1 Part B2: Hydropower B2.2 Hydropower system design.

-

Upload

francis-arnold -

Category

Documents

-

view

291 -

download

23

Transcript of 1 Part B2: Hydropower B2.2 Hydropower system design.

1

Part B2: Hydropower

B2.2 Hydropower system design

2

B2.2 Hydropower system designTopics: System design

• Entry arrangements– Forbays, penstock inlets

• Penstocks and surge control– Size of the penstock, pressure forces, anchoring

the penstock, water hammer and its control

• Exit arrangements– draft tubes

• Turbine selection– Force triangles, Turbine types, specific speed,

cavitation and its prevention

• Electronics and control– Types of generator, Turbine control,

transmission

3

B2.2.1 Hydropower system design Entry arrangements: Anatomy of a forebay

4

B2.2.1 Hydropower system design Entry arrangements: Anatomy of a forebay

5

B2.2.1 Hydropower system design Entry arrangements: Trash rack losses

4 3 2

sin2t t

t vh K

b g

Values for Kt

6

B2.2.1 Hydropower system design Entry arrangements: trash racks

7

B2.2.1 Hydropower system design Entry arrangements: Alternatives to trash racks

8

B2.2.1 Hydropower system design Entry arrangements: Velocity into the penstock

v1

v3

p1

p3

Energy linev2

p2

ht

Typical values for penstock velocities 2-5 m/s

1 2 2 tv v gh

9

B2.2.1 Hydropower system design Entry arrangements: Entry losses into the penstock

10

Type Ke

Hooded 1.0

Projecting 0.8

Sharp corner 0.5

Slightly rounded 0.2

Bell mouth (r>0.14D) 0

B2.2.1 Hydropower system design Entry arrangements: Entry losses into the penstock

2

2e e

vh K

g

11

B2.2.2 Hydropower system design Penstocks: Comparison of penstock materials

Material Friction loss

Weight Corrosion resistance

Cost Ease of Jointing

Pressure resist

Ductile iron

Asbestos cement

Concrete

Wood staves

GRP

uPVC

Mild steel

HDPE

MDPE

Poor Excellent

12

B2.2.2 Hydropower system design Penstocks: Installation

13

B2.2.2 Hydropower system design Penstocks: Friction losses in penstocks

7

B2.1.1 Fundamentals of Hydro power The energy equation: Implications: Flow in pipes: Friction: Moody diagram

9

B 2 . 1 . 1 F u n d a m e n t a l s o f H y d r o p o w e r T h e e n e r g y e q u a t i o n : I m p l i c a t i o n s : F l o w i n p i p e s : F r i c t i o n : E q u a t i o n s

• B l a s i u s e q u a t i o n– F o r h y d r a u l i c a l l y s m o o t h p i p e

( R e 4 , 0 0 0 – 1 0 0 , 0 0 0 )

0 . 2 5

0 . 3 1 6 4

R ef

• S w a m e e - J a i n e q u a t i o n– 1 0 - 6 < k / D < 0 . 0 1

( 5 , 0 0 0 – 3 x 1 0 8 )

2

1 0 0 . 9

0 . 2 5

5 . 7 4l o g

3 . 7 R e

fk

D

8

B2.1.1 Fundamentals of Hydro power The energy equation: Implications: Flow in pipes: Friction: Nomogram

• Darcy’s formula

• See B2.1.1

2

2f

L vh f

D g

Typical penstock losses are 5-10%

14

B2.2.2 Hydropower system design Penstocks: Multiple penstocks

15

B2.2.2 Hydropower system design Penstocks: Losses in bends

16

B2.2.2 Hydropower system design Penstocks: Losses in bends

r/D Kb

1 0.6

2 0.5

3 0.4

4 0.3

• For 45º use K x 0.75

• For 2 use K x 0.5

r

D

2

2b b

vh K

g

17

B2.2.2 Hydropower system design Penstocks: Other Losses

• Contractions

• Valves

D1/d2 Kc

1.5 0.25

2 0.35

2.5 0.40

5 0.50

Type Kv

Spherical 0

Gate 0.1

Butterfly 0.3

18

B2.2.2 Hydropower system design Penstocks: Energy lines

19

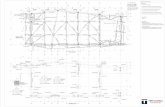

B2.2.2 Hydropower system design Penstocks: Anatomy of a penstock

20

B2.2.2 Hydropower system design Penstocks: Slide blocks

21

Fe = Force due to extensionCe = Coefficient of extension = Change in temperatureE = Young’s modulusD = Penstock diametert = Wall thickness

B2.2.2 Hydropower system design Penstocks: Thermal expansion

Fe

Fe

e eF C T E Dt

22

B2.2.2 Hydropower system design Penstocks: Expansion joints

23

B2.2.2 Hydropower system design Penstocks: Forces on bends

2 sin2hF gh A

2 sin2vF Q v

Hydrostatic

Velocity

F

= fluid densityg = gravityh = total headA = penstock areaQ = dischargev = velocity

24

B2.2.2 Hydropower system design Penstocks: Bends

25

B2.2.2 Hydropower system design Penstocks: Forces on bends: Thrust blocks

26

B2.2.2 Hydropower system design Penstocks: Anatomy of a penstock

27

B2.2.2 Hydropower system design Penstocks: Water hammer

28

Tc = critical time (s)

L = pipe length (m)

Cp = speed of sound in the pipe

Cw = speed of sound in water(1420m s-1)

G = bulk density of water(2GPa)

E = Young’s modulus

D = diameter of the pipe (m)

t = wall thickness (m)

h = additional pressure due to water hammer (m of water)

g = gravity

v = Change in flow velocity (m s-1)

B2.2.3 Hydropower system design Penstocks: Water hammer

2c

p

LT

c

1

wp

cc

G DE t

pch v

g

29

B2.2.2 Hydropower system design Penstocks: Water hammer: Dealing with it

30

B2.2.2 Hydropower system design Penstocks: Water hammer: Dealing with it: Surge tanks

31

B2.2.2 Hydropower system design Penstocks: Getting it wrong…

32

B2.2.3 Hydropower system design Draft tubes

Parallel sided Tapered

• Allows turbine to be set above water level but uses vacuum pressure on underside to increase effective head

• Recovers part of the velocity head by diffusion action

Limited by the vapour pressure of water

33

B2.2.3 Hydropower system design Draft tubes: Exercise

Using Bernoulli's equation and mass continuity, show how a tapered turbine regains velocity head and converts it to pressure reduction at the turbine

p2 v2

p1 v1

34

B2.2.3 Hydropower system design Draft tubes: configurations

35

B2.2.3 Hydropower system design Draft tubes

36

B2.2.3 Hydropower system design Draft tubes

37

Next…turbines

![Public Input No. 2NFPA 542015 [ Global Input ] · ... AWS B2.1 and replace with AWS B2.1/B2.1M. (5)AWS B2.2 and replace with AWS B2.2/B2.2M. Statement of Problem and Substantiation](https://static.fdocuments.in/doc/165x107/5afe22757f8b9aa34d8e7797/public-input-no-2nfpa-542015-global-input-aws-b21-and-replace-with.jpg)