0403000 press sectionr

-

Upload

khanhhoipnp -

Category

Business

-

view

1.288 -

download

0

Transcript of 0403000 press sectionr

VKPC – PM#1

Training

Press Section

Introduction

1. Introduction Trainer

2. Training Schedule

Introduction of the Trainer

Takeshi Nonogaki

Paper Machine Engineering Dept.

Technical Data

1. Basic Design Data

2. Technical Specification

Basic Design Data – Layout data

Design widthWire width 5.950 mmUntrimmed paper width on pope 5.300 mm

Basis weightT1 (Pulp on Top) 125 - 275 gsmT2 (100% OCC) 125 - 250 gsmCM 105 - 125 gsm

Design production At PM reel max. 744 to/24hWith efficiency 100%Moisture at reel 8%Basis weight 125 gsm (Reference liner grade)

Paper Grade Liner Board (Test Liner: T1, T2)Corrugating Medium

Basic Design Data – Layout data

Reel spoolMax. parent reel diameter: 3.000 mm

Hand of machineStanding at the headbox facing the reel: Drive on right hand side

Operating speedProduction speed range 355 - 800 m/minDrive speed 900 m/minDesign speed 900 m/minBalancing speed 900 m/min

Technology

1. Functions of the Press Section

2. Optimization of Paper Quality

3. Trouble shooting

Functions of the Press SectionSee Animation

Mechanical removal of water

Determination of surface properties

Influence bulk

Increase wet web strength

Maximum runnability

Maximum availability

Optimization of Paper Quality

Moisture cross profile

Twosidedness

Roughness

Moisture Cross Profile

It is possible, that the moisture cross profile is not satisfying after the wet end of the machinePossible reasons: HP/LP-Nozzles blocked Felt condition uneven Catch pans are overflowing Uhlebox dewatering is uneven Hydrostatic press shoe hydraulics are malfunctioning Press shoe is damaged Felt design unsuitable for machine Optimize void volume of sleeve

Twosidedness and Roughness

Twosidedness and Roughness can be influenced slightly through shifting the press loads from the first to the second press or visa versa

The main influencing factor though is the design of the press felt: All successful machines have gone through an optimisation process In this process a compromise between surface characteristics, dry content and runnability has to be found

Optimization of Press Section: General Hints

Check felt tension with hand measurement device

Use HP-shower for felt conditioning according your own

experience

Use schedule for HP-shower for roll cleaning

Adjust vacua in uhle boxes according felt life time

Trouble shooting – Dryness after Press too low

Possible causes:

Dryness after Former too low Temperature of the pulp too low Pulp too strong beaten Deflector Stripes not in ideal position Line force too low Steam blow box not in operation Press roll storage volume dirty Problems with the felts (see next slide)

Trouble shooting – Dryness after Press too low

Possible causes (Felt & Feltconditioning):

Structural resistance of the felt too high To high re-moisturization Needleing inhomogeneous Too fine felts Too light basis weight of felt End of felt life time New felt: Nip-dewatering has not startet Filler content too high in the felts

Trouble shooting – Edge Trim follows the Felt

Possible causes:

Felt too smooth in the edge section Edge moisture too high Pick-up suction roll holes plugged in the edge section Edge trim too narrow Trim-Guard settings false

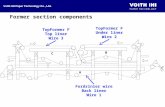

Components

1. Rolls2. Equipment3. Shower4. Movement5. Detail

- ZZ box- NipcoFlex Press

6. Hydraulic system7. Pneumatic system8. C & I

Rolls

NipcoFlex-Roll

Press Roll

Suction Roll

Felt Roll

Equipment

Stretcher

Guide

Zig-zag Suction Box

Transfer Suction Box

Doctor

Shower

Oscillating high- pressure Shower for felt cleaning

Shower for felt edge moistening unit

Low-pressure shower forroll cleaning

Chemical shower

Internal pick-up suctionroll shower

Oscillating high- pressure shower for roll cleaning

Low-pressure shower(Doctor)

Moistening Transfer Box

Movement

Top roll lifting(for sleeve, felt changing)

Pick up roll liftingLead-out roll lifting(for paper threading)

Lead-in roll lifting(for felt changing)

Lead-out roll lifting(for adjusting)

ZR-Oxid ZIG-ZAG Uhle Box Cover

Extends Felt Life

Improves Felt Cleaning

Reduces Drag Load

Improves Moisture Profile

Adjustable Slot Width

Zig-Zag Cover

ZIG ZAG

Zig Zag operational sequence

ZIG ZAG

Zig Zag operational sequence

Demonstration of Constant Slot Width in MD

The NipcoFlex Roll

Click on the Picture for Animation

Cross Section of the NipcoFlex Roll

Cross Section of the NipcoFlex Roll

pressure shoe

loading element

cooling oil distributor

pressure oil

oil return

lubricating andcooling oil

press sleeve

sleeve guide bars

beam (cast iron)

Longitudinal Section of the NipcoFlex Roll

Tenderside

Driveside

Returnspring

Presssleeve

Edgeloading

Loadingelement

Pressshoe

Beam

Clampingdisk

Spring

The Function of the Shoe

Click on the Picture for Animation

M M

x 35

A10

A8

M3

M4

A12DN 50M1

M

M2

A8DN 50

A10

14

3

NF104005

2

Blower Unit of the NipcoFlex Roll

Blower

Blower Unit of the NipcoFlex Roll

One Blower is in Operation

One Blower is Stand-By

NipcoFlex Roll

Air Inlet Filter

Hand Valve

Non Return Valve

Silencer

Motor Control Valve

The Blower

Pressurise the

NipcoFlex Roll

The Motor Control

Valve Limit the

Sleeve Pressure

Air from the

NipcoFlex Roll

and Fresh Air get

into the Blower

The Difference

Pressure is used

to Evacuate the

Oil out of the

NipcoFlex Roll

The Function of the Blower Unit

Click on the Picture for Animation

Internal Pneumatic Support Strip

A: Distance of Doctor Blade to Pneumatic Supporting Strip Center

W: Contact Angle

1. Pneumatic supporting strip

2. Water scraper holder

3. Water scraper beam

4. Press sleeve of NipcoFlex-roll

5. Water scraper blade

Function of the Pneumatic Supporting Strip

Click on the Picture for Animation

P4.14-0065

Tender side Drive side

NipcoFlex roll

Press roll

Nip load

Flow of Forces

2P 1P

Sleeve Cooling Line

LubricationLine

PressureLine

CirculationLine

Hydraulic Unit – Circuit Diagram

Operation

Stand-by

Hydraulic Unit – Tank Unit

Hydraulic Unit – 1P/2P Pump Unit (2pcs)

Hydraulic Unit – Cooling Unit 1

Hydraulic Unit – Cooling Unit 2

Press Pneumatic Valve Stand Piping Diagram (1)

Press Pneumatic Valve Stand

Press – Doctor Pneumatic Valve Stand

Press Pneumatic Valve Stand Piping Diagram (1)

Felt Guide Panel

1,2P Sleeve Pressure Gauge Panel

Operation Panel – 1P Nip Data Set

Operation Panel – 2P Nip Data Set

Operation Panel – Motion Monitor

Operation Panel – Data Monitor

Operation Panel – 1P Nip Pump

Operation Panel – NFP Pump

Operation Panel – Suction Pick-up

Operation Panel – Felt Roll

Operation Panel – Operation SW

Operation Panel – Hydraulic Pump

Operation Panel – Interlock

Operation Panel – 1PTIC setting

Operation Panel – Suction Pick-up Maintenance

Operation Panel – 1/2P Nip Test

Operation Panel – Alarm Data Set

Operation Panel – Timer Data Set

Operation Panel – PLC Input 1

ALARM EDGE GUIDE

TENSION CONTROL

Operation

Operation and Settings

- How to use Press

- How to install Sleeve

- How to install Felt

Start

Stop

Parts of the NipcoFlex Press

1. Shims s

3. Locks

5. Precentering device

6. Pretensioning cylinder

2. Locking clamp

4. Naming on the locks

5.

3.4.

6.

2.

1.

7. 7. Shims t

The roll combination

P4.14-0108

The locks are inserted

Hydraulic cylinder for lifting the top roll

Adjusting the press nip for NipcoP = Ø 1480 mm

1. Shim s 3. Intermediate piece2. Lock 4. Shim t

Diameter of Press Roll [mm]

Shim thickness s [mm]

Shim thickness t [mm]

1480 – 1475 9 15

1474.9 – 1470 11 12

1469.9 – 1465 14 10

1464.9 – 1460 16 7

1459.9 – 1455 19 5

1454.9 - 1450 21 2

Shim thickness as a funktion of Press Roll diameter (if diameter chanes more than 2mm > readjust the nip)

How to pretension the locks

pretensioning cylinder

precentering device

How to close the press

• Insert all locks according to marking on the bearing support

• Raise the NipcoFlex Roll with the pretensioning cylinders (Pressure for tightening 27.7 MPa)

• Lock the pretensioning cylinder with the lock nut (turn down)

All steps for TS and DS

The press is now closed and the locks are pretensioned

• Insert the locking clamps

The Closed press(ready for operation)

How to open the press

The pretension of the locks has been taken away, the press is open

• Supply the pretensioning cylinder with 30.5 MPa for loosen the lock nut

• Turn the lock nut completely upwards

• Relive the pretensioning cylinder

All steps for TS and DS

• The Roll is now lowered onto the intermediate piece

How to install the QualiFlex™ Sleeve

Threading/Installation device for the sleeve

How to drape the QualiFlexTM sleeve

Clamping Disc with segments

Fastening press sleeve

Torque for the screws 150 Nm

1. Sleeve 2. Lever 3. Clamping segment4. Screw 5. Clamping pin

Pull over the flap

How to fix the sleeve

step 1 step 2 step 3 ..........

Segment 2

Sleeve

Segment 1

turn 60 °

Segment 3

Sleeve Segment 1

Segment 2

turn 60 °

Segment 1

Sleeve

turn 180 °

• If damages are noticed on the guide rails they should be eliminated immediately.

• The sleeve should be lifted out of the transport case on the supplied rod.

• Don‘t pull the sleeve on the mounting device without the supplied rod

• The sleeve must be draped for at least 24 hours • It is recommended to apply oil inside the sleeve

• Shift the sleeve continously 10 mm per week

• Check both clamping disks about the shifted way and clean the moving area frequently.

How to install Felt

Felt Changing 1P Top

1. All rolls are in felt changing position.2. Use crane to put felt stretcher roll into parking support.

Felt stretcher roll

Felt Changing 1P Top

1. Remove movable platform and walkways.2. Remove the spacer blocks.

Felt Changing 1P Top

1. Install new felt into the decvice.

Traveling device

Rope(inside)Rope

(inside)

Rope(outside)

Cramp

2. Roll off the felt loop appox. 21m.

3. Set tension rope.

4. Pull up the felt with crane.

5. Attach felt cramps.

6. Run-in the felt.

CrampCramp

Traveling device 1. Traveling device with disc brake

2. Traveling device without disc brake3. Felt pole4. Fixing bolt (M12 x 25)

5. Clamping device6. Shackle7. Crane hook

1. Insert the felt traveling-in device into both sides of felt pole.

2. Fasten fixing bolts (4)

3. Tighten the clamping device (5)

4. Connect the traveling in device to crane hook using shackle and slings on the tending and the drive side.

The felt travelling-in device is suspended from the crane outside the machine.

Fastening the pull rope

Eye bolt

RopeFelt Loop

1. Pull the end of the rope through the felt loop or under the felt loop toward the tending side framing.

2. Hang the rope with the belt hook in the eye bolts.

Felt Changing 2P Top

1. All rolls are in felt changing position.

Felt stretcher roll

Felt regulating roll

2. Use crane to put felt stretcher roll into parking support.

Felt Changing 2P Top

2. Remove movable platform and walkways.1. Remove the spacer blocks.

Felt Changing 2P Top

Traveling device

Rope(inside)

Cramp

Rope(inside)

Cramp

Cramp

1. Install the new felt into the device.

2. Roll off the felt loop appox. 18m.

3. Set tension rope to the machine through the felt loop.

4. Set the device to the rail.

5. Attach felt cramps.

6. Run-in the felt.

Rail

Felt Changing 1P/2P Bottom

1. All rolls are in felt changing position.

NipcoFlex roll

Pick-up suction roll

Felt lead-in roll

1P topFelt lead-in

roll

Felt lead-out roll

1FL felt stretch roll

Felt Changing 1P/2P Bottom

1. Slide the stretch roll to the Tending side

Felt Changing 1P/2P Bottom

2. Remove movable platform and walkways.

1. Remove the spacer blocks.

20sec10sec

OperationMode

Opera-tion

Mainte-nance

1- OD- 4201 COS

1P NFPPumps

ON

OFF

1- OD- 4201 GP

NFP Circulation Pump(1- M- 4216/ 4217)ON

NFP Hyd. tank level > LL(1- LI- 4222)

Yes

No

NFP Supply oil flow > L(1- FS- 4204.N)

Yes

No

NFP Circulation Pump(1- M- 4216 & 4217)

OFF

AND

AND

1P NFP Pres. Pump(1- M- 4212 & 4213)

OFF

1P NFP Lub. Pump(1- M- 4208 & 4209)OFF

1P NFP Pres. Pump(1- M- 4212/ 4213)

ON

1P NFP Lub. Pump(1- M- 4208/ 4209)

ON

1P NFP Blower(1- M- 4218/ 4219)ON

1P Pres. Oil ON- LOAD (L)(1- SOL- 4201.AH)

ON

1P Slv cooling ON- LOAD(1- SOL- 4202.H)

ON

1P Lub. Oil ON- LOAD(1- SOL- 4204.H)

ON

20sec1sec

20sec1sec

1P Top roll “operation”(1- PX- 4223)

Yes

No

20sec1sec

NFP Supply oil temp. > 35℃ (1- TT- 4220)1P Sleeve pressure > LL (1- PT4210A)1P Sleeve cooling oil flow = 0 l/ min (1- FT-4204)1P Shaft seal lub. oil flow (T) = 0 l/ min (1- FT- 4206)1P Shaft seal lub. oil flow (D) = 0 l/ min (1- FT- 4207)1P BRG lub. oil flow (T) = 0 l/ min (1- FT- 4208)1P BRG lub. oil flow (D) = 0 l/ min (1- FT- 4209)1P Nip load = 0 kN/ m (1- PT-4202)Suc. Pick up roll “Ready Position” (1- PX- 4212)1PB Lead- in roll “Upper limit” (1- PX- 4226)1PB Lead- out roll “Lower limit” (1- PX- 4229)

Yes

No

20sec30sec

1P Sleeve cooling(1- SOL- 4203.H)

ON

1P Slv cooling oil Flow CV(1- FCV- 4204)

close

Ope.Pos.

1P Sleeve Pressure CV(1- PIC- 4210)

1P “Crawl Ready”

AND

1P Sleeve cooling(1- SOL- 4203.H)OFF

1P Slv cooling oil Flow CV(1- FCV- 4204)

open

StartPos.

1P Sleeve Pressure CV(1- PIC- 4210)

1P Nip load(1- PCV- 4202)

Close

(DRIVE)1P Run

Stop

DC PB

CrawlJ og

1P “Crawl”

1P Sleeve cooling(1- SOL- 4203.H)

ON

1P Lubrication(1- SOL- 4205.H)ON

1P > 0 m/ min

Yes

No

1P Sleeve pressure > LL (1- PT4210A)1P Shaft seal lub. oil flow (T) > LL (1- FT- 4206)1P Shaft seal lub. oil flow (D) > LL (1- FT- 4207)1P BRG lub. oil flow (T) > LL (1- FT- 4208)1P BRG lub. oil flow (D) > LL (1- FT- 4209)1P Nip load “Close” (1-PT-4202)

Yes

No

Pick- up roll scraper(1- SOL- 4220.P)ON

Pu rollScratper

ON

OFF

1- OD- 4201 GP

Operation Procedure

PuR HP-showerOscillate

ON

DCS PBPu roll HP-shower

Oscillate(1- M- 4201)

ON

1PT HP- showerOscillate ON

DCS PB

1PT HP- shower Oscillate(1- M- 4202)ON

1PB HP- showerOscillate ON

DCS PB

1PB HP- shower Oscillate(1- M- 4203)ON

1P “Crawl”

Yes

No

1P TrSB Moist.Shower HV

ON

DCS PB

1P TrSB Moist. shower HV(1- HV- 4225)

ON

PuR HP-showerHV

ON

DCS PB

Pu roll HP- shower HV(1- HV- 4223)ON

Oscillate Detect(1- PX- 4217)

Yes

NoPu roll HP- shower HV

(1- HV- 4223)OFF

1PT HP- showerHV

ON

DCS PB

1PT HP- shower HV(1- HV- 4224)ON

Oscillate Detect(1- PX- 4218)

Yes

No1PT HP- shower HV

(1- HV- 4224)OFF

1PB HP- showerHV ON

DCS PB

1PT HP- shower HV(1- HV- 4226)ON

Oscillate Detect(1- PX- 4230)

Yes

No1PT HP- shower HV

(1- HV- 4226)OFF

1P “Low-speed Ready”

1P TrSB Moist. shower HV “Open”(1- HV- 4225.LO)

Yes

No

1P Sleeve cooling oil flow > LL(1- FT- 4204)

Yes

No

1P “Run ready”

1P > “Low speed”

Yes

No

1P “Running speed”

Yes

No

1P Nip “Threading load Ready”

1P “Low speed”(DRIVE)

1P RunStop

DC PB

CrawlJ og

AND

1P Slv cooling oil Flow CV(1- FCV- 4204)

Ope.Pos.

Ope.Pos.

1P Sleeve Pressure CV(1- PIC- 4210)

Thread1P Nip

Open

Press

1-OD-4201 PB

Close1P Nip load

(1- PCV- 4202)ThreadAND

1P Pres. Oil ON- LOAD (L)(1- SOL- 4201.AH)

OFF

1P Nip load “Threading”(1- PT- 4202)

Yes

No

1P Pres. Oil ON- LOAD (H)(1- SOL- 4201.BH)

ON

1P Nip “Press Ready”

20sec60sec

20sec60sec

20sec10sec

NFP Supply oil flow > L(1- FS- 4204.N)

Yes

No2P NFP Pres. Pump(1- M- 4204 & 4205)OFF

2P NFP Lub. Pump(1- M- 4210 & 4211)OFF

2P NFP Pres. Pump(1- M- 4214/ 4215)

ON

2P NFP Lub. Pump(1- M- 4210/ 4211)ON

2P NFP Blower(1- M- 4220/ 4221)ON

2P Pres. Oil ON- LOAD (L)(1- SOL- 4209.AH)

ON

2P Slv cooling ON- LOAD(1- SOL- 4210.H)ON

2P Lub. Oil ON- LOAD(1- SOL- 4212.H)

ON

20sec1sec

20sec1sec

2P Top roll operation(1- PX- 4235)

Yes

No

OperationMode

Opera-tion

Mainte-nance

1- OD- 4201 COS

2P NFPPumps

ON

OFF

1- OD- 4201 GP

NFP Circulation Pump(1- M- 4216/ 4217)ON

NFP Hyd. tank level > LL(1- LI- 4222)

Yes

NoNFP Circulation Pump(1- M- 4216 & 4217)

OFF

AND

AND

20sec1sec

NFP Supply oil temp. > 35℃ (1- TT- 4220)2P Sleeve pressure > LL (1- PT4219A)2P Sleeve cooling oil flow = 0 l/ min (1- FT-4213)2P Shaft seal lub. oil flow (T) = 0 l/ min (1- FT- 4215)2P Shaft seal lub. oil flow (D) = 0 l/ min (1- FT- 4216)2P BRG lub. oil flow (T) = 0 l/ min (1- FT- 4217)2P BRG lub. oil flow (D) = 0 l/ min (1- FT- 4218)

2P Nip load = 0 kN/ m (1- PT-4211)Suc. Pick up roll “Ready Position” (1- PX- 4212)1PB Lead- out roll “Lower limit” (1- PX- 4229)2PB Lead- in roll “Upper limit” (1- PX- 4236)2PB Lead- out roll “Lower limit” (1- PX- 4239)

Yes

No

20sec30sec

2P Sleeve cooling(1- SOL- 4211.H)

ON

2P Slv cooling oil Flow CV(1- FCV- 4213)

close

Ope.Pos.

2P Sleeve Pressure CV(1- PIC- 4219)

2P “Crawl Ready”

AND

2P Sleeve cooling(1- SOL- 4211.H)OFF

2P Slv cooling oil Flow CV(1- FCV- 4213)

open

StartPos.

2P Sleeve Pressure CV(1- PIC- 4219)

2P Nip load(1- PCV- 4211)

Close

(DRIVE)2P Run

Stop

DC PB

CrawlJ og

2P “Crawl”

2P Sleeve cooling(1- SOL- 4211.H)

ON

2P Lubrication(1- SOL- 4213.H)ON

2P > 0 m/ min

Yes

No

2P Sleeve pressure > LL (1- PT4219A)2P Shaft seal lub. oil flow (T) > LL (1- FT- 4215)2P Shaft seal lub. oil flow (D) > LL (1- FT- 4216)2P BRG lub. oil flow (T) > LL (1- FT- 4217)2P BRG lub. oil flow (D) > LL (1- FT- 4218)

2P Nip load “Close” (1-PT-4211)

Yes

No

2PB Felt roll Doctor(1- SOL- 4228.P)ON

2PB Felt rollDoctor

ON

OFF

1- OD- 4201 GP

2PT HP- showerOscillate ON

DCS PB

2PT HP- shower Oscillate(1- M- 4204)ON

2PB HP- showerOscillate

ON

DCS PB

2PB HP- shower Oscillate(1- M- 4205)

ON

2P “Crawl”

Yes

No

2P TrSB Moist.Shower HV

ON

DCS PB

2P TrSB Moist. shower HV(1- HV- 4230)

ON

2PB HP- showerHV

ON

DCS PB

2PB HP- shower HV(1- HV- 4231)ON

Oscillate Detect(1- PX- 4245)

Yes

No2PB HP- shower HV

(1- HV- 4231)OFF

2P “Low speed Ready”

2PB DoctorShower HV ON

DCS PB

2PB Doctor shower HV(1- HV- 4228)ON

2PT HP- showerHV

ON

DCS PB

2PT HP- shower HV(1- HV- 4227)

ON

Oscillate Detect(1- PX- 4244)

Yes

No2PT HP- shower HV

(1- HV- 4227)OFF

2P TrSB Moist. shower HV “Open”(1- HV- 4230.LO)

Yes

No

2P Sleeve cooling oil flow > LL(1- FT- 4213)

Yes

No

2P “Run ready”

2P > “Low speed”

Yes

No

2P “Running speed”

Yes

No

2P Nip “Threading load Ready”

2P “Low speed”(DRIVE)

2P RunStop

DC PB

CrawlJ og

AND

2P Slv cooling oil Flow CV(1- FCV- 4213)

Ope.Pos.

Ope.Pos.

2P Sleeve Pressure CV(1- PIC- 4219)

Thread2P Nip

Open

Press

1-OD-4201 PB

Close2P Nip load

(1- PCV- 4211)ThreadAND

2P Pres. Oil ON- LOAD (L)(1- SOL- 4209.AH)

OFF

2P Nip load “Threading”(1- PT- 4211)

Yes

No

2P Pres. Oil ON- LOAD (H)(1- SOL- 4209.BH)

ON

2P Nip “Press Ready”

20sec60sec

20sec60sec

(DRIVE)Speed difference 1P/ 2P < 1%

Yes

AND1PBLead- out

roll

UP

DOWN

1- OD- 4201 GP

1PB Lead- out roll “Up”(1- SOL- 4208.AH)ON

1P Nip load “Threading” (1-PT-4202)2P Nip load “Threading” (1-PT-4211)

Suc. Pick up roll “Ready Position” (1- PX- 4212)1PB Lead- out roll “Upper limit” (1- PX- 4228)2PB Lead- out roll “Lower limit” (1- PX- 4239)2PB Felt roll Doctor “ON” (1- SOL- 4228.P)2PB Doctor shower “ON” (1- HV- 4228.LO)

Yes

No

(DRIVE)Speed difference Wire/ 1P < 1 %Speed difference 1P/ 2P < 1 %

Yes

No

AND

Pick- up roll lifting “Down”(1- SOL- 4216.BP)

ON

SuctionPick-upVacuumbreaker

Open

1-OD-4201 PB

Close Suc.P.U vacuum breaker(1- HV- 4308)

clese

1P TrSB Moist.Shower HV OFF

DCS PB

1P TrSB Moist. shower HV(1- HV- 4225)ON

2P TrSB Moist. shower HV(1- HV- 4230)

ON

Pick- up roll in “Operation”(1- PX- 4222)

Yes

No

AND

2P TrSB Moist.Shower HV

OFF

DCS PB

Pick-uproll

Up1-OD-4201 PB

DownManualStop

Pick up rollI/L

ON

OFF

1- OD- 4201 COS

AND

OR

Thread1P Nip

Open

Press

1-OD-4201 PB

Close

1P Nip load(1- PCV- 4202)

PressAND

1P Nip load “Press”(1- PT- 4202)

Yes

No

Thread2P Nip

Open

Press

1-OD-4201 PB

Close

2P Nip load(1- PCV- 4211)

PressAND

2P Nip load “Press”(1- PT- 4211)

Yes

No

AND

1P TopR Pneumatic strip(1- SOL- 4222.P)

ON

1P TopR Scraper(1- SOL- 4221.P)

ON20sec10sec

1P Top rollScraper

Auto1-OD-4201 GP

OnManualOff

Sheet break signal in 1D

Pick- up roll in “Operation”(1- PX- 4222)

Yes

No

2PB Lead- out roll “Down”(1- SOL- 4225.BP)ON

1D speed up “5%”

Tail thread to Dryer

2PBLead-out

roll

Up

1-OD-4201 GP

Down

2PB Lead- out roll “Up”(1- SOL- 4225.AP)ON

Full width paper in Dryer

(DRIVE)Speed difference 2P/ 1D < 1 %

Yes

No

AND

Momentary

Latch

2PB Lead- out roll in “Lower pos.”(1- PX- 4239)

Yes

No

2PB Lead- out roll “Down”(1- SOL- 4225.BP)OFF

Stop Sequence

Pick- up vacuum breaker“Open” (1- HV- 4308.LO)

Yes

No

Thread2P Nip

Open

Press

1-OD-4201 PB

Close2P Nip load

(1- PCV- 4211)Thread

20sec5sec

Thread1P Nip

Open

Press

1-OD-4201 PB

Close1P Nip load

(1- PCV- 4202)Thread

1P TopR Pneumatic strip(1- SOL- 4222.P)

Off

1P TopR Scraper(1- SOL- 4221.P)Off

Pick- upVacuumbreaker

Open

1- OD- 4201 PB

Suc.P.U vacuum breaker(1- HV- 4308)Open

Pick- up roll lifting “Up”(1- SOL- 4216.AP)

ON

2PBLead-out

roll

Up

1-OD-4201 GP

Down 2PB Lead- out roll “Down”(1- SOL- 4225.BP)

ON

1PBLead- out

roll

UP

DOWN

1- OD- 4201 GP

1PB Lead- out roll “Down”(1- SOL- 4208.BH)ON

(DRIVE)1P Run

Stop

DC PB

CrawlJ og

(DRIVE)2P Run

Stop

DC PB

CrawlJ og

1P “Stop”

2P “Stop”

Pick-uproll

Up1-OD-4201 PB

DownManualStop

1P Fatal errorOR

(DRIVE)1P Drive Fatal error

20sec1sec

20sec5sec

(DRIVE)1P > “Low speed”

Yes

No

(DRIVE)1P > 0m/ min

Yes

No

Suc.P.U vacuum breaker(1- HV- 4308)Open

1P Nip load(1- PCV- 4202)

close

1P TopR Scraper(1- SOL- 4221.P)

OFF

Pick- up roll lifting “Up”(1- SOL- 4216.AP)ON

1PB Lead- out roll “Down”(1- SOL- 4208.BH)ON

1P TopR Pneumatic strip(1- SOL- 4222.P)OFF

1P “Stop”

1P Sleeve cooling(1- SOL- 4203.H)OFF

OR

AND

Normal Stop

OR

1P Slv cooling oil Flow CV(1- FCV- 4204)open

StartPos.

1P Sleeve Pressure CV(1- PIC- 4210)

PuR HP-showerHV

OFF

DCS PB

Pu roll HP- shower HV(1- HV- 4223)

OFF

1PT HP- showerHV OFF

DCS PB

1PT HP- shower HV(1- HV- 4224)OFF

1PB HP- showerHV

OFF

DCS PB

1PB HP- shower HV(1- HV- 4226)

OFF

(DRIVE)1P “0m/ min”

Yes

No

Pick- up roll scraper(1- SOL- 4220.P)OFF

Pu rollScratper

ON

OFF

1- OD- 4201 GP

(DRIVE)Wire/ 1P < 2 %1P/ 2P < 2 %

Yes

No

1P Pres. Oil ON- LOAD (L)(1- SOL- 4201.AH)

ON

1P Pres. Oil ON- LOAD (H)(1- SOL- 4201.BH)

OFF

20sec60sec

ORAND

PuR HP-showerOscillate

OFF

DCS PB

PuR HP-shower Oscillate(1- M- 4201)

OFF

1PT HP- showerOscillate

OFF

DCS PB

1PT HP- shower Oscillate(1- M- 4202)

OFF

1PB HP- showerOscillate OFF

DCS PB

1PB HP- shower Oscillate(1- M- 4203)OFF

1P TrSB Moist.Shower HV

OFF

DCS PB

1P TrSB Moist. shower HV(1- HV- 4225)

OFF

1P Lubrication(1- SOL- 4205.H)OFFThread

1P Nip

Open

Press

1-OD-4201 PB

Close

1P Nip load(1- PCV- 4202)open

1P NFPPumps

ON

OFF

1- OD- 4201 GP

OperationMode

Opera-tion

Mainte-nance

1- OD- 4201 COS

OR

1P Slv cooling ON- LOAD(1- SOL- 4202.H)

OFF

1P Lub. Oil ON- LOAD(1- SOL- 4204.H)

OFF

1P NFP Pres. Pump(1- M- 4212 & 4213)OFF

1P NFP Lub. Pump(1- M- 4208 & 4209)OFF

1P Pres. Oil ON- LOAD (L)(1- SOL- 4201.AH)

OFF

AND

2P Fatal errorOR

20sec1sec20sec5sec

(DRIVE)2P > “Low speed”

Yes

No

(DRIVE)2P > 0m/ min

Yes

No

Suc.P.U vacuum breaker(1- HV- 4308)

Open

1P Nip load(1- PCV- 4202)

close

Pick- up roll lifting “Up”(1- SOL- 4216.AP)

ON

1PB Lead- out roll “Down”(1- SOL- 4208.BH)ON

2P “Stop”

2P Sleeve cooling(1- SOL- 4211.H)OFF

OR

AND

2P Slv cooling oil Flow CV(1- FCV- 4213)

open

StartPos.

2P Sleeve Pressure CV(1- PIC- 4219)

2PT HP- showerHV OFF

DCS PB

2PT HP- shower HV(1- HV- 4227)OFF

2PB HP- showerHV OFF

DCS PB

2PB HP- shower HV(1- HV- 4231)OFF

(DRIVE)2P “0m/ min”

Yes

No

(DRIVE)2P Drive Fatal error

Normal Stop

OR

(DRIVE)1P/ 2P < 2 %2P/ 1D < 5%

Yes

No 2PB Lead- out roll “Down”

(1- SOL- 4225.BP)ON

2P Pres. Oil ON- LOAD (L)(1- SOL- 4209.AH)ON

2P Pres. Oil ON- LOAD (H)(1- SOL- 4209.BH)OFF

1P Pres. Oil ON- LOAD(1- SOL- 4201.AH)

ON(LP)

2PT HP- showerOscillate

OFF

DCS PB

2PT HP- shower Oscillate(1- M- 4204)

OFF

2PB HP- showerOscillate

OFF

DCS PB

2PB HP- shower Oscillate(1- M- 4205)

OFF

2P TrSB Moist.Shower HV OFF

DCS PB

2P TrSB Moist. shower HV(1- HV- 4230)OFF

2PB DoctorShower HV

OFF

DCS PB

2PB Doctor shower HV(1- HV- 4228)

OFF

20sec60sec

ORAND

2P Lubrication(1- SOL- 4213.H)OFFThread

2P Nip

Open

Press

1-OD-4201 PB

Close

2P Nip load(1- PCV- 4211)open

2P NFPPumps

ON

OFF

1- OD- 4201 GP

OperationMode

Opera-tion

Mainte-nance

1- OD- 4201 COS

OR

2P Slv cooling ON- LOAD(1- SOL- 4210.H)

OFF

2P Lub. Oil ON- LOAD(1- SOL- 4212.H)

OFF

2P Pres. Oil ON- LOAD (L)(1- SOL- 4209.AH)

OFF

AND

2P NFP Pres. Pump(1- M- 4214 & 4215)OFF

2P NFP Lub. Pump(1- M- 4210 & 4211)OFF

NFP supply oil temp. control valves

NFPCirculation

Pump

ON

OFF

1- OD- 4201 GP

NFP Circulation Pump(1- M- 4216/ 4217)ON

NFP Circulation Pump(1- M- 4216 & 4217)

OFF

(DRIVE)1P “0m/ min”2P “0m/ min”

Yes

No

NFP Supply oil temp. CV(1- TCV- 4220)

Close

NFP Supply oil temp. CV(1- TCV- 4220)

Control

1P NFP Pressure pump “OFF” (1- M- 4208/ 4209)1P NFP Lubrication pump “OFF” (1- M- 4212/ 4213)2P NFP Pressure pump “OFF” (1- M- 4210/ 4211)

2P NFP Lubrication pump “OFF” (1- M- 4214/ 4215)

Yes

No

NFPOil coolerflushing

1- OD- 4201 GP

(DRIVE)1P “0m/ min”2P “0m/ min”

Yes

No

NFP Supply oil temp. CV(1- TCV- 4220)

Open

NFP Supply oil temp. CV(1- TCV- 4220)

Close/

cont

20sec20sec

Please flush the oil cooler every month to prevent any trouble by contaminants inside plates.

![lights . Press [Ml 12. Video his button evices. In :able ... · Press [Ml 001. Press[M1] 012. Press [Ml] 123. Press 231. Press[Ml] 017. Press[Ml] never tl Jnction of t ack to Cabh](https://static.fdocuments.in/doc/165x107/5f9dbb49f98ba33d93766928/lights-press-ml-12-video-his-button-evices-in-able-press-ml-001-pressm1.jpg)

![[MMC PRESS KIT] Press Release _ID](https://static.fdocuments.in/doc/165x107/58677ec31a28ab27408bc670/mmc-press-kit-press-release-id.jpg)