07 Ejection

description

Transcript of 07 Ejection

-

EJECTION

-

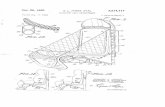

PARTS OF 2 PLATE MOLDTop plateCavity plate Core plateGuide pillarGuide BushCore Back PlateEjector pinSpacersCentering BushBottom plateEje. Guide BushEje. Guide pillarEje. Back plateSprue pull & EjectorEjector plateSprue puller bushReturn pinStop buttonSprue BushRegister ringCore insertCavity insert

-

PLAY

-

EJECTIONEjection function of a mould is delicate since the part while solidifying shrinks to grip over the core tightly which makes smooth release without distortion, strain mark, break or damage of component very difficult. Parting surface selected in mouldStraight surfaces of mould cavity & coreVacuum created by part sliding on core Undercut in part designDesign of ribs, boss and surface textureThin walled parts moulding some design aspects that causeejection difficulty :--

-

EJECTION Various ways of minimizing ejection difficultiesApply releasing agentPolish core in the direction of ejectionProvide suitable draftDecrease cooling time of mouldingDecrease injection rateDecrease holding pressureDecrease holding timeSlowdown ejection speedDecrease mould temperaturePlating with low friction surfaceProvide air poppets to release vacuum

-

TYPES OF EJECTORS Straight Pin EjectorStepped Pin EjectorSleeve EjectorBlade EjectorStripper Plate EjectorStripper Ring EjectorStripper Bar Ejector Valve EjectorAir Ejection

-

EJECTION TYPE 1. PIN EJECTORPin ejectors are the simplest and most widely used ejection types to remove the moulding from core of the mould. Pin ejectors are hardened cylindrical Steel pins held in ejector plate and made to slide through the hole in core insert. Number of such ejector pins positioned on the core make smooth ejection of moulding during the forward ejection stroke,but mark of ejection will be visible.

-

Sleeve ejector is a hollow cylindrical pin similar to pin ejector. It is also held in ejector plate and guided over core pin. During forward ejection stroke the sleeve pushes the moulding out of the core pin which holds it. Best suited for ejecting bosses on a component. EJECTION TYPES 2. SLEEVE EJECTOR

-

Sleeve Ejector Assembly

-

EJECTION TYPES 3. BLADE EJECTORFor ejection of thin walled mouldings, instead of pin ejector rectangular blades of thickness equal to part and suitable width are used so as to increase the ejection area.

-

STRIPPER PLATE EJECTIONBest ejection arrangement for thin walled moldingsIncreased area of ejection because of all- round nature of ejectionSuitable for multicavity moulds of cylindrical parts.No witness mark seen on part at ejection portion.

-

COMPONENTSTRIPPER PLATECORESTRIPPER BOLTSTRIPPER PLATE EJECTION

-

COMPONENTSTRIPPER PLATECORESTRIPPER BOLTSTRIPPER PLATE EJECTION

-

Stripper Ring EjectionCORE INSERT

-

VALVE EJECTORCORE INSERTMOULDINGVALVE EJECTOREJECTOR PLATE

-

AIR EJECTORMOULDING

-

AIR VALVE EJECTORSEALNUTSPRINGAIR VALVE3 SLOTSAIRSEC-XX

-

AIR POPPET VALVETo break vacuum and ease ejection

-

EJECTION REQUIREMENTS OF A MOULDThe minimum Ejection required for a mould is arrived at by the following thumb rule : -

Minimum Area of Ejection = 1 % of total lateral surface area of component in contact with Core. ie. No. of ejector pins x Area of each ejector pin = sum of lateral surface area of component in contact with Core / 100

-

SELECTION OF EJECTORSPin Ejectors are easy to manufacture to high accuracy and its corresponding hole in Core to slide also economically produce able.Provide more ejector pins than the calculated minimumDistribute the total no. of pins equally for uniform release.Parting surface ejector pins are more effective than face ejectors.Position no. of ejection pins near Bosses, Ribs and other obstructions.Thin walled components are better ejected by stripper or sleeveTransparent components are suitable for Blade or Stripper Ejection