10052-2.5GHz Slot Antenna Array-final

-

Upload

marius-bar -

Category

Documents

-

view

213 -

download

0

Transcript of 10052-2.5GHz Slot Antenna Array-final

-

8/16/2019 10052-2.5GHz Slot Antenna Array-final

1/4

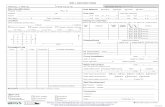

Fig. 1. One slot perimeter as seen on the FR4 material

2.5GHz Slot Antenna Array –Prototype Applicator

for Heating Applications

Emanoil SurducanMolecular and Biomolecular Physics

National Institute for R&D of Isotopic and Molecular

TechnologiesCluj-Napoca, Romania

Vasile SurducanMolecular and Biomolecular Physics

National Institute for R&D of Isotopic and Molecular

TechnologiesCluj-Napoca, Romania

Abstract —This paper describes a pragmatic approach for

design, characterization and test of a low cost microstrip slot

applicator with 140x140cm aperture, running at 2.5GHz, in the

near field approximation. The applicator structure, designed on

glass-reinforced epoxy copper clad (FR406), can handle 100-

200W microwave power. The applicator is designed to heat lossy

high dielectric liquids. A thermal map produced by theapplicator on an absorbing material (Natrosol-water solution

0.4%w/v) is revealed using a low cost thermochromic crystal

liquid sheet. The applicator is prepared to be equipped in the

very near future with infrared (IR) thermopile array.

Keywords—slot antenna, microwave antenna arrays,

microwave circuits, temperature, hyperthermia.

I. I NTRODUCTION

According to [1] “the term ‘applicator’ is used for a devicethat applies RF or microwave energy in the volume of amaterial at a level enough to create either a permanent ortemporary change of at least one material’s parameter or

property. The material is actually enclosed within theapplicator structure.” This microstrip-slot applicator is actuallyan antenna which works in specific near field propagationconditions. The distance from the applicator to the near field

boundary ( Lnf ), according to Rayleigh criterion, is given by:

02

/2 λ D Lnf < (1)

where: D = maximum size of the applicator [cm]λ 0 = open space frequency wavelength [cm]

Opposite to the microwave antenna designed for a specific bandwidth and gain, the applicator’s most important parameter

is the homogeneity of the radiated microwave field. In the

approximation that the entire microwave field is absorbed intothe sample, the homogeneity of the sample’s temperature

depends drastically on the microwave field homogeneity.

Although slot applicators have been described in the literature

[2-4], most designs use complex procedures involvingcomputer simulations.

II. APPLICATOR DESIGN AND TEST CONSIDERATIONS

A. Computing the applicator dimensions

The dominant factor in the microstrip-slot antenna design isthe perimeter of the slot ( L per ) understood in terms of thedielectric waveguide wavelengths [5]:

reff d ε λ λ /0= (2)

where: 2/)1( += r reff ε ε (3)

and εr = relative permittivity of the material which interferes

with the microwaves in the near field area. The smallest

frequency ( f L) which can pass through the slot (Fig.1) is:

reff per L LGHz f ε /1)/30(][ = (4)

where: L per =a+b[cm], a=slot length[cm], b=slot width[cm]

The slot impedance in quasi TEM (transversalelectromagnetic mode), with the slot immersed in the sample to

be heated, is given by:

)/8ln(/)1/(27.591 bc Z reff π ε += (5)

for c/b>3 and c/λ d→0; where a, b, c are presented in fig.1and λ d from (2).

B. Materials

For the slot applicator, a 1.6mm thickness, 1oz, FR406material [6] for printed circuit board (PCB) has been used. Thismaterial is proven to have low dielectric loss at requestedfrequency. The number of slots has been chosen in respect tothe dimension of the sample it must be heated (140x140mm)

glass-epoxyc

c

slot in copper

copper

ba

-

8/16/2019 10052-2.5GHz Slot Antenna Array-final

2/4

and must fit with the microstrip feed line arrangement. Theheating sample is either a Natrosol 0.4%w/v hydrogel forwhich the measured dielectric constant is εr = 77.87 - j10.36, ordistilled water (εr = 78.13 - j10.07). The dielectric permittivitywas measured with maximum 3% relative uncertainty, at roomtemperature T=20oC, using a Vector Network Analyzer (VNA)with specific accessories, (Agilent PNA-L, N5230A, 85070EDielectric Probe Kit, 85071E Material measurement software).The Natrosol mixture aspect is identical to jelly or aspic.

C. Methods

The slots dimensions have been computed (a = 3.2cm, b =0.5cm) according to (4) allowing a theoretical f L=1.29GHz(εref = 39.5). The slot impedance is around 60 ohm. One slotantenna has been manufactured in laboratory (Fig.2). Thefeeding line made by aluminium adhesive tape is graduallyapplied between positions C to O. A SMA connector ismounted at the end of the line after every adhesion of the tapeon the PCB. The feeding line dimension (microstrip line) wascomputed using the TxLine free software [7] for the FR406

parameters (70µm copper, εr = 3.93). The S11 parameter ismeasured for each feeding line position using a VNA (Fig.3).

The position of the feeding line which create resonance (S11 ≤ -10dB) at the requested frequency (position A) is used in thefinal array arrangement.

The array arrangement (Fig.4) has been configured usingSonet-Lite (the free version has a limitation which allows onlya single symmetrical slot modeling) [8], then the applicatorarray has been manufactured in laboratory using a CNC(computer numerically controlled) Protomat S62 plotter.

The array is fed at the center with microwaves (via an Nconnector) using a semi-rigid coaxial cable, from a proprietarymicrowave generator using a CW (continuous wave)magnetron as described in [9] and depicted in Fig.6-bottom.The applicator is housed in a stainless steel case (a conductiveground plane). To visualize the heating pattern produced bythe applicator, a thermochromic liquid crystal sheet (TLC) [10]is placed above the applicator surface. However, an absorbingmaterial about 5mm thick and moisturized in distilled watermust be placed between the applicator and the TLC sheet. Themicrowave field at the applicator aperture heats the water andthe absorbing material. The temperature rise changes thewavelength reflected by the TLC sheet, (no. #72-373 EdmundOptics) which was used in the experimental setup

Fig. 4. The applicator array simulation showing the feeding line

0 1 2 3 4 5 6 7 8 9

-35

-30

-25

-20

-15

-10

-5

0

S 1 1

( d B )

Frequency (GHz)

A

B

C

O

Fig. 3. S11 parameters for various positions of the feeding l ine

Fig.5 The sealed Plexiglas box mounted on the top of the slot

applicator

32

Fig. 2. Adjusting the feeding line process

OABC

-

8/16/2019 10052-2.5GHz Slot Antenna Array-final

3/4

(Fig.6-bottom). To heat various types of liquids or aqueoussolutions, a sealed box has been manufactured using 10mmPlexiglas (Poly-methyl methacrylate) walls(140x140x500mm3). The box has been glued on the applicator ,reinforced with two steel strips (Fig.5) and filled with anaqueous Natrosol solution. The electromagnetic leakagesoutside the box, at 100W input power were measured using anAgilent N1911A series power meter. It was found that theleakage is below the standardized recommendation (

-

8/16/2019 10052-2.5GHz Slot Antenna Array-final

4/4

designed based on the FR4 material properties and therequirement to adapt the applicator impedance (50 ohms) to thesample impedance. Compared with the solution described in[2] (non-symmetrical microwave excitation line), our designmake use of a symmetrical feeding line of the slots whichallows a better microwave field distribution. The 2n slots (n = 3for this application) where distributed in the applicator areaaccording to the microstrip feeder pattern. The practicalapproach (which uses empirical mathematical relations) savestime and energy, predicting the design will work in the realworld from the first revision, under the required parameters.However, the first design step of an antenna array (testing asingle slot of the array) is crucial. To comply with the nearfield propagation conditions, the effective relative permittivityof the medium (through which the wave propagates) should beconsidered, rather than the dielectric substrate permittivity ofthe PCB alone.

ACKNOWLEDGMENT

The authors acknowledge the financial support of theRomanian Ministry of Education Research and Youth, through

the National Research Projects PN-II-RU-PD-2012-3-0050 and1RO-FR_22-2011.

R EFERENCES

[1] Mehrdad Mehdizadeh, Microwave/RF Applicators and Probes forMaterial Heating, Sensing, and Plasma Generation, ISBN 978-0-8155-1592-0, October 2009, pp.36

[2] Ken Takey, Hiroshi Kondoh, “TEM slot array antenna” US 5977924,1999.

[3] Nader Behdad , and Kamal Sarabandi , “A Wide-Band Slot AntennaDesign Employing A Fictitious Short Circuit Concept”, IEEETransactions on antennas and propagation, Vol. 53, No. 1, January 2005,

pp 475-482.

[4] Electronic Warfare and Radar Systems, Engineering Handbook, -Antenna Near Field , pp (3-5.1;3-5.4), Rev 2 of 1, US Naval Air WarfareCenter, April 1999, ISBN: N/A, Pages: 299.

[5] Wen Shan Chen, “A Novel Broadband Design of a Printed RectangularSlot Antenna for Wireless Applications,” Microwave Journal, January2006.

[6] http://www.isola-group.com/wp-content/uploads/2012/09/FR406-High-Performance-Epoxy-Laminate-and-Prepreg-Data-Sheet-Isola.pdf

[7] http://www.awrcorp.com/sites/default/files/content/attachments/Freewar e/TXLine.zip

[8] http://www.sonnetsoftware.com/products/lite/download.html

[9] Surducan V., Surducan E., Ciupa R., Neamţu Camelia, “MicrowaveGenerator for Scientific and Medical Applications”, Proceeding of theProcesses in Isotopes and Molecules, 29 sept.-01 oct. 2011, AIP Conf.Proc. 1425, pp. 89-92; http://dx.doi.org/10.1063/1.3681974

[10] The thermochromic liquid crystal sheet,http://www.edmundoptics.com/testing-targets/calibration-standards/temperature-sensitive-liquid-crystal-sheets/1642

[11] ICNIRP “Guidelines for limiting exposure to time- varying electric,

magnetic and electromagnetic fields (up to 300 GHz)”, Health Physics74(4), 494-522 (1998)