1502 HOBAS PipeLine Railway Jacking

-

Upload

babyosiana -

Category

Documents

-

view

19 -

download

3

description

Transcript of 1502 HOBAS PipeLine Railway Jacking

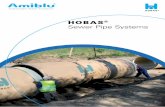

h Railway Jacking 1 | h CC-GRP Culverts DN 3000 Jacked Under Railway, Cikowice, PL

3 | h Jacking Pipes Installed under a Railroad, Ettelbruck, LU

4 | h Jacking Pipes Premiere in Hong Kong

5 | h Pipes Jacked at Port Cape Lambert, AUS

6 | XXL h GRP Jacking Pipes replace Concrete Railway Culvert, PL

7 | Interview with Kimberly Paggioli – h GRP Pipe: Jack Of All Trains

8 | Trenchless Project on the Rails with h GRP Pipes, Budapest, HU

8 | Auger Boring Small Diameter h GRP Pipe Beneath Dutch Railway, NL

9 | Croatia‘s Most Challenging Project Realized with h Pipes

10 | Russian Railways Authorize h Products

11 | h GRP Jacking Pipes Under Railway Track in Třinec, CZ

12 | Polish Railway Project on the Fast Track with h, Chiechanów, PL

PipeLineIssue 2/2015

When a pipeline route crosses a railway em-bankment, jacking is usually the optimal installa-tion method as it does not require disruptions in rail traffic. In the village of Cikowice in Southern Poland, four culverts with a diameter of 3000 mm and a length of 34 m each have been jacked under a railway line for the sake of flood control. HOBAS Poland supplied the required GRP pipes for this challenging project.

In 2010, the Raba River overflowed its banks and flooded Cikowice and its neighbouring vil-lages. Unfortunately, Cikowice is bordered by a railway embankment to the north, which acted

E Engineering GmbH | Pischeldorfer Str. 128 | 9020 Klagenfurt | Austria

T +43.463.48 24 24 | F +43.463.48 21 21 | [email protected] | www.hobas.com

h CC-GRP Culverts DN 3000 Jacked Under Railway

as a dam, causing an additional accumulation of water. The water level on the village side was almost a meter higher than that on the opposite side, an area consisting largely of meadows. In order to prevent such incidents in the future and enable the outflow of excessive water, a flood prevention project was initiated in 2014. It was realized in the context of the modernisa-tion of the railway line E30/C-E 30 and involved the construction of four large culverts beneath the railway embankment. If the water level rose again, the culverts should allow for the water to pass freely to the other side.

Year of construction

2014

Construction time

2 months

Total length of pipeline

136 m in total,

4 parallel lines of

34 m each

Diameter

De 3000

Pressure class

PN 1

Stiffness class

SN 40000, SN 64000

Application

Culvert beneath railway

for flood protection

Installation method

Trenchless installation /

pipe jacking

Client

PKP (Polskie Linie

Kolejowe) S.A.

(Polish rail infrastructure

company)

Contractor / Subcontractors

Intercor / PROI, PROI2

Advantages

Smooth inner and outer

wall surface, high

structural strength

h PipeLine | Issue 2/2015 | Page 02

HOBAS Poland supplied the required pipes with an external diameter of 3000 mm for the realization of the culverts. The pipes’ smooth inner surface ensures that flood water which

flows through them and usually contains various impurities does not lead to siltation. HOBAS Pipes also made it much easier to resume jacking works after an installation

interruption due to heavy rain: The water causes the sandy soil to become slightly compacted and adhesive, and the thrust force required to restart works after the in-terruption is usually quite high. Thanks to the smooth outer surface, the necessary forces would be comparably lower and a restart quite easy.

Before the start of the jacking works, the rail tracks were equipped with special beams that transferred the load from the trains evenly to the rails in case of any ground movements. The structure of the pipes, on the other hand, was strong enough that even in the course of their installation the vibration induced by passing trains was not felt inside. The jacking machinery was secured against sliding on the sandy and slippery soil and positioned in a way to install the pipes with a slight slope, so that the water would eventually flow in the right direction. Once a culvert had been jacked through the embankment, its ends were specially prepared: One side was bevelled from the top, while on the uninhabited side of the embankment the culverts were equipped with special flaps, which prevent the backflow of water to the village.

The construction of culverts in Cikowice took around two months. The project is in successful operation and the client satisfied with the HOBAS Solution.

Fmd: [email protected]

w

h PipeLine | Issue 2/2015 | Page 03

Year of construction

2009

Construction time

3 days

Total length of pipeline

40 m

Diameter

De 1720

Wall Thickness 68 mm

Stiffness class

SN 64000

Application

Protection Pipe

Client

SIDEN

Contractors

Kuhn, K-Boringen

Special Features

Jacking under a railroad

line, fast installation,

low weight, small out-

side diameter

On the Right Track with h – h Jacking Pipes Installedunder a Railroad, LU

Installing pipelines that run under railroad lines is always a difficult under-taking. While you can usually close roads for limited periods and divert traffic, when it comes to trains construction poses far greater problems. This is why engineers tend to opt for trenchless technology, particularly in railroad projects. An added bonus is that very long pipelines can also be jacked without visible construction sites at the surface.

Not only the installation method but also material selection calls for care-ful consideration. Electric rail systems create electromagnetic fields during operation, which can lead to corrosion in materials such as steel or cast iron. In addition, leakage current could flow to the metal components in the pipes. Risks that have to be avoided at all costs.

A new pipeline running under railroad tracks was planned in Ettelbruck in Luxembourg. Various networks were then to be installed in the pipe-line. The planners initially selected a protective concrete pipe but soon changed their minds when they heard about the unbeatable benefits of HOBAS Jacking Pipes. Built up layer by layer, the GRP pipes do not contain any metal components and are both corrosion resistant and non-conducting. Leakage current does therefore not affect HOBAS Pipelines.

In February 2009, HOBAS Pipes (De 1720) were jacked under the railroad at a depth of 3 m. After installation, the pipeline was filled with a

25 cm thick layer of concrete to facilitate future mainte-nance work on the third party lines inside it. Once

construction had been completed, the client and contractor alike were impressed by the rapid

installation rate and very pleased with the pipes’ low weight and small outside

diameter, which meant that the jack-ing pits were much smaller than

anticipated. Quality from HOBAS – solutions for all situations!

Fmd: [email protected]

h PipeLine | Issue 2/2015 | Page 04

h Jacking Pipes Premiere in Hong Kong – Trenchless Installation of Protection Pipes beneath Rail Tracks

In December 2013, HOBAS Pipes De 1026 SN 320000 were jacked in the Chinese metropolis Hong Kong underneath a railway track as protection for power lines.

Hong Kong’s Mass Transit Railway (MTR) includes more than 200 km of rail. With an average of 2.45 million passengers per day, it is one of the world’s most profitable rapid transit railway systems. Its operating company, the MTR Corporation, is currently ex-tending the network in the vicinity of Hung Hom railway station in the urban area of Kowloon. Since the space around the existing rail track was very limited, the construction company had to remove parts of the adjacent slope over a length of 400 m and relocate the existing power transmission lines. With the new planned route crossing beneath the double-track, the project managers sought for the least invasive and most sustainable solution. They found what they were looking for in HOBAS Pipe Systems: HOBAS CC-GRP Pipes with an outer diameter of De 1026 mm and a stiffness class of SN 320000 were jacked over a length of 12 meters in 2.3 m depth beneath the double-track as protection pipes for the power lines. Thanks to the non-conductive material and high load capacity, HOBAS Pipes are ideally suited for the given conditions.

The installation was challenging in several respects. Due to the limited working space on the track’s ballast bed, the starting pit had to be kept quite narrow (4 x 4.5 m) and the pipes could not be stored on site but had to be rolled to the jacking pit one after the other on temporary tracks over 50 m distance. As the railway track is in operation 19 hours a day from 5:30 to 00:30 a.m., the client al-lowed the jacking works to be conducted at nighttime between 1:30 and 4:00 a.m. only. The contractor had to work very efficiently to achieve each night’s installation

goal within these 2.5 hours. With their smooth outer surface and quick and easy coupling system, HOBAS Pipes increased the installation efficiency significantly.

Due to the restricted space on the other side of the tracks, it was not possible to build a receiving pit.

Instead, the boring head was partly dismantled inside the pipe after the installation and

withdrawn through the starting pit. After 6 nights and a jacking time of 15 hours,

the installation was successfully completed.

Fmd: [email protected]

Year of construction

2013

Construction time

6 nights / 15 hours

Diameter

De 1026

Pressure class

PN 1

Stiffness class

SN 320000

Application

Protection pipes for

power lines

Client

MTR Corporation

Limited

Planner

Ove Arup & Partners

Hong Kong Limited

Constructor

Gammon – Kaden SCL

1111 Joint Venture

Jacking Contractor

Victory Trenchless

Engineering Company

Limited

Advantages

Non-conductive

features, high load

capacity, smooth outer

surface, easy coupling

system

h PipeLine | Issue 2/2015 | Page 05

Year of construction

2012

Construction time

6 months

Total length of pipeline

308 m

Pipe specifications

De 2250, PN 1, SN 32000

Client

Rio Tinto

Designer

Sinclair Knight Mertz

Contractor

NRW, Tunnel Boring

Australia

Advantages

Low jacking forces,

small inner/outer

diameter ratio

The Pilbara Region in north-western Australia was first inhabited by the ancestors of today’s Ab-original people some 50,000 years ago. Since 2012, HOBAS Jacking Pipes De 2250 are playing an important role as stormwater drainage lines for the emerging mining industry.

In the 1950’s, it was discovered that the Pilbara area is home to one of the world’s largest iron ore deposits. Since then it has been an integral contributor to the Australian economy with the help of mining companies such as Rio Tinto. With most of the ore being exported today, a rail infrastruc-ture and large ports have been built to accommodate the ore transportation. One of the largest of these ports is Rio Tinto’s Cape Lambert. Trains travel in from Rio Tinto mines throughout the region, carrying around 80 million tonnes of iron ore per year into Cape Lambert for processing and ship loading.

Cape Lambert is currently undergoing an upgrade, which will see its capacity more than double by mid 2015. At the project’s completion, an estimated 200 million tonnes of iron ore will be exported per year from this port. An integral part of the upgrade project was the extension of the “Sam’s Creek” drainage lines, which run under the existing rail lines allowing the release of stormwater during the wet season. The rail lines needed to stay in constant operation throughout the construction works in order to ensure the continual loading of ships. Stopping the productivity was not an option, making trenchless installation the only choice.

The designer of the new drainage culvert Sinclair Knight Merz planned two rows of 2100 mm internal diameter pipes with approximately 100 meters length each. HOBAS Jacking Pipes with an outside diameter of 2250 mm and a stiffness of SN 32000 were specified for this purpose. With the soil being hard and rocky, the initially calculated jacking force added up to 7850 kN. Thanks to the smooth outer surface of HOBAS Jacking Pipes, the actually ap-plied jacking forces were much lower than expected. The substantially smaller outside diameter as compared to an alternative concrete pipe had the additional benefit of allowing increased ground cover beneath the rail line, reducing both risk and installation time. Further-more, the lead-time for HOBAS was substantially shorter than that of locally supplied concrete pipe, and given the tight timeframe for the project, HOBAS proved to be the best solution.

The installation set a new record in terms of the largest diameter HOBAS Jacking Pipe ever installed in Australia, and it paved the way for similar projects in the ever-growing mining industry in Australia. The Rio Tinto drainage system was also used as an opportunity for creating cultural awareness: Local artists were invited to paint the HOBAS Pipes in the artistic style of the traditional landowners. The imagery is supposed to bring good for-tune to the land and HOBAS Pipes have become truly part of the local landscape.

Fmd: [email protected]

h Jacking Pipes Down Under h GRP Pipes Jacked at Port Cape Lambert, AUS

h PipeLine | Issue 2/2015 | Page 06

Year of construction

2013

Construction time

2 months

Diameter

De 3600

Pressure class

PN 1

Stiffness class

SN 40000

Application

Railway Culvert

Client

PKP Polskie Linie

Kolejowe

Contractor

Przedsiębiorstwo Usług

Technicznych (PUT)

INTERCOR, PROI2

Advantages

No interruptions of the

rail traffic, non-conduc-

tive and highly durable

pipe material

XXL h GRP Jacking Pipes replace Concrete Railway Culvert h Pipes De 3600 Jacked Beneath Rails in Gdańsk, PL

Since the concrete culvert crossing beneath the railway line E65 Warsaw - Gdynia in the polish city Gdańsk could no longer handle high water levels from the nearby stream, it was decided to

replace it. For this purpose, HOBAS Pipes with an external diameter of 3600 mm were jacked beneath the railway embankment.

The 2 x 1.2 m concrete culvert could no longer handle the nearby Królewski stream’s elevated water levels during periods of heavy rain, which occasionally flooded the sur-rounding area. There was no doubt it had to be replaced. The first respective plan involved two parallel 2 x 2 m square concrete culverts, laid in open trench. It soon became clear however that the design was unsuitable for the given circumstances and that a different approach was necessary. In 2013, a new rehabilitation project was initiated that involved the construction of a single circular. It was decided to install the new culvert by means of jacking and to use HOBAS GRP Pipes with a diameter of De 3600 for this purpose.

The jacking works were carried out using a set of hydraulic jacks and a cutter head that was specially designed for the project. Where the routes of the old and the new pipeline intersected, the old culvert was demolished and removed. At the end of the installation process, the annular space between the old and new structure was grouted with cement.

For safety reasons, the rail tracks had to be equipped with beams. In the case of any ground movements caused by the jacking process, these beams would transfer the load

from the trains evenly to the rails.

The E65 is a main-line railway with trains passing every 3 minutes. Although the trains‘ speed was reduced to 30 km/h in this section because of the construction works, the trains could stay

in operation without interruptions thanks to trenchless installation. The contractors, PUT INTER-COR from Zawiercie and PROI2 from Katowice were highly satisfied with the

project result – they have already installed HOBAS Pipe Systems several times in the past and appreciate the products’ high quality.

Fmd: [email protected]

Click on the picture or the below link to watch a short video about the installation in Gdańsk.

http://bit.ly/1GuANDU

h PipeLine | Issue 2/2015 | Page 07

The American Railway Engineering and Maintenance-of-Way Associa-tion (AREMA) has recently added fiberglass pipes to the 2015 edition of AREMA’s Manual for Railway Engineering. This means that HOBAS Pipes are covered in the new specifications and may expand the use of HOBAS Pipes use in rail applications. Kimberly Paggioli, vice president of quality control and marketing at HOBAS Pipe USA, talks about the usage of HO-BAS Fiberglass Pipes for railway projects in the US and in general.

What are the special challenges when it comes to jacking projects beneath railways? KIM: In the vast majority of rail crossings, the tracks must remain in use and undisturbed during the pipe installation. This means that trenchless methods are usually be utilized at these locations. Whether it is a culvert relining or in the case of jacking of new pipes, HOBAS Pipes meet the specifications developed by AREMA.

Which requirements do pipes that can be specified for such projects need to fulfill?KIM: The pipe must be structurally capable of handling the live road im-posed by the rail above. In addition, the non-metallic nature of the HOBAS Pipes ensures that the pipes will not be affected by stray electrical currents that may be present. For this reason, often HOBAS Pipes are found to be preferable over steel for casing applications. Finally, as well as meeting the long-term performance requirements, HOBAS Pipes can be manufactured with the required axial capacity to meet the jacking forces foreseen by the installer.

Any other advantages that make HOBAS Pipes particularly suitable for railway jacking?KIM: Generally our pipes under railroads are for sanitary sewers, so their corrosion-resistance is another important benefit. The tight tolerance gasket-sealed joints yield a fast assembly and a leak-free performance. HOBAS Pipes also feature a smooth, constant, non-absorbing outer surface, resulting in lower jacking loads as well as safer and longer possible jacking drives.

How challenging is it to get enter the AREMA Specifications, and what exactly does this mean/change for HOBAS in the US? KIM: Our pipes have already been widely used under various rails across the country dating back to the late 1980’s. However, now with the inclusion of fiberglass pipe in the AREMA specifications, it will be even

easier to specify and use HOBAS Pipes under railways. In fact, every time that a pipeline track crosses a rail, the engineer or the contractor needs to submit a permit by the owner of the rights-of-way. This process may be significantly expedited when the product that is utilized is already included in these standard specifications.

The AREMA committees that evaluate prod-ucts do a very thorough job and accept only the highest performing products. The inclusion in the Manual is therefore a great testimony to the quality of our pipes.

How many railway projects have already been successfully realized by HPUSA?KIM: So many I can’t even count them. And there are definitely many more to come.

The Manual for Railway Engineering (MRE) is an annual publication released every April and may be purchased at www.arema.org/catalog.aspx

If you have any further questions regarding the usage of HOBAS CC-GRP Pipes for railway appli-cations, please send an e-mail to [email protected].

h GRP Pipe: Jack Of All Trains Interview with Kimberly Paggioli, Vice President of Quality Control & Marketing at HOBAS Pipe USA

h PipeLine | Issue 2/2015 | Page 08

Year of construction

2007

Total length of pipeline

30 m

Diameter

De 1720

Pressure class

PN 1

Stiffness class

SN 32000

Advantages

Low impact on environ-

ment and traffic, optimal

structural properties

Trenchless Project on the Rails with h GRP Pipesh Jacking Pipes Installed Beneath Streetcar Track in Hungary

For safety reasons, the Hungarian public railway company MÁV has special requirements for structures to be installed beneath railways. The only traditional pipe solution and material used to be double steel pipes with grouted annular space.

In 2002, HOBAS obtained the individual permit from MÁV for a jacking project in Aszófő with 18 meters De 820 (SN 32000, PN 1) pipes. HOBAS Pipes convinced the railway company in terms of the material’s structural properties, its resistance to stray current corrosion, long lifetime and easy installation. As a result of this successful first project and after thorough tests and calculations, MÁV granted HOBAS a general permit for railway projects in 2010. Numerous projects have been successfully implemented ever since.

The creek Ördögárok, also known as Devil’s Ditch, leads rain water from the Buda Moutains into the Danube in Budapest. While the creek flows freely in the upper part of the mountains, it runs through a culvert midway down. In Hűvösvölgyi street in Budapest, this culvert passes underneath a streetcar track. When it needed to be replaced in 2007, the

contractor opted for trenchless installation with HOBAS Pipes to keep the impact on the environment and traffic as low as possible and to benefit from the GRP materi-

al’s excellent features. 30 meters of pipe De 1720, SN 32000 were jacked beneath the rails – the project was completed to the contractor’s utmost satisfaction.

Fmd: [email protected]

In 2010, due to the establishment of new industrial plants in Rotterdam’s harbor, a new 10,000 volt power line became necessary for sufficient power supply. Since the railway network’s safety measures demand a protective pipe for all pressure lines and cables running beneath the rail-way, ProRail, the company in charge of the Dutch railway network, set about seeking for an adequate small

diameter solution.

Quick installation was a crucial factor, so that the usually employed GRE pipe which

has to be glued at the joints was ruled out. ProRail turned to HOBAS Benelux: The

easy-to-handle, light weight HOBAS GRP Pipes are quickly assembled due to their

Auger Boring of Small Diameter h Pipe Under Dutch Railway

push-to-fit couplings. HOBAS Benelux had been an authorized supplier for pipelines undercross-ing Dutch railways for a decade. Until then, the smallest outside diameter for HOBAS GRP listed by ProRail had been 427 mm. Thanks to the flexibility in the design of HOBAS Pipes, the required Jacking Pipes De 220 were produced with a wall thickness of 20 mm to suit the required maximal auger boring force of 148 kN and to comply with all of the network’s other safety measures. The 36-meter host pipe was installed in 4 meters depth within one day only. The contractor was pleased with the result and further small diameter auger boring and jacking projects beneath the railway were implemented with GRP, so that ProRail extended the listed range of GRP diameters by DN 200.

Fmd: [email protected]

Year of construction

2011

Length of pipe

36 m

Diameter

De 220,

pipe wall thickness 20 mm

Installation method

Auger boring

Application

Protective pipe

Contractor

ProRail

Advantages

Quick installation due to

push-to-fit couplings, light

but sturdy material, flexibi-

lity in pipe design

h PipeLine | Issue 2/2015 | Page 09

Year of construction

2011

Construction time

3 months

Total length of pipeline

513 m

Diameter

De 2047,

pipe wall thickness 65 mm

Pressure class

PN 1

Stiffness class

SN 32000

Application

Irrigation pipeline

Investor

Hrvatske Vode

Designer

Institut IGD d.d.,

Kršimir Galić d.i.g.

Contractor

Aquaterm d.o.o. Karlovac

Advantages

Short installation time,

low weight, abrasion

resistance, low life cycle

costs

Jacking Beneath Railway and StreetCroatia‘s Most Challenging Project Realized with h Pipes

Slavonia is a region in eastern Croatia and known as the country’s bread-basket. To ensure a successful harvest, a reliable irrigation system is necessary – and this is why 513 m HOBAS Pipes De 2047 have been jacked as part of a large-scale irrigation project.

Croatia’s so far most challenging jacking project, realized with HOBAS Pipes by the construction company and jacking expert Aquaterm, passes beneath a highway and a railroad line. Three parallel sections were drilled as planned in order to align the jacking pipes accurately. Heavy rain and snowfall during the construction works posed a challenge to both the workers and the equipment, but not to HOBAS Pipes, which can be laid regardless of weather conditions. The project attracted strong inter-est from the entire Alps-Adriatic region: Experts in the fields of design, construction, and finances from Croatia, Bosnia, Serbia, and Slovenia visited the site and were introduced to jacking technologies. The investor is more than satisfied with the unique characteristics of HOBAS Products and the quick installation – as a matter of fact, he used HOBAS Pipes of the same diameter in a follow-up order for another ir-rigation project.

Fmd: [email protected]

h PipeLine | Issue 2/2015 | Page 10 h PipeLine | Issue 2/2015 | Page 11

Year of construction

2013

Construction time

4 months

Pipe length

137 m

Diameter

De 1414 and 1638

Pressure class

PN 1

Stiffness class

SN 32000 and 40000

Application

Culvert beneath rail

tracks

Installation method

Jacking,

open trench

Client

Российские железные

дороги (Russian Rail-

ways – RŽD)

Advantages

Corrosion and abrasion

resistance, high

structural integrity,

easy installation

Only few pipe producers offer a broad range of technical solutions and are authorized to in-stall their products beneath Russian rail tracks. In order to receive approval, the products

need to comply with the requirements and standards of the Russian Railways (RŽD), one of the three largest rail companies worldwide. Safety is absolutely essential.

In summer 2012, RŽD granted HOBAS the permission to implement a pilot project on the railway section between Surgut and Tobolsk in the Russian oblasts Samara and Tjumen. A second rail track is under construction in this area, and the old culvert running beneath it needed to be replaced, since the old corrugated steel pipe showed heavy signs of corrosion that had affected its structural integrity. In addition to this, the contractor asked for the installation of protective measu-res against flooding during the construction works and not to alter the natural riverbeds. Disruptions to rail traffic should be avoided as well.

Given the circumstances, the contractor decided for HOBAS Pipes De 1434 which should be jacked directly next to the old pipe beneath the railway track by means of auger boring. It was planned to first dispose of the spoil with an auger transporting it through a steel casing. Once the boring head had made its way through to the receiving pit, HOBAS GRP Pipes were connected to the steel casing in the thrust pit and driven to the receiving pit. Subsequently,

HOBAS Pipes De 1638 were installed in open trench. For the duration of the construction works on the rail around the site, trains were slowed to 40 km/h.

Thanks to trenchless installation, the train traffic could be maintained.

HOBAS Products not only scored with their structural properties and corrosion resistance (especially regarding stray currents) but also with a long service life and

easy installation. The construction works were completed in October 2012, after four months only and to the complete satisfaction of everyone involved.

After this project’s success, RŽD gave HOBAS Russia the official authorization for using HOBAS Products also in future projects that run beneath the Russian railway.

Fmd: [email protected]

Russian Railways Authorize h Products GRP Pipes Jacked under Railway

h PipeLine | Issue 2/2015 | Page 11

Pipelines crossing traffic routes, streams or buildings pose a big challenge to contractors. Detours and the therefore required pipe-line extension would in many cases increase costs considerably so that they could sometimes not be implemented. A common solution for this problem is therefore trenchless installation with HOBAS Pipes – such as was the case in Třinec, Czech Republic, where HOBAS Pipes were jacked beneath a railway track.

The construction of the 330 m long sewer line started in November 2010, when winter set in with heavy snow falls and freezing cold temperatures. These unfriendly condi-tions represented, however, no obstacle for HOBAS Pipes which can be installed regardless of cold or hot tempera-tures. Jacking was conducted without difficulties in frost-free depth.

Several tracks intersect at the rail junction in Třinec. The soil is very stony in this area. In order to protect the GRP pipes from be-ing damaged by the hard soil conditions, the contractor opted for a three-step jacking process: After the pilot drill, protective steel casings were pushed through the soil before the GRP pipes were installed. Since it was assumed that the steel would gradually corrode due to stray currents from the railway tracks, the HOBAS Pipes De 427 were designed to provide full, autonomous structural stability. GRP Pipes, on the contrary, are non-conductive and therefore insensitive to magnetic fields. In the end, the remaining annulus was filled with a cement/fly-ash mixture.

Fmd: [email protected]

Make Way for the Train with h h GRP Pipes Jacked Under Railway Track in Třinec, CZ

Year of construction

2010-2011

Total length of pipeline

330 m

Diameter

De 427

Pressure class

PN 1

Stiffness class

SN 100000

Installation

Jacking

Application

Sewer

Client

Glasspol Kroměříž

Contractor

Michlovský

protlaky a.s. Zlín

Advantages

Temperature and cor-

rosion resistance, long-

term structural stability,

leak-tightness

h PipeLine | Issue 2/2015 | Page 12

Polish Railway Project on the Fast Track with h

The construction of HOBAS Culverts beneath the railway line in the area of Ciechanów was carried out as part of the nationwide project

“Modernization of E65 Warsaw – Gdynia Railway Line”. The main aims of this extensive project were to improve travel

comfort, increase safety and shorten the journey by 27 minutes on this 103-km-long section.

An initial idea was to construct the culverts under the railway line near Ciechanów in open trench. In order to save time and respect the given time schedule, the method was, however, abandoned in favor of microtunneling. HOBAS Pipes were jacked to establish three culverts 16, 24 and 32 meters in length, with an external diameter of 1720 mm and a nominal stiffness of 100000 kN/m². Another 22-meter section was implement-ed with HOBAS Pipes De 2047, SN 64000.

The client, the Polish State Railways (PKP Polskie Linie Kolejowe S.A.), was already familiar with HOBAS Products, which are technically approved by the Road and Bridge Re-

search Institute (IBDiM) and the Polish Railway Institute (IK). The first HOBAS GRP Railway Culvert, a DN 1300 section, had been installed under the E20 railway at Mienia in 2003. One

year later, the second followed at Ostrów Wielkopolski using a pipe with an external diameter of 2047 mm. In 2005, a line De 1229 to 1434 in diameter had been installed under the railway

between Mińsk Mazowiecki and Terespol. Numerous further projects followed.

The engineering team from HOBAS worked closely with the design office in order to determine adequate stiffnesses for the pipes, and the load capacity was calculated on the basis of the finite element method (FEM). Highly experienced in directional drilling and similar jobs, the Polish contractor Przedsiębiorstwo Przewiertowe MOTYL made sure that microtunneling ran smoothly and was completed successfully. In order to streamline the installation process and save on time, the company ordered angular cut pipes and equipped these with precast headwalls from HOBAS Poland. This way, the works were completed in a couple of days only.

Constantly scrutinizing and double checking the performance of pipes to provide clients with optimal solutions, HOBAS decided to monitor the performance of the employed De 2047 pipes. To this end, external experts in strength analysis were assigned to measure the pipes before and after they were installed. After two years of operation they will be measured once again for final results.

Fmd: [email protected]

Microtunneling GRP Culverts under the E65 Railway Line

Year of construction

2010 - 2011

Total length of pipeline

94 m

Diameter

De 1720, De 2047

Pressure class

PN 1

Stiffness class

SN 64000

SN 100000

Application

Stormwater,

animal passageways

Installation method

Microtunneling

Client

PKP Polskie Linie

Kolejowe S.A.

Contractor

Przedsiębiorstwo

Przewiertowe MOTYL

Advantages

Quick installation,

corrosion resistance