branch seminars, and other times in order to connect a face with a voice. They will be looking for you as well. An often heard comment is “I’ve been talking to you on the telephone all these years, it’s finally nice to meet you in person”.

Transferring calls to your local branch remains an optionAs we service more calls through the centralized system the option of being transferred directly to your local branch still exists. While many day to day orders can be handled centrally, there will undoubtedly be times when a particular person is needed to answer questions. Questions may be specific to billing and account status, require the construction department, or need to go straight to technical services. These options remain open and will actually become more efficient as the primary nature of a call is determined by your initial menu selection.

We won’t send calls to India or elsewhere in the far eastReferencing our lives as consumers again, many of us dislike having our high tech questions routed to India or some other far east country for service. My experience has been that each comment has to be made at least twice, both by me so the customer service person understands what I’m asking, and by the rep so I can understand what I’m being told. Aggravating is an understatement. Griffin’s promise to customers…calls will never go to foreign country for service. That said, all we need to agree on is that growers in Georgia won’t consider customer service reps in Massachusetts as foreigners. Reciprocally, growers in Maine won’t consider customer service reps in Tennessee as foreigners either. Now if we can get used to one another’s accents everything will be fine.

5W W W . G R I F F I N S . C O M

For the 2009 growing season we tested the waters when we launched the TrixiLiners from Selecta First Class Plants. These were 3 cuttings per liner, each different, that created an instant color coordinated combination planter or basket. Along with Trixi’s come a host of other breeders who trialed their own varieties in combinations and came up with their best mixes for 2010.

2010 Multiple Liner Programs

TrixiLinerThe TrixiLiner continues to evolve. With a few tweaks in variety selection and adding some new colors, they are back strong again for 2010 with 15 different recipes available. Available from Gro ‘n Sell, these are grown in a 72-cell standard tray and the liners are pinched, growth regulated and ready to grow for a quick finish. The 72-cell format keeps shipping affordable but is still large enough for a great energy-charged liner.

Pleasant View Gardens Multi-Liner programPleasant View introduces Multi-liners in 12 different combination choices. The goal of this program is to provide growers with a multi-genera liner featuring the top selling combinations within the Proven Winners lineup. These are proven combinations that ensure success for the grower, retailer and home gardener. Grown in a 50 cell, they are available from weeks 4-34. There is a large Combination Specific Tag for each combination and these can be ordered in bundled of 50 or 21 per tray. Multi-Liners decrease tag waste, reduce freight and labor costs, while ensuring uniform combinations. Recommended crop time is 6 weeks for 1 liner in a 6.5” to 1 gallon pot, or 8-10 weeks for 3 liners in a 10” pot.

Syngenta Flowers Kwik KombosThese 3-in-1, custom grown mixed liners feature designer blends of Syngenta’s best performers chosen from the GoldFisch line of annuals. The mixes include Lanai Verbena, Sanguna Petunia, and Callie Calibrachoa, plus others. They are available in 17 exclusive designer combinations selected for compatibility and strong retail presentation. These are grown in a 30mm x 40mm cell in 26 strips and combined into a 104 tray for shipping. They are 5 to 6 weeks old when shipped, pre-pinched and ready for transplanting. The plant-and-go process eliminates the design and setup delays which dramatically increases your transplanting productivity. Three liners are recommended for finishing 12” baskets. If you plant only 2 liners, you should schedule an additional pinch and add 2-3 weeks to your production time. Growth regulators will help provide a full and denser finish, but rates and applications will vary depending on the combinations selected. Allow 6-8 weeks crop time for 1 liner in a 6” or gallon pot, and 7-9 weeks for 3 liners in a 10-12” pot.

Barone Gardens Quick Turn 3 in 1 LinersThis is a program consisting of 12 mixed liners selected from Suntory and Ecke/Danziger genetics. They include 3 Million Bells Calibrachoa combinations, 3 Surfinia Petunia combinations, 2 Temari Verbena combination, and 4 mixtures of different species including Lobelias and Bacopas. These are rooted in 30mm Ellepots grown spaced in a 12 count strip and sold as 71 per tray.

All of these programs are ideal for taking the guesswork out of designing premium baskets, mixed containers and 6 inch pots. Call the Griffin Plant Department GPSHort for information, and full listing of color combinations available at 800-732-3509, or ask your Griffin sales representative.

Exciting Instant Color Combination Options for 2010!

Plant CornerBy Nanette Marks

1

2

3

4

5

6

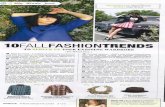

Cover Photo: Cymbidium, Griffi n Orchids sold in full bloom

1. Calibrachoa Trixi Berry Fields, 2. Calibrachoa Trixi Lemon Sorbet, 3. PVG Multi Liner Lively in Lavender, 4. Syngenta Kwik Kombo Fire and Ice, 5. Syngenta Kwik Kombo Passion, 6. Syngenta Kwik Kombo Display

Timely Tips: Frequently Asked Questions By Virginia Brubaker, Technical Support Specialist

G R I F F I N G A Z E T T E F A L L 2 0 0 9 I S S U E6

Septoria on Rudbeckia

Prolonged rainy spells often leads to outbreaks of Septoria leaf spot on rudbeckia. Septoria is a fungus that produces thread-like fungal spores. Under wet conditions these spores germinate, infect leaves and causes dark brown angular leaf lesions, typically starting on the lower leaves. Spots can be up to ¼” in diameter and when numerous, they can overlap and form larger irregularly shaped blotchy symptoms. Septoria can also be found on herbaceous perennials such as: coreopsis, veronica, heuchera and gaillardia. It occurs on several annuals as well, including tomatoes, sunfl owers and pansies. Development of Septoria is favored by frequent leaf wetting and high humidity common in late spring and early summer. Combinations of both cultural and chemical controls are required to control Septoria. Since splashing water is a primary means of spread use drip irrigation if possible. Hand watering should be done in such a way that it minimizes leaf wetting. Greenhouse produced crops will benefi t from horizontal air fl ow (HAF) fans that reduce humidity at the leaf surface and the duration of leaf wetting. Proper spacing of plants to prevent over-crowding is another key factor to reducing further infection.

Crop debris harbors the Septoria spores and provides an ideal environment for this disease. Remove and properly dispose of affected leaves promptly to reduce the spread of the disease. While Septoria leaf spot is unsightly, the damage is primarily cosmetic and infected plants will continue to bloom. A preventative fungicide application early in the crop helps to reduce the incidence of Septoria. Periodic sprays during wet weather will be needed to help keep Septoria in check. Effec-tive fungicides labeled for control of Septoria include: Cease, Clevis, Compass, Daconil, Eagle, Medallion, Spectro, Protect T/O and Zyban.

1. What are the irregular shaped brown spots on my rudbeckia? After thrips control, Botrytis

was the next most com-monly mentioned problem by growers seeking assis-tance from Griffi n’s Techni-cal Services department this year. The damp rainy weather that we continue to experience started at the most inconvenient time – right before Mother’s Day and has continued to plague most of our growing areas. With greenhouses fi lled to capacity and plants in full bloom, the persistent wet weather provided a launch pad for Botrytis. Botrytis symptoms can vary in appearance due to several factors including where on the plant it occurs and the current environmental conditions. Symptoms include leaf spots, petal blights, stem cankers and even seedling death from girdled stems. It may start as blotches on a petunia petal, a fl ower bud not opening or as a damaged leaf decaying. As it grows, fuzzy gray spores develop which eventually covers the entire fl ower, foliage or can even cause cankers on the stem.

Managing Botrytis needs to be addressed by evaluating the greenhouse environment. Begin by supplying adequate air circulation to reduce the relative humidity in the greenhouse. Allow as much space between plants as is physically and economically possible. Don’t be tempted to open vents on rainy days. If it is raining or foggy outside, keep the greenhouse closed up and supply some heat. HAF fans have proved to be quite valuable in assisting to dry out the air. Restricting irrigation to when it is absolutely necessary is also important. If drip irrigation is not available, limit overhead watering to the morning to allow the leaves to dry during the day. The prompt removal of infected leaves and blooms from the greenhouse also helps to reduce disease pressure.

Even with the best cultural controls, fungicides are often still needed. Examples of effective fungicides for Botrytis include: Cease, Chipco 26019, Daconil, Decree, Endorse, Medallion, OHP GT-O, Pageant and Veranda-O. It is always recommended to trial

pesticides on small quanti-ties of plants to evaluate for phytotoxicity before mak-ing large scale applications. These products may not be registered for use in all states.

Consult the Insecticide and Fungicide Options for 2009 bulletin for a comprehensive list including rates and use patterns. This bulletin is free of charge to Griffi n custom-ers. Read and follow the en-tire pesticide label. Products other than those mentioned

may be safe and effective.

2. What do I do to control Botrytis?

Botrytis on Petunia

Botrytis on Primula

Technical Tips

W W W . G R I F F I N S . C O M 7

By Peter Konjoian

Practical Tips on Supplemental Lighting

Both Rick Yates and Jim Willmott of Griffin’s Technical Services department have written and spoken about a resurgence in interest in supplemental lighting for spring floriculture crops. Those articles have appeared in past issues of this publication and in the our new GGSPro magazine. My co-horts have spoken on the topic at Griffin Grower Expos and seminars from Maine to Georgia.

Rather than discuss the why’s and when’s growers should consider in learning to use more supplemental lighting to produce shorter crop times, improved quality, and so on, in this article I am going to focus more on how to operate the units to achieve optimal results.

Photoperiod and Flowering: the BeamflickerUntil this light fixture became available it was generally agreed that photoperiod control was best achieved using common incandescent bulbs rather than high intensity discharge (HID) bulbs. The reason is that it only requires a low intensity of light to effect a plant’s day length sensors compared to the high intensity needed to fuel photosynthesis. The Beamflicker unit is an HID light with an interesting twist. It’s reflector is mounted in a way that allows it to rotate, allowing its light beam to slowly move from one end of a greenhouse to the other and back again. The high intensity light is used to reach from the middle of a greenhouse to the end, thereby eliminating the need to string incandescent fixtures with bulbs every four to six feet down the length of each bench. The only restriction to using the Beamflicker properly is the hanging basket load in the house. It makes sense that a single source of light radiating from the center of a house will be interrupted by baskets hanging above the crop given that the Beamflicker will be mounted close to the peak of the house to allow for the best light lines.

Photosynthesis and Growth: PL HID unitsAs we continue to connect supplemental lighting to crop economics and profitability it is becoming very clear that certain crops pay handsome dividends to investing in HID lighting for photosynthetic stimulation. I decided to focus comments on the economics of this form of supplemental lighting to illustrate the payback. I was told by Dan Morrissey of Griffin’s Construction department that the most common unit sold by Griffin is P.L. Light System’s 230 volt, 1 phase, 600 watt fixture with a list price of $300. Let’s run a few calculations to better understand how this unit makes money for growers. Let’s assume use of one of these fixtures for early stage growth of vegetative or seed annuals in plug trays post germination or rooting and prior to hardening and transplant. For simplicity, we’ll assume a single unit will cover a ten foot by ten foot bench space, 100 square feet total. Let’s also assume the following; the unit will be run continuously for twelve hours per day, say 6:00 a.m. to 6:00 p.m. for example. The crops will be spring annuals which means we’re talking about running the lights during the months of February and March for reference. My local cost of electricity in Andover, MA is about $0.18 per kilowatt hour of power.

The overhead cost of using this fixture will be the initial cost of $300 plus installation and maintenance costs. We’ll assume the unit will last ten years and the total cost of the unit, installation, and maintenance will be $500. This allows us to calculate an overhead cost of $50/year for this unit. The cost of operating the unit is calculated as follows. The bulb wattage of 600 is multiplied by the number of hours per day the lamp will be run, twelve hours. Twelve hours x 600 watts = 7200 watt hours or 7.2 kilowatt hours per day (1000 watts = 1 kilowatt). At the cost of $0.18/kwh it will cost 7.2 kwh/day x $0.18/kwh or $1.30/day to run the lamp. Let’s assume next that a crop will be lit on this bench for a period of four weeks before it’s transplanted and another crop will be grown under the light. The cost of lighting the 100 square feet of bench space for four weeks will be $1.30/day x 28 days or $36.40. If we really simplify this example and assume the light is only used for these two crops, a total of eight weeks per year, the cost of lighting each of the plug crops will be $25 (half of the $50 overhead cost) plus $36.40 for the electricity, for a total of $61.40. Now let’s examine how this input cost will effect the crop’s profitability. Both Rick and Jim have done an excellent job explaining how supplemental lighting benefits crop growth. The basic effect is to stimulate photosynthesis during the early stage of plug growth which translates into shorter crop time and higher quality of growth. My final calculation will show how much we will spend to light a crop for four weeks on a per plug basis. Then, I’ll end with the question of whether this added investment is a wise business decision. A standard 1020 plug tray occupies approximately 1.5 square feet of space. The 100 square feet of bench space lit by the lamp will provide light for 66 plug trays. So, taking the total cost of lighting of $61.40 it will cost $0.93, a little less than $1 per tray. Assuming a tray capacity of 100 plugs, the total cost of lighting each young plant will be about one penny. Remember that we need to use the light minimally for two crops per year for ten years with the assumptions we’ve used. Finally, the question becomes: If I spend one penny per plant to light the plugs, can I save more than one penny in production cost or make more than one penny in profit due to improved quality from using the HID lamp? Rick and Jim have told us the answer for a growing number of crops is yes. Some crops see crop times reduced by a whole week as a result of this early growth stimulation. Others see improved branching and fuller growth resulting in fewer plants per hanging basket or higher quality sustaining higher selling price. Either way, both the science and economics support significantly expanded use of supplemental lighting to stimulate profitability.

8 G R I F F I N G A Z E T T E F A L L 2 0 0 9 I S S U E

Are You Ready to Try Biological Control? By Jim Willmott, Technical Services Specialist

You have probably heard success stories of growers using biological control agents (BCAs) for insect and mite control. Grower interest has increased rapidly for several reasons. In some cases pests, thrips for example, have become increasingly difficult to control with insecticides. In other situations growers recognize the opportunity to appeal to customers who see BCAs as a “Green Alternative”. Most importantly there has been significant progress that includes utilizing new BCA’s, including banker plants and trap crops as well as refining release timing and numbers. The wider acceptance of BCA’s in ornamental greenhouses adds to the knowledge base and contributes to more successful results.

Implementation of a BCA program is not easy. As more growers have become interested in biological controls some have obtained less than desirable results because they either tried to do too much too quickly, had unrealistic expectations, or simply did not pay attention to detail. Just as for growing new crops, learning a new technique requires persistence in order to achieve success within your own unique production systems. Many progressive growers have welcomed the challenge as an opportunity to gain a competitive advantage.

Before beginning, plan ahead and review pesticide application records, for the previous six months, to determine if any may interfere with your program. Consider beginning with small steps: focus on one key pest such as fungus, gnats or thrips. As you gain experience you can always expand your efforts. Griffin technical, sales and customer service representatives are all committed to assisting you. However, you must do your part to work hard and remain committed.

To be successful with biological control you should:

1. Have a good understanding of pest and BCA life cycles

2. Consider pest management a priority - including pest exclusion and sanitation

3. Commit time to scheduling orders, BCA releases and monitoring of BCAs and pests

4. Practice pest scouting using sticky cards and plant inspection

5. Know which pesticides are compatible with BCAs

6. Run a well organized and managed operation

7. Have the support of managers or owners

8. Have a realistic attitude:

• BCA’s can be very effective, but they are not a simple solution

• Learning requires commitment

• Adoption of BCAs requires dedication

• Willingness to tolerate low pest populations

W W W . G R I F F I N S . C O M 9

There has been a great deal of attention aimed at numer-

ous grant programs designed to help growers begin installing

renewable, sustainable systems in their greenhouses and on

their farms. Some of these programs include recent Congressional

stimulus funds, federal and state renewable energy grant

programs, energy conservation programs, and water

conservation programs.

The list of agencies offering money becomes confusing

quickly and can be frustrating as each agency has different

procedures applicants need to follow. Putting aside the paperwork

challenge for the moment, let’s break down the discussion by

simply reporting the stories of four growers who have successfully

navigated the process to install exciting, effi cient technologies to

help operate their businesses more sustainably.

Grower A received a joint New Hampshire - USDA government

grant through the Rural Development for Renewable Energy

program. The application process was quite diffi cult (Grower A

rated the effort as an eleven on a scale of one to ten with one

being easy!). The grant totaled approximately $500,000 which

provided about 25% of the project’s total cost. Because the

project was a large one Grower A feels the effort was well worth

the effort.

Grower B received a joint Connecticut – USDA Rural Development

grant totaling $195,650 in federal funding to initiate energy

effi cient improvements in a new four bay greenhouse range. He

also received $391,000 in long term, low interest loans.

Grower C applied for and received two grants. The fi rst was a

Massachusetts Flower Growers Greenhouse Energy Conservation

grant that he used to install an energy blanket. This program

was designed as a matching funds program to help growers

afford energy conservation upgrades. The second grant was from

a Farm Viability Enhancement program which totaled $75,000

toward ebb and fl ood benching. Grower C reports that fi lling out

the paperwork was moderately diffi cult and the people in charge

were more than willing to take the time to answer questions. He

feels the effort was absolutely worth his time.

Grower D installed wind and solar systems and applied to several

programs including the Massachusetts Technology Collaborative,

NRCS, USDA Rural Development, and MDAR Environmental

Enhancement Program. A few requirements he had to meet

included proper site selection, various permits, and overall energy

consumption needs. The grants covered between 50-75% of the

project and he feels the effort was completely worthwhile even

though the process was diffi cult. So far he feels the solar system

is more impressive than the wind.

These reports of grower experiences confi rm that free money

is available and worth the effort to pursue. Growers throughout

Griffi n territory should not feel intimidated by the various

programs’ paperwork. With a little effort renewable energy

systems can be installed using money from these programs to

help take the sting out of the cost. Every grower who has pursued

and installed these technologies feels the process was worth

the effort.

By Mike Foley and Peter Konjoian

Free Money from Energy Grant Programs

For more information: www.dsireusa.org/ - This is a comprehensive source of information on federal, state, local and utility incentive programs. It lists them individually noting funds available, eligibility, purpose and authorized use. For a complete listing e-mail maria.saade@griffi nmail.com.

Shop Talk:

Water, tissue and media tests will give you better solutions.For greenhouse and nursery growers, the more you know, the better plants you can raise. Knowing your water type is the fi rst step in choosing the right water soluble fertilizers. Growing media testing helps you monitor nutritional programs, while tissue testing helps diagnose the possible causes of various problems. And for turf managers and landscapers, a comprehensive soil test is critical to an effective turf management program.

Whatever you’re growing, installing or maintaining, you can get better results when you know exactly what nutrients and minerals are naturally in your resources...and where you need to supplement. Once upon a time, growers and landscapers had to rely on symptoms and try different solutions until they hit on something that worked. Now, The Scotts Testing Lab can help take all the guesswork out of it. With affordable, comprehensive water, growing media, plant tissue and mineral analysis, you’ll get fast, clear-cut answers well before a little problem turns into a big one.

Scotts is dedicated to providing accurate, affordable analysis through The Scotts Testing Lab. The Lab provides easy-to-understand reports for all of your growing needs. And only Scotts matches that with the expertise of their technical advisors, plus the industry’s most successful water soluble and timed release fertilizers.

Contact your Griffi n Sales Rep for more information on a coupon for a FREE water test.

The Scotts Testing Lab It’s better if you don’t pass this test!

Osmocote Pro 17-5-11

The Scotts Company has announced a new formulation in their 2nd generation Osmocote Pro line of blended controlled released fertilizers. For greenhouse use, nursery stock production, and landscape use.

Osmocote Pro 17-5-11 - 3-4, 5-6, 8-9, 12-14 month release patterns with improved micronutrients.

These formulations feature 100% coated, homogeneous N-P-K prills blended with a proven Scotts micronutrient package. Benefi ts to growers include:• Contains no urea nitrogen so these products can be used in covered production as well as outdoor nursery, foliage, and landscape plants.

• Micronutrient package, equivalent to Scotts Micromax, provides plants essential minor elements for high quality growth in a form they can easily utilize.

• Elevated level of iron in sulfate form which is easily taken up to encourage good foliage color

• Same size fertilizer and micronutrient particles to ensure even distribution in bag, when incorporated in soil and when top dressed on containers.

• This versatility allows growers to use the same fertilizer product in many different areas of their operation, which can help save time and money.

• A choice of longevities: 3-4, 5-6, 8-9, 12-14 months offer the fl exibility to provide consistent, reliable, nutrition for as long as the crops need it.

• Analysis of 17-5-11 gives good cost-in-use valueThese new blended formulations offer the grower the performance of a homogeneous N-P-K release pattern, complete minor element package, elevated iron, same prill size accuracy, with the economical price of a blended controlled release fertilizer. For additional details and product information sheets, visit www.OsmocoteIsBest.com.

By Bob Storry, Griffin Nursery Specialist

10 G R I F F I N G A Z E T T E F A L L 2 0 0 9 I S S U E

11W W W . G R I F F I N S . C O M

High-quality signage, at aff ordable prices, with NO minimums!

• 2 sided printing on Coroplast• Full color print • UV coated• Grommets for easy hanging (24x36)

No. PP-2436CU* - 24” x 36” Custom $84.95

No. PP-1623CU* -16 1/2” X 23” Custom $64.95

*Delays possible pending minimum manufacture order.Ask your Griffin Salesperson for complete details on custom orders.

Looking for custom posters?Want to feature a special plant variety? Maybe you would like to put your business name on it? Or how about even a picture of your establishment? Then the below posters are for you!

Point of Purchase

Posters

For more information or to order call: 1.800.659.4346

24” X 36” No. PP-2436PE - Perennials $69.95

No. PP-2436PO - Poinsettias $69.95

No. PP-2436SH - Shade Annuals $69.95

No. PP-2436SU - Sunny Annuals $69.95

No. PP-2436VG - Vegetables $69.95

No. PP-2436CR - Coir Pots $69.95

No. PP-2436A5 - 5 Poster Set $319.95 (Includes: Perennials, Poin., Sh. Annuals, Sun. Annuals & Veg.)

Best

Value

16 1/2” X 23” No. PP-1623PE - Perennials $49.95

No. PP-1623PO - Poinsettias $49.95

No. PP-1623SH - Shade Annuals $49.95

No. PP-1623SU - Sunny Annuals $49.95

No. PP-1623VG - Vegetables $49.95

No. PP-1623CR - Coir Pots $49.95

No. PP-1623A5 - 5 Poster Set $229.95 (Includes: Perennials, Poin., Sh. Annuals, Sun. Annuals & Veg.)

Best

Value

PRSRT STDUS POSTAGE

PAIDPERMIT #6

HUDSON, MA

GriffinGazetteP.O. Box 36, Tewksbury, MA 01876-0036

Dimensions in Inches* CapacityProduct Outside Cubic Volume CompatibleDescription Item Number Diameter Height Inches US Price /CS Trays3.00 Stnd Coir Pot (CRS0300) 58-17300 3 ¼ 3 ¼ 15.9 8.32 fl oz $146.05 MPB0635, TRV85184.00 Stnd Coir Pot (CRS0400) 58-17401 3 7⁄8 3 3⁄8 24.8 13.8 fl oz 158.87 TRS1040, TRS15414.50 Stnd Coir Pot (CRS0450) 58-17450 4 3⁄8 4 36.6 1.26 pt 112.56 TRS1045, TRS1245 TRS1545, TRS15466.00 Stnd Coir Pot (CRA0600) 58-17602 5 7⁄8 4 77.5 1.34 qt 153.84 TRS066E, TRS06151 Gallon Short Coir 58-17100 6 ¾ 6 ¼ 148.2 2.56 qt 197.74 TRPTGAL, TRI0601,Nursery Container (CRNST1G) TRS0617

Sign size is 16 1/2” x 23”

Stand up sign holder also

included

$75.00 Value

Super Saver:

Get a Free Coir Pot Point of Purchase Sign when you buy 10 or more cases of Coir Pots. (Sign shown to the right)

Look for Griffi n at these Tradeshows:

MANTSJanuary 6-8, 2010Baltimore Convention Center Baltimore, MDwww.MANTS.com

Mid-States Hort. ExpoJanuary 12-13, 2010Kentucky Expo CenterLouisville, KY

SE Reg. Fruit & Veg. Conf. January 8-9, 2010Savannah Convention Center, Savannah, GA

NE Veg. & Fruit Conf.December 15-17, 2009Center of New Hampshire Radison, Manchester, NH

GGIA WinterGreenJanuary 28-29, 2010Gwinnett Civic CenterDuluth, GA

NE GrowsFebruary 3-5, 2010Boston Convention CenterBoston, MA www.newenglandgrows.org