1 Contour Bandsaw Parts and Accessories Unit 36. 2 Vertical Bandsaw Latest machine tool to be...

-

Upload

peregrine-arnold -

Category

Documents

-

view

244 -

download

5

Transcript of 1 Contour Bandsaw Parts and Accessories Unit 36. 2 Vertical Bandsaw Latest machine tool to be...

1

Contour Bandsaw Parts and Accessories

Unit 36

2

Vertical Bandsaw

• Latest machine tool to be developed• Early 1930s

• Widely accepted by industry• Fast and economical method of cutting metal

and other materials• Continuous cutting action on workpiece

3

Advantages of the Vertical Bandsaw

Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

4

Advantages of the Vertical Bandsaw

Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

5

Advantages of the Vertical Bandsaw

Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display.

6

ContourBandsawParts

• Fabricated from steel

• Basic parts• Base• Column• Head

7

Base

• Supports column and houses drive assembly• Provides drive for saw blade• Lower Pulley

• Supports and drives saw band• Driven by variable-speed pulley

• Can be adjusted to various speeds by variable speed handwheel

8

Base

• Table• Attached to base by means of trunnion• Can be tilted 10 to left and 45 to right• Turned by table tilt handwheel

• Lower saw guide• Attached to trunnion• Supports blade to keep it from twisting

• Filler plate slide and center plate• Removable and mounted in table

9

Column

• Supports head, left-hand blade guard, welding unit and variable speed handwheel

• Variable speed handwheel• Used to regulate speed of bandsaw blade

• Blade tension indicator and speed indicator• Welding unit

• Used to weld, anneal, and grind saw blade

10

Head

• Upper pulley• Supports saw band, adjusted by tension and tracking

controls• Upper saw guide

• Attached to saw guidepost• Supports/guides saw blade to stop twisting

• Saw guard and air nozzle• Keeps area free from chips

11

Types of Band Machines

• Smaller capacity• has two band carrier wheels• Used in many toolrooms

• Larger capacity• Have three carrier wheels• Both upper wheels may be tilted• When blade becomes too short, can be shortened to

fit over upper and lower band carrier wheels

12

Bandsaw Common Applications

• Notching• Sections of metal removed

in one piece

• Slotting– Quick and accurate without

expensive fixtures

13

Bandsaw Common Applications• Three-dimensional shaping

• Simply follow layout lines

• Radius cutting– Internal or external contours– Internal sections removed

in one piece

14

Bandsaw Common Applications

• Splitting• Accomplished quickly with

minimum waste

• Angular cutting– Work clamped at any angle– Table may be tilted

15

Coolants

• Power-feed models have cooling system• Circulates and discharges coolant against faces

of blade and work• Mist coolant system

• Uses air to atomize coolant and direct it (efficient)• Recommended for high-speed machining of nonferrous

metals• Grease-type lubricants and coolants may be applied

directly to blade on machines with no system

16

Power Feed

• Work and table fed toward blade by hydraulic system

• Fixed-table machines use gravity to provide steady mechanical feeding pressure

• Allows operator to use both hands to guide• Work forced into blade by cables, pulleys, and

weights• Force

• Varied up to about 80 lb. (regular 30-40 lbs)

17

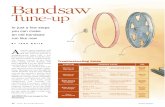

Bandsaw Blade Types

• Three kinds of blades commonly used• Carbon-alloy• High-speed steel• Tungsten-carbide tipped

• For best results, must consider• Kind of saw-blade material and tooth form• Pitch set• Width• Gage needed

18

Tooth Forms• Precision (regular)

• Most generally used• 0º rake angle, 30º back clearance• Used for fine finish

• Claw (hook)• Positive rake on cutting face• Faster cutting, longer lasting than buttress

• Buttress (skip)• Teeth spaced farther apart• Tooth angles same as

precision teeth• Used on thick work sections

19

Pitch

• Numbers of teeth per standard reference length• Inch standard = No. teeth/inch• Metric standard = No. teeth/25 mm

• Thickness of material to be cut determines pitch of blade to use

• Coarse: thick, Fine: thin• Two teeth in contact with work at all times

20

Set

• Amount teeth offset on either side of center to produce clearance for back of band

• Wave set• Group of teeth offset to right and next to left• Structural steel or pipe

• Straight set• One tooth offset to right

and next to left• Light nonferrous castings

• Raker set• One tooth offset to right, one to left,

and third tooth straight

21

Width

• Wide blade used for straight, accurate cuts• Narrow blades used to cut small radii• Radius charts show proper width of blade are

found on all bandsaws• Choose widest blade that can cut smallest radius

22

Gage

• Thickness of saw blade• Thick blades stronger than thin blades• Thickest blade possible should be used for

sawing tough material• Standardized according to blade width

½ in wide are .025 in. thick5/8 in. and ¾ in. wide are .032 in. thick1 in. wide are .035 in. thick

23

Calculate Lengthof Saw Blade

• Packaged in coils 100 to 150 ft. in length

• Cut length required and weld ends• Twice center distance between each

pulley and add it it one pulley's circumference

CD

Blade length = 2 (CD) + µ D D