11074

-

Upload

akhileshkjha -

Category

Documents

-

view

219 -

download

0

Transcript of 11074

-

8/7/2019 11074

1/10

DYNAMIC MODULUS ESTIMATION ANDSTRUCTURAL VIBRATION ANALYSIS*A. Gu pt a, S. Kh an da swamy, S. YellepeddiDepa rtmen t of Mech an ica l E ngin eer in g

Nor t her n I llin ois Univer sit yDeKalb, IL 60115T. Mu lca hy, J . H ull

Energy Technology Divis ionArgonne Nat ion al Labor a tor y

Ar gon ne, IL 60439

The submitted manuscript has been created by theUniversi ty of Chi cago as Operator of Argonne Nsti onalLaboratory (Argonne) undw Contract No. W-31-109-ENG-38 with the U.S. Department of Energy. The U.S.Government retsina for itself, and others acting en R behaif,a paid-up , nonexclus ive, i rr svo+eb le worldwide I icanss insaid artiite 10rspmdwca, prepare derivative works, distributecopies to the public, and perform pubfiily and display

JMiafv, bvor cmbsha ti o f the Govammant .

DistributionR. W. WeeksR. B. P oeppelU . BalachandranR . A. Va len t inAuthorsESA Sect ionET Division F ileF. Y. Fr adinH . DruckerS. La ke

To be presen ted at 17th In ternat iona l Moda l Analysis Conference, Kissimmee, FL,F ebr ua ry 8-11, 1999.*Work par t ia lly supported by the U.S. Department of Energy, Energy Efficiency andRenewable Energy, as par t of a program to develop elect r ic power technology, underCont ract W-31 -109-Eng-38.

-

8/7/2019 11074

2/10

DISCLAIMERThis report was prepared as an account of work sponsoredby an agency of the United States Government. Neither theUnited States Government nor any agency thereof, nor anyof their employees, make any warranty, express or implied,or assumes any legal liability or responsibility for theaccuracy, completeness, or usefulness of any information,apparatus, product, or process disclosed, or represents thatits use would not infringe privately owned rights. Referenceherein to any specific commercial product, process, orservice by trade name, trademark, manufacturer, orotherwise does not necessarily constitute or imply itsendorsement, recommendation, or favoring by the UnitedStates Government or any agency thereof. The views andopinions of authors expressed herein do not necessarilystate or reflect those of the United States Government orany agency thereof.

-

8/7/2019 11074

3/10

DISCLAIMERPofiions of this document may be illegibiein electronic imageproduced from thedocument.

products. Images arebest available original

-

8/7/2019 11074

4/10

.. .

DYNAMIC MODULUS ESTIMATIONAND STRUCTURALVIBRATIONANALYSIS

A. Gupt a, S. Kh an dammnzy, an d S. YeIleped dfNorthernIllinois UniversityDcKdb, IL 601M

ABsrmcrOfb, the dynamic el~-c modulus of a ~al with frequencydapmdent propettics is diffioult to -CSlmstC Ill- Uncetraincics. am compounded in any struotuxai viion analysis udng the-al propmics. HZ different G%PemM@ ?CehrlquCs*Uscdwcsthate the pmpcrt iesof a particular elastomeric mmerialev~a bt oedf tc que q rage. k f hep roper tie saredetemindvarious Suucturq incorpocaring the aIastom arc Soalpd by anitemtivcfinite c19ncotmcdlcci mdetcmdnenmai ffequcnciesdmode shapes. Then, the finite ekmsnt nsuits are arrelated withresuIts obtained by axperhncnml modal anelysk

NoMENcLAnJRE.A = (MY(2+DTW?)Ac = aoas-seuion of cyiindtical qAmen, *B = 1/6(1+7)2C. = c4cfIioient for mode n, of claped-f~ (Oberst) barc, = 0-s5959C2 - 35~9G = 9.8194D = p, /p, density ratioE = Youngs modulus of Obemt bar, PaEC _ complut rrmdulua R E +jqG ~ ah- m~~]~ of ~wl~~ ~, pa~ = thj~~f~~,mHZ = thkbl= of ~~c ~~, mL ==length ofoylinddcal ~ntcn, mM _ mass of metal dd on top of speck% KgM, = M of qmcimcn = p, AL KgT = H, ~ thickn~ ratio~ = loss ftior of viscoelaatic matctial. dimensionless% = M, /~, Ios fa~or of sandwiched spaiman, dimensionlessP - density of Obcrst bar, kg/mlp, = density of damping matciial, kg/m

T. Mukahy and J . H ullArgonne NationalLaboratory~gonne, IL 60439

4, = half-power bandwidth for modes of ownpositc bar, Hz/n E rexmance fiequmcy for made n of Obast bar, Hz/s = resonaha i%equsnoy f6r modes of coqmsite bar, Hzs = indanum&. 1, Z3 . . . . ..(5sn)! = kqth of bar, m

I. lNTRODUCTXONViscoeksic materials due to their low elastic tnduhis end highloss modulus ate wed in many cases. However, modulus of aviaoOCl*crn smr idis high lydcpcndsmon nt soypsmncms Suohas fqlency. tempmtwc main amplitudq prdoad etc. [1]. Dueto mdaapread use of viscdastic matdda in various indusaicsinoludiig automoti% biimechanid, and StmCtum4 WIixls testmcthodsbavcbecn pmposcdtocha=Kzaizethsacmataialsandnosingle or test ntctld has &n adopted univaraalIy.Onead method i Wets bar method[2]. !%= modulusof ticmetmaI beiig inWStigMd is vety low, a sandwich ap&rnco asshown in FW I was tested in a Bmel & Kjaarqmratus P] .r

Fig. 1. Sandwich Beams fw Obcrs t exdment

9N3 H23W 8S :6a 366 T-SI-130

-

8/7/2019 11074

5/10

. . .

Nahmd ftcquencics and damping ratb were WSSUrCdfirstfor thebare specimen with antikvcr end conditions and then for thesandwiched specimen. Magnaic excitors and pickups were usedto avoid msss Iosdiig of the bearm This method is apparentlypopukar in automotive ind~ wh~ diffkrent mstaial.s arecxplomd for thmrmud d viirarion damping applications.Another method (hcreafler mf~ to as tripd nvmhod)has beanproposed by Niel*rI cd 54]. k this mctbod oylindrioel wstspecimens * mccd plates at one end is compressed by aninverwd shaker as shown in Figure 2. Measuring the force andaccderation (an impedance hesd was ussd to messure both) thernoduhta and loss fsctor oan be calculated using a numericalitomtivc ~ Strain gages were bondsd to the S~irncn tomonitor strain due to prehwi as well as dynamic strain. 71dsmethod (so cdlcd non-resonant method) is used to compute~ and loss f-or continuously over a wide frsaumcy rarwe.

.

Fig. 2, ?Yipod experimental setuph was decicki that s structure mode of the same viscoelasrkmaterial -uld be t~td by cxaml modal analysis todetermine its natural ~eneies. The same stmctura would alsobe modelled by finite element method using ANSYS [5] and thestifhcss of theviwelam cmaterielwou ldbedjxt d t ornmch theexpa%emal result

2. THEORY

2xC EHH2[(A -B) - 2(A - ~)> -2 (AT@] -G. P .(1)

and loss factor is given byA~,

~= (A- B)-2(A-E12-2(AV) (2)

For tie uipod method alwm in Fitguq% the complex modulus ECurement of amplian= [4] ascan bc solvd from themfsAL(Q) = Sin(p)compliancc(~) = fo rcc(u) Q:~,$XCO@-MXS~~) (3)

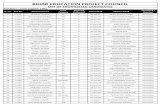

RESULTSl%edimsmdons of wo sandwich - for the Obcrsl mctid=40~rn R~l. ~etimtirnf~(I)d@)are based on cantilever end conditions. In order to verify &o endeditions natural fkqrenciesof the bare bars in O&m appmtuswete meaaurd and ate prasentai in Teblc I along wish thetheoretical values. It maybe notsd that the first mode rssults ereignored as suggostd in the test procedure @].

*Beam Thickness Theoretical Ex#mental(m) Frequency < Frquancy &(HZ) (HZ)

0.9144 66.8 65.6187.4 184.33673 361.3

1.524 111.4 111.2312.4 311.8I 612 .1 611.8 ITable 1: Nanml ikquencics of bare hers

So it seems that cantilever bwtdary conditions is satistklapproximately for the thinner beam whmeas ~1 is vq wctlfor the thicker beam.Next naturalfrequenciesand damphg ratios of the ssndwichspecimens were reared by u$iu the o~~ aPPMUW ~dmagnetic aenso~ connected to Bruel & Kjacr 3550 frsquencyanalyzer and wansfeting the data to a computer where STARMODAL [6] is used to estirnatc natural frquencics and dempingratios. The values obtained am prcsmted in Tabte I

-

8/7/2019 11074

6/10

. .

Sandwich Natuml DampingS~imut # Frequency ~ Ratio q,(Hz) q/*1 200.4 15.0

418.4 20.52 228.8 13.0493.9 13.6783.7 2.24

Table 2: Sandwich -Combmingrsaults of both sandwich spdnans, bawd on theinformation presentedin Tables 1and z shsarmodulus and lossfactor (twice the damping ratio) were estkmsl usiag formulae(1) and (2). Assuming a Poissons ratio of 0.45, elastic moduluswas also estimated.Frequency shear IAss Elastic(f@ Modulus G Factor q Modulus E(MPa) (MPa)200.4 2.987 0.408 I 8.66 228.8 3.691 0384 10.70418.4 8.679 0S48 25.17493.9 10.483 0.4s4 30.40783.7 13.4 0.1 38.86Table 3 : P roper t ie sof viscoelaetic materiel by Oberst

CxpcrimentThcra Wem four awnpks reared to .eatunare dynamic modulus bym-pod method folIowing equation (3). W samples havedimensio~ as ~ Table 4.

Sample # Length L Diamcts Msas of(mm) Qnrn) EndPlate Mm)

1 49.68 I8.5 2.22 45.43 26.54 &s3 41.85 34.73 13343

Table 4: Specimens for mipod tedng

AFig. 3. E for sample 3 ac E-+ - in amplitudeIIll\]. Fig. 440ss factor fOra&lc 3 at 403M5stniin amplitu

Moddii were obtainrd over frequency range ~icaIly up to 450 h maybe rrwmtioncd that in the Obcrst tcs method, srminHz as shown in Figuru 3 and 4. Beyond 450 HZthe cestdts WGR amplitude is not catatant and it varies along thelengthduetocmoncous(probablyefkctai by thercsotmna$. Inorder to oantilevcr gaonwtry whereas for the tripod test stminis castantcomparethis tes dara wirh other test methods, the rnodulii throughout the sample which is unclesoompeion. In od= ~0ohind for diff.t specimens wi& diflcmnt ~stmins end ~e -ul~ !hn both of these methods, avemge vaiues ofstrain amplitudes et four ficquenciss ( 100HZ 200 Hz 300 Hz elastic modulus and 10SSt%tor (without consisting eff= ofand 400 Hz) are presented in Table 5. pre-stmin and stmin amplitude) arc prescntdin Tablc 6.

-

8/7/2019 11074

7/10

Wm >cMPLXJ4C)LS REAL MEAS MAIN f: ::.;;Y: IOOM [1 x:x: IOOHZ + 800Hz LXN#AVM 10 YMAX : 89.5M

iP

-50E6

-iooE6

1---- I--. .... . .. . . ..-. -. .. .. . - .-. . .- --- . . . . .. . . . --i

s e t u p wMeasurement: DUAL-CH . SPECTRUM AVERAGING 800 linesTrigger: GENEFiATOHAveraging: L314 10;;:; . SPAN 800Hz df: IHz l-: 1!3 dt: 977us., Centre Freq: 500HzW&ixhting: ~;~F&NGLJLAR. DIRECT /-0 , 71+z -\oN 22. 5mV/un i tch:B; - DIRECT /-0 . 7Hz -\oN Ss 10, 21nv/m/eaGenerator: &TXSINE O.OdB ref 1.00V WHITE DC OuvRepet it ion : CO14T

-

8/7/2019 11074

8/10

1 . 0

000

0.6

O*4

0.2

0

Wm >LOSSJACTOR MAIN Y: 435mlJY: i.00IJ RMS LIN [1 x: 400Hzx: 100tiz + 800t-lz LIN#AVM 10 YMAX : 43.OUT ~A-.-d..d{ L1--- I-... . ..- -.. -.. -..... . . . . . -4i

I+JI1--- ;. .....IR

..- -------

.

1L- ~----- , ~ -v-----i200 300 400 !500 600 700 800 900Setup WMeasurement: OUAL-CH, SPECTRUM AVERAGING 800 linesTrigger: GENEBATORAve~aging: LIN 10;:;:. SPAN 800HZ df: ll+z n 1s dt: 977us.

q Centre Freq: 500HzWeighting: RECTANGULARch.A: 200mV DIRECT /-0.7Hz -\oN 22.5mV/unitch,B: Iv - DIRECT /-0.7Hz --\oN 10.2mV/m/52Generato~: MULTISINE O.OdB ref i.00V &TE DC: C)U$Repetition: CONT

F,9ii

-

8/7/2019 11074

9/10

.,-

Sample # pre- Stmin Elastic Modulus E bs Factor qstrain Amplitude MPax lo< x 10*iOOHz 200 300 400 100 200 300 400

Hz Hz Hz Hz Hz Hz Hz1 60 10 36.9 43.1 45.8 48.0 0.447 0-476 0.519 0.53180 40 39.3 465 49.2 51.6 0.462 0.474 0s02 0519100 60 39.3 46.5 48.8 51,3 0.449 0.473 0.499 0.5172 80 10 37.1 44.8 49.2 52.3 0.436 0.457 0.469 0.47s100 30 43.7 48.6 55.7 58.7 13.439 0.462 0,454 0,466

100 60 395 52.1 55.5 58.1 0.431 0.425 0.432 0.4423 80 10 52.0 64.1 69.4 72.7 0.409 ., 0.416 0.423 0.434100 20 52.6 62.1 68.2 74.0 0.442 0.418 0.42I 0.434

120 40 53-2 62.3 6S.7 74.5 0.402 0.419 0-426 0.43s4 60 10 42.3 50.6 55,9 60.7 o.4i4 0.414 0.409 0.406 ~

100 20 45,2 5s.1 60.2 65.1 0.427 0.440 0.402ilo 30 43.1 55.00.398 ~

60-3 65.6 0.499 0.409 0.387 0.382Y.LI . G n-.-:. .-A I ... L ... T.AJ .-

Fscquency ElasticModLI1uaE MaHz ( MPa) F-or

100 43.7I

0.438200 52.6 0.440300 57.2 0,445I 400 I 61.1 I 0.454Table 6. Average value of dynamicmodulusfiotnTripod testNow a s&uoture made of two ahurtinum disk are joinssl byvkc@astic - (SSshown in Figure 5) and is td for natural

Fig. S. Aluminum disks bonded by viscods~c tttSCeri8i

frequenciesand mode ahapcs. The inner disk is a sofid disk oftadii 119.38 rnmand outsrdisk isananmtlardisk of inside radiusof 122.17 mm and the outside mdius of 1524 mm The space inbetweenthe disks is filled with the viscoetzsricmatcrid undercoasidemtion. The disk is suspendal by an elastic cord and isimpacrai by a hammer in hotizmntal direction. T?ISnatutadfrequencyfm 2 nodaldiameterOnodalcirclemodewasobservalat 1110Hz Ntuctthe finiteelementsolutionwas obtained withmodulus of aluminum as 73 GP~ Poissons ration of O-33, anddens@ of 2700IC#tT?and.Poissonsratioof viacoelasticnaacerialas 0.45, and density of 103?.1 K@. The modulus E ofvisooelastic material was varied as shown in Table 7 until thenatuml frequency of 2 nodal d~nodal oirckmodeconcspondtotheexperimentvalueof lllOHz

Ekstic hhduhls E Frsquency and 2 nodal(MPz) diameter maic(w10 919.120 995.140 1092.445 I 1109.4Table 7. Elastic modulus of viscoelastic material used in FEM

CONCLUS1ON[n the Oberst rnerhod, the specimens MCin cantilever configurationresulting in non-uniform stmitt. Thus any suain dc~en~phenomenon cannot be obsetvcd in the OberSCmethod. HOWCV*,comparing average values, the methods do not agmc with achorher. Also the tripod method gives data continuously over a mnge

.s@d 9T17ElKLs13 .9N3 .H331d t5:6El366T-ST-130

-

8/7/2019 11074

10/10

as opposed [O the obcmt method which gives data u only a fewfrequencies Shce a viacoeltic materiidhas diffaent charwm.sitsover different foquencc range (@May, glass tubk rransitlo~rubbay and flow region) any interpolation or extmpolation of datamay bc questionable. Ptcscmly a DMA tsst is being catried out todetermine is characteristh such as transition tmpmture along withmodulus aa a function of tampemmre and frequency, The onlynatural frequency of the composite aluminum disk that could beexcitd fall outside the mnge of mossurd properties. A newampleis being prepared to have natural fkequancywiddn the mngc forwhich pro~s are known. Ovemll, the tripodmethod seams theprcfemble method though it involves a IOKmore instrummtation thanthe Oberst method and also only V* small pre-suain or SUain-amplinide oould be applied,ACKNOWLEDGEMENTSPar t of t h iswork was suppmed by the Summer Faculty Rt%mrchParticipation Program of &onne National &boratory.App reciation is also exr en ded t o M r. David La rson of S & VSolutions for asaistanoc with tic Oberst experiment.

REFERENCES[1]

[2]

[3]

[4]

[s][6]

Nashi~ A.D., Jones, DJ.G.and HenderaomJ.P., VIMonDamping, JohnWiIcy and Sons, 1985.ASl%i Iks.igmrion E 756-93, Standard Test Method firMesuring Vibration-Damping PropaR&s of Mataii%Annual Book of ASTMStandards,vo l . 04 .06 , pp 827-833.1993.Complex MOdUIUSAppiUZUUSTYPG3930,Bxucland Kjacr, ppI-u 1964.Nic~ L.F., Wismor, N,J. and Gad% S., Improved Methodfor Gmnplex Modulus Eatimtim Bruel & Kjaet ApplicationNote, pp 1-7, 1997.ANSYSversion5.4,ANSYSInc,PA,1998.STAR MODAL version 5.23, Spectral dynami% IIIC.,CA.1996.