09 Skidding, Jacking & Moving techniques.

Transcript of 09 Skidding, Jacking & Moving techniques.

When objects becometoo big to lift or move bytrailers, skiddingbecomes the preferredoption for moving. Youwill learn about thevarious skidding &moving techniques andthe major companiesactive in this field.

When objects becometoo big to lift or move bytrailers, skiddingbecomes the preferredoption for moving. Youwill learn about thevarious skidding &moving techniques andthe major companiesactive in this field.

09 Skidding, Jacking & Moving techniques.

www.seacamel.com 1May 20, 2021

Module Summary

– Various Skidding & Moving techniques– Skidding Techniques– Example skidding system– Stainless Steel on P.T.F.E. Blocks (Teflon).

Lubricated with backing oil– Self propelled skidbeam system (1)– Self propelled skidbeam system (2)– Hydra-Slide skidding systems– Using winches– Skid system for extreme heavy loads– Load-out of 17700 mT deck– Working Principle of Strand jacks– Using Strand jacks as lifting devices– ALE’s Super Crane SK-190/SK-350 using strand

jacks (1)– ALE’s Super Crane SK-190/SK-350 using strand

jacks (2)– Jacking methods

– Jacking Towers and Gantries– ALE’s Mega Jack System (40,000T) and Mammoet

Push-Up System– ALE’s Mega Jack System (40 - 60,000 T Cap.)– Alternatives moving method: Airbags– Airbags Procedure– Air pressure in bags and stability– Rules for loading operations for loadouts. Friction

May 20, 2021 www.seacamel.com 2

Various Skidding & Moving techniquesSkidding frictions:– Hard wood timber with grease (4-10%)– Rolling with steel rollers (2-5%)– Stainless steel on Teflon (2-6%)

Jacking methods:– Strands Jacks– Climbing jacks (steel or aluminium)– Mega Jack systems (ALE)– Push-Up Systems (Mammoet)

May 20, 2021 www.seacamel.com 3

Load-out methods:– On Platform trailers (SPMT’s or Conventional)– Rail bogies– Skidding

Alternative moving methods:– Rolling on airbags (3-4% friction)– Using Water skates (2-4% friction)– Using Air pallets (2% friction)– Hillman rollers (4-10% friction)– Hydraulic Gantries

Skidding TechniquesSkidding methods:– Hard wood timber with grease (4-10%)– Rolling with steel rollers (2-6%)– Stainless steel on Teflon (2-6%)Propulsion methods:– Wire rope tackles with winches (need anchor points)– Hydraulic push/pull cylinders (no anchor points)– Strand jacks.– Natural slope (shipyard slipway)

May 20, 2021 www.seacamel.com 4

Hard wood timber with grease Stainless steel on Teflon

Rolling

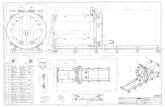

Example skidding systemHydraulic cylinders can be either ontop or next to the skidbeam.In the sketch load is transferred almostdirectly into the top plate of theskidbeam.Operating pressure example system is350bar and tested at 520 bar.

May 20, 2021 www.seacamel.com 5

Stainless Steel on P.T.F.E. Blocks (Teflon). Lubricated with backing oil

6

1. The hydraulic jacks (one in each skid-shoe)equalize the load between skid shoes

2. Movement is made by a hydraulicpush-pull cylinder

May 20, 2021 www.seacamel.com

7

Skid shoes can be moved with strand jacksor can be self propelled. With self propelledskid shoes, there are no push loads in thequay of cargo itself which is an advantage

Self propelled skidbeam system (1)

May 20, 2021 www.seacamel.com

Self Propelled Skidshoe SystemSpecification SPSS

1200SPSS1000

SPSS0650

SPSS0500

SPSS0300

SPSS0150

SPSS0090

Capacity (t) 1200 1000 650 500 300 150 90

Length (mm) 6000 5500 4720 4674 3700 2500 2000

Weight (kg) 13000 9000 5372 4500 1730 610 345Cylinder 1200 2x500 650 500 300 150 90Cylinderstroke 460 300 600 600 400 250 150

Distance 1000 1000 1000 1000 750 500 500Pushing 83/64.3 83/64.3 83/64.3 83/64.3 42.4 16.3 16.3

Pulling 52/33.9 52/33.9 52/33.9 52/33.9 24.3 8.5 8.5

Stroke (mm) 1250/1400

1250/1400 1400 1250/

14001000/1250 600 600

ALE

Mammoet

Self propelled skidbeam system (2)

May 20, 2021 www.seacamel.com 8

Mammoet and ALEhave similar

systems.

Top: MammoetBottom: ALE

6500

1400

-205

0

1517

9

1. The 400 Ton capacity hydraulically poweredHydra-Slide™ "LP" skidding system provides acost-effective, safe, simple and reliable methodfor moving, loading or unloading all types ofheavy loads...

2. Transformers, generators, compressors, pressurevessels, machines, etc….

3. All parts of the skidding system are handportable

LP-400 Low Profile Skid System

http://www.hydra-slide.ca

Hydra-Slide skidding systems

May 20, 2021 www.seacamel.com

Using winches

May 20, 2021 www.seacamel.com 10

Also skidding on woodand grease withwinches will do.

For smaller modulesthis is cheaper.

Wires reeved in winchblocks

Winch with tensionmonitoring.Keep track friction duringthe skidding process

Use breakout jacks toover come initial firstfriction.This is higher thanduring skiddingThis avoids that thestructure breaks outabruptly and uncontrolled.

Use hardwood at bottomof loadout frame.Grace us used to lowerthe friction. Paraffin isused to avoid that thegrease is absorbed by thewood during theconstruction period.

Load-out of 17700 mT deck

May 20, 2021 www.seacamel.com 11

Samsung Heavy IndustriesVyborg deck (Korea)Weight of Deck 17,731 mtVCG (from BoS) 10.49 MLength 84.48 MWidth 72.72 MTotal height 92.00 M

Working Principle of Strand jacksThe strand jack is a linear winchthat originates from the concretepost tensioning principle.A bundle of steel cables orstrands are guided through ahydraulic cylinder. At each sideof the cylinder are wedgesaround the strands (grips)ensuring that the strands canonly pass through in onedirection.By stroking the cylinder in andout while the grips are engagedin the anchors, a lifting orskidding movement is achieved.

May 20, 2021 www.seacamel.com 12

Strand used as tensionmember in crane

Strand jacks used forskidding a crane on barge

Pushing a jacket

ALE SK190 used while lifting a 1200 tonspressure vessel. (Ruwais Refinery ExpansionProject, UAE)

ALE SK190 used while lifting a 1200 tonspressure vessel. (Ruwais Refinery ExpansionProject, UAE)

Using Strand jacks as lifting devices

May 20, 2021 www.seacamel.com 13

ALE’s SK-190 / SK-350 demonstrated in TheNetherlands in Sept. 2008ALE’s SK-190 / SK-350 demonstrated in TheNetherlands in Sept. 2008

Sarens’ Floating Foundation Installer (FFI)performs installation of footings for the NewChamplain Bridge, Canada

Sarens’ Floating Foundation Installer (FFI)performs installation of footings for the NewChamplain Bridge, Canada

1. Mobile Lifting A-Frame to place Modules ontoFPSO’s.Max. Cap 5000 T at 20 m outreach (with 60.8 mmain boom at 69.2m radius) (Outreach countsfrom front of boom foot, radius counts from pivotpoint of crane)

2. Or 3667 tons at 34 m outreach (with 95.4 m mainboom at 83.2 m radius)

3. Max. Load moment 354,000 ton meter

4. Foot of A-Frame (2 x 3000 Tons load) is slewed bymeans of skidding in a curved track

5. Ground load can be limited to + 36 ton/m2

6. Max. jib length: 141 m

ALE’s Super Crane SK-190/SK-350 using strand jacks (1)

May 20, 2021 www.seacamel.com 14

Pivot point ofCrane

ALE’s Super Crane SK-190/SK-350 using strand jacks (2)

May 20, 2021 www.seacamel.com 15

SK-190 Plan view

Hydraulic skid shoes under the ballast areused for weight indication of ballast andsideways movement

Hydraulic skid shoes under the ballast are used for weightindication of ballast and sideways movement

Jacking methods1. Cylindrical jacks2. Climbing jacks3. Mega Jack System4. Hydraulic Gantry systems

May 20, 2021 www.seacamel.com 16

2. Climbing jacks

1. Cylindrical jacks

3. Mega Jack System 4. Hydraulic Gantry systems

Jacking Towers and Gantries– Enerpac SL400 hydraulic gantry is a safe and

efficient solution for lifting and positioningheavy loads. With a lifting capacity of 450 tons(4000 kN) and a maximum lift height of 30 ft(9.1 m).

– Hydraulic gantry in combination with innovativeShark-Link system to lift Generator into buildingor Tunnel boring machine into/out of pit

May 20, 2021 www.seacamel.com 17

ALE’s Mega Jack System (40,000T) and Mammoet Push-Up System

ALE Mega Jack is capable of lifting 60,000 ton to aheight of 25m. It has been developed to help theoffshore industry jack-up increasingly need to liftheavy oil and gas platform modules and otherlarge structures.The system uses jacking towers with a capacity of5,200 ton. Each tower consists of four jackingbases that contain a hydraulic jack with a stroke of1250mm.The number of towers can be increased accordingto the size, weight and balance of the structure.

Mammoet's JS 2400 push-up system allowsclients to build a structure on the ground and raiseit only after it has been fully assembled. Itsmodular nature and cumulative jacking capacity,the system can be configured to lift almost anyload. Each of the towers consists of a modularcolumn that hydraulically raises the object in smallstrokes of 480 millimeters. After each stroke, thesection is secured with a half can, then jacked upanother 480 mm and replaced with a 960 mm fullcan, which is bolted to the set of cans above. Thisprocess is repeated until the structure reaches thedesired height

May 20, 2021 www.seacamel.com 18

ALE’s Mega Jack System (40 - 60,000 T Cap.)

The system is based on 8 similar jacking towers witha capacity of 5000 Tons each, or a combination of3 x 15,000 ton + 2 x 10,000 ton TowersAfter jacking the deck to the required height, thesupport structures or hull structure can be moved inBasic dimension of each jacking tower is 6 x 6 mJacking cylinders (4 x 1,250 T) are at ground level

May 20, 2021 www.seacamel.com 19

ALE, the 42,780-tonne topside is the heaviest load everjacked. It took 11 hours to complete the 24 m lift,.

Rolling on airbags– Lower initial investment

• Towing winch• Air compressor• Marine Airbag

– almost in any types of condition mud road.

Alternatives moving method: Airbags

May 20, 2021 www.seacamel.com 20

Procedure:1. Check on the uneven scar caused by the welding of heavy steel structure to ensure its smooth surface.2. Ensure the structure/ship fully welded before mobilized.3. Tidy up the slope launching slipway to ensure harmful big sharp stone or metal material entirely avoided.4. Mobilization slipway should be in the flat and spacey ground where the structure should always be in the centre

of gravity on top of the airbag.5. Slope decline not greater than 1/7, however, depending on the capability of towing winch machine.6. Air gasbag working altitude should not less than 0.3 meters from the ground to ensure the the structure not in

contact with the ground when slow-moving. For the ship launching process, the working height should not lessthan 0.5 meters.

7. Attach the towing winch with structure and tighten the wire.8. Place the airbags with a distance of 0.5 ~ 3.0m. In the way of sharp keel bottom structures, the distance

between the air gasbag should not more than 1.0m.9. Adjust the required working height. This should not less than 0.5m by compressed inner pressure selected

airbag.10.Initiate the towing winch by gradually pulling. Due to the inertia, the object will move against gravity and

friction.11.Check stability on land and in the water

Airbags Procedure

May 20, 2021 www.seacamel.com 21

http://WWW.MAX-GROUPS.COM

Air pressure in bags and stability

May 20, 2021 www.seacamel.com 22

Flat bottom

V-shape bottom

– Be aware of jumping loads when using strand jack or winches.è Demonstration.– Use break out cylinders and consider skew loads.

Rules for loading operations for loadouts. Friction

May 20, 2021 www.seacamel.com 23

Upper bound design friction coefficientsSliding (rolling) Surfaces Static Moving Notes

1 Steel/steel 0.3 0.2 a) It is assumed that the sliding surfaces are properlylubricated.

b) Break out factor to account for extra loading due tolong term effects such as adhesion, settlements, etc.is included in the static coefficients.

c) The values are valid only for contact stresses loweror equal to the allowable contact stresses for theconsidered medium. Allowable contact stressesshould be obtained from the manufacturer or from anapplicable code or standard.

d) Wood should normally be surface treated by wax orby other adequate means in order to avoid that thelubrication is absorbed by the wood.

e) The “friction” in items 7 to 9 is “rolling resistance”and properly compacted gravel is assumed in item 9.

2 Teflon/steel 0.25 0.1

3 Teflon/stainlesssteel

0.2 0.07

4 Teflon/wood(without wax)

0.4 0.1

5 Teflon/waxed wood 0.2 0.07

6 Steel/Waxed wood 0.2 0.12

7 Steel rollers/steel 0.02 0.02

8 Rubber tires/asphalt 0.03 0.03

9 Rubber tires/gravel 0.05 0.05

Offs

hore

Sta

ndar

d DN

V-O

S-H2

01,

April

201

2