09200 Precision Frog Grinder - Railtech UK PRECISION FROG GRINDER ... Matweld reserves the right to...

Transcript of 09200 Precision Frog Grinder - Railtech UK PRECISION FROG GRINDER ... Matweld reserves the right to...

632 South 3rd StreetP.O. Box 2816 • Paducah, KY 42002

270-444-0085Fax: 270-443-6180

Website: www.matweld.comEmail: [email protected]

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

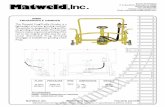

09200 PRECISION FROG GRINDERThe Matweld “PRECISION FROG GRINDER” is a hydraulic powered, track mounted machine thatprovides a precision guide frame with multiple axis adjustment enabling the operator to makeconsistent refinishing grinds.

Accessories 00499 - 8 x 1 x 5/8 GRINDING STONE09299 - 4 x 3 x 5/8-11 CUP STONE

Weight Base: 38 lbs (17.25 kg)Grinder: 84 lbs (38 kg)Overall: 122 lbs (55.5 kg) PATENT PENDING

2

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

3

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

GENERAL SAFETY PRECAUTIONS:

TOOL OPERATORS AND MAINTENANCE PERSONNEL MUST ALWAYS COMPLY WITH THESAFETY PRECAUTIONS GIVEN IN THIS MANUAL, AND WITH ALL STICKERS AND TAGS AT-TACHED TO THE TOOL AND HOSE. ALL SAFETY PRECAUTIONS ARE GIVEN FOR YOUR SAFETY.READ TO UNDERSTAND AND FOLLOW ALL SAFETY, MAINTENANCE AND OPERATION INSTRUC-TIONS BEFORE YOU USE OR MAINTAIN THE TOOL. REVIEW THE MANUAL DAILY BEFOREUSING THE TOOL. IN ADDITION, FOLLOW ALL SAFETY GUIDELINES GIVEN YOU BY YOURSUPERVISOR. DO NOT USE THE TOOL IF YOU HAVE ANY QUESTIONS ABOUT THE OPERA-TION, SAFETY OR MAINTENANCE OF THIS TOOL. FAILURE TO FOLLOW THESE INSTRUC-TIONS CAN RESULT IN PERSONAL INJURY OR EQUIPMENT DAMAGE.

MATWELD HAS NO CONTROL OVER TOOL USE OR OPERATION ONCE IT LEAVES THEMATWELD PLANT. MATWELD HAS NO CONTROL OVER OPERATOR OR MAINTAINER SELEC-TION. THE CUSTOMER MUST ASSUME RESPONSIBILITY FOR THE TOOL’S SUITABILITY FORA PARTICULAR FUNCTION. DURING USE OF TOOL, GOOD JUDGEMENT MUST BE USED TOWORK SAFELY AND EFFICIENTLY WITHOUT ENDANGERING THEMSELVES OR BYSTANDERS.UNDERSTANDING OF THE OPERATION AND MAINTENANCE MANUAL IS ESSENTIAL FORANYONE USING OR MAINTAINING THE TOOL.

• DO NOT OPERATE THE TOOL UNTIL YOU HAVE BEEN THOROUGHLY AND PROPERLYTRAINED OR UNDER THE SUPERVISION OF AN INSTRUCTOR.

• CHECK POWER SOURCE DAILY TO DETERMINE IF CORRECT FLOW AND PRESSURE AREAVAILABLE. NEVER EXCEED FLOWS OR PRESSURES FOR THE TOOL BEING USED. PER-SONAL INJURY OR DAMAGE TO THE TOOL CAN RESULT.

• OPERATORS MUST CLEAR THE WORK AREA OF NON-ESSENTIAL PERSONNEL. FLYINGDEBRIS CAN CAUSE SERIOUS INJURY.

• THE OPERATOR MUST BE FAMILIAR WITH ALL PROHIBITED WORK AREAS SUCH AS UN-SAFE GRADES, POOR FOOTING AREAS AND OVERHEAD HAZARDS.

• MAINTAIN BALANCE AND PROPER FOOTING AT ALL TIMES. NEVER OVERREACH TO THEEXTENT THAT A BROKEN PART OR SUDDEN MOVEMENT OF THE TOOL CAN CAUSE YOUTO LOSE YOUR BALANCE AND FALL, OR CAUSE INJURY TO YOUR SELF OR SOMEONEELSE.

• WHEN WORKING NEAR ELECTRICAL CONDUCTORS, ALWAYS ASSUME THAT THE CON-DUCTORS ARE ENERGIZED AND THAT HOSES AND CLOTHING CAN CONDUCT HARMFULELECTRICITY. USE HOSES LABELED AND CERTIFIED AS NON-CONDUCTIVE.

• DO NOT OPERATE THE TOOL AT EXCESSIVE FLUID TEMPERATURES OPERATOR DIS-COMFORT AND POTENTIAL BURNS CAN RESULT AT HIGH OIL TEMPERATURES.

• NEVER WEAR LOOSE CLOTHING THAT CAN GET ENTANGLED IN THE WORKING PARTSOF THE TOOLS OR BE CARELESS WITH HANDS, FEET OR OTHER BODY PARTS AROUNDTHE WORKING PARTS OF THE TOOLS. HYDRAULIC TOOLS EXERT HIGH TORQUE ANDFORCE AND CAN CAUSE SERIOUS INJURY OR DEATH IF IMPROPERLY USED.

4

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

• TO AVOID PERSONAL INJURY OR EQUIPMENT DAMAGE, ALL TOOL REPAIR, MAINTENANCEOR SERVICE MUST ONLY BE PERFORMED BY AUTHORIZED AND PROPERLY TRAINEDPERSONNEL.

• ALWAYS WEAR SAFETY EQUIPMENT SUCH AS OIL INJECTION RESISTANT WORK GLOVES,SAFETY GLASSES, SAFETY BOOTS, EAR PROTECTION AND OTHER SAFETY APPARELDICTATED BY YOUR SUPERVISOR APPLICABLE FOR THE JOB YOU ARE DOING AND THETOOL YOU ARE USING.

• DO NOT CLEAN INSPECT OR REPAIR THE TOOL WHILE CONNECTED TO THE POWERSOURCE. ACCIDENTAL ENGAGEMENT OF THE TOOL CAN CAUSE SERIOUS PERSONALINJURY.

• OIL INJECTION HAZARD EXISTS WITH THIS TOOL. OIL INJECTION IS A CONDITION WHEREHYDRAULIC OIL IS INJECTED UNDER THE SKIN FROM PRESSURE IN THE LINE. ALWAYSWEAR GLOVES AND REPAIR ANY LEAKS IMMEDIATELY. NEVER CARRY A TOOL BY THEHOSES.

• DO NOT USE DAMAGED EQUIPMENT. IMMEDIATELY REPLACE ANY DAMAGED HOSES,FITTINGS, OR OTHER COMPONENTS SHOWING WIRE BRAID, NICKS, CUTS, DAMAGE ORABRASIONS. FAILURE TO DO SO MAY RESULT IN EQUIPMENT DAMAGE AND / OR PER-SONAL INJURY OR DEATH.

• CLEAN UP ANY OIL OR FLUID SPILLS IMMEDIATELY.

• HAVE SUPERVISOR ADD ADDITIONAL PRECAUTIONS RELATING TO THE SPECIFICWORK AREA AND LOCAL SAFETY REGULATIONS BELOW:

*

*

*

*

*

*

*

**

*

*

5

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

6

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

09200 PRECISION FROG GRINDER

SAFETY PRECAUTIONS:

1. ALWAYS WEAR PROTECTIVE EQUIPMENT SUCH AS GLOVES, SAFETY GLASSES, EARPROTECTION AND SAFETY SHOES.

2. DO NOT WEAR CLOTHING WHICH MAY BECOME ENTANGLED IN THE TOOL.

3. ALWAYS KEEP WORK AREA FREE OF TOOLS OR ANY OTHER OBJECTSWHICH MAY IMPAIR SOUND FOOTING.

4. CAUTION OIL INJECTION HAZARD EXISTS WITH THIS TOOL. OIL INJECTION IS A CONDI-TION WHERE THE HYDRAULIC OIL IS FORCED UNDER THE SKIN THROUGH PRESSUREIN THE LINE. ALWAYS WEAR GLOVES, DO NOT CARRY THE TOOL BY HYDRAULIC HOSES,AND REPAIR LEAKS IMMEDIATELY..

5. NEVER CHANGE STONES WITH THE POWER SOURCE VALVE(S) IN THE “ON” POSITION,TURN THE POWER SOURCE “OFF”.

6. NEVER ATTEMPT TO CARRY THE GRINDER WITH THE POWER SOURCE IN THE “ON”POSITION, TURN THE POWER SOURCE “OFF”.

7. NEVER TOUCH OR TRY TO STOP A MOVING STONE.

8. ALWAYS CHECK THE WORK AREA FOR ANY TRASH WHICH MAY IGNITE FROM SPARKS.

9. ALWAYS CHECK THE AREA FOR SMOLDERING TIES OR TRASH BEFORE LEAVING THESITE.

10. WHEN CHANGING STONES, FOLLOW ALL GRINDING STONE MANUFACTURERS INSTRUC-TIONS FOR SAFETY AND OPERATION. USE ONLY STONES THAT COMPLY WITH ANSISTANDARDS. BEFORE USING, RUN NEW GRINDING STONE FOR ONE MINUTE AT FULLSPEED TO CHECK FOR DEFECTS OR VIBRATION.

11 MOST HYDRAULIC OILS HAVE A FLASHPOINT OF APPROXIMATELY 450 DEGREES (F). MAKESURE HOSES ARE COMPLETELY CLEAR OF SPARKS AND HOT DEBRIS. HAVE ANOTHERPERSON STAND CLOSE TO HYDRAULIC POWER SOURCE CONTROLS TO OBSERVE OP-ERATION AND FOR EMERGENCY SHUTDOWN IF NECESSARY.

7

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

09200 PRECISION FROG GRINDER

FLOW: 10 GPM (38 LPM)PRESSURE: 2000 PSI (140 BAR)MAX BACK PRESSURE: 250 PSI (17 BAR)RPM: 4000

OPERATION:

1. SET THE BASE ON THE FROG CENTERING IT ON THE WORK AREA

2. THE OPERATOR SHOULD BE ON THE SIDE FACING THE TWO ADJUSTMENT HANDLES.THE OPERATOR HANDLE ON RIGHT CLAMPS TO THE FROG. THE OPERATOR HANDLE ONTHE LEFT CLAMPS AND ADJUSTS THE BASE FRAME GRINDING POSITION.

3. SET GRINDER ON THE BASE; LOCK IT IN POSITION USING THE ROLLER CLAMP ON EACHSIDE. THE GRINDER IS FREE TO ROLL ON THE BASE FRAME.

4. CONNECT GRINDER TO A 10 GPM POWER SOURCE.

5. GRINDING STONE IS SET TO VERTICAL POSITION IN ORDER TO GRIND THE TOP SUR-FACE OF THE FROG. TIGHTEN THE LOCKING HANDLE TO SECURE THE GRINDING HEAD INTHIS POSITION.

8

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

6. USE THE HAND-WHEEL TO MOVE THE STONE UP AND DOWN. USE THE CRANK HANDLESTO ADJUST THE STONE FROM SIDE-TO-SIDE.

7. BASE FRAME ALIGNMENT FOR VARIOUS CUTS:

a) SURFACE GRINDING(TOP OF RAIL): POSITION THE WORK AREA OF THE BASE FRAME IN-LINE WITH THE CENTER-LINE OF THE FROG.

b) TAPER CUT ON THE FROG POINT: POSITION THE BASE FRAME ON CENTER-LINE OF THEFROG AND ELEVATE THE BACK OF THE FRAME USING THE SCREW HEIGHT ADJUSTMENT TOACHIEVE THE DESIRED JOB TAPERED SLOPE

c) SIDE ANGLE CUT ON FROG POINT: SELECT THE SURFACE TO BE WORKED AND ROTATETHE BACK OF THE BASE FRAME FROM SIDE TO SIDE UNTIL THE BASE FRAMEWORKMATCHES THE TURN-OUT DEGREE OF THE FROG POINT. THIS METHOD IS REQUIRED FORINSIDE OR OUTSIDE ANGLE CUTS, MOVING FROM AN INSIDE CUT TO AN OUTSIDE CUT RE-QUIRES UNLOCKING THE GRINDER AND TURNING IT AROUND ON THE BASE FRAME AND RE-LOCKING.

09200 PRECISION FROG GRINDER

9

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

09200 PRECISION FROG GRINDER

MAINTENANCE:

1. CHECK TOOL DAILY FOR PROPER OPERATION, LEAKS, OR DAMAGE.

2. INSPECT HOSES DAILY. REPLACE CUT, BURNED, OR OTHERWISE DAMAGED HOSES.

3. KEEP QUICK DISCONNECT COUPLERS CLEAN AND LUBRICA TED.

4. USE HYDRAULIC FLUIDS THAT COMPLY WITH HTMA SPECIFICATION 5.7, THE HYDRAULICFLUID SHOULD HAVE A VISCOSITY BETWEEN 100 AND 400 SSU (20-82 CENTISTOKES) ATTHE MAXIMUM AND MINIMUM EXPECTED OPERATING TEMPERATURES. PETROLEUM BASEDHYDRAULIC FLUIDS WITH ANTI-WEAR PROPERTIES AND A VISCOSITY INDEX OF OVER 140WORK FOR A WIDE RANGE OF OPERATING CONDITIONS.

THE FOLLOWING OILS MEET HTMA SPECIFICATION 5.7:AMOCO RYKON MV CITGO A/W ALL TEMPSUNVIS 706 MOBIL D.T.E. 13CHEVRON EP-MV TEXACO “RANDO” HDAZ

OTHER FLUIDS THAT MEET OR EXCEED THIS SPECIFICATION CAN BE USED.

5. HAVE TOOL INSPECTED, AT LEAST ANNUALLY, BY MATWELD OR A MATWELD QUALIFIEDSERVICE REPRESENTATIVE TO DETERMINE IF TOOL IS IN NEED OF SAFETY CHANGESOR WORN PART REPLACEMENT.

6. CONTACT MATWELD ON A PERODIC BASIS, AT LEAST ANNUALLY, FOR SERVICE BULLE-TINS, SAFETY NOTICES, OR OTHER IMPORTANT INFORMATION PERTAINING TO THIS TOOL.

COLD WEATHER OPERATION:

HYDRAULIC SYSTEM PERFORMANCE IS AFFECTED WHEN THE TEMPERATURE DROPS BE-LOW 50 F. THEREFORE MEASURES SHOULD BE TAKEN TO PRE-WARM TOOLS AND FLUIDSBEFORE OPERATING.

10

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

09200 PRECISION FROG GRINDER

CHANGING THE 8” GRINDING STONE:

1.) DISCONNECT THE TOOL FROM THE POWER SOURCE.

2.) USING THE WRENCH PROVIDED LOOSEN THE TWO HEX FASTENERS AND REMOVE THESTONE GUARD.

3.) ROTATE THE STONE SLOWLY BY HAND WHILE DEPRESSING THE SHAFT LOCKING PINMECHANISM LOCATED ON THE SIDE OF BEARING HOUSING.

4.) WHEN THE PIN ENGAGES, LOCKING THE SHAFT, REMOVE THE NUT HOLDING THE STONEAND FLANGES TO THE SHAFT

5.) INSTALL THE NEW STONE. BE SURE THAT THE FLANGES HAVE BEEN REPLACED ANDTHAT THE GRINDING STONE IS EQUIPPED WITH A BLOTTER.

6.) TIGHTEN THE NUT ON THE SHAFT. DO NOT OVER TIGHTEN AS THIS MAY CAUSE THESTONE TO FAIL WHILE IN USE.

7.) RELEASE THE LOCKING MECHANISM AND CHECK TO MAKE SURE IT IS RELEASED FROMTHE SHAFT BEFORE BEGINNING TO USE.

8.) RE-INSTALL THE STONE GUARD.

9.) REFER TO MANUFACTURER’S SPECIFICATIONS FOR TORQUE SETTINGS ON STONE AT-TACHMENT

11

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

09200 PRECISION FROG GRINDER

CHANGING THE 4” CUP STONE:

1.) DISCONNECT THE TOOL FROM THE POWER SOURCE.

2.) USING THE WRENCH PROVIDED LOOSEN THE TWO HEX FASTENERS AND REMOVE THESTONE GUARD.

3.) ROTATE THE STONE SLOWLY BY HAND WHILE DEPRESSING THE SHAFT LOCKING PINMECHANISM LOCATED ON THE SIDE OF BEARING HOUSING.

4.) WHEN THE PIN ENGAGES, LOCKING THE SHAFT, CONTINUE DEPRESSING THE LOCKINGPIN WHILE TURNING THE 4” CUP STONE BY HAND TO LOOSEN AND REMOVE.

5.) LEAVE THE BACKING FLANGE IN PLACE AND INSTALL THE NEW CUP STONE. MAKE SURETHE NEW CUP STONE HAS A PAPER BLOTTER INSTALLED.

6.) RELEASE THE LOCKING MECHANISM AND CHECK TO MAKE SURE IT IS RELEASED FROMTHE SHAFT BEFORE BEGINNING TO USE.

7.) RE-INSTALL THE STONE GUARD.

12

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

REVIEW OF HYDRAULIC PRINCIPLES

A. TOOL CIRCUIT

1. HYDRAULIC FORMULAS:

CID X RPM GPM X PSI GPM = 231 HP = 1714 (.85)

1456.9

Example: HP required to deliver 10 GPM at 1500 PSI.

10 GPM X 1500 PSI = 15000 = 10.3 HP1456.9 1456.9

(subtract back pressure for tool HP)

Estimated HP delivered by pump or used by tool.

PSI GPM 500 1,000 1,500 2,000 2,500 3,000 3 1.03 2.06 3.09 4.12 5.15 6.18 5 1.72 3.43 5.15 6.86 8.58 10.30 10 3.43 6.86 10.3 13.70 17.20 20.60 15 5.15 10.30 15.40 20.60 25.70 30.90

2. BACK PRESSURE

BACK PRESSURE MEASURED AT THE TOOL RETURN PORT MUST NOT EXCEED THE MANU-FACTURERS BACK PRESSURE RATING. MOST MANUFACTURERS LIST THE MAXIMUM BACKPRESSURE FOR THEIR HYDRAULIC TOOLS AT 250 PSI. BACK PRESSURE MEASURED ONTHE RETURN SIDE OF THE TOOL IS THE FORCE REQUIRED TO GET THE OIL BACK TO THETANK. IN ALMOST ALL CASES THE LOWER THE BACK PRESSURE THE BETTER THE TOOLPERFORMANCE. FIRST, THE BACK PRESSURE IS SUBTRACTED FROM THE MAXIMUM TOOLPRESSURE TO ARRIVE AT A MAXIMUM TOOL OPERATING PRESSURE. FOR EXAMPLE, TOOLSWITH 2000 PSI OPERATING PRESSURE ARE INSTALLED ON A SYSTEM WITH 250 PSI BACKPRESSURE. THIS LEAVES 1750 PSI AS A MAXIMUM TOOL PRESSURE. IMAGINE A SYSTEMWITH 500 PSI BACK PRESSURE. 2000 MINUS 500 PSI BACK PRESSURE LEAVES ONLY 1500PSI FOR THE TOOL. SECOND, TOOLS ARE DESIGNED FOR PRESSURE TO BUILD ON THEPRESSURE SIDE OF THE TOOL. IF TOO MUCH PRESSURE BUILDS ON THE RETURN SIDE,NOT ONLY IS PERFORMANCE EFFECTED, BUT SEALS MAY BLOW. THIS IS WHY IT IS VERYIMPORTANT TO DIRECT THE FLOW INTO THE TOOL CORRECTLY. REVERSING THE HOSES TOTEST MAY RESULT IN BLOWN SEALS, DAMAGE TO THE TOOL, AND PERSONAL INJURY.

13

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

GENERAL NOTES09200 PRECISION FROG GRINDER

14

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

09200PRECISION FROG GRINDER

BASE FRAME ASSEMBLY

15

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

ITEM NO. PART NO. DESCRIPTION QTY.

09200 PRECISION FROG GRINDER

092010920209203092040920509206092070920809210092110921209235A1001A1021A1028A1452A1458A2062A2190A2191A559000804-01

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

19202122

BASE FRAME ASSEMBLY 1STRUT BEARING CAP 4BEARING BLOCK-FEED ROD 1FLANGE BEARING-3/4 x 5/8 6RAIL CLAMP-LH 3RAIL CLAMP-RH 1CLAMP/FEED HANDLE 3FEED ROD-LH 2FEED ROD-DUAL 1BASE ADJUSTMENT KNOB 2SWIVEL BASE 2FLAP GUARD 21/4 x 3/4 HEX HEAD BOLT 225/16 x 3/4 HEX HEAD BOLT 35/16 x 2-1/2 HEX HEAD BOLT 25/16-18 JAM NUT ZP 21/2 - 13 JAM NUT ZP 21/4-20 NUT INSERT 41/4 SAE FLAT WASHER 45/16 SAE FLAT WASHER 310-24 x 1/4 SET SCREW 3DRIVESHAFT KEY-3/16 x 13 3

16

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

BASE FRAME ASSEMBLY 09200PRECISION FROG GRINDER

05/08/07

17

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

09200 PRECISION FROG GRINDER

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18192021222324

09201A09201-01A0920209203092040920509206092070920809210092110921209235A1001A1021A1024A1028A1452A1458A2062A2190A2191A559000804-01

BASE STRUT ASSEMBLY 2BASE FRAME RAIL 2STRUT BEARING CAP 4BEARING BLOCK-FEED ROD 1FLANGE BEARING-3/4 x 5/8 6RAIL CLAMP-LH 3RAIL CLAMP-RH 1CLAMP/FEED HANDLE 3FEED ROD-LH 2FEED ROD-DUAL 1BASE ADJUSTMENT KNOB 2SWIVEL BASE 2FLAP GUARD 21/4-20 x 3/4 HEX HEAD BOLT 225/16 x 3/4 HEX HEAD BOLT 35/16-18 x 1-1/2 HEX HEAD BOLT 85/16 x 2-1/2 HEX HEAD BOLT 25/16-18 JAM NUT ZP 21/2 - 13 JAM NUT ZP 21/4-20 NUT INSERT 41/4 SAE FLAT WASHER 45/16 SAE FLAT WASHER 1110-24 x 1/4 SET SCREW 3DRIVESHAFT KEY-3/16 x 13 3

ITEM NO. PART NO. DESCRIPTION QTY.

18

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

09200PRECISION FROG GRINDER

GRINDER ASSEMBLY

19

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

ITEM NO. PART NO. QTY.

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21 22

232425262728293031323334353637383940

09200 PRECISION FROG GRINDER

DESCRIPTION

001090013700138A00145001460079500796092040920709213092140921509216092170921909233092340923600804-1231P-0469-08-08A1006A1012A1021A1024A1026A1047-FULLA1092A1454A2046A2048A2050A2054A2190A2191A2192A2194A5590SERIAL TAGSSB4-6S

RAIL WHEEL BEARING 8VALVE - CONTROL 1CONTROL VALVE KNOB 1QUICK DISCONNECT COUPLER 1QUICK DISCONNECT NIPPLE 1FLOW CONTROL MANIFOLD 1VALVE - FLOW REGULATOR 1FLANGE BEARING-3/4 x 5/8 2CLAMP/FEED HANDLE 2FLANGED ROLLER WHEEL 4GRINDER FRAME ASSEMBLY 1FEED ROD SUPPORT BRACKET 2CROSS FEED ROD 1SLIDE ROD 2GUIDE WHEEL 2RECTANGULAR PLUG 4TOGGLE CLAMP 2SPACER BLOCK 2DRIVESHAFT KEY-3/16 x 13 2#4 O-RING PLUG 21/2 NPT HEX NIPPLE 21/4 x 2 HEX HEAD BOLT 81/4 x 3-1/2 HEX HEAD BOLT 25/16 x 3/4 HEX HEAD BOLT 25/16 x 1-1/2 HEX HEAD BOLT 45/16 x 2 HEX HEAD BOLT 43/8 x 2-1/4 FULL THREAD 21/2 x 3-3/4 HEX HEAD BOLT 43/8-16 JAM NUT ZP 21/4-20 NYLOCK NUT 105/16-18 NYLOCK NUT 43/8 - 16 NYLOCK NUT 21/2-13 NYLOCK NUT 41/4 SAE FLAT WASHER 125/16 SAE FLAT WASHER 123/8 SAE FLAT WASHER 41/2 SAE FLAT WASHER 810-24 x 1/4 SET SCREW 2SERIAL NUMBER TAG 11/8 x 3/8 SS RIVET 4

20

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

09200PRECISION FROG GRINDERGRINDER HEAD ASSEMBLY

21

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

09200 PRECISION FROG GRINDER

ITEM NO. PART NO. DESCRIPTION QTY.

1 2 3 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18 19 20 21 22

232425262728293031323334353637383940414243444546474849505152535455565758

0040300404004050040600410B004120041300415005020070500706HD007100071300806-0103930A05919059400921809220092210922209223092240922509226092280922909230092310923209232-010923709238315-08-10515-08-106500-08-08A1005A1021A1041A1043 - CARRIAGEA1452A1481A2046A2190A2192-NA2192-TA220003858A3860A5434A5620A5624A5751A6311A6358A696000402A1436

INTERNAL RETAINING RING 1SEAL 1EXTERNAL RET. RING 1BEARING-DRIVE SHAFT 1TOP PORT MOTOR 1LOCKING PIN 1SPRING 1PLUG 1DRIVE SHAFT-CCW 11 5/8 INT. RET. RING 23/4 EXT. RET. RING HD 1SEAL-HEIGHT ADJ. TUBE 1BEARING-HEIGHT ADJ. 1MOTOR SHAFT KEY-3/16 x 3 1CRANK HANDLE KNOB 1HAND WHEEL 11/2”WAVE WASHER 1SLIDE BEARING 3HEIGHT ADJUSTMENT ASSEMBLY 1HEIGHT ADJUSTMENT SHAFT 1HEIGHT ADJUSTMENT SCREW 1BEARING HOUSING 1SUPPORT SHAFT 1ANGLE ADJUSTMENT ASSEMBLY 1ANGLE LOCK PLATE 18” STONE GUARD ASSEMBLY 1SUPPORT BLOCK 1GUARD MOUNT 14” CUPSTONE GUARD 1ADJUSTABLE HANDLE 1LOCK KNOB SHAFT 1SUPPORT SHAFT BLOCK 1PRESSURE/RETURN HOSE 21/2 T x #10 MALE CONN. 11/2 T x 10 STR. THRD. 90 1#8 MJIC x #8 FJIC SWIVEL 11/4 x 1-3/4 HEX HEAD BOLT 45/16 x 3/4 HEX HEAD BOLT 13/8 x 3/4 HEX HEAD BOLT 13/8 x 1-1/4 CARRIAGE BOLT 15/16-18 JAM NUT ZP 21/2 x 1 SHOULDER BOLT 11/4-20 NYLOCK NUT 41/4 SAE FLAT WASHER 83/8 WASHER NYLON 13/8 TOOLING WASHER 13/4 x 1-1/4 WASHER 15/16 x 1-1/4 FENDER WASHER 13/8 x 1-1/4 FENDER WASHER 11/4-20 x 3/4 SHCS 125/16-18 x 1/2 SET SCREW 25/16-18 x 1/2 SET SCREW - N 25/16-18 x 1.75 COUPLING NUT 25/16 x 3/4 FLAT HEAD BOLT 45/16 x 3/4 BHCS 43/4 x 1 SHOULDER BOLT 1STONE FLANGE 25/8-11 HVY HEX NUT 1

22

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

09200 PRECISION FROG GRINDER

DECAL LEGEND

23

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

LIMITED WARRANTY

MATWELD, INC., PADUCAH, KY., WARRANTS TO THE ORIGINAL PURCHASE OF THIS PROD-UCT THAT THE PRODUCT WILL BE FREE FROM DEFECTS IN MATERIAL AND WORKMANSHIPFOR THE PERIOD OF ONE (1) YEAR AFTER THE DELIVERY OF SUCH PRODUCT TO THE CUS-TOMER. OTHER EQUIPMENT AND PARTS USED, BUT NOT MANUFACTURED BY MATWELDINC. ARE COVERED DIRECTLY BY THE WARRANTY OF THE MANUFACTURER OF THOSE PROD-UCTS. PROOF OF PURCHASE MUST BE DOCUMENTED INCLUDING REFERENCE TO A SE-RIAL NUMBER LOCATED ON EACH TOOL. THE PURCHASER’S ONLY REMEDIES UNDER THISLIMITED WARRANTY SHALL BE LIMITED AT MATWELD’S SOLE OPTION TO THE FOLLOWING:REPAIR, REPLACEMENT OR REFUND OF THE PURCHASE PRICE OF THE DEFECTIVE PROD-UCTS. EACH OF THESE REMEDIES REQUIRES TIMELY NOTIFICATION OF THE DEFECT IN THEPRODUCT AND SUBSTANTIATION THAT THE PRODUCT HAS BEEN PROPERLY STORED, MAIN-TAINED AND USED. MATWELD’S OBLIGATIONS HEREUNDER EXTEND ONLY TO THE PUR-CHASER OF THE PRODUCT AND NOT TO ANY THIRD PARTY.

AS A CONDITION PRECEDENT TO MATWELD’S OBLIGATION HEREUNDER, THE DEFECTIVE PROD-UCT MUST NOT HAVE BEEN ALTERED OR MODIFIED WITHOUT THE EXPRESS WRITTEN AP-PROVAL OF MATWELD, INC. THE PRODUCT MUST NOT HAVE BEEN SUBJECTED TO DELIBERATEDAMAGE, SHIPPING DAMAGE, NEGLECT, TAMPERING BY UNAUTHORIZED PERSONNEL OR DAM-AGE BY IMPROPER USE, STORAGE OR MAINTENANCE. SERIAL NUMBERS MUST NOT HAVEBEEN ALTERED, DEFACED OR REMOVED. SUCH ACTION VOIDS LIMITED WARRANTY.

EXCLUSIONS TO LIMITED WARRANTY

THIS LIMITED WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY OTHER WARRANTY, WRIT-TEN OR ORAL, EXPRESSED OR IMPLIED, INCLUDING, WITHOUT LIMITATION, ANY IMPLIEDWARRANTY OR MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

LIMITED WARRANTY DOES NOT COVER NORMAL WEAR AND TEAR ITEMS SUCH AS FILTERS,HOSES, COUPLERS, BITS, SOCKETS, AUGERS, AND BATTERIES.

LIMITATION OF LIABILITY

EXCEPT AS PROVIDED ABOVE, MATWELD SHALL IN NO EVENT BE LIABLE OR RESPONSIBLEFOR ANY INJURY, LOSS OR DAMAGE, DIRECT, INCIDENTAL OR CONSEQUENTIAL, ARISINGOUT OF THE USE OR MISUSE OR INABILITY TO USE THE PRODUCT, HOWEVER CAUSED ANDON ANY THEORY OF LIABILITY INCLUDING, WITHOUT LIMITATIONS, BREACH OF CONTRACT,TORT, (INCLUDING NEGLIGENCE OR STREET LIABILITY) AND NOT WITHSTANDING ANY FAIL-URE OF ANY REMEDY HEREIN OF ITS ESSENTIAL PURPOSE, EVEN IF MATWELD WAS AWAREOF THIS POSSIBILITY OF SUCH DAMAGE. MATWELD’S LIMITED WARRANTY AS SET FORTHABOVE SHALL NOT BE ENLARGED, DIMINISHED OR AFFECTED BY, AND NO OBLIGATION ORLIABILITY SHALL ARISE OR GO OUT OF THE RENDERING OF TECHNICAL ADVICE OR SER-VICE BY MATWELD OR ITS AGENTS. THE FOREGOING MAY NOT BE CHANGED EXCEPT BYWRITTEN AGREEMENT SIGNED BY AN AUTHORIZED OFFICER OF MATWELD, THE REMEDIESSET FORTH HEREIN ARE EXCLUSIVE.

24

MATWELD, INC. PHONE:(270) 444-0085 FAX:(270) 443-6180Matweld reserves the right to change parts, features, or specifications without notice.

Rev. 03/07

Name _____________________________________________________

Company___________________________________________________

Serial # of your Matweld tool___________________________________( Upon receiving your Matweld tool, make sure to list serial number above so that a good record is kept for orderinformation.)

MATWELD HYDRAULIC T OOL LISTAll Matweld Hydraulic Tools operate at

5 or 10 GPM @ 2000 PSI

18. CUSTOMER INFORMATION

POWER UNITS:07000 – HYDRA POWERED MODULAR SYSTEM02900A – DIESEL POWER UNIT00100K – DUAL CIRCUIT POWER UNIT02050 – GASOLINE 1-5 GPM05500 – TWIN POWER DUAL CIRCUIT UNIT 1-10 GPM OR 2-5 GPM & 5000 WATT GENERATOR03700A – ELECTRIC POWER UNIT09800 - TRACK ROVER

TRACK TOOLS:01600A – 5 GPM 1” IMPACT WRENCH02500 - 10 GPM 1” IMPACT WRENCH04500D – ½” IMPACT DRILL00800A – 16” RAIL SAW03900A – REVERSING RAIL SAW01100 A– SPIKE PULLER08200– TIE TAMPER08300– SPIKE DRIVER01500 – RAIL DRILL01000 – CHAIN SAW03500 – SELF FEED RAIL DRILL03100C - RAIL PULLER02800 - BRIDGE SPREADER05000- HAND PUMP WELD SHEAR05100A - POWER WELD SHEAR06600 - POWER UNIT TRANSPORT CART07500 - CHAMFER TOOL

OTHER PRODUCTS:HYDRAULIC MANIFOLDSHYDRAULIC TEST GAUGESHOSE REELSHYDRAULIC HOSESACCESSORIES

GRINDERS:04600 & 04650– STRAIGHT STONE CW & TRIGGER VERSION04700 & 04750 – STRAIGHT STONE CCW & TRIGGER VERSION00600 & 00600C - 8” CUPSTONE GRINDER04800 & 04850 – CUPSTONE & TRIGGER VERSION00700 – RAIL SURFACING GUIDE02400 – 10” OR 14” FROG AND SWITCH GRINDER05900 – FROG/PROFILE GRINDER – ON/OFF FLOW CONTROL05950 – FROG/PROFILE GRINDER – SAFETY TRIGGER06000 – PROFILE GRINDER05400 – ANGLE GRINDER05600 – BULL NOSE GRINDER06950 & 06950A - MULTI-PURPOSE GRINDER