011 Electric 6DOF Motion system st eadline36 pt1. mm ... · 011 st eadline36 pt1. mm second line...

Transcript of 011 Electric 6DOF Motion system st eadline36 pt1. mm ... · 011 st eadline36 pt1. mm second line...

01_1st Headline_36 pt/14.4 mm second lineElectric 6DOF Motion system eMotion-1500

2 eMotion-1500 | Proven in practice

Typical Applications: f Driving Simulation for cars, trains, trams, other rail

vehicles, trucks, rough terrain vehicles, etc. f Flight Simulation for small aircrafts and light helicopters f Motion Ride for entertainment applications

Advantages: f Optimal motion control thanks to in-house developed

and maintained motion cueing software and full digital control

f Best in class smoothness thanks to high quality compo-nents, advanced friction compensation control software, ball screw spindles, oil lubrication and low friction seals

f Low noise and low vibrations thanks to oil filled actua-tor, optimized Spindle-Nut design and Bosch Rexroth Silent Belt

f Economic design with high performance at low power consumption thanks to optimized transmission ratio and integrated static compensation

f Highly optimized motion envelope thanks to parallel mounted Bosch Rexroth Servo Motor with integrated brake

f Safe Operation thanks to integrated cushioning system, built-in holding brake, incorporated safety electronics and software

f Easy installation and commissioning thanks to compact subsystems

f Completely assembled and tested units at delivery f Bosch Rexroth Safety on Board Drive line for increased

safety f Bosch Rexroth 4EE Energy Efficiency on board f Easy, low interval maintenance

Scope of Supply: f Motion Base Assembly including six electric servo actua-

tors, motion platform and base frame including floor mounting plates

f System Electronics including drive controllers and power units

f Motion Computer with digital I/O and Ethernet commu-nication interface

f Motion control software, with motion cueing or ride-file play and replay capabilities

f User friendly, menu-driven user interface, including remote access service and diagnostic procedures

f Interconnecting cabling f Documentation including System Description, Interface

Control Document and Operating and Maintenance Manuals

Options: f Access ramp to the simulator f Alternative host interfacing (e.g. reflective memory) f User tuneable software f Tailor made motion cueing tuning f Creation of a motion ride file f Assembly, commissioning, fine tuning, maintenance and

operator training on site

Electric 6DOF Motion system Proven in practice

In motion simulation, Rexroth offers electrically driven motion systems for today’s simu-lation market. The eMotion-1500 is designed for today’s middle payload range in the electric driven motion systems product line: 1500 kg. The proven in-practice design is a synergy of our Drive and Control skills and profound application knowledge. This knowledge is gained in over 30 years of practice as a supplier for high performance motion systems for training, research and entertainment applications. The electrically driven linear servo actuators are developed and manufactured within Rexroth. All motion system components are in-house products from the Rexroth program.

Specifications | eMotion-1500 3

f Envelope study of customer’s specific payload geometry f Service/ Maintenance contract

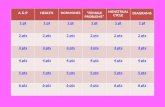

General performance

Payload 1500 Kg

Actuator stroke 650 mm

Ixx 2000 Kgm²

Iyy 2000 Kgm²

Izz 2000 Kgm²

(Relative to COG of the payload)

Settled height 1.26 m

Distance of COG above topside platform

1 m

Performance (operational, non-simultaneous)

Excursions pos. neg.

Surge 0.63 m - 0.50 m

Sway 0.50 m - 0.50 m

Heave 0.37 m - 0.38 m

Roll 24 deg - 24 deg

Pitch 28 deg - 25 deg

Yaw 27 deg - 27 deg

Velocity

Surge +/- 0.80 m/s

Sway +/- 0.81 m/s

Heave +/- 0.55 m/s

Roll +/- 34.3 deg/s

Pitch +/- 37.4 deg/s

Yaw +/- 41.3 deg/s

Specifications

General:Actuators: Linear electrically drivenPlatform shape: Triangular

Accelerations Acceleration Acceleration onset

Surge +/- 0.7 g +/- 10 g/s

Sway +/- 0.7 g +/- 10 g/s

Heave +/- 1.0 g +/- 10 g/s

Roll +/- 250 deg/s² +/- 600 deg/s²/s

Pitch +/- 250 deg/s² +/- 600 deg/s²/s

Yaw +/- 500 deg/s² +/- 900 deg/s²/s

The above performance figures are with the starting position ‘neutral’ and with the design payload.

Interfaces: f Electric Power: 400/480 VAC, 50/60 Hz f Host computer

f Ethernet connection f Update rate upto 250 Hz f Foot-print: 2300 x 2700 mm f Floor attachment: Bolted using floor anchors

Worldwide customer support: f Local Rexroth representatives in over 80 countries f 24-hour service and maintenance support by Rexroth’s

global service organization

For further details please visit our website or feel free to contact us.

Bosch Rexroth AG04_Body text U4_7.7 pt/3.84 mm Address

© Bosch Rexroth BV 2017All rights and changes reserved.

Bosch Rexroth BVPO Box 325280 AA Boxtel, NetherlandsKruisbroeksestraat 15281 RV Boxtel, NetherlandsTel: +31 (411) 651951www.boschrexroth.com/[email protected]