RFS 4000 Series - Motorola Solutions Homepage - Motorola Solutions USA

15 Cp Lee Motorola

-

Upload

vanessa-lawrence -

Category

Documents

-

view

216 -

download

0

Transcript of 15 Cp Lee Motorola

-

8/8/2019 15 Cp Lee Motorola

1/15

Six Sigma Conference 2008Kuala Lumpur

Six Sigma, Our JourneyCP Lee

Vice President of Human ResourcesAsia Pacific regionMotorola Inc.

-

8/8/2019 15 Cp Lee Motorola

2/15

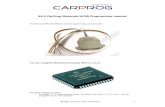

Our Heritage

The game changing invention: Six Sigma

the area P under the standard normal probability curve

-

8/8/2019 15 Cp Lee Motorola

3/15

Defects Reduction

DEFECT TRACKING AND REDUCTION

Defects Per Million Opportunities

3.4

233

6,210

66,810

1

10

100

1,000

10,000

100,000

1 2 3 4

Sigma

DPMO

Series1

3 4 5 6

Goal Line

-

8/8/2019 15 Cp Lee Motorola

4/15

Quality Goal Setting

Quality of ABC

10X Improvement Every 2 Years

7 or 5.85 sigma

68 or 5.34 sigma

681 or 4.70 sigma

6,810 or 3.97 sigma

66,810 or 3.00 sigma

1

10

100

1,000

10,000

100,000

1 2 3 4 5

Time (Years)

DPMO

Series1

1988 1990 1992 1994 1996

GOAL

-

8/8/2019 15 Cp Lee Motorola

5/15

Motorolas Quality Roadmap

Focus on The

Right QualityTargets

Deploy The

Right QualityTeam

Execute The

RightImprovementProjects

Apply The

Right QualityMethods &Systems

Establish A Culture Where Quality is Priority #1+

-

8/8/2019 15 Cp Lee Motorola

6/15

How Do The Pieces Fit Together?Focus on TheRight Quality

Targets

Deploy TheRight Quality

Team

Execute TheRight

ImprovementProjects

Apply TheRight QualityMethods &Systems

Establish A Culture Where Quality is Priority #1

CustomerAdvocacy

QualityFrameworks

SixSigmaBelts

Business SpecificInitiatives

QualityPlaybook DD OO VVCC DD OO VVCC

DD OO VVCC DD OO VVCC

QualityTools

QualitySystems

VitalSigns

QualityIQ

Quality

Dashboards

T2

T3 T1 SLTGovernance

Strict ProjectGovernance

MIP QualityGoals

-

8/8/2019 15 Cp Lee Motorola

7/15

Quality in Human Resources

AP HR Quality Council

Internal Clients Surveys Quality Vital Signs 3600

Certifications

Clients Driven DSS Projects

Suppliers Quality

Quality Management System

-

8/8/2019 15 Cp Lee Motorola

8/15

-

8/8/2019 15 Cp Lee Motorola

9/15

Examples of DSS Projects

Optimization of Work Shift Patterns

Electronics Relocation ActivationProcess

Hiring Cycle Time Reduction

Operation Efficiency of MotorolaUniversity

-

8/8/2019 15 Cp Lee Motorola

10/15

Optimization of Work Shift Patterns

DL productivityMeasure = Improvement in

DL Retention

Xs =

Big Y =

Small Ys =

Reduce 10% turnover rate ofgood performing contractors- Pay for performance &position to motivatecontractors morale- Labor agencies managementto keep same guideline andpractice- Crease job security for topperformer contractors

Advanced technical trainingfor experienced DLs

Manufacturing Integration and Optimization(From Global Mfg 2006 Scorecard)

Measure = Reduce Labor Costs and improve productivity

DL Labor CostMeasure = Reduction in

DL labor cost

IDL Labor CostMeasure = Reduction in

IDL labor cost

Redesign ProductionShift Pattern- Analyze & comparecost in different shiftpattern- Convert to costeffective shift pattern

- Manage OT compliedlaw restriction to reachthe most cost saving

Vender management DL hiring qualityimprovement Shuttle bus efficiency to

reduce cost

Talent Retention Program-Compensation-Training-Career Development

IDL HC control

IDL travel cost efficiency

Organization layer review

D M A I C

-

8/8/2019 15 Cp Lee Motorola

11/15

VOC vs. CCRs DL base pay have to be increased by Labor

law requirement in 2006.

In 3 crews pattern, we need to arrange OTas most as we can. But sometimes, it willbreak the legal restriction. There is a big

potential risk for the company. In 4 crews pattern, we have to hire more

people, but total labor cost will go up.

DL Labor cost increase will bring the highimpact to our conversation cost.

Some employees are not willing to takemore OT continuously and voluntarily in thepeak season. Supervisors encounter thedifficulty to have the required workforce inOT shift.

No OT in the low demand month,employees cash income will be decreased.They will be de-motivating.

Improved conversion cost Global Mfg 2006 scorecard

We expect to have a costeffective solution on workshift pattern design.

D M A I C

Critical Customer Requirement

Voice of Customer

-

8/8/2019 15 Cp Lee Motorola

12/15

DL Labor Cost Saving

Amount Gained by ShiftPattern Design

D M A I C

Cost Saving US$130.18k

within 7mths only

-

8/8/2019 15 Cp Lee Motorola

13/15

Business Case

Motorolas ExpatriateExpatriate program potentially affects all Motorolans.

ACS Global Assignment Center the GACGAC plays a critical role in assisting Motorolain its end-to-end relocation efforts.

Unfortunately, the entire ExpatriateExpatriate process has proven at times to be both lengthy andcumbersome. Specifically, a lot of dissatisfaction and inefficiencies have centeredaround the time involved in initiating an International RelocationRelocation assignment.

Improving the effectiveness and expediency of initiating RelocationsRelocations can potentially saveMotorola -- on an annual basis -- thousands of unnecessary hard- and soft-dollar costs.

In addition, process improvements may lead to a more favorable perception andacceptance of the programs efficacy.

Go to Team Charter

For breakthrough improvement, a Six Sigma TeamSix Sigma Team is needed to use the DMAICDMAICmethodology in order to properly, thoroughly, and effectively identify and correcttiming and inefficiency issues with ExpatriateExpatriatess Initiation PhaseInitiation Phase.

eRAP

Project(DMAIC)

Reduce CycleTime and Waste!

(Reduction of COPQ)

Improve ourBusiness Process!(A Robust Process Between MOT & ACS)

Make ourCustomer Happy!

Electronics Relocation Activation Process

(On Time Assignment)

-

8/8/2019 15 Cp Lee Motorola

14/15

As Is vs. To Be Process Key Differences

Pre-PlanningMeeting

0.0

RequireJustification

DeleteAssignment BHR

Add HostFinance Rep

Add Host BHR

Assigned Back-Office Expertise

EnterPersonal Data

3

6.0

ViewPersonal Data

7.0

ReviewAssignment

3

8.0

ApproveRelocation

6

9.0

ARF

InitiateRelocation

1.0

AssignConsultants

3

2.0

EstimateCost

5

3.0

ReviewCost Estimate

and EnterJustification

4

4.0

ConfirmRelocation

4

5.0

Delete Initiator

Add Expat Broker

Delete AssignmentBHR

Delete Home BHR

Add AssignmentManagers Manager

Add Expat Broker

-

8/8/2019 15 Cp Lee Motorola

15/15

Example of Customer ProjectsMotorola University in China

# Company # GB Projects # BB Projects Annula Savings

1 ATL 4 1,003,475

2 YICT Class I 13 607,476

3 YICT Class II 883,007

4 Daimlerchrysler NEA 11 693,675

5 Supplier GB 9 1,605,451

6 Supplier BB 8 3,120,878

7 China Mobile Kaifong Branch 1 716,588

Total 37 9 7,913,961

On Going Projects:

1 BYD 132 YICT 10

3 CAOE 18 4

4 Haier 10

5 Nidec 3

6 Flextronics 3