07 - Cylinder - Piston

-

Upload

erick-rivas -

Category

Documents

-

view

215 -

download

0

Transcript of 07 - Cylinder - Piston

-

8/11/2019 07 - Cylinder - Piston

1/9

SERVICE INFORMATION 7-1

TROUBLESHOOTING 7-1

CYLINDER REMOVAL 7-2

PISTON REMOVAL 7-3

PISTON INSTALLATION 7-5

CYLINDER INSTALLATION 7-6

SERVICE INFORMATION

GENERAL

C lean all disassem bled parts w ith clean solvent and dry them by blow ing them off w ith com pressed air before inspection.

SPECIFICATIONSUnit: mm (in)

ITEM Standard Service lim it

C ylinder I.D . 63.500-63.510 (2.5000-2.5003) 63.60 (2.504)

Taper 0.10 (0.004)

O ut of round 0.10 (0.004)

W arpage across top 0.10 (0.004)

, Piston O .D . 63.470-63.490 (2.4988-2.4996) 63.42 (2.495)

Piston pin bore 15.002-15.008 (0.5906-0.5908) 15.04 (0.592)

Piston pin O .D . 14.994-15.000 (0.5903-0.5906) 14.96 (0.589)

Piston-to-pin clearance 0.002-0.014 (0.0001-0.0006) 0.02 (0.001)

Top 0.025-0.055 (0.001-0.002) 0.09 (0.004)

Second 0.015-0.045 (0.0006-0.0017) 0.09 (0.004)

Top 0.20-0.35 (0.008-0.014) 0.5 (0.02)

Second 0.35-0.50 (0.014-0.020) 0.7 (0.03)

O il ring (side rail) 0.20-0.70 (0.008-0.028) 0.9 (0.04)

C ylinder-to-piston clearance 0.010-0.040 (0.0004-0.0016) 0.10 (0.004)

C onnecting rod sm all end I.D . 15.010-15.028 (0.5909-0.5917) 15.06 (0.593)

C onnecting rod-to-piston pin clearance 0.010-0.034 (0.0004-0.0013) 0.10 (0.004)

XL200 7. CYLINDER/PISTON

7-1

Piston ring end gap

Piston ring-to-ringgroove clearance

Piston, pistonpin, piston rings

TROUBLESHOOTING

Low or unstable compression OverheatingW orn cylind er or p iston ring E xcessive carb on b uilt-up on p iston or com bustion cham b er

Excessive smoke Knocking abnormal noise

W orn cylind er, p iston, or p iston ring W orn p iston and cylind erIm proper installation of piston ring Excessive carbon built-up on piston or com bustion cham ber

Scored or scratched piston or cylind er w all

-

8/11/2019 07 - Cylinder - Piston

2/9

XL200C YLIN D ER /PISTO N

7-0

-

8/11/2019 07 - Cylinder - Piston

3/9

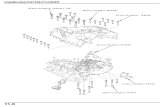

GASKET

DOWEL PINS

CYLINDER

XL200

7-2

CYLINDER REMOVAL

R em ove the eng ine.

R em ove the cylinder head.

R em ove the cylind er.

R em ove the follow ing :

G asket

D ow el pins

C lean off any gasket m aterial from the cylinder surface.

N O T E

B e careful not to dam ag e the gasket surface.

INSPECTION

C heck the cylind er for w arpag e w ith a straight ed ge and a feeler

gauge.

SERVICE LIMIT: 0.10 mm (0.004 in)

Insp ect the cylind er bore for w ear or dam ag e.

M easure the cylind er I.D . at three places; m iddle and bottom

area of piston travel, and in tw o directions at right angles to each

other.

SERVICE LIMIT: 63.60 mm (2.504 in)

M easure the piston O .D . (pag e 7-4) and calculate the piston-to-

cylind er clearance using the m axim um cylind er I.D

m easurem ent.

SERVICE LIMIT: 0.10 mm (0.004 in)

C YLIN D ER /PISTO N

-

8/11/2019 07 - Cylinder - Piston

4/9

XL200 C YLIN D ER /PISTO N

7-3

M easure the cylind er for taper at three levels in an X and Y axis.

Take the m axim um reading to d eterm ine the tap er.

SERVICE LIMIT: 0.10 mm (0.004 in)

M easure the cylind er for out of round at three levels in an X and

Y axis.

Take the m axim um reading to d eterm ine the out of round .

SERVICE LIMIT: 0.10 mm (0.004 in)

PISTON REMOVAL

Place clean shop tow el in the crankcase to prevent the piston pin

clips or other parts from falling into the crankcase.

R em ove the p iston p in clip w ith p liers.

Press the piston pin out of the piston from the opposite side w ith

your finger.

R em ove the piston.

R em ove the piston ring s being careful not to d am age them .

N O T E

Spread each p iston ring and rem ove it by lifting up at a

point opposite side.

PISTON/PISTON RING INSPECTION

C lean the top of the piston.

Insp ect for evidence of pitting or deterioration.

U se and old piston ring to rem ove the carbon and oil dep osits

from the ring groove.

h

Do not damage the piston ring grooves.

Do not use a wire brush to clean ring grooves and lands: a

wire brush can damage these areas.

PISTON PIN CLIP

PISTON

(2) TOP

EXIN

(4) MIDDLE

(5) BOTTOM

PISTON

PISTON

PISTONRING

PISTON RING

-

8/11/2019 07 - Cylinder - Piston

5/9

XL200

7-4

Tem porarily install the piston rings in their proper positions w ith

the m arks facing up.

M easure the p iston ring-to-ring groove clearance w ith a feeler

gauge.

SERVICE LIMIT:

Top: 0.09 mm (0.004 in)Second: 0.09 mm (0.004 in)

Insp ect the piston for w ear or dam ag e.

Insert each piston ring into the cylinder using the piston head

and m easure the ring end gap in the cylind er at a p oint 10 m m

(0.4 in) from the bottom .

SERVICE LIMIT:

Top: 0.5 mm (0.02 in)Second: 0.7 mm (0.03 in)Oil: 0.9 mm (0.04 in)

M easure the piston O .D . at 10 m m (0.4 in) from the bottom of the

skirt.

SERVICE LIMIT: 63.42 mm (2.495 in)

C om pare this m easurem ent ag ainst the service lim it and use it to

calculate piston-to-cylinder clearance (see page 7-2).

M easure the piston pin bore I.D . in tw o direction at right angle to

each other.

SERVICE LIMIT: 15.04 mm (0.592 in)

M easure the piston pin O .D . at the left, center and right in tw o

direction at right angles to each other.

SERVICE LIMIT: 14.96 mm (0.589 in)

C alculate the piston-to-piston pin clearance.

SERVICE LIMIT: 0.02 mm (0.001 in)

C YLIN D ER /PISTO N

PISTON

CYLINDERPISTON RING

(10 mm (0.4 in)

PISTON

PISTON PIN

-

8/11/2019 07 - Cylinder - Piston

6/9

XL200 C YLIN D ER /PISTO N

7-5

M easure the connecting rod sm all end I.D .

SERVICE LIMIT: 15.06 mm (0.593 in)

C alculate the piston pin-to-connecting rod clearance.

SERVICE LIMIT: 0.10 mm (0.004 in)

PISTON INSTALLATION

PISTON RING INSTALLATION

N O T E

C arefully install the piston rings w ith the m arking facing up.

Stagger the piston ring end gap s 120 d eg rees ap art from eachother as show n.

A fter installation, the piston rings should be free to rotate in the

grooves.

Insert the outside surface of the ring into the proper ring

groove and roll the ring around in the groove to m ake sure

that the ring has a free fit around the pistons

circum ference.

Be careful not to d am ag e the piston and piston ring s during

installation.

D o not interchang e the top ring w ith the second ring .

W hen installing the oil ring, install the sp acer first and then

the side rails.

D o not align the gaps of the oil ring side rails.

(1) PISTON RING MARK

(2) GAP

-

8/11/2019 07 - Cylinder - Piston

7/9

XL200

7-6

PISTON INSTALLATION

Place clean shop tow el in the crankcase to prevent the piston pin

clips or other parts from falling into the crankcase.

A pply oil to the outer surface of the p iston p in.

Install the piston w ith the INm ark facing the intake side.

Install the p iston p in and new piston p in clips.N O T E

D o not reuse piston pin clips.

D o not align the piston pin clip end gap w ith the piston cut-out.

R em ove any gasket m aterial from the cylind er gasket surface on

the crankcase.

N O T E

D o not dam ag e the g asket surface.D o not let any m aterial fall into the crankcase.

CYLINDER INSTALLATION

Install the follow ing:D ow el pins

N ew cylinder gasket

C oat the cylinder, piston rings/grooves and piston w ith clean

engine oil.

Install the cylinder w hile com pressing the piston rings w ith your

finger.

N O T E

Install the cylinder head (page 6-14).

Install the engine (C ap. 5 or 28).

B e careful not to dam ag e the piston ring s.

D o not let the cam chain fall into the crankcase.

C YLIN D ER /PISTO N

DOWEL PINS

CLIP PISTON PIN

PISTON

GASKET

DOWEL PINS

CYLINDER

-

8/11/2019 07 - Cylinder - Piston

8/9

XL200 C YLIN D ER /PISTO N

7-7

NOTAS

-

8/11/2019 07 - Cylinder - Piston

9/9

G ENERA L IN FO RM ATIO N

HOW TO USE THIS MANUAL

This service m anual describes the service

proced ure for the XL200.

Throughout the m anual, the follow ing

abbreviations are used to identify individual

m odels.

Follow the M aintenance Sched ule (Section 3)

recom m endations to ensure that the vehicle is in

peak operation cond ition.

Perform ing the first scheduled m aintenance is very

im portant. It com pensates for the initial w ear that

occurs during the break-in p eriod .

Section 1 through 3 apply to the w hole m otorcycle,

w hile section 4 throug h 18 describe parts of the

m otorcycle, grouped according to location.

Find the section you w ant on this p ag e, then turn to

the tab le of contents on pag e 1 of that section.

M ost sections start w ith an assem bly or system

illustration, service inform ation and troubleshooting

for the section, the subsequent pag es g ive detailed

procedures.

If you dont know the source of the trouble, go to

section 20 TRO U BLES H O O TIN G .

A ll inform ation, illustrations, directions and

sp ecifications included in this publication are

based on the latest product inform ation available

at the tim e of approval for printing. M O TO

H O N D A D A A M AZ N IA LTD A. Reserves the

right to m ake chang es at any tim e w ithout notice

and w ithout incurring any oblication w hatever.

N ot part of this pub lication m ay be reprod uced

w ithout w ritten perm ission.

CONTENTS

G ENERA L IN FO RM ATIO N 1

LU BR IC A TIO N

2M AIN TENAN C E 3

FUEL SYSTEM 4

EN G IN E RE M O VA L/IN STALLATIO N 5

C YLIN D ER H EAD /VALVES 6

C YLIN D ER /PISTO N 7

C LUTC H /G EAR SH IFT LIN KA G E 8

ALTERN ATO R/STARTER CLUTC H 9

C RA N KSH AFT/KIC KSTAR TER/TRAN SM ISSIO N 10

FRO N T W H EEL/SU SPEN SIO N /STEERIN G 11

REA R W H EEL/SU SPENSIO N 12

H YDR AU LIC BRA KE 13

FAIR IN G /EXH A U ST SYS TEM 14

C H ARG IN G SYSTEM 15

IG N ITIO N SY STEM

16ELEC TRIC STA RTER 17

LIG H TS/M ETERS /SW ITC H ESELECTRIC

ST

ARTER

FRAME

ENGINE

18

W IRIN G D IAG RA M 19

TRO U BLESHO O TIN G 20

C ode A rea (type)

D K G eneral Type

2LA Latin A m erica

http://informat.pdf/http://informat.pdf/http://lubricat.pdf/http://lubricat.pdf/http://mainten.pdf/http://mainten.pdf/http://fuel.pdf/http://fuel.pdf/http://engine.pdf/http://engine.pdf/http://head.pdf/http://head.pdf/http://cylinder.pdf/http://cylinder.pdf/http://clutch.pdf/http://clutch.pdf/http://alternat.pdf/http://alternat.pdf/http://transmis.pdf/http://transmis.pdf/http://transmis.pdf/http://suspens.pdf/http://suspens.pdf/http://rearwhee.pdf/http://rearwhee.pdf/http://brake.pdf/http://brake.pdf/http://fairing.pdf/http://fairing.pdf/http://battery.pdf/http://battery.pdf/http://ignition.pdf/http://ignition.pdf/http://starter.pdf/http://starter.pdf/http://lights.pdf/http://lights.pdf/http://diagram.pdf/http://diagram.pdf/http://troubles.pdf/http://troubles.pdf/http://troubles.pdf/http://diagram.pdf/http://lights.pdf/http://starter.pdf/http://ignition.pdf/http://battery.pdf/http://fairing.pdf/http://brake.pdf/http://rearwhee.pdf/http://suspens.pdf/http://transmis.pdf/http://alternat.pdf/http://clutch.pdf/http://cylinder.pdf/http://head.pdf/http://engine.pdf/http://fuel.pdf/http://mainten.pdf/http://lubricat.pdf/http://informat.pdf/