15801 DWDM System Common Platform Installation Manual.pdf

Transcript of 15801 DWDM System Common Platform Installation Manual.pdf

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

1/98

Corporate Headquarters

Cisco Systems, Inc.170 West Tasman DriveSan Jose, CA 95134-1706USAhttp://www.cisco.comTel: 408 526-4000

800 553-NETS (6387)Fax: 408 526-4100

Cisco ONS 15801 DWDM System

Common Platform Installation Manual

April 2002

Text Part Number: 78-12898-04

http://www.cisco.com/http://www.cisco.com/ -

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

2/98

THE SPECIFICATIONS AND INFORMATION REGARDING THE PRODUCTS IN THIS MANUAL ARE SUBJECT TO CHANGE WITHOUT

NOTICE. ALL STATEMENTS, INFORMATION, AND RECOMMENDATIONS IN THIS MANUAL ARE BELIEVED TO BE ACCURATE BUT ARE

PRESENTED WITHOUT WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. USERS MUST TAKE FULL RESPONSIBILITY FOR THEIR

APPLICATION OF ANY PRODUCTS.

THE SOFTWARE LICENSE AND LIMITED WARRANTY FOR THE ACCOMPANYING PRODUCT ARE SET FORTH IN THE INFORMATIONPACKET THAT SHIPPED WITH THE PRODUCT AND ARE INCORPORATED HEREIN BY THIS REFERENCE. IF YOU ARE UNA BLE TO

LOCATE THE SOFTWARE LICENSE OR LIMITED WARRANTY, CONTACT YOUR CISCO REPRESENTATIVE FOR A COPY.

Modifications to this product not authorized by Cisco Systems, Inc. could void the FCC approval and negate your authority to operate t he product.

The Cisco implementation of TCP header compression is an adaptation of a program developed by the University of California, Berkeley (UCB) as part of

UCBs public domain version of the UNIX operating system. All rights reserved. Copyright 1981, Regents of the University of California.

NOTWITHSTANDING ANY OTHER WARRANTY HEREIN, ALL DOCUMENT FILES AND SOFTWARE OF THESE SUPPLIERS ARE PROVIDED

AS IS WITH ALL FAULTS. CISCO AND THE ABOVE-NAMED SUPPLIERS DISCLAIM ALL WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, THOSE OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE AND

NONINFRINGEMENT OR ARISING FROM A COURSE OF DEALING, USAGE, OR TRADE PRACTICE.

IN NO EVENT SHALL CISCO OR ITS SUPPLIERS BE LIABLE FOR ANY IN DIRECT, SPECIAL, CONSEQUENTIAL, OR INCIDENTAL

DAMAGES, INCLUDING, WITHOUT LIMITATION, LOST PROFITS OR LOSS OR DA MAGE TO DATA ARISING OUT O F THE USE OR

INABILITY TO USE THIS MANUAL, EVEN IF CISCO OR ITS SUPPLIERS HAVE BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAG ES.

AccessPath, AtmDirector, Browse with Me, CCDA, CCDE, CCDP, CCIE, CCNA, CCNP, CCSI, CD-PAC, CiscoLink, the Cisco NetWorks logo, the Cisco

PoweredNetwork logo, Cisco Systems Networking Academy, the Cisco Systems Netw orking Academy logo, Fast Step, Follow Me Browsing, FormShare,

FrameShare, GigaStack, IGX, Internet Quotient, IP/VC, iQ Breakthrough, iQ Expertise, iQ FastTrack, the iQ Logo, iQ Net Readiness Scorecard, MGX,

the Networkers logo, Packet, RateMUX, ScriptBuilder, ScriptShare, SlideCast, SMARTnet, TransPath, Unit y, Voice LAN, Wavelength Router, and

WebViewer are trademarks of Ci sco Systems, Inc.; Changing the Way We Work, Live, Play, an d Learn, Discover All Thats Possibl e, and Empowering

the Internet Generation, are service marks of Cisco Systems, Inc.; and Aironet, ASIST, BPX, Catalyst, Cisco, the Cisco Certified Internetwork Expert logo,

Cisco IOS, the Cisco IOS logo, Cisco System s, Cisco Systems Capital, the Cisco Systems logo, Enterprise/Solver, EtherChannel, EtherSwitch, FastHub,

FastSwitch, IOS, IP/TV, LightStream, MICA, Net work Registrar, PIX, Post-Routing, Pre-Routing, Registrar, Str ataView Plus, Stratm, SwitchProbe,

TeleRouter, and VCO are registered trademarks of Cisco Systems, Inc. and/or its affiliates in the U.S. and certain other countries.

All other brands, names, or trademarks mentioned in this document or Web site are the property of their respective owners. The use of the word partner

does not imply a partnership r elationship between Cisco and any other company. (0104R)

Cisco ONS 15801 DWDM System Common Platform Installation Manual

Copyright 2001, Cisco Systems, Inc.

All rights reserved.

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

3/98

iii

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

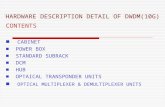

C O N T E N T S

Preface xi

Safety Summary xi

General Safety Precautions xi

Electrical Safety Precautions xi

Optical Safety Precautions xii

Laser Safety Features xiii

ESD Precautions xiv

Safety Symbols and Labels xiv

Area Warning Sign xiv

Electrical Safety Labels xv

Front and Back Door Safety Labels xv

Subrack Safety Labels xvi

Module Safety Labels xvii

Conventions xviii

Documentation InfoSet Structure xix

Obtaining Documentation xx

World Wide Web xx

Ordering Documentation xx

Documentation Feedback xx

Obtaining Technical Assistance xxi

Cisco.com xxi

Technical Assistance Center xxi

Contacting TAC by Telephone xxii

Contacting TAC Using the Cisco TAC Website xxii

CHAPTER 1 Introduction 1-1

Purpose of This Publication 1-1

Manual Structure 1-1

References 1-2

Applicable Standards 1-2

Additional ONS 15801 System Information 1-2

Related Standards References About Wavelength Division Multiplexing 1-2

Equipment Classification 1-4

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

4/98

Contents

iv

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

CHAPTER 2 Unpacking and Storage 2-1

Equipment Verification 2-1

Preliminary Inventory Check 2-3

Damage Reporting 2-3

Site Verification 2-3

Unpacking 2-5

Unpacking Tips 2-5

Unpacking ONS 15801 System Racks 2-5

Unpacking ONS 15801 System Subracks 2-7

Unpacking ONS 15801 System Air Ducts 2-7

Unpacking ONS 15801 System Modules 2-7

Unpacking Cable Kits 2-8

Storage 2-8

Equipment Handling 2-8

CHAPTER 3 Installation 3-1

General Installation Guide 3-2

Installation Planning 3-3

ONS 15801 System Common Platforms 3-3

Standard System Configurations 3-5

Required Items 3-5

Grounding Requirements 3-6

Grounding Requirements 3-6

ONS 15801 System Equipment Rack 3-7

Installation Procedures 3-9

Preparing Racks for Installation 3-9

Rack Installation on Concrete Flooring 3-10

Rack Installation on Raised Computer Flooring 3-13

OSR-WE Subrack Installation 3-16

OSRE-DCU Subrack Installation 3-18

Air Duct Installation 3-18

Air Duct Installation in Subrack 3-19Air Duct Top Installation 3-20

Protective Earth Connection 3-20

Rack Earth Connection 3-21

Subrack Earth Connection 3-21

Bay Power Installation 3-22

Sub-Rack Power Installation 3-24

Ethernet Cabling 3-25

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

5/98

Contents

v

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Control Bus Intershelf Cabling 3-25

Control Bus Interbay Cabling 3-26

Multiplexer and Combiner Module Installation 3-27

SCF and BAT Module Installation 3-29

SCF Module Installation 3-30

BAT Module Installation 3-31

Cable Lacing and Dressing 3-32

Door Assembly 3-32

CHAPTER 4 Setup 4-1

Subrack Address (SRADD) Switch Settings 4-1

System Installation 4-3

CHAPTER 5 Test 5-1

Input Voltage Installation Check Procedure 5-1

System Installation 5-5

CHAPTER 6 Connectors and Cabling 6-1

Power Distribution Panel Connections 6-1

Subrack Connector and Cabling Functions 6-1

Station Cabling 6-3

A-IN Connector Cabling 6-3ALM Connector Cabling 6-3

CBUSA, CBUSB Connector Cabling 6-5

CMPBUS Connector Cabling 6-6

D-IN Connector Cabling 6-7

D-OUT Connector Cabling 6-7

F1P1 Connector Cabling 6-8

F1P2 Connector Cabling 6-9

GPBUS Connector Cabling 6-10

IOCBUS Connector Cabling 6-12

LSMBUS Connector Cabling 6-13

OP-I/O Connector Cabling 6-14

QA Connector Cabling 6-15

RMA Connector Cabling 6-16

X.25 Connector Cabling 6-16

PCtoONS 15801 System Connection 6-17

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

6/98

Contents

vi

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

7/98

F I G U R E S

vii

Cisco ONS 15800 DWDM System Common Platform Installation Manual

78-12898-04

Figure 1 Cisco ONS 15800/15801 System Startup Warning xiii

Figure 2 Sample Laser-Controlled Area Warning Sign xiv

Figure 3 Electrical Energy Hazard Symbol xv

Figure 4 Attention Symbol xv

Figure 5 Danger Label on Front and Back Doors of Cisco ONS 15800 Subracks xv

Figure 6 Danger Label on Front and Back Doors of Cisco ONS 15801 Subracks xvi

Figure 7 ONS 15800 System Backplane Safety Label xvi

Figure 8 ONS 15801 System Backplane Safety Label xvi

Figure 9 Backplane Aperture Laser Safety Label xvii

Figure 2-1 Example of Shipping LabelFront 2-1

Figure 2-2 Example of Shipping LabelTop 2-2

Figure 2-3 ONS 15801 System Equipment Rack Unpacking 2-6

Figure 3-1 Typical ONS 15801 System Equipment Rack 3-2

Figure 3-2 ONS 15801 System Common Platform (OSR-WE Subrack) 3-4

Figure 3-3 OSRE-DCU Subrack 3-5

Figure 3-4 ONS 15801 System Equipment Rack Dimensions 3-8

Figure 3-5 Rack Mounted with Plywood Stabilizers for Shipping 3-10Figure 3-6 Rack Footprint 3-11

Figure 3-7 Fiber Channel Installation 3-12

Figure 3-8 Unistrut Placement 3-14

Figure 3-9 Side Detail of Hanger Rod Installation in Raised Computer Floor 3-15

Figure 3-10 Interbay Optical Fiber Routing 3-17

Figure 3-11 Possible Configurations of Air Ducts 3-19

Figure 3-12 Air Duct Insertion in Subrack 3-20

Figure 3-13 Shelf Power Connection to PDP 3-24

Figure 3-14 CBUS Backplane Interconnections 3-26

Figure 3-15 Interbay CBUS Cabling 3-27

Figure 3-16 Multiplexer/Combiner Module Installation 3-28

Figure 3-17 BAT Module, SCF Module, and Fan Tray Locations 3-30

Figure 3-18 SCF ModuleOSR-WE Subrack DIP Switch Configuration 3-31

Figure 4-1 SRADD Switch 4-2

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

8/98

Figures

viii

Cisco ONS 15800 DWDM System Common Platform Installation Manual

78-12898-04

Figure 4-2 Subrack Address Switch Settings 4-2

Figure 5-1 BAT Module Front Panel 5-2

Figure 5-2 Shelf Power Connections 5-3

Figure 5-3 SCF Module Front Panel 5-4Figure 6-1 ONS 15801 System OSR-WE Backplane 6-2

Figure 6-2 ALM Connector Cabling 6-5

Figure 6-3 PC Connection to an OSR-WE Subrack 6-18

Figure 6-4 PC RS-232 (9-pinto25-pin) Connector Cable 6-19

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

9/98

T A B L E S

ix

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Table 2-1 Shipping Label Field and Bar Code Descriptions 2-2

Table 2-2 Floor-Loading Requirements by Site Type 2-4

Table 2-3 Power Consumption Requirements by Site Type 2-4

Table 2-4 Required Equipment Access Clearance 2-4

Table 3-1 Installation Procedures and Paragraph Links 3-9

Table 3-2 Grounding Connections 3-22

Table 4-1 Subrack Address Switch Settings 4-2

Table 6-1 Power Distribution Panel Connections 6-1

Table 6-2 Shelf-Specific Backplane Connectors 6-2

Table 6-3 Module-Specific Backplane Connectors 6-2

Table 6-4 A-IN Connector Signal Functions 6-3

Table 6-5 ALM Connector Signal Functions 6-4

Table 6-6 CBUSA and CBUSB Connector Signal Functions 6-6

Table 6-7 CMPBUS Connector Signal Functions 6-6

Table 6-8 D-IN Connector Signal Functions 6-7

Table 6-9 D-OUT Connector Signal Functions 6-8

Table 6-10 F1P1 Connector Signal Functions 6-9Table 6-11 F1P2 Connector Signal Functions 6-10

Table 6-12 GPBUS Connector Signal Functions 6-11

Table 6-13 Slot Number to Address Number 6-12

Table 6-14 IOCBUS Connector Signal Functions 6-13

Table 6-15 LSMBUS Connector Signal Functions 6-14

Table 6-16 OP-I/O Connector Signal Functions 6-15

Table 6-17 RMA Connector Signal Functions 6-16

Table 6-18 X.25 Connector Signal Functions 6-17

Table 6-19 ONS 15801 SystemtoF (PC) Connector Signal Functions 6-19

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

10/98

Tables

x

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

11/98

xi

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Preface

This section provides the following information:

Safety SummarySafety precautions and safety labeling for the Cisco ONS 15800/15801 system

ConventionsWriting conventions used throughout the documentation InfoSet

Documentation InfoSet StructureDescription of the documents contained in the InfoSet

Obtaining DocumentationInformation on how to obtain product documentation

Obtaining Technical AssistanceInformation on how to obtain technical assistance

Safety SummaryThis section covers safety considerations to ensure safe operation of the Cisco ONS 15800/15801

system. Personnel should not perform any procedures in this manual unless they understand all safety

precautions, practices, and warnings for the system equipment.

General Safety Precautions

The following general safety precautions are not related to any specific procedures and do not appear

elsewhere in this publication. These are recommended precautions that personnel must understand and

apply during installation, testing, and use of the Cisco ONS 15800/15801 system.

Know and understand electrical safety, wiring, and connection practices.

Be familiar with modern methods of resuscitation. This information can be obtained from the

Red Cross or its local equivalent. This knowledge is imperative for personnel working with or near

equipment with voltage levels capable of causing injury or death.

Electrical Safety PrecautionsThe following electrical safety precautions, procedures, and rules are required when working on the

Cisco ONS 15800/15801 system:

The Cisco ONS 15800/15801 system must be connected to a power supply that never exceeds

voltage limits.

The Cisco ONS 15800/15801 system power must be supplied by a power supply system with

reinforced insulation.

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

12/98

xii

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Preface

Safety Summary

The Cisco ONS 15800/15801 system must be installed and used in a controlled access location.

Access must be limited to service personnel and users that have been instructed about the reasons

for the controlled access and any precautions that must be taken.

Touching electrical connectors or other exposed electrical circuitry inside the system subracks can

cause injury to personnel.

All doors must be closed and locked when the equipment is switched ON.

A disconnection device (fuse) must be present on the power supply line. The power supply line fuse

must be removed before wiring.

The power supply line fuse must be removed before disconnecting the earth ground for maintenance

or installation purposes.

Do not touch anything inside the subrack or introduce anything into the subrack (except modules)

when it is turned ON. If module removal is necessary, replace the empty slot with a blank panel

immediately.

All Cisco ONS 15800/15801 system electrical interfaces are intended to be connected to local

devices, that is, devices in the same room or in the same building as the ONS 15800/15801 system

(not in unprotected environments).

Optical Safety Precautions

The following optical safety precautions, procedures, and rules are required when working on the

Cisco ONS 15800/15801 system:

Terminate all fiber outputs properly before connecting fiber inputs.

Disconnect the fiber input connector before disconnecting the fiber output connector. Ensure that

the fiber output is safely terminated before reconnecting the fiber input.

Handle glass fiber with care. It is subject to breakage if mishandled. Permanent equipment damage

can result from using broken fiber.

Protect skin from exposed glass fiber. It can penetrate the skin.

Limit personnel having access to light-wave transmission systems. These personnel are to be

authorized and properly trained if access to laser emission is required.

Limit the use of laser test equipment to authorized, trained personnel during installation and service.

This precaution includes using the optical loss test set and the optical time domain reflectometer

equipment.

Exclude all unauthorized personnel from the immediate laser radiation area during service and

installation when there is a possibility that the system may become energized. Consider the

immediate service area to be a temporary laser-controlled area.

Cisco laser equipment functions in the 1550-nm window, which is considered invisible radiation.

Personnel cannot see the laser light being emitted by a fiber, a pigtail, or a bulkhead connector. Use

appropriate eye protection during fiber optic system installation or maintenance whenever there is

potential for laser exposure, as recommended by health and safety procedures. Observe this

precaution, appropriate to the class of equipment, whether warning labels have or have not been

posted.

Eye protection must meet a wavelength specification of 800 to 1800 nm and have an optical density

greater than two. Protective glasses such as the Laser-Gard Green CO2 (LGE Spectacle, LGS

Goggle, LGW wraparound, or LGF Full-View) or an equivalent type of covering equipment is

recommended.

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

13/98

xiii

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Preface

Safety Summary

Laser Safety Features

When a fiber break or cut occurs in the Cisco ONS 15800/15801 system, the automatic laser shutdown

feature activates. An optical safety circuit reduces optical power to a safer level in the direction toward

the fiber break. This optical power is reduced to a Class I hazard within one second of break detection.

At the Class I level, the system is considered safe. Once the system reaches the output power shutdowncondition triggered by the automatic laser shutdown, the optical system signal can be manually restarted

Caution When restarting the system manually, such as after an automatic laser shutdown, avoid using an

optical power level capable of causing any potential hazard until the line disruption has been

eliminated. The output power must be maintained under the Class IIIa upper limit.

A software code is required to turn on the laser in the manual startup procedure. In accordance with

safety rules, a dialog box like the one in Figure 1 appears with warning messages about laser radiation

Figure 1 Cisco ONS 15800/15801 System Startup Warning

When the system is manually restarted after broken fiber is repaired:

The manual startup turns the units on in a reduced class (I or IIIa).

The safety override operates at a reduced power level for installation and maintenance.

Optical power increases to the maximum only if the line continuity is verified from the system

interlocking procedure.

Protections against accidental exposure to dangerous optical radiation during the startup procedure

include:

The required startup software code

The interlocks provided by optical connectors

The automatic laser shutdown feature

Proper training for personnel with access to restricted locations

COMMAND EXECUTION

WILL ACTIVATE

LASER RADIATION

AVOID EXPOSURE TO BEAM

Execute Cancel

64278

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

14/98

xiv

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Preface

Safety Summary

ESD Precautions

Some Cisco ONS 15800/15801 components are classified as Class 0 ESD-sensitive devices. Follow

these rules when handling ESD-sensitive devices:

Assume that all solid-state electronic devices are ESD-sensitive.

Use a grounded wrist strap (or equivalent equipment) while working with ESD-sensitive devices.

Transport, store, and handle ESD-sensitive devices in static-safe environments.

Safety Symbols and Labels

Cisco ONS 15800/15801 equipment is clearly labeled with warnings about the equipment radiation

level. All warning labels must be read and understood by personnel before working with the equipment.

Cisco ONS 15800/15801 systems transmitting 10-Gbps channels operate with higher optical power than

systems transmitting 2.5-Gbps channels. The warning labels differ for these transmission speeds and

power levels.

Area Warning Sign

Signs explaining the existence of a potential laser hazard should be posted prominently at the entrance

to the service area and in the vicinity of the installation area where laser-furnished fiber optic equipment

is installed, in accordance with IEC 60825. Since the service area is a temporary laser-controlled area,

these signs should signal that access is limited to authorized personnel. A sample sign is illustrated in

Figure 2. The symbol for a laser hazard is to be prominently displayed at the top of this sign.

Figure 2 Sample Laser-Controlled Area Warning Sign

Controlled Laser Area

Access by unauthorized staff is not permitted.

Protective eyeglasses must be worn in this area.64283

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

15/98

xv

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Preface

Safety Summary

Electrical Safety Labels

The Cisco ONS 15800/15801 equipment is labeled with hazard symbols to alert personnel to electrical

hazards. Additionally, the Cisco ONS 15800/15801 equipment is labeled with attention symbols to alert

personnel to potential hazards.

The electrical energy hazard symbol alerts personnel to electrical hazards within theCisco ONS 15800/15801 system equipment. The potential for electrical hazards exists when equipment

doors are open, when power supply cables are disconnected, and when a module is removed and

replaced. The electrical energy hazard symbol is illustrated in Figure 3.

Figure 3 Electrical Energy Hazard Symbol

The attention symbol label alerts personnel to exercise caution while working on the Cisco

ONS 15800/15801 system. The attention symbol is illustrated in Figure 4.

Figure 4 Attention Symbol

Front and Back Door Safety Labels

The doors of the Cisco ONS 15800/15801 system subracks are labeled with laser radiation warnings.

The front and back doors of subracks have danger labels similar to the ones shown in Figures 5 and 6.

Figure 5 Danger Label on Front and Back Doors of Cisco ONS 15800 Subracks

64287

64288

INVISIBLE LASER RADIATION

AVOID DIRECT EXPOSURE TO BEAM

Maximum output power 50 mWWavelength range 1280-1605 nm

Avoid exposure - invisible laser radiation isemitted from optical connectors

This product conforms to all applicablestandards under 21 CFR 1040.10

WARNINGFOLLOW INSTRUCTIONS OF TECHNICAL MANUAL

DO NOT DISCONNECT OUTPUT WHEN LASER IS ON

CLASS IIIb LASER PRODUCT

68

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

16/98

xvi

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Preface

Safety Summary

Figure 6 Danger Label on Front and Back Doors of Cisco ONS 15801 Subracks

Subrack Safety LabelsThe backplanes of the Cisco ONS 15800/15801 subracks are also labeled to warn against exposure to

laser radiation. The backplanes have danger labels similar to the ones shown in Figures 7 and 8.

Figure 7 ONS 15800 System Backplane Safety Label

Figure 8 ONS 15801 System Backplane Safety Label

64285

INVISIBLE LASER RADIATIONAVOID DIRECT EXPOSURE TO BEAM

Maximum output power 50 mWWavelength range 1280-1605 nm

CLASS IIIb LASER PRODUCT

Avoid exposure - invisible laser radiation isemitted from optical connectors

This product conforms to all applicablestandards under 21 CFR 1040.10

WARNINGFOLLOW INSTRUCTIONS OF TECHNICAL MANUAL

DO NOT DISCONNECT OUTPUT WHEN LASER IS ON

DO NOT SWITCH ON LASERUNLESS OUTPUT IS CONNECTED

64276

INVISIBLE LASER RADIATION

DO NOT STARE INTO BEAM OR VIEW

DIRECTLY WITH OPTICAL INSTRUMENTS

HAZARD LEVEL 3AMaximum output power 50 mW - Wavelength range 1460-1605 nm

This product has been labeledin accordance with IEC publication 60825-2 1995

WARNINGDO NOT DISCONNECT OUTPUT WHEN LASER IS ON

DO NOT SWITCH ON LASER UNLESS OUTPUT IS CONNECTED

64286

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

17/98

xvii

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Preface

Safety Summary

The label illustrated in Figure 9 is placed on the backplane near ports with a laser radiation hazard.

Figure 9 Backplane Aperture Laser Safety Label

Module Safety Labels

The Cisco ONS 15800/15801 modules are individually labeled with safety warnings. The labels differ

according to the following factors:

Type of hazard (such as laser radiation)

Module wavelength range

Laser class (if applicable)

Applicable safety standard citation

Module maximum output power

64277

AVOID EXPOSUREINVISIBLE LASER RADIATION

EMITTED FROM THIS APERTURE

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

18/98

xviii

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Preface

Conventions

ConventionsThis publication uses the following conventions:

Warning Means danger. The user is in a situation that could cause bodily injury. Before working on anyequipment, be aware of the hazards involved with electrical circuitry and optical lasers and befamiliar with standard practices for preventing accidents.

Caution Means reader be careful. In this situation, the user might do something that could result in equipment

damage or loss of data.

Note Means reader take note. Notes contain helpful suggestions or references to material not covered in

the manual.

Convention Application

boldface Commands and keywords.

italic Command input that is supplied by the user.

[ ] Keywords or arguments that appear within square brackets are optional.

{ x | x | x } A choice of keywords (represented by x) appears in braces separated by

vertical bars. The user must select one.

Ctrl The control key. For example, where hold down the Control key while

pressing the D key. Ctrl + D is written.

screen font Examples of information displayed on the screen.

boldface screen font Examples of information that the user must enter.

< > Command parameters that must be replaced by module-specific codes.

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

19/98

xix

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Preface

Documentation InfoSet Structure

Documentation InfoSet StructureCisco Optical Networking System 15800 and 15801 Series DWDM Documentation InfoSet contains the

following manual types:

System DescriptionsProvides an overview of operation, engineering, administration,

maintenance, performance, system-level technical specifications, supervision tools, and craft

terminal software associated with the system.

System Technical SpecificationsSummarizes system-level and module-level technical

specifications, including supervision, analog and digital alarm threshold settings, engineering

specifications, and system performance.

Common Platform Installation ManualsProvides procedures for installing and configuring

components common to all systems. Also includes safety, unpacking and storage, equipment and

site verification, power and grounding, and post-installation procedures.

Installation, Setup, and Test ManualsProvides procedures for installing, setting up, and testing

standard hardware and software components within a system. Also includes safety, unpacking and

storage, equipment and site verification, power and grounding, and post-installation procedures.

System Configuration ManualsDescriptions and detailed illustrations of standard system

configurations.

Module HandbooksEach handbook provides functional descriptions, technical specifications, and

system relationship information for a single hardware module. Each handbook also provides

installation, removal, and configuration procedures associated with the module.

Message ManualProvides a reference guide for software commands and responses between

software and firmware during setup, polling, and reporting on the system.

Software Installation ManualsEach manual provides installation and removal information for a

specific software application.

Software Administrator ManualsEach manual describes the operation, security implementation,

and management of a software product at a system administrator access level.

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

20/98

xx

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Preface

Obtaining Documentation

Obtaining DocumentationThe following sections provide sources for obtaining documentation from Cisco Systems.

World Wide WebYou can access the most current Cisco documentation on the World Wide Web at the following sites:

http://www.cisco.com

http://www-china.cisco.com

http://www-europe.cisco.com

Ordering Documentation

Cisco Optical Networking System documentation is available in a CD-ROM package that is available in

the following ways:

Registered Cisco Direct Customers can order Cisco Product documentation from the Networking

Products MarketPlace:

http://www.cisco.com/cgi-bin/order/order_root.pl

Registered Cisco.com users can order the Documentation CD-ROM through the online Subscription

Store:

http://www.cisco.com/go/subscription

Nonregistered Cisco.com users can order documentation through a local account representative by

calling Cisco corporate headquarters (California, USA) at 408 526-7208 or, in North America, by

calling 800 553-NETS(6387).

Documentation Feedback

If you are reading Cisco product documentation on the World Wide Web, you can submit technical

comments electronically. ClickFeedback in the toolbar and select Documentation. After you complete

the form, clickSubmit to send it to Cisco.

You can e-mail your comments to [email protected].

We appreciate your comments.

http://www.cisco.com/http://www.cisco.com/http://www-china.cisco.com/http://www-china.cisco.com/http://www-europe.cisco.com/http://www-europe.cisco.com/http://www.cisco.com/cgi-bin/order/order_root.plhttp://www.cisco.com/go/subscriptionhttp://www.cisco.com/go/subscriptionhttp://www.cisco.com/cgi-bin/order/order_root.plhttp://www-europe.cisco.com/http://www-china.cisco.com/http://www.cisco.com/ -

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

21/98

xxi

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Preface

Obtaining Technical Assistance

Obtaining Technical AssistanceCisco provides Cisco.com as a starting point for all technical assistance. Customers and partners can

obtain documentation, troubleshooting tips, and sample configurations from online tools. For Cisco.com

registered users, additional troubleshooting tools are available from the TAC website.

Cisco.com

Cisco.com is the foundation of a suite of interactive, networked services that provides immediate, open

access to Cisco information and resources at anytime, from anywhere in the world. This highly

integrated Internet application is a powerful, easy-to-use tool for doing business with Cisco.

Cisco.com provides a broad range of features and services to help customers and partners streamline

business processes and improve productivity. Through Cisco.com, you can find information about Cisco

and our networking solutions, services, and programs. In addition, you can resolve technical issues with

online technical support, download and test software packages, and order Cisco learning materials and

merchandise. Valuable online skill assessment, training, and certification programs are also available.

Customers and partners can self-register on Cisco.com to obtain additional personalized information and

services. Registered users can order products, check on the status of an order, access technical support,

and view benefits specific to their relationships with Cisco.

To access Cisco.com, go to the following website:

http://www.cisco.com

To register for Cisco.com, go to the following website:

http://www.cisco.com/register/

Technical Assistance Center

The Cisco Technical assistance Center (TAC) website is available to all customers who need technical

assistance with a Cisco product or technology that is under warranty or covered by a maintenance

contract.

Technical assistance and customer service for Cisco ONG products are available from these sources:

Optical Networking Group (ONG) TAC in the United States: 1-877-323-7368

Europe, Middle East, and Asia (EMEA) ONG TAC: +32 2704 5601

Customer Service in the United States and Canada: 1-800-553-NETS (1-800-553-6387)

Customer Service in all other countries: 1-408-526-7208

Customer Service global e-mail: [email protected]

http://www.cisco.com/http://www.cisco.com/register/http://www.cisco.com/register/http://www.cisco.com/ -

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

22/98

xxii

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Preface

Obtaining Technical Assistance

Contacting TAC by Telephone

If you have a priority level 1 (P1) or priority level 2 (P2) problem, contact TAC by telephone and

immediately open a case.

P1 and P2 level problems are defined as follows:

P1Production network is down, causing a critical impact to business operations if service is notrestored quickly. No workaround is available.

P2Production network is severely degraded, affecting significant aspects of business operations.

No workaround is available.

Contacting TAC Using the Cisco TAC Website

Use the Cisco TAC website to find answers to priority level 3 (P3) or priority level 4 (P4) problems:

http://www.cisco.com/tac

P3 and P4 level problems are defined as follows:

P3Network performance is degraded. Network functionality is noticeably impaired, but mostbusiness operations continue.

P4Information or assistance about Cisco product capabilities, product installation, or basic

product configuration is needed.

If the technical issue cannot be resolved by using the TAC online resources, Cisco.com registered users

can open a case online by using the TAC Case Open tool at the following website:

http://www.cisco.com/tac/caseopen

http://www.cisco.com/tachttp://www.cisco.com/tac/caseopenhttp://www.cisco.com/tac/caseopenhttp://www.cisco.com/tac -

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

23/98

C H A P T E R

1-1

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

1

Introduction

This chapter describes the purpose and structure of the ONS 15801 DWDM System Common Platform

Installation Manual. Additionally, this chapter lists the standards and manuals that are referred to in this

publication.

Purpose of This PublicationThis manual provides installation and test procedures for the ONS 15801 system subracks and modules

common to all ONS 15801 systems. Information regarding safety, unpacking, storage, and handling is

also included. This manual also covers the Optical Subrack - ETSI (OSR-WE) and the Optical Subrack

ETSI - Dispersion Compensating Unit (OSRE-DCU).

Note The safety information in the Safety Summary must be read and understood by all personnel who

work on the ONS 15801 system.

This publication is intended for the following personnel:

Installation technicians

Maintenance technicians

Repair technicians

Manual StructureThis manual is divided into the following six chapters:

Chapter 1, Introduction,covers the purpose of this publication, its structure, standards referred to

in the publication, and where to get help from Cisco Customer Service.

Chapter 2, Unpacking and Storage,provides instructions for verifying that the proper equipment

has been received and that the site is prepared for equipment installation. Instructions for unpacking,

handling, and storage are included.

Chapter 3, Installation,covers installation planning and specific installation procedures for the

optical subrack and common modules.

Chapter 4, Setup, covers site setups.

Chapter 5, Test,covers test procedures.

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

24/98

1-2

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 1 Introduction

References

Chapter 6, Connectors and Cabling, covers electrical connectors.

References

ONS 15801 system design, construction, and performance adhere to the standards in the ApplicableStandards section. Additional ONS 15801 system references are listed in the Additional ONS 15801

System Informationsection. Standards related to wavelength division multiplexing (but not cited in this

manual) are listed in the Related Standards References About Wavelength Division Multiplexing

section.

Applicable Standards

This manual contains references to the following standards:

EIA/TIA-232

IEC 60825-X

Additional ONS 15801 System Information

The following manuals provide more information about the ONS 15801 system:

Cisco ONS 15801 DWDM System Description Manual

Cisco ONS 15801 DWDM System Technical Specifications Manual

Cisco ONS 15801 DWDM System Installation, Setup, and Test Manual

Cisco ONS 15801 DWDM System Configuration Manual

Cisco ONS 15801 system module handbooks

Optical Connector Cleaning Procedures

Return Material Authorization and Fault Symptom Report

Related Standards References About Wavelength Division Multiplexing

The following standards relate to DWDM and the ONS 15801 system but are not directly cited in this

manual:

ANSI T1.105.03

ANSI T1.105.06

ANSI T1.315 ANSI Z.136-X

BT HRD4

EN 55022

EN 60825-X

EN 61000-4-2.6

ETR 126

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

25/98

1-3

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 1 Introduction

References

ETS 300 019

ETS 300 119-1-4

ETS 300 132

ETS 300 232

ETS 300 253

ETS 300 386

ETS 300 462-3

ETS 300 493

ETS 300 671

ETS 300 672

ETS 300 746

ETS 300 781

FCC Part 15 Subpart A

GR-253-CORE

GR-326-CORE

GR-947-CORE

GR-1209-CORE

GR-1377-CORE

GR-2882-CORE

GR-2883-CORE

GR-2918-CORE

GR-3112-CORE

IEC 60478-X

IEC 60874

IEC 61204

IEC 61280-2-4

IEC 61280-2-5

IEC 61290

IEC 61291

IEC 61292

IEC 61300-X-X

ITU-T G.652

ITU-T G.653

ITU-T G.654

ITU-T G.655

ITU-T G.661

ITU-T G.662

ITU-T G.663

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

26/98

1-4

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 1 Introduction

Equipment Classification

ITU-T G.664

ITU-T G.671

ITU-T G.681

ITU-T G.707

ITU-T G.784

ITU-T G.803

ITU-T G.805

ITU-T G.821

ITU-T G.823

ITU-T G.824

ITU-T G.825

ITU-T G.826

ITU-T G.827

ITU-T G.841

ITU-T G.842

ITU-T G.691

ITU-T G.692

ITU-T G.957

ITU-T G.958

ITU-T G.975

ITU-T M.3010

ITU-T M.3100

ITU-T Q.811

ITU-T Q.812

ITU-T Q.822

ITU-T SG13-Opt-Arch

TS 101 009

TS 101 010

Equipment Classification

The equipment classification of the ONS 15801 system is Class III, therefore, the followingconsiderations must be followed:

The ONS 15801 system is to be mechanically fixed to the building structure and permanently

connected to the power supply.

The ONS 15801 system is to be installed in an protected environment (indoors) and in a Restricted

Access Area.

The ONS 15801 system must be connected to a power supply line circuit that is classified Safety

Extra Low Voltages (SELV).

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

27/98

1-5

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 1 Introduction

Equipment Classification

The Power Distribution Panel (PDP) power supply: 48 VDC, 27 A

Sub-rack power supply: 48 VDC, 9 A

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

28/98

1-6

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 1 Introduction

Equipment Classification

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

29/98

C H A P T E R

2-1

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

2

Unpacking and Storage

This chapter covers procedures to ensure correct verification, handling, and unpacking of the ONS 15801

system. Procedures for verifying the correctness of shipped ONS 15801 system equipment at the site are

addressed in the Equipment Verification section. The Equipment Verificationsection also addresses

checking preliminary inventory and reporting damaged equipment. Illustrations of shipping labels and

guidelines for decoding them are included. The Site Verificationsection provides guidelines for

determining the suitability of a site for installation and lists the site requirements. Tips and instructions

for nondestructive unpacking are listed in the Unpacking section. The storage of ONS 15801 system

equipment is described in the Storage section. The handling of ONS 15801 system equipment is

described in the Equipment Handlingsection.

Equipment VerificationTwo labels are on the outside of the shipping container. The information on the labels, both in bar-code

format and alphanumeric format, provides site location information and identifies the specific item being

shipped.

Figure 2-1 shows an example of the shipping label on the front of the shipping container. Table 2-1describes the fields and bar codes for the label.

Figure 2-1 Example of Shipping LabelFront

Bar Code 4

Bar Code 3

Bar Code 2

Bar Code 1

(35) PKG. ID:

(Q) QUANTITY:

(K) TRANS. ID:

(P) CUSTOMERPROD. ID:

PACKAGE WEIGHT:

PACKAGE COUNT:

SHIPPED FROM:

Field 1

Field 2

Field 3

Field 4

Field 5

Field 6

Field 7

Field 8

64279

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

30/98

2-2

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 2 Unpacking and Storage

Equipment Verification

Note Cisco shipments use Telcordia Common Language Equipment Identification (CLEI) HECI coding on

all shipping labels. This label coding is used by the telecommunications industry when equipment is

ordered, shipped, maintained, or assigned to a field location.

Figure 2-2shows an example of the shipping label on the top of the shipping container. It is smaller and

has fewer fields than the shipping label on the front of the shipping container, but it provides some of

the same information. Refer to Table 2-1 for a description of the field and bar codes in Figure 2-2.

Figure 2-2 Example of Shipping LabelTop

Table 2-1 Shipping Label Field and Bar Code Descriptions

Field Description

Field 1 Label serial number

Field 2 Name and address of recipientField 3 Number of units in the container

Field 4 Ship-to site identifier (not ship-to address)

Field 5 Human-interface equipment catalog item (HECI) code

Field 6 Number of packages in shipment

Field 7 Weight of package

Field 8 Name of item being shipped

Bar Code 1 Label serial number

Bar Code 2 Number of units in the container

Bar Code 3 Ship-to site identifier (not ship-to address)

Bar Code 4 HECI code

Bar Code 4

Bar Code 2

(P) PRODUCT ID:

(Q) QUANTITY

1

64992528WCM-EM-N01

Field 5

Field 8

Field 364264

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

31/98

2-3

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 2 Unpacking and Storage

Equipment Verification

Preliminary Inventory Check

Compare the packing list information with the information provided on the shipping labels. The packing

list and shipping labels should contain the same information. If there are any discrepancies between the

shipping label information and the packing list information, call Cisco Customer Service to verify the

shipment.

Damage Reporting

The procedure and form for reporting damage to shipped articles is covered in the supplement Return

Material Authorizat ion and Fault Symptom Report. This publication can be ordered from Customer

Service.

Site Verification

Before beginning the installation, ensure that the intended site for the ONS 15801 system subracks meets

minimum requirements. Proper installation of the subracks depends on the following items:

The site must conform to all environmental specifications in the Cisco ONS 15801 DWDM System

Technical Specifications Manual.

Equipment racks in which the ONS 15801 system subracks are to be installed must be properly

mounted according to the manufacturer's directions. In addition, all equipment racks must be level

to ensure proper installation and operation.

Subracks are designed to fit into standard 600-mm x 600-mm (23.64 in. x 23.64 in.) equipment

racks. A maximum of three OSR-WE subracks will fit into an equipment rack.

Determine wire size for power and ground wiring based on cable length and the National Installation

standards (local engineering standards and practices). Power and grounding wire must be capable of

handling the power requirements for the entire system.

These procedures assume that the front of the equipment racks face the aisle and that battery power

and grounding cables enter from the top right.

Plan power cable runs from the battery distribution bay (BDB) to the power distribution panel(s)

(PDP) located in the equipment racks. Then plan the power cable runs from the PDP to the individual

subracks, proceeding down along the right side of the equipment bay. Enter the subrack connector

(located on the rear side of the backplane) through the right side of the equipment.

Plan grounding cable runs from the ground window down along the right side of the rack and to the

rear of the subracks.

Plan to route the optical cables from the connectors located on the front of each module through the

opening on the lower-left side of each subrack, up along the left side of the equipment rack, and on

to the overhead cable transport tray.

Plan to route the optical cables from the connectors located on the rear of the subrack backplane

through the opening in the lower left side of each subrack, and on to other subracks in the site.

Plan to route the alarm and orderwire cables from the rear of the upper-left side of the amplifier

subrack.

The floor or mounting area where the equipment will be installed must be capable of supporting the

equipment weight load. Refer to Table 2-2 for specific floor-loading requirements of each site type

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

32/98

2-4

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 2 Unpacking and Storage

Equipment Verification

The installation location must meet the power requirements necessary for the site(s) to be installed.

These requirements are in Table 2-3.

The installation location must accommodate the heat dissipation requirements of each site type to

be installed.

The minimum clearances must be provided for front and back access to bays, opening front shelf

covers, and clearing the top of the bay. The clearances are in Table 2-4.

Note The following tables are based on typical site configurations. Floor loading, power consumption, heat

dissipation, and clearances may vary in customer-specific configurations.

Table 2-2 Floor-Loading Requirements by Site Type

Rack Configuration Weight Floor Loading Requirements

Rack with one fully loaded

OSR-WE + PDP

170 kg (374.78 lb.) 0.05 kg/cm2 (0.28 lb./in2)

Rack with one fully loadedOSR-WE + PDP + OSR-DCU

220 kg (485.01 lb.) 0.065 kg/cm2

(0.364 lb./in2

)

Rack with two fully loaded

OSR-WE + PDP

220 kg (485.01 lb.) 0.065 kg/cm2 (0.364 lb./in2)

Rack with two fully loaded

OSR-WE + PDP + OSR-DCU

270 kg (595.24 lb.) 0.075 kg/cm2 (0.42 lb./in2)

Rack with three fully loaded

OSR-WE + PDP

270 kg (595.24 lb.) 0.075 kg/cm2 (0. 42 lb./in2)

Rack with one fully loaded

OSR-WE + PDP

170 kg (374.78 lb.) 0.05 kg/cm2 (0.28 lb./in2)

Table 2-3 Power Consumption Requirements by Site Type

System Setup

Site Power Max. Dissipation (W)

Terminal Regenerator Line

OADM

R or B Band Full B Band

32 x 2.5 Gb/s (M) 1135 2270 225 853 690

32 x 2.5 Gb/s (F) 2023 2446 225 853 1289

32 x 10 Gb/s (M) 1982 3859 225 928 816

32 x 10 Gb/s (F) 3076 3282 225 928 1100

Note (M) designates an open configuration using WCM type M; (F) designates a closed configuration using WCM and

RXT type F.

Table 2-4 Required Equipment Access Clearance

Item Clearance Required

Bay access needed for maintenance 78.74 cm (31 in.)

Back clearance to bays 78.74 cm (31 in.)

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

33/98

2-5

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 2 Unpacking and Storage

Unpacking

UnpackingThis paragraph contains instructions for unpacking the ONS 15801 system configuration items.

Unpacking Tips

Consider the following when unpacking and storing ONS 15801 equipment:

Leave equipment packed until it is needed for installation. Store packed equipment to be installed later under the temperature and environmental conditions

described in the Cisco ONS 15801 DWDM System Technical SpecificationsManual.

After equipment has been unpacked, save and store the packaging material in case the equipment

must be returned.

If the packaging is damaged and there is possible equipment damage, preserve as much of the

packaging as possible to allow Customer Service and the shipper to analyze the damage. Report any

unacceptable conditions to the shipper and to your Customer Service representative. Use the

procedure in theReturn Materials Authorization and Fault Symptom Reportsupplement to report

damage.

Unpacking ONS 15801 System RacksFollow these steps to unpack ONS 15801 system racks. Figure 2-3 illustrates the unpacking of an ONS

15801 system rack.

Clearance to open shelf covers 53.34 cm (21 in.)

Height of ceilings and raceway to accommodate

bays

2.44 m (8 ft.)

Table 2-4 Required Equipment Access Clearance

Item Clearance Required

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

34/98

2-6

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 2 Unpacking and Storage

Unpacking

Figure 2-3 ONS 15801 System Equipment Rack Unpacking

Caution When opening a shipping container, use caution to avoid damaging the contents.

Caution Verify the difference between the banding straps that secure the container for shipping and the ropehandles for moving the container. Do not remove the rope handles.

Step 1 Place the rack container in the horizontal position on its back.

Step 2 Remove the banding straps that secure the container.

Step 3 Remove the cover of the container.

Step 4 Carefully remove the protective packing material from the rack.

Step 5 If any optical fiber jumper cables or electrical cables are included in the container, remove and retain

them for use during the optical and electrical cabling installation.

Step 6 Use the rope handles at each end of the container to turn over the container. The top of the container

(where the cover was removed) should be facing the floor once the container is turned over.

Step 7 Push the rope handles inside the cardboard container and pull the container off the rack.

Step 8 Place the rack in a horizontal position on the floor, leaving the plywood stabilizers at each end attached.

Equipment rack

Equipment rack

Cover

64290

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

35/98

2-7

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 2 Unpacking and Storage

Unpacking

Unpacking ONS 15801 System Subracks

The following procedure should be used for unpacking the ONS 15801 system subracks.

Caution When opening a subrack container, use caution to avoid damaging the contents.

Caution Static electricity can damage electro-optical equipment. While unpacking and handling optical and

electrical modules, wear a grounding wrist strap to discharge the static buildup. Each subrack is

equipped with grounding wrist strap connectors. Before unpacking and installing modules or making

system interconnections, connect the grounding wrist strap. The grounding wrist strap is designed to

prevent equipment damage caused by static electricity.

Step 1 Remove the banding straps that secure the container.

Step 2 Remove the top of the container.

Step 3 Open the cardboard container and remove the protective packing material from around the subrack.

Step 4 If any optical or electrical cables are included in the container, remove and retain them for use during

installation of the optical and electrical cabling.

Step 5 Remove the subrack from the container.

Unpacking ONS 15801 System Air Ducts

Follow these steps to unpack ONS 15801 system air ducts.

Caution When opening a shipping container, use caution to avoid damaging the contents.

Step 1 Open the container and remove the air duct(s) and packing material.

Step 2 Carefully remove the packing material from the air duct(s).

Unpacking ONS 15801 System Modules

Follow these steps to unpack ONS 15801 system modules.

Caution When opening a module container, be careful to avoid damaging the contents.

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

36/98

2-8

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 2 Unpacking and Storage

Storage

Caution Static electricity can damage electro-optical equipment. While unpacking and handling optical and

electrical modules, wear a grounding wrist strap to discharge the static buildup. Each subrack is

equipped with grounding wrist strap connectors. Before unpacking and installing modules or making

system interconnections, connect the grounding wrist strap. The grounding wrist strap is designed to

prevent equipment damage caused by static electricity.

Step 1 Open the container and remove the module(s) and packing material.

Step 2 Carefully remove the protective foam packing material from the module(s).

Step 3 If any SC-PC/FC-PC adapters are included in the container, remove and retain them for use during

installation of the module front-panel optical cabling (Chapter 3, Installation).

Unpacking Cable Kits

Follow these steps to unpack ONS 15801 system cable kits.

Caution When opening a shipping container, use caution to avoid damaging the contents.

Step 1 Open the container and remove the cable kit(s) and packing material.

Step 2 Carefully remove the protective packing material from the cable kit(s).

StorageIf is necessary to store the equipment, do not store it for more than 12 months. The silica gel capsules

that help control moisture during storage may become ineffective after that time. Always store the

packaged equipment indoors in a well-ventilated and static-safe environment. For the recommended

storage temperature range, refer to the applicable system technical specifications.

Equipment HandlingThe ONS 15801 system equipment is shipped in large containers. The largest components are the bays

where subracks are to be mounted. They must be handled with specific precautions to prevent damage:

Lift containers by the rope handles at each end of the container.

Wear gloves when lifting containers by the rope handles.

Never use a forklift to handle a bay container.

Never stack more than two bay containers.

Make sure bay containers are stacked squarely on top of each other.

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

37/98

C H A P T E R

3-1

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

3

Installation

Note The instructions in this chapter primarily address the installation of the Cisco ONS 15801 system

racks and subracks (common platforms) supplied by Cisco. Installation of electrical wiring,

raceways, and other equipment not covered in this manual should follow all local, state, and federal

codes and regulations.

The equipment delivered to a site may include partially pre assembled racks with subracks, air ducts, and

backplane intrarack optical and electrical wiring in place, or it may include unassembled subracks and

racks. This chapter provides instructions for installing racks and subracks (common platforms).

Additional information is provided on electrical, Ethernet, and control bus wiring. Figure 3-1 illustrates

a typical ONS 15801 system equipment rack.

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

38/98

3-2

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 3 Installation

General Installation Guide

Figure 3-1 Typical ONS 15801 System Equipment Rack

General Installation GuideCisco ONS 15801 system equipment installers should be thoroughly familiar with the instructions in this

manual before beginning any work. The work of installing equipment should proceed as follows:

All safety precautions must be read and understood before equipment installation and must be

observed during equipment installation.

Optical

Subrack

(OSR-WE)

Air duct top

Grounding Wrist Strap

Connector (one in each

OSR-WE)

64304

Air duct

Air duct

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

39/98

3-3

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 3 Installation

Installation Planning

Immediately upon arrival, verify ONS 15801 system equipment according to the procedures in

Chapter 2, Unpacking and Storage. If there is a problem with the equipment, contact Customer

Service.

If the equipment is not to be installed upon arrival, store as specified in Chapter 2, Unpacking and

Storage.

Unpack equipment only after the site has been prepared and is ready for installation as described inChapter 2, Unpacking and Storage.

When installing equipment at a site, follow the procedures in this chapter in the order presented.

Following equipment installation, the site should be configured as described in Chapter 4, Setup

and tested as described in Chapter 5, Test.

After subracks have been installed and tested, refer to the Cisco ONS 15801 DWDM System

Installation, Setup, and Test Manual to complete the system installation.

Installation PlanningBased on the system to be installed, determine the size, number, and location of racks and subracks

required by referring to the Cisco ONS 15801 DWDM System Installation, Setup, and Test Manual. All

ONS 15801 system OSR-WE subracks will fit in 600-mm x 600-mm (23.64-in. x 23.64-in.) racks.

Additionally, the racks must provide rear access to facilitate equipment installation.

Plan the rack and subrack installation based on the following considerations:

When installing multiple subracks, refer to the Cisco ONS 15801 DWDM System Installation, Setup,

and Test Manual to determine layout of the racks.

Install the lowest subrack in a rack first.

Determine wire size based on cable length and local engineering standards and practices.

Plan power cable runs from the battery distribution bay (BDB) to the power distribution panel(s)

(PDP) located in the racks. Then plan the power cable runs from the PDP to the individual subracks,proceeding down along the right side of the equipment bay. Enter the subrack connector (located on

the rear side of the backplane) through the right side of the equipment.

Plan grounding cable runs from the ground window down along the right side of the rack, and

connect the cable to the connector on the rear of the equipment.

Plan to route the optical cables from the connectors located on the front of each module, through the

opening on the lower left side of each subrack, up along the left side of the rack, and on to the

overhead cable transport tray.

Plan to route the alarm and orderwire cables through the rear of each subrack.

Plan to route the optical cables from the connectors located on the rear of the subrack backplane

through the openings in the top rear and bottom rear of each subrack and on to other subracks in the

site.

ONS 15801 System Common Platforms

A Cisco ONS 15801 system common platform installation (Figure 3-2) consists of the following

equipment:

One subrack (OSR-WE), including four pre installed fan units

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

40/98

3-4

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 3 Installation

Installation Planning

One Subrack Common Function (SCF) module

One Battery Management (BAT) module, consisting of two BATMOD units mounted in a frame

Figure 3-2 ONS 15801 System Common Platform (OSR-WE Subrack)

An ONS 15801 system site configuration may include more than one common platform. The site

configuration may also require the installation of an Optical Subrack ETSI - Dispersion Compensating

Unit. This chapter also includes installation procedures for the multiplexer and combiner modules and

the OSRE-DCU (Figure 3-3).

ON

OFF

ON

OFF

This product, and/or

the system including it,

is covered by at least

one of the following

U.S. Patents:

X,XXX,XXX X,XXX,XXX

X,XXX,XXX X,XXX,XXX

X,XXX,XXX X,XXX,XXX

X,XXX,XXX X,XXX,XXX

X,XXX,XXX X,XXX,XXX

X,XXX,XXX X,XXX,XXX

X,XXX,XXX X,XXX,XXX

X,XXX,XXX X,XXX,XXX

X,XXX,XXX X,XXX,XXX

MAJ PWR

MIN

LEDTEST

SCF

FAN1 FAN2

FAN3 FAN4

B-CRT B-MAJ

B-PWR B-MIN

Groundingwrist strapconnector

BATMOD

BATMOD

PCconnection

Backpanelmuxtiplexer

monitorconnections

64308

Opening forfront paneloptical cabling

SCFmodule

Fan trays

BATmodules

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

41/98

3-5

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 3 Installation

Installation Planning

Figure 3-3 OSRE-DCU Subrack

All procedures in this chapter must be performed in the order that they appear. Before installing

equipment, verify and prepare the installation site and unpack the equipment as instructed in Chapter 2,

Unpacking and Storage.

Each common platform must be protected by means of a short circuit protection device, one for line A

and another one for line B. The protection devices can be either fuses or circuit breakers. The circuit

breakers or fuses must have the following features:

Current rate: 12A

Breaking capacity current must be more than the maximum short current of the power supply line

(station bars)

Able to function with direct current

Proper voltage rating

After the common platforms are installed, refer to the ONS 15801 DWDM System Installation, Setup,

and Test Manual to complete the site installation.

Standard System Configurations

Information about the rack, common platform installation, and module configuration in this manual is

standard for the ONS 15801 system. Instructions for specific types of configurations can be found in the

Cisco ONS 15801 DWDM System Configuration Manual.

Required Items

To install racks and common platforms, customary installation and electrical tools are required. The

following items are also required:

Hydraulic crimp tool (depending on wire gauge)

DCU-B - Dispersion Compensating Unit - Blue Band module

DCU-R - Dispersion Compensating Unit - Red Band module

64303

1 2 3 4 5 6 7 8

DCU-B or DCU-R modules

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

42/98

3-6

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 3 Installation

Installation Planning

Multimeter

Torque wrench (capable of measuring 81.4 nm [60 ft.-lb.])

Hammer (or rotary) drill with depth gauge

Reciprocating saw or scroll saw

18-mm masonry drill bit

HEPA vacuum

Pre assembled racks

Mounting hardware for racks

6-inch magnetic level

Metric torque screwdriver

Slot screwdriver with screw-holder attachment

All modules necessary for the specific site configuration (Refer to the ONS 15801 DWDM System

Configuration Manual.)

DIN - coax extraction tool (needed only to reconfigure backplane Ethernet cabling on ONS 15801system)

Standard battery wire with sufficient length to connect the BDB and the PDP and the common

platforms. (Wire type and gauge are determined based on local engineering standards and practices).

The minimum wire gauge for the power supply line to the PDP is indicated o The minimum wire

gauge of the power supply cable from the PDP to the subracks is 15 AWG.

Electrical cables for intershelf connections. (These cable are available from Cisco Customer

Service, or they can be fabricated from the electrical pinout information in Chapter 6 of this

manual.)

10Base2 coaxial cable (minimum 4.6 m [1) with male BNC connectors

Grounding Requirements

Warning Grounding each subrack is important for both safety and proper system operation. The earthground bar or earth ground cable of the station must be connected to the rack point indicated with

the earth ground symbol.

The ONS 15801 system has five ground connections described below:

Internal ground (GND)

Common ground (COMM)

Ethernet ground (QGND)

Positive of service voltages (VSERV+)

Internal ground (GND)

Grounding must be performed to local engineering standards and practices. The purpose of GND is to

connect the subrack ground to the protective earth ground of the rack. See Table 3-2 for details.

Hydraulic crimp tool (depending on wire gauge)

Multimeter

Torque wrench (capable of measuring 81.4 nm [60 ft.-lb.])

Hammer (or rotary) drill with depth gauge

Reciprocating saw or scroll saw

18-mm masonry drill bit

HEPA vacuum

Pre assembled racks

Mounting hardware for racks

6-inch magnetic level

Metric torque screwdriver

Slot screwdriver with screw-holder attachment

All modules necessary for the specific site configuration (Refer to the CiscoONS 15801 DWDM

System Configuration Manual.) DIN - coax extraction tool (needed only to reconfigure backplane Ethernet cabling on ONS 15801

system)

Standard battery wire with sufficient length to connect the BDB and the PDP and the common

platforms. (Wire type and gauge are determined based on local engineering standards and practices).

The minimum wire gauge of the power supply cable from the PDP to the subracks is 15 AWG.

Electrical cables for intershelf connections. (These cable are available from Cisco Customer

Service, or they can be fabricated from the electrical pinout information in Chapter 6, Connectors

and Cabling of this manual.)

10Base2 coaxial cable (minimum 4.6 m [15 ft.]) with male BNC connectors

Grounding Requirements

Warning Grounding each subrack is important for both safety and proper system operation. The earthground bar or earth ground cable of the station must be connected to the rack point indicated with

the earth ground symbol.

The ONS 15801 system has five ground connections described below:

Internal ground (GND)

Common ground (COMM)

Ethernet ground (QGND) Positive of service voltages (VSERV+)

Internal ground (GND)

Grounding must be performed to local engineering standards and practices. The purpose of GND is to

connect the subrack ground to the protective earth ground of the rack. See Table 3-2 for details.

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

43/98

3-7

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 3 Installation

Installation Planning

Warning Grounding the rack, PDP unit, and each subrack is important for both safety and proper systemoperation. The ground strip of the subracks must be connected to the earth bar of the rack.

Warning Do not perform ground cabling on an electrically live system. Ensure that all power is removedfrom the subrack before continuing with this procedure.

Warning Leave one subrack QGND connected to GNDM via the comb for each Ethernet network.

ONS 15801 System Equipment Rack

The rack used for the ONS 15801 system installation is a standard rack with 600-mm x 600-mm (23.64

in. x 23.64 in.) mounting. The rack can house up to three ONS 15801 system OSR-WE subracks and

their associated air ducts, as well as the associated air duct top. The rack can also house a OSRE-DCUsubrack. An ONS 15801 system equipment rack is shown in Figure 3-4.

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

44/98

3-8

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 3 Installation

Installation Planning

Figure 3-4 ONS 15801 System Equipment Rack Dimensions

GroundingWrist StrapConnector 600 mm

(23.6 in.)

2200 mm(86.6 in.)

600 mm(23.6 in.)

64291

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

45/98

3-9

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 3 Installation

Installation Procedures

Installation Procedures

Caution Static electricity can damage electro-optical equipment. While unpacking and handling optical and

electrical modules, wear a grounding wrist strap to discharge the static buildup. Each subrack is

equipped with grounding wrist strap connectors. Before unpacking and installing modules or making

system interconnections, connect the grounding wrist strap. The grounding wrist strap is designed to

prevent equipment damage caused by static electricity.

Table 3-1lists the ONS 15801 system installation procedures covered in this paragraph. Links are

provided for each procedure.

Preparing Racks for Installation

Caution The equipment rack can be unstable and is easily tipped over until it is securely bolted to the floor.

Stabilize and secure an upright unmounted rack to prevent possible damage.

To prepare racks for installation:

Step 1 Place blocks beneath the two side supports of the rack to remove the weight from the plywood

stabilizers. The rack and stabilizers are illustrated in Figure 3-5.

Table 3-1 Installation Procedures and Paragraph Links

Topic Paragraph Link

Preparing Equipment Racks for Installation Preparing Racks for Installation

Rack Installation on Concrete Flooring Rack Installation on Concrete Flooring

Rack Installation on Raised Computer Flooring Rack Installation on Raised Computer Flooring

OSR-WE Subrack Installation OSR-WE Subrack Installation

OSRE-DCU Subrack Installation OSRE-DCU Subrack Installation

Air Duct Installation Air Duct Installation

Protective Earth Connection Protective Earth Connection

Bay Power Installation Bay Power Installation

Shelf Power Installation Sub-Rack Power Installation

Ethernet Cabling Ethernet Cabling

Control Bus Intershelf Cabling Control Bus Intershelf Cabling

Control Bus Interbay Cabling Control Bus Interbay Cabling

Optical Multiplexer and Combiner Installation Multiplexer and Combiner Module Installation

SCF and BAT Module Installation SCF and BAT Module Installation

-

7/29/2019 15801 DWDM System Common Platform Installation Manual.pdf

46/98

3-10

Cisco ONS 15801 DWDM System Common Platform Installation Manual

78-12898-04

Chapter 3 Installation

Installation Procedures

Figure 3-5 Rack Mounted with Plywood Stabilizers for Shipping

Step 2 Unscrew the mounting hardware to remove the cover plate from the base of the rack. The base cover

plate is illustrated in the lower part ofFigure 3-1.

Step 3 Remove the bolts holding the plywood stabilizers at the top and bottom of the rack. Place the rack upright

on its base.

Rack Installation on Concrete Flooring

Caution Anchor brackets must be properly installed. The rack must be secured to a concrete floor using a

seismic floor-mounting kit. Installing this equipment incorrectly can affect load capacity and seismic

performance.

Note The following procedure is for a typical rack installation. Measurements are approximate.

To install racks on concrete flooring:

Step 1 Mark 4 holes that match the rack footprint on the floor where the rack is to be installed ( Figure 3-6).

Mark the holes as far apart as possible within each bolt cutout. The base of the rack can be used as a

template for the holes, but the ONS 15801 system equipment must be removed from the area or protected

to prevent concrete dust from contaminating it while the holes are being drilled.