10.1007_s12541-012-0245-6

Transcript of 10.1007_s12541-012-0245-6

-

8/13/2019 10.1007_s12541-012-0245-6

1/8

INTERNATIONAL JOURNAL OF PRECISION ENGINEERING AND MANUFACTURING Vol. 13, No. 10, pp. 1869-1876 OCTOBER 2012 / 1869

DOI: 10.1007/s12541-012-0245-6

NOMENCLATURE

h = Film Thickness

L = Length of the bearing

p = Pressure

Qz= End leakage of the bearing

T = Temperature

Ta= Atmospheric Temperature

U = Speed of the bearing

W = Load Capacity

z = Axial coordinate

= Percent weight concentration of nanoparticles

= Bearing eccentricity ratio

= Coordinate along perpendicular to line of centers

= Velocity component perpendicular to line of centers

= Viscosity of lubricant with nanoparticles

0= Viscosity of base lubricant

= Attitude angle

= Angular coordinate

2= Film extent

d= Damped Frequency

= Threshold Speed

= Coordinate along line of centers

= Velocity component along line of centers

1. Introduction

The current trend of modern industry is to use machineries

rotating at high speed and carrying heavy loads. In such

applications hydrodynamic bearings are widely used. When a

bearing operates at high speed, the heat generated due to large shear

rates in the lubricant film raises its temperature, which lowers the

viscosity of the lubricant and in turn affects the performance of

journal bearing. Addition of nanoparticles in the lubricant may

enhance the viscosity of the lubricant and in turn changes the static

and dynamic performance characteristics of the bearing. Therefore,

a thermohydrodynamic analysis is necessary to predict the

performance characteristics of the journal bearing operating under

nanolubricants (lubricants, which contain nanoparticles). In this

paper, the static and dynamic performance characteristics of journal

Analysis of Static and Dynamic Performance

Characteristics of THD Journal Bearing OperatingUnder Lubricants Containing Nanoparticles

Sreedhar Babu Kalakada1, Prabhakaran Nair Kumarapillai1,#, and Rajendrakumar Krishnan Perikinalil1

1 Mechanical Engineering Department, National Institute of Technology Calicut, Calicut, India-673601# Corresponding Author / E-mail: [email protected], TEL: +91-9447325988, FAX: +91-4952287250

KEYWORDS: Journal bearing, Lubricant additives, Nanoparticles, Performance characteristics

In this paper, the static and dynamic performance characteristics of journal bearing in terms of load capacity, attitudeangle, end leakage, frictional force, threshold speed and damped frequency are presented when the bearing operating under

lubricants, which contain nanoparticles and viscosity of these lubricants varies with temperature. The nanoparticles used for

the present work are copper oxide (CuO), cerium oxide (CeO2) and aluminum oxide (Al2O3). Viscosity models for the

lubricants are developed with the available experimental data. The modified Reynolds and energy equations are used to

obtain pressure and temperature distribution across the lubricant film and these equations are solved by using the finite-

element method and a direct iteration scheme. The static and dynamic performance characteristics of journal bearing are

computed for various values of eccentricity ratios for isoviscous and thermoviscous lubricants. The computed results show

that in isoviscous case, addition of nanoparticles does not change performance characteristics considerably but in

thermoviscous case, changes are significant.

Manuscript received: November 30, 2011 / Accepted: May 24, 2012

KSPE and Springer 2012

-

8/13/2019 10.1007_s12541-012-0245-6

2/8

1870 / OCTOBER 2012 INTERNATIONAL JOURNAL OF PRECISION ENGINEERING AND MANUFACTURING Vol. 13, No. 10

bearing in terms of load capacity, attitude angle, end leakage,

frictional force, threshold speed and damped frequency are

presented when the bearing operating under lubricants, which

contain nanoparticles and viscosity of these lubricants varies with

temperature.

In the existing literature, several THD studies have been

reported notably by Lin et al,1Gethin,2Khonsari et al,3Hirani et al,4

Rao and Biswas,5 Rho and Kim,6 Singhal and Khonsari,7 Ighil et

al,8Navthar et al,9Laraqi et al10 conducted a literature survey on the

effects of variable viscosity on maximum pressure, maximum

temperature, bearing load, frictional loss, side leakage, threshold

speed and damped frequency in high-speed journal bearing

operation and are examined. It is found that the consideration of

variable viscosity on the calculation of the bearing load and

frictional power loss of journal bearings operating at high speed

cannot be ignored. The viscosity - temperature effect of lubricant

had a great influence on the performance of journal bearing with the

larger eccentricity ratio. Many investigators, Lee et al,11Murshed et

al,

12

Chandrasekar et al,

13

Abedian and Kachanov,

14

have beenreported that addition of the weight fraction of nanoparticles in the

liquids increase viscosity of liquids. Lee and Kim,15Lee et al,16Ku

et al,17Thottackkad et al18investigated the role of nanoparticles in

nano-oil lubrication and suggested that addition of nanoparticles

may enhance the viscosity of lubricant. Bair,19 Bair et al20

investigated on the variation of viscosity of lubricant with

temperature and pressure for various real lubricants and reported

that lubricant viscosity varies with temperature and pressure, andhence it varies load capacity of the bearing, Vijayaraghavan and

Brewe,21 Elsharkawy.22 These suspended solid particles produce

thickness of lubricants, which in turn affects the various

performance characteristics of journal bearing. Nair et al23

computed performance characteristics of hydrodynamic circular

journal bearing operating under lubricant with nanoparticles, but the

studies are carried out without considering the variation of viscosity

of nanolubricants with temperature.

In the existing literature, the studies of the static and dynamic

performance characteristics of journal bearing operating under

nanolubricants and considering the variation of viscosity of

nanolubricants with the increase in temperature are scarce.

Therefore, it is felt that there is a need to carryout the performance

characteristics of journal bearing operating under lubricant with

addition of nanoparticles and variation of viscosity with

temperature on the performance characteristics. The presence of

nanoparticles, the friction couples often locate at the regime of

boundary lubrication or mixed lubrication. In the present work, the

fluid film regime is considered fully developed hydrodynamic

regime and friction couples effect can be neglected. In general,

lubricants may make core shell on nanoparticles, which may reduce

the hardness of the particle. However, in the present analysis, the

effect of the hardness has been neglected.

In the present work to obtain pressure and temperature

distribution in the fluid film, modified Reynolds and energy

equations are used, and these equations are solved by FiniteElement Method. A relationship between viscosity, concentration of

nanoparticles and temperature for different nanolubricants were

developed by using the available experimental data.24,25The static

and dynamic performance characteristics in terms of load capacity,

attitude angle, end leakage, friction force, threshold speed and

damped frequency are obtained at different values of eccentricity

ratios for the following cases.

1. Isoviscous

2. Thermoviscous

The computed results show that the addition of nanoparticles

changes the performance characteristics in both isoviscous and

thermoviscous case, and the changes are significant in

thermoviscous case.

2. Basic equations

Modified Reynolds and energy equations are used to obtain

pressure and temperature distributions in the fluid film of journal

bearing.

2.1 Reynolds Equation

The modified form of two-dimensional Reynolds equation is

used to determine the nondimensional pressure distribution across

the lubricant film. The Reynolds boundary condition at the trailing

edge of the film is established by the iterative scheme.

3 3

1

12 12 2

h p h p hCos Sin

z z

+ =

(1)

The following boundary conditions are used to determine pressure

distribution.

2

2

0 0,2

0

Lp at and z

dpat

d

= = = =

= =

2.2 Energy Equation

To obtain nondimensional temperature distribution across the

lubricant film the following modified energy equation which

obtained after making assumptions and simplifications26,27is used

2 2

3 3 3

2 12 12 12

h h p T h p T h p p

z z h z

= + +

(2)

The above energy equation is obtained by assuming there is no heat

transfer from the fluid to the surroundings (journal and bearing

housing). To solve energy equation the following boundary

conditions are used.

0

2 2

a

T T at

L LT Consant at z to

= =

= = +

2.3 Static performance characteristics

The various static performance characteristics as detailed belowcan be calculated using the pressure field obtained above. The static

-

8/13/2019 10.1007_s12541-012-0245-6

3/8

INTERNATIONAL JOURNAL OF PRECISION ENGINEERING AND MANUFACTURING Vol. 13, No. 10 OCTOBER 2012 / 1871

characteristics of the bearing are calculated by assuming no journal

motion other than rotation. The static characteristics are calculated

from the pressure field when the journal centre is in static

equilibrium. The non dimensional performance characteristics are

evaluated using the following equations.23

2.3.1 Load capacity

The components of fluid film force along the line of centers and

perpendicular to line of centers on the journal are given by

2

1

2

2

L

L

W CosWCosp d dz

W SinWSin

+

= =

(3)

1 / 2

2 2

W W W

= + (4)

2.3.2 Attitude Angle

It is the angle subtended by the line of centers of the journal and

the bearing of the load line.1

WTan

W

=

(5)

2.3.3 Frictional Force

Friction force in the bearing is given by

2 2

1 1

2 2

2

2

L

L

L L

pF h d dz Ud dz

h

+

+

= +

(6)

2.3.4 End LeakageThis is the difference of oil flowing into the gap at the start of

the pressure curve and that flowing out at the end of the positive

pressure curve.

2

1

3

2

2

12

L

z

L

h pQ d

z

+

=

(7)

2.4 Dynamic performance characteristics

The dynamic characteristics of the journal bearing system can

be described in terms of film stiffness and damping coefficients and

margin of stability in terms of threshold speed and damped

frequency. These coefficients are calculated from integration of

Reynolds equation for small displacements about the steady state

position of the journal center and for small velocities of the journal

center.

2.4.1 Damping Coefficient

When the journal centre is distributed by its equilibrium

position, it acquires whirling and squeezing velocities, the resulting

fluid film forces are identified as damping coefficients, which are

given by

i

i j

j

w

Bx

=

(where i, j = 1,2) (8)

Where the first subscript denotes the direction of force and the

second subscript denotes the direction of velocity.

2.4.2 Stiffness Coefficient

When the journal centre experiences a small displacement from

its equilibrium position, out of balance forces represents as stiffness

coefficients, which are given by

i

i j

j

wS

x

=

(where i, j =1,2) (9)

Where the first subscript denotes the direction of force and the

second subscript denotes the direction of displacement.

2.4.3 Stability Parameters

The journal motion which gives rise to large vibration is called

instability. The stability margins of the journal bearing system can

be obtained in terms of the threshold speed and the whirl

frequency of the journal by using Rouths stability criterion called

damped frequency .d

3. Models of viscosity

The complete viscosity database of the commercial lubricant

(the lubricant used is SAE 15W40 multi grade engine oil) with

CuO, CeO2and Al2O3nanoparticles at temperatures varying from

300C-700C is obtained from the Ramu et al,24 Meti and

Rajendrakumar.25 The variation of relative viscosity (relative

viscosity is defined as the ratio of viscosity of nanolubricant at any

temperature to viscosity of base lubricant at the same temperature)

of commercial lubricant with CuO, CeO2 and Al2O3nanoparticles

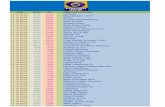

and the effect due to temperature is shown in Figs. 1-3. It has been

seen that, in general, relative viscosity of nanolubricants increases

with an increase in concentration of nanoparticles at any

temperature.

Viscosity models12,13 for water nanofluids are available. A

model has been developed with available data to obtain the

relationship between viscosity, concentration of nanoparticles and

temperature. The models developed are given below. The variation

of viscosity of oil with concentration of CuO, CeO2 and Al2O3

nanoparticles and variation of viscosity of same oil with CuO, CeO2

and Al2O3nanoparticles at different temperatures are shown in Figs.1-3. From the data, regression models are developed to obtain the

relationship between viscosity and temperature at different weight

concentrations of nanoparticles. The nondimensional regression

models obtained for CuO, CeO2 and Al2O3nanoparticles are given

as follows.

1 2

( K - K T )

0

=e

where

TT

Ta

= (10)

Nano-

particlesK

1

K2

CuO 1.194-0.631 +1.553 2

-1.449 3

1.194-0.660 +1.668 2

-1.680 3

Al2

O3

1.194-0.450 +1.230 2

-1.749 3

1.194-0.526 +2.560 2

-4.000 3

CeO2

1.194-0.040 -0.295 2

-0.072 3

1.194-0.107 -0.477 2

+ 0.487 3

-

8/13/2019 10.1007_s12541-012-0245-6

4/8

1872 / OCTOBER 2012 INTERNATIONAL JOURNAL OF PRECISION ENGINEERING AND MANUFACTURING Vol. 13, No. 10

1

1 . 0 5

1 . 1

1 . 1 5

1 . 2

1 . 2 5

3 0 4 0 5 0 6 0 7 0

TEMPERATURE(0

C)

RELATIVE

VISCOSITY

0.1% CuO

0.25% CuO

0.5% CuO

Fig. 1 Variation of relative viscosity of oil with % weight fraction of

CuO nanoparticles at different temperatures

1

1 . 0 5

1 . 1

1 . 1 5

1 . 2

1 . 2 5

3 0 4 0 5 0 6 0 7 0

T E M P E R A T U R E (

0

C )

R

E

L

A

T

I

V

E

V

I

S

C

O

S

I

T

Y

0 . 1 % C e O 2

0 . 2 5 % C e O 2

0 . 5 % C e O 2

Fig. 2 Variation of relative viscosity of oil with % weight fraction of

CeO2nanoparticles at different temperatures

1

1.05

1.1

1.15

1.2

1.25

30 40 50 60 70TEMPERATURE (

0

C)

RELATIVE

VISCOSITY

0.1%Al2O3

0.25%Al2O3

0.5%Al2O3

Fig. 3 Variation of relative viscosity of oil with % weight fraction of

Al2O3nanoparticles at different temperatures

1

1.05

1.1

1.15

1.2

1.25

30 40 50 60 70T E M P E R A T U R E (

0

C )

R

E

L

A

T

I

V

E

V

I

S

C

O

S

I

T

Y

Developed Viscosity Model

0.5% CuO Experimental Data

Fig. 4 Comparison of developed viscosity model with experimentaldata for 0.5% weight concentration CuO nanoparticles in oil

The developed regression model from the data obtained is validated

with experimental data for 0.5% CuO nanoparticles in oil and is as

shown in Fig. 4.

4. Solution procedure

In order to obtain the isoviscous and thermoviscous static and

dynamic performance characteristics of journal bearing operating

under lubricant with nanoparticles both modified Reynolds and

energy equations are solved with appropriate boundary conditions.

Both equations are solved by using the powerful technique finite

element method.28-30The modified Reynolds equation is solved to

obtain the non-dimensional pressure distribution and the film is

extended with suitable boundary conditions by the iterative scheme.

For isoviscous lubricants static and dynamic performance

characteristics are obtained by assuming the viscosity field remains

constant. But in thermoviscous case, the viscosity field varies with

temperature distribution. To obtain the temperature distributionacross the lubricant film, the modified energy equation is used. The

temperature distribution obtained by solving the energy equation is

used to update the viscosity field. Viscosity temperature models

developed from the experimental data is used to modify the

viscosity field. The modified viscosity field is substituted in the

Reynolds equation to obtain the modified pressure field. The

iterative process is continued till a convergence is achieved. The

various static and dynamic characteristics defined by load carrying

capacity, friction force, end leakage, attitude angle, threshold speed

and damped frequency are computed using the relevant formulae

for different eccentricity ratios. In order to verify the algorithm of

the solution and the simulation program, the dimensionless load

capacity compared with the published results by Lin et al1 as

illustrated in Fig. 5 for thermoviscous 0% weight fraction of

nanoparticles. All the results show good agreement.

5. Results and discussion

The static and dynamic performance characteristics in terms of

load capacity, friction force, end leakage, attitude angle, threshold

speed and damped frequency are computed for different values of

eccentricity ratios, aspect ratio(L/D) 1 and lubricants containing

with different nanoparticles (CuO, CeO2 and Al2O3) for the

isoviscous and thermoviscous cases. The computed results are

shown in Figs. 5-14.

The variations of load capacity with the concentration of CeO 2

nanoparticles for isoviscous and thermoviscous cases as shown in

Fig. 5. It shows that in isoviscous case increase of weight

concentration of CeO2 nanoparticles does not produce the

considerable effect on load capacity of bearings, especially at low

values of the eccentricity ratio. For thermoviscous case, the

concentrations of nanoparticles produce the significant effect on the

load capacity at higher eccentricity ratios. The present results arecompared with the published results by C R Lin for thermoviscous

-

8/13/2019 10.1007_s12541-012-0245-6

5/8

INTERNATIONAL JOURNAL OF PRECISION ENGINEERING AND MANUFACTURING Vol. 13, No. 10 OCTOBER 2012 / 1873

0% weight fraction of nanoparticles. All the results show good

agreement.

Effect of % weight concentration of CuO and Al2O3

nanoparticles in the lubricant on load capacity of journal bearing at

the eccentricity ratio 0.8 shown by Fig. 6. This figure shows that at

high eccentricity ratios increase of concentration of nanoparticles

affects the load capacity slightly in isoviscous case. However, in

thermoviscous case it produces a significant effect. At 0.5%weight

concentration of Al2O3and eccentricity ratio 0.8, the load capacity

obtained is 10.5% greater than that obtained without addition of

nanoparticles. Figures 7-9 show the percentage variation of load

capacity with the increase of weight concentration of nanoparticles

CuO, CeO2 and Al2O3 at any eccentricity ratio. These figures

clearly show that in thermoviscous case, the percent increase of

load capacity of the journal bearing operating under lubricant with

nanoparticles are more significant at high eccentricity ratios. For

example, at high eccentricity =0.9 it is seen that the addition of

0.5% weight concentration of nanoparticles in the lubricant

increases the load capacity approximately 14.45% (CuO), 13.98%

(CeO2) and 12.53% (Al2O3) than those obtained without addition of

nanoparticles in thermoviscous case. This shows that addition ofnanoparticles at the high temperature enhances viscosity

considerably and increases the load capacity of the bearing.

Figure 10 shows the variation of friction force with

concentration of nanoparticles for both isoviscous lubricants and

lubricants that contain CuO, CeO2 and Al2O3 nanoparticles at

eccentricity ratio 0.9. For any eccentricity ratio addition of

nanoparticles increases friction force in both isoviscous and

thermoviscous cases. In thermoviscous case at eccentricity 0.9 the

value of friction force obtained is 8.6% (CuO), 7.8% (CeO2) and

7.6% (Al2O3) higher than those obtained without addition of

nanoparticles. The variation of end leakage with concentration ofnanoparticles for both isoviscous lubricants and lubricants that

0

5

10

15

20

25

0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

E C C E N T R I C I T Y R A T I O

L

O

A

D

C

A

P

A

C

I

T

Y

(

N

O

N

D

I

M

E

N

S

I

O

N

A

L

)

0% CeO20.1%CeO20.25% CeO20.5% CeO2C R Lin(published results)

Iso viscous

Thermo viscous

Fig. 5 Effect of % weight concentration of CeO2nanoparticles in

oil on load capacity of journal bearing

9

9 . 5

1 0

1 0 . 5

1 1

1 1 . 5

1 2

1 2 . 5

1 3

0 0 . 0 5 0 . 1 0 . 1 5 0 . 2 0 . 2 5 0 . 3 0 . 3 5 0 . 4 0 . 4 5 0 . 5

C O N C E N T R A T I O N O F N A N O P A R T I C L E S ( % )

L

O

A

D

C

A

P

A

C

I

T

Y

(

N

O

N

D

I

M

E

N

S

I

O

N

A

L

)

C u O

A l 2 O 3

I s o v i s c o u s

T h e r m o v i s c o u s

Fig. 6 Effect of % weight concentration of CuO and Al2O3

nanoparticles in oil on load capacity of journal bearing at

eccentricity ratio 0.8

0

5

1 0

1 5

2 0

0 . 1 0 . 2 0 . 3 0 . 4 0 . 5 0 . 6 0 . 7 0 . 8 0 . 9

E C C E N T R I C I T Y R A T I O

%

L

O

A

D

I

N

C

R

E

A

S

E

0 . 1 % C u O

0 . 2 5 % C u O

0 . 5 % C u O

Fig. 7 % increase of load capacity of bearing with effect of %

weight concentration of CuO nanoparticles in oil thermoviscous

case

0

5

1 0

1 5

2 0

0 . 1 0 . 2 0 . 3 0 . 4 0 . 5 0 . 6 0 . 7 0 . 8 0 . 9

E C C E N T R I C I T Y R A T I O

%

L

O

A

D

I

N

C

R

E

A

S

E

0 . 1 % C e O 2

0 . 2 5 % C e O 2

0 . 5 % C e O 2

Fig. 8 % increase of load capacity of bearing with effect of %

weight concentration of CeO2nanoparticles in oil thermoviscous

case

0

5

1 0

1 5

2 0

0 . 1 0 . 2 0 . 3 0 . 4 0 . 5 0 . 6 0 . 7 0 . 8 0 . 9

E C C E N T R I C I T Y R A T I O

%

L

O

A

D

I

N

C

R

E

A

S

E

0 . 1 % A l 2 O 3

0 . 2 5 % A l 2 O 3

0 . 5 % A l 2 O 3

Fig. 9 % increase of load capacity of bearing with effect of %

weight concentration of Al2O3nanoparticles in oil thermoviscous

case

-

8/13/2019 10.1007_s12541-012-0245-6

6/8

1874 / OCTOBER 2012 INTERNATIONAL JOURNAL OF PRECISION ENGINEERING AND MANUFACTURING Vol. 13, No. 10

contain CuO, CeO2 and Al2O3nanoparticles at eccentricity ratio 0.6

as shown in Fig. 11 and it shows that for any eccentricity ratio

addition of nanoparticles decreases end leakage in both isoviscous

and thermoviscous cases. The effect of concentration of CuO and

Al2O3nanoparticles in the lubricant on the attitude angle of journal

bearing for both isoviscous and thermoviscous cases at eccentricity

ratio 0.8 as shown in Fig. 12. From this figure it is observed that the

addition of any nanoparticles decrease the attitude angle of the

journal bearing when the viscosity varies with temperature.The stability margins of the journal bearing system in terms of

the threshold speed and damped frequency at any eccentricity ratio

for different concentration of nanoparticles as shown in Figs. 13-14.

The effect of concentration of CeO2nanoparticles in the lubricant

on threshold speed of journal bearing for both isoviscous and

thermoviscous cases at any eccentricity ratio as shown in Fig. 13

and it is observed that the addition of any nanoparticles in the

lubricant increases the threshold speed of the journal bearing when

the viscosity varies with temperature. For example, at the high

eccentricity ratio =0.7 it is seen that the addition of 0.5% weight

concentration of nanoparticles in the lubricant increases the

threshold speed approximately 6.97% (CuO), 5.86% (CeO2) and

5.82% (Al2O3) than those obtained without addition of

nanoparticles in thermoviscous case. Figure 14 shows the variation

of damped frequency with concentration of Al2O3nanoparticles for

both isoviscous and thermoviscous nanolubricants at any

eccentricity ratio, and it shows that the addition of nanoparticles

decreases damped frequency in both isoviscous and thermoviscous

cases. For example, at high eccentricity =0.7 it is seen that the

addition of 0.5% weight concentration of nanoparticles in the

lubricant decreases the damped frequency approximately 3.47%

(CuO), 3.26% (CeO2) and 3.07% (Al2O3) than those obtained

without addition of nanoparticles in thermoviscous case. The

computed values of static and dynamic performance characteristicsof journal bearing for isoviscous and thermoviscous nanolubricants

3 2

3 3

3 4

3 5

3 6

0 0 . 0 5 0 . 1 0 . 1 5 0 . 2 0 . 2 5 0 . 3 0 . 3 5 0 . 4 0 . 4 5 0 . 5

N A N O P A R T I C L E C O N C E N T R A T I O N ( % )

F

R

I

C

T

I

O

N

F

O

R

C

E

(

N

O

N

D

I

M

E

N

S

I

O

N

A

L

)

C u O

C e O 2

A l 2 O 3

I s o v i s c o u s

T h e r m o v i s c o u s

Fig. 10 Effect of % weight concentration of CuO, CeO2and Al2O3

nanoparticles in oil on frictional force of journal bearing at =0.9

0 . 9 0

0 . 9 2

0 . 9 4

0 . 9 6

0 . 9 8

1 . 0 0

0 0 . 0 5 0 . 1 0 . 1 5 0 . 2 0 . 2 5 0 . 3 0 . 3 5 0 . 4 0 . 4 5 0 . 5

N A N O P A R T I C L E C O N C E N T R A T I O N ( % )

E

N

D

L

E

A

K

A

G

E

(

N

O

N

D

I

M

E

N

S

I

O

N

A

L

)

C u O

C e O 2

A l 2 O 3

I s o v i s c o u s

T h e r m o v i s c o u s

Fig. 11 Effect of % weight concentration of CuO, CeO2and Al2O3

nanoparticles in oil on end leakage of journal bearing at =0.6

3 2

3 4

3 6

3 8

4 0

0 0 . 0 5 0 . 1 0 . 1 5 0 . 2 0 . 2 5 0 . 3 0 . 3 5 0 . 4 0 . 4 5 0 . 5

N A N O P A R T I C L E C O N C E N T R A T I O N ( % )

A

T

T

I

T

U

D

E

A

N

G

L

E

C u O

A l 2 O 3

I s o v i s c o u s

T h e r m o v i s c o u s

Fig. 12 Effect of % weight concentration of CuO and Al2O3

nanoparticles in oil on attitude angle of journal bearing at =0.8

2 . 2

2 . 4

2 . 6

2 . 8

3 . 0

3 . 2

0 . 4 0 . 5 0 . 6 0 . 7

E C C E N T R I C I T Y R A T I O

T

H

R

E

S

H

O

L

D

S

P

E

E

D

(

N

O

N

D

I

M

E

N

S

I

O

N

A

L

)

0 % C e O 2

0 . 1 % C e O 2

0 . 2 5 % C e O 2

0 . 5 % C e O 2

I s o v i s c o u s

T h e r m o v i s c o u s

Fig. 13 Effect of % weight concentration of CeO2nanoparticles in

oil on threshold speed of journal bearing

0 . 4

0 . 5

0 . 6

0 . 7

0 . 8

0 . 9

0 . 1 0 . 2 0 . 3 0 . 4 0 . 5 0 . 6 0 . 7

E C C E N T R I C I T Y R A T I O

D

A

M

P

E

D

F

R

Q

U

E

N

C

Y

(

N

O

N

D

I

M

E

N

S

I

O

N

A

L

)

0 % A l 2 O 3

0 . 1 % A l 2 O 3

0 . 2 5 % A l 2 O 3

0 . 5 % A l 2 O 3

I s o v i s c o u s

T h e r m o v i s c o u s

Fig. 14 Effect of % weight concentration of Al2O3nanoparticles in

oil on damped frequency of journal bearing

-

8/13/2019 10.1007_s12541-012-0245-6

7/8

INTERNATIONAL JOURNAL OF PRECISION ENGINEERING AND MANUFACTURING Vol. 13, No. 10 OCTOBER 2012 / 1875

shows that addition of nanoparticles to lubricant influences the

performance characteristics considerable in thermoviscous case.

6. Conclusions

In isoviscous case increase of weight concentration of

nanoparticles does not change the performance characteristics of

bearing especially at low values of eccentricity ratios. For

thermoviscous case addition of nanoparticles increase the load

capacity of journal bearing at any eccentricity ratio, and this

increase is significant at high values of the eccentricity ratio. For

example, 0.5% weight concentration of nanoparticles increases the

load capacity by 14.45% (CuO), 13.98% (CeO2) and 12.53%

(Al2O3) on thermoviscous case when bearing operates at =0.9. The

friction force of bearing increases with the increase in concentration

of nanoparticles for both isoviscous and thermoviscous cases. At

any eccentricity ratio, both end leakage and attitude angle decreases

with the increase in concentration of nanoparticles in bothisoviscous and thermoviscous cases, and these decreases are

considerable for thermoviscous case and at higher eccentricity

ratios. The stability parameters in terms of threshold speed

increases by the addition of nanoparticles at any eccentricity ratio

and the damped frequency decreases with addition of nanoparticles.

This indicates that at any eccentricity ratio when the

thermohydrodynamic bearing operates under lubricants, which

contain nanoparticles, the stability higher than that obtained without

addition of nanoparticles.

REFERENCES

1. Lin, C. R. and Rylander Jr., H. G., Performance characteristicsof compliant journal bearings, Journal of Tribology, Vol. 113,

No. 3, pp. 639-644, 1991.

2. Gethin, D. T., Modelling the thermohydrodynamic behaviourof high speed journal bearings, Tribology International, Vol. 29,

No. 7, pp. 579-596, 1996.

3. Khonsari, M. M., Jang, J. Y., and Fillon, M., On thegeneralization of thermohydrodynamic analyses for journal

bearings, Journal of Tribology, Vol. 118, No. 3, pp. 571-579,1996.

4. Hirani, H., Rao, T. V. V. L. N., Athre, K., and Biswas, S.,Rapid performance evaluation of journal bearings, Tribology

International, Vol. 30, No. 11, pp. 825-832, 1997.

5. Rao, T. V. V. L. N., Biswas, S., Hirani, H., and Athre, K., Ananalytical approach to evaluate dynamic coefficients and

nonlinear transient analysis of a hydrodynamic journal

bearing, Tribology Transactions, Vol. 43, No. 1, pp. 109-115,

2000.

6.

Rho, B. H. and Kim, K. W., A study of the dynamiccharacteristics of synchronously controlled hydrodynamic

journal bearings, Tribology International, Vol. 35, No. 5, pp.

339-345, 2002.

7. Singhal, S. and Khonsari, M. M., A simplifiedthermohydrodynamic stability analysis of journal bearings, J.

Engineering Tribology, Vol. 219, No. 3, pp. 225-234, 2005.

8. Ighil Tala, N., Bounif, A., and Maspeyrot, P., Thermo-hydrodynamic study of the journal bearing under static load, J.Mechanical Engineering Science, Vol. 222, No. 9, pp. 1801-

1809, 2008.

9. Navthar, R. R. and Halegowda, N. V., Stability Analysis ofHydrodynamic Journal Bearing using Stiffness Coefficients,

International Journal of Engineering Science and Technology,

Vol. 2, No. 2, pp. 87-93, 2010.

10.Laraqi, N., Rashidi, M. M., Garcia De Maria, J. M., and Bari,A., Analytical model for the thermo-hydrodynamic behaviour

of a thin lubricant film, Tribology International, Vol. 44, No. 9,

pp. 1083-1086, 2011.

11.Lee, J. H., Hwang, K. S., Jang, S. P., Lee, B. H., Kim, J. H.,Choi, S. U. S., and Choi, C. J., Effective viscosities and

thermal conductivities of aqueous nanofluids containing low

volume concentrations of Al2O3 nanoparticles, International

Journal of Heat and Mass Transfer, Vol. 51, No. 11-12, pp.

2651-2656, 2008.

12.Murshed, S. M. S., Leong, K. C., and Yang, C., Investigationsof thermal conductivity and viscosity of nanofluids,

International Journal of Thermal Sciences, Vol. 47, No. 5, pp.

560-568, 2008.

13.Chandrasekar, M., Suresh, S., and Chandra Bose, A.,Experimental investigations and theoretical determination of

thermal conductivity and viscosity of Al2O3/water nanofluid,

Experimental Thermal and Fluid Science, Vol. 34, No. 2, pp.

210-216, 2010.

14.Abedian, B. and Kachanov, M., On the effective viscosity ofsuspensions, International Journal of Engineering Science, Vol.

48, No. 11, pp. 962-965, 2010.

15.Lee, K., Hwang, Y., Cheong, S., Choi, Y., Kwon, L., Lee, J., andKim, S. H., Understanding the role of nanoparticles in nano-oil

lubrication, Tribol. Lett., Vol. 35, No. 2, pp. 127-131, 2009.

16.Lee, C. G., Hwang, Y. J., Choi, Y. M., Lee, J. K., Choi, C., andOh, J. M., A study on the tribological characteristics of

graphite nano lubricants, Int. J. Precis. Eng. Manuf., Vol. 10,

No. 1, pp. 85-90, 2009.

17.Ku, B.-C., Han, Y.-C., Lee, J.-E., Lee, J.-K., Park, S.-H., andHwang, Y.-J., Tribological effects of fullerene (C60)

nanoparticles added in mineral lubricants according to its

viscosity, Int. J. Precis. Eng. Manuf., Vol. 11, No. 4, pp. 607-

611, 2010.

18.Thottackkad, M., Perikinalil, R., and Kumarapillai, P.,Experimental evaluation on the tribological properties ofcoconut oil by the addition of CuO nanoparticles, Int. J. Precis.

-

8/13/2019 10.1007_s12541-012-0245-6

8/8

1876 / OCTOBER 2012 INTERNATIONAL JOURNAL OF PRECISION ENGINEERING AND MANUFACTURING Vol. 13, No. 10

Eng. Manuf., Vol. 13, No. 1, pp. 111-116, 2012.

19.Bair, S., The variation of viscosity with temperature andpressure for various real lubricants, Journal of Tribology, Vol.

123, No. 2, pp. 433-436, 2001.

20.Bair, S., Jarzynski, J., and Winer, W. O., The temperature,pressure and time dependence of lubricant viscosity, Tribology

International, Vol. 34, No. 7, pp. 461-468, 2001.

21.Vijayaraghavan, D. and Brewe, D. E., Effect of rate ofviscosity variation on the performance of journal bearings,

Journal of Tribology, Vol. 120, No. 1, pp. 1-7, 1998.

22.Elsharkawy, A. A., Effects of lubricant additives on theperformance of hydrodynamically lubricated journal bearings,

Tribology Letters, Vol. 18, No. 1, pp. 63-73, 2005.

23.Prabhakaran Nair, K., Ahmed, M. S., and Al-Qahtani, S. T.,Static and dynamic analysis of hydrodynamic journal bearing

operating under nano lubricants, Int. J. Nanoparticles., Vol. 2,

No. 1, pp. 251-262, 2009.

24.Ramu, A., Rajendrakumar, P. K., Jayadas, N. H., and Sobhan, C.B., Experimental Investigations on the Effect of Nanoparticle

Additives on Tribological Properties of Lubricating Oils,

International Conference on Industrial Tribology (ICIT), 2008.

25.Meti, V. and Rajendrakumar, P. K., ExperimentalInvestigations on the Effect of Nanoparticle Additives on

Lubricating Properties, International Conference on Frontiers

in Mechanical Engineering (FIME2010), 2010.

26.Crosby, W. A., Thermal considerations in the solution of finitejournal bearings, Wear, Vol. 64, No. 1, pp. 15-32, 1980.

27.Banwait, S. S. and Chandrawat, H. N., Study of thermalboundary conditions for a plain journal bearing, Tribology

International, Vol. 31, No. 6, pp. 289-296, 1998.

28.Nuruzzaman, D. M., Khalil, M. K., Chowdhury, M. A., andRahaman, M. L., Study on pressure distribution and load

capacity of a journal bearing using finite element method and

analytical method, International Journal of Mechanical &

Mechanics Engineering, Vol. 10, No. 5, pp. 1-8, 2010.

29.Durany, J., Pereira, J., and Varas, F., Numerical solution tosteady and transient problems in thermohydrodynamic

lubrication using a combination of finite element, finite volumeand boundary element methods, Finite Elements in Analysis

and Design, Vol. 44, No. 11, pp. 686-695, 2008.

30.Durany, J., Pereira, J., and Varas, F., Dynamical stability ofjournal-bearing devices through numerical simulation of

thermohydrodynamic models, Tribology International, Vol. 43,

No. 9, pp. 1703-1718, 2010.