1 Logistics & Supply Chain Management 2014

-

Upload

vanda-piranty -

Category

Documents

-

view

216 -

download

0

Transcript of 1 Logistics & Supply Chain Management 2014

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 1/64

LOGISTICS & SUPPLY CHAIN

MANAGEMENT

Introduction & Course Outline

I Nyoman Pujawan, Ph.D, CSCP

Professor of Supply Chain Engineering

Department of Industrial Engineering

ITS SURABAYA

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 2/64

Text Books

The following text books are recommended, but not required:

• Chopra, S., and Meindl, P. (2007). Supply chain

management: Strategy, planning, and operations .3rd Ed. New Jersey - Prentice-Hall.

• Pujawan, I N. & Mahendrawathi Er. (2010). Supply

Chain Management. 2nd Edition, Guna Widya

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 3/64

Pujawan, N. & Mahendrawathi (2010). Supply Chain Management. Edisi Kedua, Guna Widya.

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 4/64

EVALUATION

• Exam 1 35%

• Exam 2 35%

• Tugas2 dll 30%

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 5/64

Agenda

• Introduction to Logistics & SCM

• Supply Chain Strategy

• Demand Management, Inventory Control, Information

Distortion

• Supply Management

• Network design

• Transportation and distribution

• Warehousing

• Supply Chain Process & Performance

• Technology in Supply Chain

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 6/64

Lecture 1

Introduction to Logistics & SupplyChain Management

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 7/64

1940s, 1950s

Unit load

(Pallet)

Intermodal

container

1960s

Rail to truck ,

joint decision

[transport, MH,

storage]

“PhysicalDistribution”

1963: National

Council of

Physical

Distribution

1974

SOLE wasformed

1982

First time

use of term

“Supply

Chain”

1985

Council name

changed to:

Council of

Logistics

Management

to reflect

integration

spirit

Early use of

term “Third

party

logistics”

1990s

ERP and IT

fueled

further

Logistics

Widespreaduse of the

term

“Supply Chain

Management”

1999

Council name:Council of

Supply Chain

Management

Professionals

ISCM -

Surabaya

2005

Supply Chain

Management:program is

everywhere

2002

Nyoman Pujawan, 2014: dari berbagai sumber

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 8/64

Top Supply Chain Players 2012 (Gartner)

10,1 – 4.4% – 37.7%

74,1 – 20.2% – 51.5%

142,4 – 16.0% – 7.2%

5,5 – 9.2% – 2.5%

35,6 – 6.8% – 2.7% 5,8 – 13.0% – 19.7%

TOR–

ROA–

Revenue Growth

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 9/64

The objective of a

supply chain is to

deliver value to

customers in a cost

effective way

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 10/64

Supply Chain Should Have A Strategy for Delivering

Value to Customers

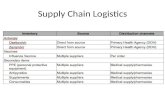

Company Customer Value Proposition SC Strategy

High fashion content at areasonable price

Speed to market

Everyday low pricing Cost efficiency

Market responsiveness Responsiveness throughadjusting supply to demandon hourly basis

Product innovation Efficiency through

outsourced manufacturingand logistics

Customer experience Responsiveness throughconfigure-to-order

Adapted from Simchi-Levi, 2011

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 11/64

Supply Chain Management

What are

happening

before you can

drink a cup ofcoffee?

Who did the

processes?

And where

they took

place?

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 12/64

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 13/64

http://www.slideshare.net/cfsc/leveraging-institutional-dollars-for-a-just-and-healthy-food-system-coffee-supply-chain

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 14/64

Apparel Supply Chain

http://www.supplychain247.com/article/global_supply_chains_deciding_the_way_forward

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 15/64

A product flows through a very long process before

consumed by the customers

How can these customers

obtain products with high

quality, competitive price,

and quick response?

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 16/64

What is SC?

• A series (or network) of companies who workcollectively to make and deliver products andservices to the end customers. This span from theraw materials extractors (at the upstream end) to the

retailers / shops (at the downstream end).

• In a SC there are three flows: materials, information,

and cash / funds.

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 17/64

SIMPLE SC STRUCTURE

SUPPLIER MANUFACTURER RETAILERDISTRIBUTOR WHOLESALER ENDCUSTOMER

UPSTREAMDOWNSTREAM

physical flow

information flow

Cash, invoice, pricing, credit terms flow

Payments flow

Capacity, delivery schedule, orders, point of sale

Materials/products, returns

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 18/64

What is a Supply Chain?

• All stages involved, directly or indirectly, in fulfilling acustomer request

• Includes manufacturers, suppliers, transporters, warehouses,

retailers, customers

• Within each company, the supply chain includes all functions

involved in fulfilling a customer request (product

development, marketing, operations, distribution, finance,

customer service)

• All stages may not be present in all supply chains

(e.g., no retailer or distributor for Dell)

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 19/64

What is Supply Chain

Management

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 20/64

SUPPLY CHAIN MANAGEMENT DEFINITION

• A process orientation, integrated approach to procuring, producing, and

delivering products and services to customers (MIT)

• A collaborative-based strategy to link cross enterprise business operations to

achieve a shared vision of market opportunity (D.J. Bowersox, Michigan

State)

• The delivery of enhanced customer and economic value through

synchronized management of the flow of physical goods and associated

information from sourcing to consumption (LaLonde, Ohio State)

• The process of strategically managing the procurement, movement and

storage of materials, parts, and finished inventory (and the related

information flows) through the organization and its marketing channels in

such a way that current and future profitability are maximized through the

cost-effective fulfillment of orders (Martin Christopher, Cranfield University)

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 21/64

Supply Chain Processes

Distribution

Management

Demand

forecast

Event

Management

Customer

service

Product

development

Production

Planning

Inventory

Control

Resource

Planning

PLC

Management

Supplier

selection

Sourcing

Performance

monitoring

Supplier

development

Supplier involvement in

product developmentSales & Operations Planning

Collaborative Planning, Forecasting

& ReplenishmentVendor Managed Inventory

Subcontracting

Warehouse

Management

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 22/64

SUPPLY CHAIN MANAGEMENT FUNCTIONS

Two basic functions:

Physically converting raw materials and components intoproducts and delivering them to the end customers.

Make sure that products/services delivered satisfy customer’saspiration.

Related to physical costs

Related to market mediation costs

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 23/64

Supply Chain Processes

• Physical

– Pengadaan

– Produksi

– Transportasi – Pergudangan

– Penanganan retur

• Market Mediation

– Promosi

– Perancangan produk

– Survey pasar – Diskon harga

(markdown)

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 24/64

EVOLUTION OF INTEGRATION(Adapted from Christopher, 1998)

Purchasing Material Ctrl Production Sales Distribution

Materials Mgmt Mfg. Mgmt Distribution

Suppliers Internal SC Customers

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 25/64

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 26/64

Maturity Model of SCM

Multipledysfunction

Semifunctional enterprise

Integratedenterprise

Extendedenterprise

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 27/64

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 28/64

Dell’s Model

DELL (Texas)

SONY

(Mexico)

CUSTOMER

Assembly point

Customer order

monitor

computer assembly

Airbone takes monitor & computer assembly

and send them to the customers

The best computer company is the one that does not make it!

(Jarillo, 2002)

A survey of SCM

Progress by Computer

Sciences Corp. and

Supply Chain

Management Review

Survey (2003): Wal-Mart& Dell far and away

received the most

number of mentions for

‘best in class’ SC.

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 29/64

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 30/64

Supply Chain is Going Global

E i f l b l l h i

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 31/64

https://operationsroom.wordpress.com/2013/05/09/will-the-bangladeshi-factory-collapse-change-global-apparel-supply-chains/

Economic reasons for a global supply chain

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 32/64

Supply Chain is Going Global

http://gifsgallery.com/supply+chain+gif

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 33/64

Tugas 1

• Amati supply chain sebuah produk /

perusahaan

• Gambar strukturnya

• Gambar aliran produk dan informasi

• Identifikasi persoalan

•Buat beberapa rekomendasi perbaikan

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 34/64

Supply Chain Strategy

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 35/64

Diskusi

Bandingkan antara air dalam kemasan dengan

HP dari sisi:

• Ketidakpastian pasar yang dihadapi

• Value proposition (competitiveness factor)

• Pricing strategy

•Capacity strategy

• Transportation strategy

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 36/64

SUPPLY CHAIN MANAGEMENT FUNCTIONS

Two basic functions:

Physically converting raw materials and components intoproducts and delivering them to the end customers.

Make sure that products/services delivered satisfy customer’saspiration.

Related to physical costs

Related to market mediation costs

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 37/64

Supply Chain Processes

• Physical

– Pengadaan

– Produksi

– Transportasi – Pergudangan

– Penanganan retur

• Market Mediation

– Promosi

– Perancangan produk

– Survey pasar – Diskon harga

(markdown)

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 38/64

material produksi transport simpan marketg markdown margin

material produksi transport simpan marketg markdown margin

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 39/64

Different Focus of Supply Chains

Efficient supply chain

Market responsive supply chain

Emphasis on physical activities

Emphasis market mediation activities

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 40/64

Different Product Characteristics

INN

O

V

A

TIV

E

F

U

N

C

TI

O

N

A

L

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 41/64

Product Types (Reflect Market Requirements)

Aspek Fungsional Inovatif

Siklus hidup

Panjang, bisa lebih dari 2tahun

Pendek, antara 3 bulansampai 1 tahun

Variasi per ketegori Sedikit, 10 – 20 variasi Banyak, bisa mencapai

ribuan

Volume per SKU tinggi rendah

Peramalan permintaan

Relatif mudah, akurasitinggi

Sangat sulit, kesalahanramalan tinggi

Tingkat kekurangan

produk (stockout rate)

Hanya 1% - 2% Bisa sampai 10% - 40%

Kelebihan persediaan di

akhir musim jual

Jarang karena musim jual

sangat panjang

Sering terjadi

Biaya penurunan harga

jual (markdown)

Mendekati 0%

10 – 25%

Marjin keuntungan per

unit yang terjual

dengan harga normal

rendah tinggi

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 42/64

Elements of SC Strategy

SC Strategy

Facility

location

Production

systemInventory Transport

Product

develop

ment

Supply

T Di i i SC S i

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 43/64

Two Distinctive SC Strategies (reflect resource consolidation)

Keputusan taktis

Efisien

Responsif

Lokasi fasilitas

Tempatkan pabrik di negarayang ongkos tenaga

kerjanya murah.

Cari lokasi yang dekat pasar, punya akses tenaga terampil

dan teknologi yang memadai

Sistem produksi Tingkat utilitas sistem produksi

harus tinggi

Sistem produksi harus fleksibel

dan ada kapasitas ekstra

Persediaan

Perlu upaya meminimasi tingkat

persediaan

Diperlukan persediaan

pengaman yang cukup di

lokasi yang tepat

Transportasi Pengiriman TL / CL atau

subkontakkan ke pihak

ketiga

Diperlukan transportasi cepat.

Bila perlu tetapkan

kebijakan LTL / LCL

Pasokan

Pilih supplier dengan harga dankualitas sebagai kriteria

utama

Pilih supplier berdasarkankecepatan, fleksibilitas, dan

kualitas

Pengembangan

produk

Fokus ke minimasi ongkos Gunakan modular design dan

tunda differensiasi produk

sebisa mungkin

( postponement )

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 44/64

Strategic Fit

efisien

responsif

fungsional inovatif

Tidak cocok

Tidak cocok

Strategic

Fit

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 45/64

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 46/64

Differences In DP / OPP Strategies

MTS

ATO

MTO

ETO

perancangan

produk

fabrikasi perakitan pengiriman

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 47/64

Moving DP / OPP Backward / Forward

• What would be the implications on:

–Inventory levels?

–Lead times?

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 48/64

Postponement

• Manufacturing Postponement

manufacturing postponement is to retain the

product in a neutral and non-committed

status as long as possible in the manufacturingprocess. This means to postpone

differentiation of form and identity to the

latest possible point

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 49/64

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 50/64

Why Manufacturing Postponement?

• To support mass customization• Large product variety with uncertain mix

• Many common components / sub-assemblies

• Relatively short lead time for final configuration(compared to waiting time tolerated by customers)

• Stages often postponed: final assembly, packing,

labeling, color mixing, etc.

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 51/64

An Illustrative Case

• You manage a company producing toys. Assume youhave 2 basic forms and 10 different colors. Thecurrent process of producing the toys are:

– Buy standard A1 paper

– Color the paper

– Cut it into two different forms

• Draw the production process

• Do you see any problem in your production system?How would you improve it?

Th t f M f t i P t t

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 52/64

The concept of Manufacturing Postponement

Customized

products

The concept of Manufacturing Postponement

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 53/64

The concept of Manufacturing Postponement

Material

(white paper)

inventory

Customized

products

Coloring

process Paper

Cutting

process

WIP of colored

papers

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 54/64

The Concept of manufacturing Postponement

• How if the mix of colors becoming more

uncertain?

• How if the number of color options grows to

100?

• How if the production process is arranged

differently?

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 55/64

The concept of Manufacturing PostponementCustomized

products

The concept of Manufacturing Postponement

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 56/64

The concept of Manufacturing Postponement

Standard

raw material

Standard

components

Customized

products

Stable volume, uncertain mix

Too risky to differentiate early!!!

Coloringprocess

Paper

Cutting

process

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 57/64

An Illustration of Manufacturing Postponement

Standard items,

differs only in size

Customization process,

products have different colors

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 58/64

UNITED COLORS OF BENETTON

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 59/64

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 60/64

Benetton Postponement

• Why the change? – The change enables Benetton to start manufacturing before color

choices are made

•What does the change result in? – Delayed forecasts of specific colors

– Still use aggregate forecasts to start manufacturing early

– React to customer demand and suggestions

• Issues with postponement – Costs are 10% higher for manufacturing

– New processes had to be developed

– New equipment had to be purchased

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 61/64

Modelling Postponement Impact

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 62/64

Postponement Example

• Demand for Blue and Green t-shirts

– 50% probability 100

– 50% probability 200

• Production alternatives

Produce 150 of each color ahead of time

Produce 300 plain t-shirt which can be dyed after

demand is observed

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 63/64

Postponement: Example

First Alternative – 25% probability -- short 50 of each

– 25% probability -- extra 50 of each

– 50% probability -- short 50 of one, extra 50 of theother

Second Alternative – 25% probability -- short 50 of each

– 25% probability -- extra 50 of each

– 50% probability -- no shortage or extra

8/16/2019 1 Logistics & Supply Chain Management 2014

http://slidepdf.com/reader/full/1-logistics-supply-chain-management-2014 64/64

Perhitungan Expected Profit

• Each t-shirt has a cost of IDR 100,000,- and

sold at normal price of IDR 200,000,- but if not

sold at normal price it has to be discounted at

IDR 50,000,-

• What is the expected profit for the above two

alternatives?