126 pm

-

Upload

4th-international-conference-on-advances-in-energy-research-icaer-2013 -

Category

Technology

-

view

87 -

download

1

description

Transcript of 126 pm

A Paper

Presentation on

“Optimizing the Compression Ratio for C.I. Engine Fuelled with Undi Methyl

and Ethyl Ester & its Blends with Diesel.”

Presented by

Mr. Madane Pravin A.Guide

Dr. A. T. PiseDeputy Director DTE Maharashtra state,

Govt. College of Engineering, Karad

IV th International Conference on Advances in Energy Research Indian Institute of Technology

Bombay, Mumbai

Outline

Introduction Preparation of Biodiesel Experimental Method Results & Discussion Conclusion Future Scope References

Why Biodiesel ??

The ever rising demand of petroleum fuels

Scarce availability of petroleum fuels

Increasing environmental problems

Shortage & increasing cost of petroleum fuels

found in konkan area and along coastal areas and adjacent lowland forests costal area. Fruits - April and May. Biofuel Yield 40 to 45%

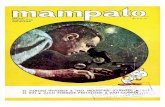

Undi (Calophyllum Lin)

Fig. 1 photo image of Fruits of Undi.

Blends Preparation for the Experiment

B10 (10% biodiesel & 90% diesel)B20 (20% biodiesel & 80% diesel)B30 (30% biodiesel & 70% diesel)B40 (40% biodiesel & 60% diesel)B50 (50% biodiesel & 50% diesel)B100 (100% biodiesel)

PROPERTIES OF BIODIESEL BLENDS Measured at Nikhil Analytical & Research Laboratory (Approved by Govt. of India) at room temperature.

No. Property Diesel B10 B20 B30 B40 B50 B100

1 Density (gm/cc) 0.84 0.842 0.845 0.847 0.85 0.852 0.8562 Viscosity (cst) 2.65 3.15 3.27 3.4 3.45 3.52 3.583 Flash Point (°C) 80 80 95 120 139 146 160

4 Fire Point (°C) 110 95 133 140 152 162 1705 Cal. Value(kJ/kg) 43800 42700 42470 41900 41500 40800 392106 Ash Content (%) 0.01 0.0046 0.005 0.0054 0.0058 0.006 0.0067 Cetane No. 50 51 52 55 57 58 60

No. Property Diesel B10 B20 B30 B40 B50 B100

1 Density (gm/cc) 0.84 0.809 0.811 0.816 0.824 0.838 0.854

2 Viscosity (cst) 2.65 3.03 3.16 3.34 3.58 3.99 4.38

3 Flash Point(°C) 80 78 102 125 148 176 200

4 Fire Point (°C) 110 90 110 130 162 182 210

5 Cal. Value (kJ/kg) 43800 42800 42500 41950 41600 40900 39300

6 Ash Content (%) 0.01 0.0043 0.0048 0.0053 0.0058 0.0062 0.007

7 Cetane No. 50 50 51 54 56 57 59

Table 1: Properties of Undi Methyl ester Blends

Table 2: Properties of Undi Ethyl ester Blends

Higher viscosity is a major problem in using vegetable oil as fuel for diesel engines.

The flash and fire points of Undi Methyl and Ethyl ester was quite high compared to diesel. Hence, Undi Biofuel is extremely safe to handle.

Higher carbon residue from may possibly lead to higher carbon deposits in combustion chambers of the engine. It can also lead to choking and trumpet formation on the injectors to such an extent that fuel atomization will not occur properly.

Presence of oxygen in fuel improves combustion properties and emissions but reduces the calorific value of the fuel. Undi Methyl and Ethyl ester has approximately 90% calorific value compared to diesel.

Experimental Method

Test Rig. Specifications of Engine

Make Legion Brothers

Rated Output 3.7 KW

Rated Speed 1500 rpm

Type Four Stroke

Bore 80 mm

StrokeCR

110 mm5:1 to 20:1

Type of Ignition

SI & CI

Method of Loading

Eddy Current dynamometer

Method of Starting

Manual Crank starting

Method of Cooling

Water Cooling

Schematic diagram Experimental Set-up

• The pressure transducer was mounted into the engine head which measures the combustion pressure having accuracy of 0.0001 bars.

• NEETAL Ltd make five gas analyzer was used to measure the exhaust emissions. Emissions CO, CO2,and O2are measured in terms of percentage having accuracy of 0.01%.Also the other emissions like HC, NOx in ppm with accuracy 1 (ppm) were measured.

• A Hartridge Smoke Meter was used to measure the smoke density of the engine having accuracy 1 HSU.

• The K type thermocouples were used to measure the temperatures of the engine exhaust, calorimeter exhaust, water inlet of calorimeter, water outlet of calorimeter and engine cooling water outlet with least count of0.1 0C.

Experimental Procedure summary

Sr.

No.Fuel

Engine Compression RatioLoad Steps

(Kg)16 17 18 19 20

1 Diesel √√ √ √ √

0.0, 2.5, 5.0, 7.5,

10.0

2 B10 √√ √ √ √

3 B20 √√ √ √ √

4 B30 √√ √ √ √

5 B40 √√ √ √ √

6 B50 √√ √ √ √

7 B100 √√ √ √ √

Results & DiscussionFrom the measured parameters the performance parameters computed and they were compared with pure diesel.

Brake Thermal Efficiency (BTE)

Brake Specific Fuel Consumption (BSFC)

Carbon Monoxide(CO %)

Carbon Dioxide(CO2 %)

Hydrocarbons (HC)

Nitrogen Oxide (NOx)

Smoke Density (HSU)

Brake Thermal Efficiency (BTE)

BTE increases with the load and it reaches maximum at the full load at each CR.The trend indicates that BTE increased as the CR increased while it decreased as the percentage of the diesel increased. At higher CR, BTE almost higher for blended fuels. This can be attributed to the poor combustion at lower compression ratio for blended fuels.The self-ignition temperature of the biodiesel blends is more than that of the diesel. Increased compression ratio increases the air temperature inside the cylinder consequently reducing ignition lag causing better and more complete burning of fuel. The performance of biodiesel blends is better at a higher compression ratio.

Brake Specific Fuel Consumption (BSFC)

• Minimum values of BSFC for different compression ratios is

given in kg/kW.hr. • The average Brake Specific Fuel Consumption for biodiesel

blended fuels is more than the diesel

• ethyl esters have less BSFC than methyl esters because of ethyl esters have high calorific value than methyl esters when blended with diesel

• The difference in calorific values of diesel and biodiesel is decreases as the percentage of biodiesel decreases. This causes more BSFC values for biodiesel blends than diesel.

Carbon monoxide(CO)

For Methyl & Ethyl esters minimum percentage of Carbon monoxide for different compression ratios is given in Percentage. The amount of CO emissions was measured lower in case of biodiesel blends than diesel. Ethyl esters have less CO% than Methyl esters. This might be due to more (11%) oxygen molecules in the biodiesel that causes complete combustion of fuel which leads to reduction of CO emissions. The more oxygen present in biodiesel acts as a combustion promoter inside the cylinder results in better combustion and CO reduces drastically. Hence due to incomplete combustion the CO present in the exhaust reduces drastically for biodiesel blended fuels.

Carbon Dioxide (CO2)

•For Methyl & Ethyl esters minimum percentage of Carbon monoxide for different compression ratios is given in Percentage•Methyl ester have higher value CO2 emissions than ethyl ester.

•As the load and CR increases percentage of emissions also increases for methyl esters but there is no much changes for ethyl esters.

•In the range of whole engine load, the CO2 emissions of diesel fuel are all higher than that of the other fuels

•all cases reduction of CO2 production was observed with increase in biodiesel percentage in blends for each load in constant speed test

Hydrocarbons(HC)

• For Methyl & Ethyl ester minimum value of hydrocarbons for different compression ratios is given in ppm

• Values of HC is minimum Because of higher values of oxygen in biofuel

Nitrogen Oxide(NOx)

• For Methyl & Ethyl ester minimum value of Nitric oxide for different compression ratios is given in ppm

• Ethyl esters have less NOx emission than methyl ester because of oxygen content decreased during production process

• The NOx emission is strongly related to lean fuel with high cylinder temperature or high peak combustion temperature. A fuel with high heat release rate at premix or rapid combustion phase and lower heat release rate mixing. This increase of NOx production was due to presence of more oxygen in biodiesel.

• When the percentage of biofuel in diesel increases the Nox.

Smoke Density(HSU)

For Methyl & Ethyl ester minimum value of Smoke density for different compression ratios is given in ppmAs the load increases the smoke level from engine also increases for diesel and biodiesel blended fuels methyl ester have less Smoke Density value than ethyl esterThe engine exhaust contains solid carbon soot which is generated during combustion seen as exhaust smoke

Conclusion

The biodiesel blends performance found better at higher compression ratios. At these compression ratios higher BTE and lower BSFC found.

The Undi Methyl and Ethyl ester and its biodiesel blends performance found better at optimum compression ratio of 20 At this compression ratios higher BTE and lower BSFC found.

All the exhaust emissions (i.e. CO, CO2, HC, NOx, HSU) for Undi Methyl and Ethyl ester is lower at 20 compression ratio.

Undi Methyl ester is more beneficial than Undi Ethyl Ester because it have Higher BTE, less BSFC and lower exhaust emissions than Undi ethyl estersFrom engine test results, it has been established that Undi,Palm and Simarouba biodiesel can be substituted for existing diesel in CI engine without any major modifications.Higher viscosity is a major problem in using vegetable oil as fuel for diesel engines. Significant reduction in viscosity was achieved by heating the oil and dilution of vegetable oil with diesel in varying proportions biodiesel along with diesel reduces the environmental impacts of transportation, dependency on crude oil imports and offers business possibilities to agricultural enterprises for period of excess agricultural production.

Scope for Future Work

Study the effect of varying injection angle on the engine performance.

Study the effect on the engine performance and engine emissions by changing the injection pressure with each compression ratio.

Optimizing the swirl level by using a masked inlet valve.

Lifecycle testing of engine with biodiesel is required so that the effects on the various components can be observed.

REFERENCES

[1] Agarwal D, Agarwal AK. Performance and emission characteristics of Jatropha oil in a direct injection compression ignition engine. CIGRE Agriculture Journal Manuscript 2003.

[2] Rao A, Mohan P. Performance Evaluation of DI and IDI Engi nes with Jatropha Oil based Biodiesel. Agriculture Journal.2005: 86:72-76

[3] Reddy JN, Ramesh A. Parametric studies for improving the performance of a Jatropha oil-fuelled compression ignition engine. Renewable Energy 2006:31: 1994-016.

[4] Singh R, Singh S, Pathak B. Performance of renewable fuel based C I engine. Agricultural Engineering International CIGR Journal 2007: Manuscript EE 0014. IX.

[5] Reheman H, Ghadge SV. Performance of diesel engine with biodiesel at varying compression ratio and ignition timing. Fuel 2008: 2659-66.

[6] Singh I, Rastogi V. Performance analysis of a modified four-stroke engine using biodiesel fuel for irrigation purpose. International Journal of applied envir sciences 2009: ISSN 0973-6077: VI 4-2.

[7] Rao R, Raju VR, Rao MM. Optimizing the compression ratio for a mahua fuelled C.I. Engine. ARPN journal of engineering and applied sciences 2009:VI 4-3.

[8] Jehad A, Yamin A, Sakhnin N, Sakhrieh A. Performance of C.I. engines using biodiesel as fuel. Amman-Jorden, GCREEDER (2009).