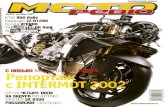

106 Keraflex UK NoRestriction

Transcript of 106 Keraflex UK NoRestriction

-

7/30/2019 106 Keraflex UK NoRestriction

1/4

CLASSIFICATION IN COMPLIANCE WITHEN 12004Keraflex is an improved (2) slip resistant (T)cementitious adhesive (C) with extended open time (E)classified as C2TE.

Keraflexis CE marked, as declared inITTcertificateN 25040476/Gi (TUM) issued by the TechnischeUniversitt Mnchen laboratory (Germany).

WHERE TO USEInterior and exterior bonding of ceramic tiles porcelain,stone materials and mosaics on floors and walls.

Also suitable for spot bonding of insulating materialssuch as expanded polystyrene, rock and glass wool,

Eraclit (wood-cement panels), sound-deadening/reduction panels, etc.

Some application examples Bonding ceramic tiles, natural stone and mosaics on

the following substrates: cement rendered walls; interior aerated concrete block walls; gypsum or anhydrite after having first applied

Primer G or Eco Prim T; underfloor heating installations; cement screeds; interior painted walls, as long as the paint is firmly

anchored and resistant to alkalis; waterproof membranes of Mapelastic,

Mapegum WPS or Mapelastic AquaDefense.

Tile on tile of existing flooring with tiles up to300x300 mm.

Kerafleerafle

xKeraf

lexEN 12004

EMICODE

GEV

High performance high

grab polymer modifiedcementitious adhesivewith no vertical slip andextended open timefor ceramic tilesand stone material

INCOMPL

IANC

EWITHEUROPEANSTANDARDS

CEMENT

ITIOUSADHESIVEFORCE

RAM

ICTIL

ES

EN12004

106_keraflex_uk (22.06.2012 - 10 Bozza/2 Ciano/PDF)

-

7/30/2019 106 Keraflex UK NoRestriction

2/4

Applying the mixKeraflex is applied to the substrate usinga notched trowel. Choose a trowel thatgives the correct coverage of the tilebacks, depending on the expected serviceconditions.

To achieve good adhesion, spread an initialthin layer of Keraflex on the substrate usingthe flat side of the trowel. Immediately, apply

Keraflex using a suitable notched trowel,depending on the type and size of the tiles(see Consumption).

For external ceramic tiling, tiles greater than300x300 mm, floors subject to heavy loads,when applying in swimming pools and waterfeatures, spread the adhesive on the backof the tile (back-buttering) in order to ensurecomplete coverage.

Installing the tilesThere is no need to wet the tiles beforeinstalling them. Only with very dusty backsis it recommended to dip the tiles in clean

water. Dry before fixing.

Tiles should be installed with firm pressure toensure good coverage with the adhesive.

In normal temperature and humidityconditions, the open time of Keraflex ismaximum 30 minutes. Unfavourable weatherconditions (strong sun, drying wind, hightemperatures, etc.) or a highly absorbentsubstrate can reduce the open time to just afew minutes.

It is therefore necessary that careful checksare made to ensure that a skin does not formon the surface of the spread adhesive.If not, apply adhesive.

It is not recommended to wet the adhesivewith water once a skin has formed because,the water will form an anti-adhesive film.

If necessary, tiles should be adjusted within60 minutes of installation.

Tiling installed with Keraflex must not bewashed or exposed to rain for at least24 hours and must be protected from frostand strong sun for at least 5-7 days.

Spot-bonding insulating materials

For spot-bonding sound-deadening orinsulating panels, apply Keraflex with atrowel or a float.

GROUTING AND SEALINGWall joints can be grouted after 4-8 hours andfloor joints can be grouted after 24 hours withthe relevant MAPEI cementitious or epoxygrouts, available in up to 27 different colours.Expansion joints must be sealed with therelevant MAPEI sealants.Mapesil AC silicone sealant is available inmatching 26 colours.

LIGHT FOOT TRAFFIC

Floors are able to take light foot traffic afterapprox. 24 hours.

READY FOR USESurfaces are ready for use after approx.14 days.

Bonding small format tiles in swimmingpools and water features.

Bonding tiles to floors subject to heavyloading.

TECHNICAL CHARACTERISTICSKeraflex is a grey or white powdercomposed of cement and graded aggregates.It contains a high quantity of synthetic resins

and special additives.A mortar with the following features isobtained when mixed with water:

Easily workable.

Highly thixotropic; Keraflex can be appliedon a vertical surfaces without slump or tileslip, even with heavy tiles.

Perfect adhesion to all materials normallyused in building.

Hardens with minimal controlled shrinkage.

Extended open time.

Water and frost resistant.

Excellent bond strength.

RECOMMENDATIONSDo not use Keraflex:

On concrete subject to shrinkage.

On metal surfaces.

For installations that require an adhesivethickness greater than 5 mm.

APPLICATION PROCEDUREPreparing the substrateTThe substrate must be flat, free ofcontamination, loose particles, grease, oils,paints, wax, etc. Damp substrates can slowdown the setting of Keraflex.

Cement substrates should not continue toshrink after the installation of the ceramictiles. Renders must cure at least 2 weeksand cement screeds must have an overallcure time of at least 3 weeks, unless theyare produced with special binders such asMapecem, Mapecem Pronto, Topcem orTopcem Pronto.

Dampen with water to cool surfaces whichhave become heated from exposure tosunlight.

Gypsum substrates and anhydrite screedsmust be perfectly dry (max. residual moisture0.5%), sufficiently hard and free fromlaitance. It is essential that they be treatedwith Primer G or Eco Prim T (diluted 1:2with water).

Preparing the mixMix Keraflex with clean water until a smooth,lump-free paste is obtained. Leave to restapproximately 5 minutes and re-stir.Use 26-28 parts water for every 100 parts

by weight of Keraflex Grey(24-26 parts forKeraflex White), which is equal to approx.5.2-5.6 litres of water for every 20 kg ofpowder (4.8-5.2 for the white). Mixed thisway, Keraflex has a pot life of approximately8 hours.

Keraf

leeraflexKeraflex

Installation ofpolished marbleon floors

Installation ofsingle-fired tile onexpanded foamconcrete block walls

Single-fired tileon terrazzo tile of

an external wall

-

7/30/2019 106 Keraflex UK NoRestriction

3/4

TECHNICAL DATA (typical values)In compliance with: European EN 12004 such as C2TE

ISO 13007-1 such as C2TE

American ANSI A 1184-1999

Canadian 71 GP 30 M type 2

PRODUCT IDENTITY

Type: powder

Colour: white or grey

Bulk density (kg/m): 1,300

Dry solids content (%): 100

EMICODE: EC1 R Plus - very low emission

COMPOSITION AND PROPERTIES OF THE MIXTURE (at +23C and 50% R.H.)

Mixing ratio: 100 parts Keraflex Greywith 26-28 parts water byweight100 parts Keraflex White with 24-26 parts water byweight

Consistency of mix: creamy paste

Density of the mix (kg/m): 1,500

pH of mix: 13

Pot life: over 8 hours

Application temperature range: from +5C to +40C

Open time (acc. EN 1346): > 30 minutes

Adjustability time: approx. 60 minutes

Ready for grouting on walls: after 4-8 hours

Ready for grouting on floors: after 24 hours

Set to light foot traffic: 24 hours

Ready for use: 14 days

FINAL PERFORMANCES

Bonding strength according to EN 1348 (N/mm): initial bonding after 28 days: bonding after heat exposure: bonding after immersion in water: bonding after freeze/thaw cycles:

1.81.71.21.4

Resistance to alkali: excellent

Resistance to oils: excellent (poor to vegetable oils)

Resistance to solvents: excellent

Temperature when in use: from 30C to +90C

Tile on tile withKeraflex grey

-

7/30/2019 106 Keraflex UK NoRestriction

4/4

Swimming pools and water features can befilled after 21 days.

CleaningTools and containers should be cleaned withplenty of water while Keraflex is still wet.Surfaces should be cleaned with a dampcloth, before the adhesive dries.

CONSUMPTION

Bonding ceramic tiles Mosaics and small sizesin general (trowel n. 4): 2 kg/m

Normal sizes (trowel n. 5): 2.5-3 kg/m

Large sizes, exterior floors(trowel n. 6): 5 kg/m

PACKAGINGKeraflex white and grey are available in20 kg paper bags, 5 kg alupak bags.

STORAGEKeraflex can be stored 12 months in anormal environment in original packaging.

The product complies with the conditions ofAnnex XVII to Regulation (EC) N 1907/2006(REACH), item 47.

SAFETY INSTRUCTIONS FORPREPARATION AND APPLICATIONKeraflex is irritant, contains cement which,in contact with perspiration or other bodyfluids, produces an irritating alkaline reactionand may cause allergic reactions to thosepredisposed. Wear protective gloves andgoggles.For further and complete information aboutthe safe use of our product please refer tothe latest version of the Material SafetyData Sheet.

PRODUCT FOR PROFESSIONAL USE.

WARNINGAlthough the technical details andrecommendations contained in this productdata sheet correspond to the best of ourknowledge and experience, all the aboveinformation must, in every case, be taken asmerely indicative and subject to confirmationafter long-term practical application; for

this reason, anyone who intends to use theproduct must ensure beforehand that it issuitable for the envisaged application. Inevery case, the user alone is fully responsiblefor any consequences deriving from the useof the product.

Please ensure that the current version ofthe Technical Data Sheet is being used.Check the website www.mapei.com

Keraf

leeraflexKeraflex

Anyreproductionofte

xts,photosandillustrationspublished

hereisprohibitedandsubjecttoprosecution

(U.K

.)A.G.

BETA

BUILDING THE FUTURE

This symbol is used to identify Mapei productswhich give off a low level of volatile organiccompounds (VOC) as certified by GEV (Gemein-schaft Emissionskontrollierte Verlegewerkstoffe,Klebstoffe und Bauprodukte e.V.), an international

organisation for controlling the level of emissionsfrom products used for floors.

Our Commitment To The EnvironmentMore than 150 MAPEI products assist ProjectDesigners and Contractors create innovative LEED(The Leadership in Energy and Environmental

Design) certified projects, incompliance with the U.S. GreenBuilding Council.

All relevant referencesfor the product are available

upon request and fromwww.mapei.com

Laying polystyrenefoam slabs with

Keraflex white

106-6-2012

An example of anistallation of glazedceramic pool tiles.

Leisure centre