1. Introduction to IC Engines

Transcript of 1. Introduction to IC Engines

-

*Internal Combustion Engine

The internal combustion (IC) engine is a heat engine that converts chemical energy in a fuel into mechanical energy, usually made available on a rotating output shaft.

History of IC engines:

1700s -Steam engines (external combustion engines)1860 -Lenoir engine (h = 5%)1867 -Otto-Langen engine (h = 11%, 90 RPM max.)1876 -Otto four stroke spark ignition engine (h = 14%, 160 RPM max.)1880s - Two stroke engine1892 -Diesel four stroke compression ignition engine1957 -Wenkel rotary engine

-

*Atmospheric Engine

Process 1-2: Fuel air mixture introduced into cylinder at atmospheric pressureProcess 2-3: Constant pressure combustion (cylinder open to atmosphere)Process 3-4: Constant volume cooling (produces vacuum)Process 4-5: Isentropic compression (atmosphere pushes piston)Process 5-1: Exhaust process312Po45PVVALVEPatm

-

*Historical IC EnginesFLYWHEEL

-

*Two-stroke Lenoir Engine

Process 1-2: Fuel air mixture introduced into cylinder at atmospheric pressureProcess 2-3: At half-stroke inlet valve closed and combustion initiated constant volume due to heavy piston producing high pressure productsProcess 3-4: Products expand producing workProcess 4-5: At the end of the first stroke exhaust valve opens and blowdown occursProcess 5-1: Exhaust stroke

312Po45PV

-

*Two-stroke Otto-Langen Engine

Process 1-2: Fuel air mixture introduced into cylinder at atmospheric pressureProcess 2-3: Early in the stroke inlet valve closed and combustion initiated constant volume due to heavy piston producing high pressure productsProcess 3-4: Products expand accelerating a free piston momentum generates a vacuum in the tubeProcess 4-5: Atmospheric pressure pushes piston back, piston rack engaged through clutch to output shaftProcess 5-1: Valve opens gas exhaustedDisengagedoutput shaftEngagedoutput shaft

-

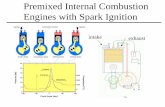

*

Four stroke Spark Ignition (SI) Engine

Stroke 1:Fuel-air mixture introduced into cylinder through intake valve Stroke 2:Fuel-air mixture compressedStroke 3:Combustion (roughly constant volume) occurs and product gases expand doing workStroke 4:Product gases pushed out of the cylinder through the exhaust valve

-

*Crank shaft 90o180oBCTC0o270oqEngine Operating CycleSpark plug for SI engineFuel injector for CI engineTop Center(TC)BottomCenter(BC)ValvesClearancevolumeCylinder wallPistonStroke

-

*Pressure-Volume Graph 4-stroke SI engine

One power stroke for every two crank shaft revolutions1 atmSparkTCCylinder volume BC Pressure Exhaust valveopensIntake valveclosesExhaust valveclosesIntake valveopens

-

*IVO - intake valve opens, IVC intake valve closesEVO exhaust valve opens, EVC exhaust valve opensXb burned gas mole fractionMotored Four-Stroke Engine10Pressure (bar)100

IntakeExhaustTCBC

-

*IVO - intake valve opens, IVC intake valve closesEVO exhaust valve opens, EVC exhaust valve opensXb burned gas mole fractionFour-Stroke SI EngineValve overlapExhaust gas residual10Pressure (bar)100

IntakeExhaust

-

*CompressionStrokePowerStrokeExhaustStrokeA I RCombustionProductsIntakeStroke AirFuel InjectorFour stroke Compression Ignition (CI) Engine

Stroke 1:Air is introduced into cylinder through intake valve Stroke 2:Air is compressedStroke 3:Combustion (roughly constant pressure) occurs and product gases expand doing workStroke 4:Product gases pushed out of the cylinder through the exhaust valve

-

*SOI start of injection EOI end of injectionSOC start of combustionEOC end of combustionFour-Stroke CI EngineFuel mass flow rateFuel mass burn rateCylindervolumeCylinderpressure

-

*Engine Anatomy

-

*Poppet Valve Actuation with Overhead CamshaftCamshaftSpringAir manifoldStemGuideValve headValve seatPistonSparkplug

-

*Cylinder Head DesignHonda VTEC (variable intake valve timing)

-

*Modern Two-Stroke Spark Ignition Engine

Stroke 1:Fuel-air mixture is introduced into the cylinder and is then compressed, combustion initiated at the end of the stroke

Stroke 2:Combustion products expand doing work and then exhausted

* Power delivered to the crankshaft on every revolution

-

*Two Stroke Spark Ignition EngineIntake (Scavenging)CompressionIgnitionExhaustExpansionFuel-air-oilmixtureFuel-air-oilmixtureCrankshaftReedvalveExhaustPort*TransferPort**No valves and thus no camshaft

-

*EPO exhaust port open EPC exhaust port closedIPO intake port openIPC intake port closedTwo-Stroke CI EnginescavengingAiAeIntake area (Ai)Exhaust area (Ae)PiPeExhaust Press (Pe)Intake Press (Pi)Cylinder Press (P)110 CA

-

*Cross Loop UniflowScavenging in Two-Stroke Engine

-

*Advantages of the two stroke engine:

Power to weight ratio is higher than the four stroke engine since there is one power stroke per crank shaft revolution. No valves or camshaft, just ports

Most often used for low cost, small engine applications such as lawn mowers, marine outboard engines, motorcycles.

Disadvantages of the two-stroke engine:

Incomplete scavenging or to much scavenging Burns oil mixed in with the fuel

-

*Single Cylinder EngineSingle-cylinder engine gives one power stroke per crank revolution (360 CA) for 2 stroke, or every two revolutions for 4 stroke.

The torque pulses on the crank shaft are widely spaced, and engine vibration and smoothness are significant problems.Used in small engine applications where engine size is more important180 CA0 CA(TC)720 CA (TC)540 CA360 CA (TC)180 CA4-stroke2-stroke

-

*Multi-cylinder EnginesMulti-cylinder engines spread out the displacement volume amongst multiple smaller cylinders. Increased frequency of power strokes produces smoother torque characteristics.

Most common cylinder arrangements are in-line 4 and V-6:Engine balance (inertia forces associated with accelerating and decelerating piston) better for in-line versus V configuration.

-

*V-6 EngineAir intakemanifoldInlet runner

-

*Power Regulation For proper combustion the ratio of the mass of air to the mass of fuel in the cylinder must be roughly 15.

An IC engine is basically an air engine, the more air you get into thecylinder, the more fuel you can burn, the more power you get out.

Vary throttle position - Maximum intake pressure (and power) achieved at wide-open-throttle (WOT) minimum at idle

WOTIdlePatmPint < PatmIntake manifoldFuel

-

*Power Regulation MethodsBasic methods:

Manifold pressure2) Air mass flow rate3) Throttle position

Engine Control Unit (ECU) activates the fuel injector solenoid for a duration corresponding to measurementPatmPint < PatmIntake manifoldFuelAir massflow meterPressuretransducerThrottlepositionsensor

-

* In spark ignition engines the air and fuel are usually mixed prior to entry into the cylinder.

Initially a purely mechanical device known as a carburetor was used to mix the fuel and the air

Most modern cars use electronic fuel-injection systems:

- 1980s single injector used to spray fuel continuously into the air manifold- 1990s one injector per cylinder used to spray fuel intermittently into the intake portFuel-Air Mixing

-

*Basic Carburetor VenturiThrottleAir FlowMixture to manifoldFuel

-

*Fuel Injection SystemThrottleFuel tankAir intakemanifoldDuring start-up the components are cold so fuel evaporation is very slow, as a resultadditional fuel is added through a second injecting valve200 KPa

-

*Diesel Fuel Injection SystemWith diesel engines fuel is sprayed directly into the cylinderspower is varied by metering the amount of fuel added (no throttle)

Diesel fuel injection systems operate at high-pressure, e.g., 100 MPa fuel pressure must be greater than the compression pressure need high fuel jet speed to atomize droplets small enough for rapid evaporationTraditional Diesels high pressureproduced locally within the injector

Latest Diesels use high pressure common rail with solenoid actuated injectors

-

*Gasoline Direct Injection (GDI) Engine Fuel is injected directly into the cylinder during the intake stroke or the compression stroke

High pressure injector required, 5-10 MPa Need bowl in piston design to direct the fuel spray towards the spark plug

-

*Engine that combines the best features of SI and CI engines: Operate at optimum compression ratio (12-15) for efficiency byinjecting fuel directly into engine during compression (avoiding knock associated with SI engines with premixed charge)

Ignite the fuel as it mixes (avoid fuel-quality requirement of diesel fuel)

Control engine power by fuel added (no throttling no pumping work)

During intake stroke fuel cools the cylinder wall allowing more air into the cylinder due to higher densityBenefits of GDI Engine

-

*Direct-Injection Stratified-Charge Engines Create easily ignitable fuel-air mixture at the spark plug and a leanerfuel-air mixture in the rest of the cylinder.

Lean burn results in lower emissions and higher energy efficiency

Example:

Mitsubishi GDI engine achieves complete combustion with an air-fuel ratio of 40:1 compared to 15:1 for conventional engines

This results in a 20% improvement in overall fuel efficiency and CO2 production, and reduces NOx emissions by 95% with special catalyst

-

*Stratified Charge EngineDuring intake stroke air enters the cylinder

Near the end of the compression stroke fuel is injected and directed by the piston head bowl towards the spark plug

The mixture at the spark plug is rich in fuel thus easy to ignite butthe amount of fuel injected results in an overall lean fuel-air mixture

Lowers heat transfer to the walls but increases thermal cyclic load onthe spark plug, and standard catalytic converter doesnt work

-

*Mitsubishi Two-Stage Ignition GDI Engine

-

*RichintakeLeanintakeTwo-Chamber Torch or Jet Ignition Engine

-

*Other Types of IC EnginesHomogeneous Charge Compression Ignition (HCCI)

Premixed fuel-air mixture injected into cylinder which contains combustion products from previous cycle.

Ignition occurs spontaneously at the end of compression.

Hybrid Cars

Use a combination of IC engine and electric motor

Electric motor is used exclusively during cruise and idle

IC engine kicks in when additional power is needed like during acceleration

-

*Supercharger and TurbochargerThese devices are used to increase the power of an IC engine by raisingthe intake pressure and thus allowing more fuel to be burned per cycle.

Knock or autoignition phenomenon limits the amount of precompression.

Superchargers are compressors that are mechanically driven by the engine crankshaft and thus represent a parasitic load.CompressorPatmPint > Patm

-

*Positive Displacement CompressorsPositive displacement compressors: piston, Roots, and screw

Most common is the Roots compressor pushes air forward without pressurizing it internally. Pressurization occurs in the manifold when the air flow rate supplied is larger than that ingested by the cylinders.

Produces constant flow rate independent of boost pressure (P2)P1P2

-

*Performance of Positive Displacement Compressorss/co = rotor tip Mach# ~ pump speedc = compressor efficiency : work required relative to isentropic compression

Extra energy goes to heat up air leading to a reduction in densitycScrewRoots

-

*Dynamic CompressorsDynamic compressor has a rotating element that adds tangential velocity to the flow which is converted to pressure in a diffuser.

Most common is the radial, or centrifugal typeProduces a constant boost pressure independent of the mass flow rate

-

*Mass flow rate (Pounds of air per minute)To the left of surge line the flow is unstable (boundary layer separation and flow reversal)To the right of 65% line the compressor becomes very inefficient: a) air is heated excessivelyb) takes excess power from the crank shaft

-

*Turbochargers couple a compressor with a turbine driven by the exhaust gas. The compressor pressure is proportional to the engine speedCompressor also raises the gas temperature, so aftercoolers are used after the compressor to drop the temperature and thus increase the air density.

-

*The peak pressure in the exhaust system is only slightly greater than atmospheric small DP across turbine

In order to produce enough power to run compressor the turbine speed must be very fast (100k-200k rev/min) long term reliability an issue

It takes time for turbine to get up to speed so when the throttle is opened suddenly there is a delay in achieving peak power - Turbo lag

Waste gate valve used to control the exhaust gas flow rate to the turbineIt is controlled by the intake manifold pressureINTAKEAIREXHAUSTFLOW

MECH 435MECH 435*MECH 435MECH 435*