0045-Aoki.pdf

Transcript of 0045-Aoki.pdf

8/10/2019 0045-Aoki.pdf

http://slidepdf.com/reader/full/0045-aokipdf 1/4

45

Aoki, T., Pull tests of long-embedded cablebolts

ISRM 2003–Technology roadmap for rock mechanics, South African Institute of Mining and Metallurgy, 2003.

Pull tests of long-embedded cablebolts

Aoki, T.*, Shibata, K.

*, Nakahara, F.

*, Maeno, Y.

**, Kawano, R.

**, Obara, Y.

**

*

Taisei Corporation,

**

Kumamoto University

The mechanical behaviors of fully-grouted long-embedded cablebolts actually used in situ are very

non-linear in pull tests and are different from those of short-embedded cablebolts. We have

conducted the pull tests of long-embedded cablebolts installed in mockup rock test blocks, which

are 4m in the longitudinal length. In order to investigate the mechanical behaviors inside the test

block, the axial load distribution along the cablebolt and locations of acoustic emission events

were measured during each pull test. It was found that the axial force distributions were quite

linear and that the gradients were interpreted as the grout bond strength by taking into

consideration the stress balance at the infinitesimal segment of a cablebolt.

Les boulons-câbles longs entièrement cimentés qui sont réellement utilisés sur place présentent, au

cours des essais de traction, des comportements mécaniques considérablement non linéaires etdifférents de ceux des boulons-câbles courts. Nous avons mené des essais de traction des boulons-

câbles longs installés dans une maquette de fond rocheux servant d’éprouvette d’une longueur

longitudinale de 4 m. Afin d’étudier les comportements mécaniques intérieurs de l’éprouvette, la

répartition de la force axiale du boulon-câble et l’émission acoustique ont été mesurées durant

chaque essai de traction. Il s’est avéré que les répartitions de la force axiale sont sensiblement

linéaires et que leurs gradients représentent la résistance d’adhésion en prenant en compte

l’équilibre de contraintes à la partie infinitésimale d’un boulon-câble.

Das mechanische Verhalten von ganz eingegossenen, lang eingebetteten Kabelbolzen, die vor Orteingesetzt werden, ist bei Zugprüfungen sehr nichtlinear und anders als das von kurz eingebetteten

Kabelbolzen. Es wurden Zugprüfungen mit lang eingebetteten Kabelbolzen durchgeführt, die inPrüfblöcken (Gesteinsattrappen) mit 4 m Länge eingelassen waren. Zur Untersuchung des

mechanischen Verhaltens in den Prüfblöcken wurden die Axiallastverteilung entlang desKabelbolzens sowie das Auftreten von Schallemission im Verlauf jeder Zugprüfung gemessen. Es

ergab sich, dass die axiale Kraftverteilung recht linear ist, und die Gradienten wurden unter

Berücksichtigung des Kräftegleichgewichts am infinitesimal kleinen Punkt eines Kabelbolzens als

Haftfestigkeit interpretiert.

Introduction

Cablebolts, composed of multi-wire strand, are capable of

being installed as long reinforcement bolts from small adits

due to their flexibility. As a rational rock-reinforcement

method, cablebolting has been used in construction projectsof large cross-sectional three-lane road tunnels1) and a large

underground powerhouse cavern2) in Japan.

The authors have carried out laboratory pull tests of

cablebolts to investigate the mechanical behaviors of

cablebolts in the scope of establishing the quantitative

evaluation of the effects of rock reinforcement by means of

cablebolting.3) 4) In these studies, cablebolts of short

embedded length of 350mm were used in their pull test and

differences in grout bond strength etc. for types of

cablebolts were discussed. However, it has been reported

that cablebolts of long embedded length actually used in

situ show significant non-linearity in the load-displacement

relations of the pull tests1) whereas those of short-embedded

length show fairly linear behavior before reaching the peak

bond strength.3) 4)

In this study, we have conducted the pull tests of long-

embedded cablebolts installed in large-scale mockup rock

test blocks, which are 4m in the longitudinal length. The

axial load distributions are measured together with the load-

displacement relations during the pull tests. In addition,

locations of acoustic emission events generated around the

cablebolts are measured. Differences in axial force

distribution and behaviors of bond failures are discussed for

different types of cablebolts.

Laboratory Pull Tests

Test procedures and test blocks

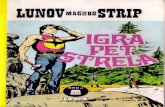

Layout of a test block with cablebolts installed for pull tests

is shown in Figure 1. Two types of mockup rock test

blocks were made as shown in Table 1: Block A stands for

medium-hard rock and Block B stands for weak rock.

Two types of cablebolts are used as illustrated in Figure

2: one is plain strand made of seven-wire steel strand

(SWPR7B) and the other is bulbed strand that has inflatedparts, as illustrated in Figure 2, each spaced by 0.5m so as

to increase bonding performance with grout. The

specification of the two types of cablebolts are basically thesame as given in Table 2.

Three boreholes of 45mm in diameter are made in each

test block as shown in Figure 1 and cablebolts are installed

and grouted with cement past whose water-cement ratio is

8/10/2019 0045-Aoki.pdf

http://slidepdf.com/reader/full/0045-aokipdf 2/4

46 ISRM 2003 – TECHNOLOGY ROADMAP FOR ROCK MECHANICS

0.4. On each cablebolt, strain gauges are installed at five

positions as illustrated in Figure 1 so as to detect thedistributing axial forces along a cablebolt embedded in the

test block.Moreover, nine acoustic emission sensors whose

resonant frequency is 140kHz are installed at positions

indicated in Figure 3: the AE wave generated around thecablebolt is expected to propagate through the separator

rebars that run near the borehole in the orthogonal direction

and thus AE sensors can pick up the AE events. Each

detected AE wave is examined to exclude noise due to

disturbance e.g. winds.

The layout of a pull test is illustrated in Figure 4. In

each pull test, the pull load is applied by an approximatelyconstant rate of 10kN/min. The test is terminated when the

pull load reaches the yield force of the cablebolt or when it

shows the peak load resulting from the grout bond failurealong the whole embedded part of the cablebolt.

Test Results

Load-displacement curves

The load-displacement curves obtained from the pull tests

of Blocks A and B are given in Figures 5 and 6. The

displacement used here is one measured at the base.

Two tests were conducted for each plain and bulbed

strands installed in Blocks A; good repeatability was

attained. The pull load increased in a fairly non-linear

convex curve with rapid increase in displacement at the pullload level of about 255kN when the cablebolt of the free

500 500 500 500

Position of strain gauges

4000

t=600Plain strand 1 2 0 0

375

No.1 No.2 No.3 No.4 No.5

Bulbed strand

125 500

Position of bulbs

Figure 1 Layout of test block

Figure 2 Types of cablebolt

4000

t=600 1 2 0 0

250

2250

Separator rebar

ƒ ³=7mm

AE sensor 9pcs@250mm

Figure 3 Arrangement of AE sensors

Hydraulic ram

Test

block

Cable bolt

Frame bolster

Displacement transducers

Pedestal

Pedestal

Figure 4 Layout of a pull test

Table 1 Properties of test blocks and grout

Age UCS E50

[day] [MPa] [GPa]

Block LC 24 1.92 30.8 19.3 0.20

Block SM 14 1.99 12.6 9.3 0.17

GroutCement

paste10 2.01 50.1 10.0 -

LC:Lightweight aggregate concrete SM:Soil Mortar

material S.G. ν

Table 2 Specifications of cablebolt

DiameterCross-sectional

Area

Yield

load

Breaking

strength

[mm] [mm2] [kN] [kN]

15.2 138.7 222 261

0

50

100

150

200

250

300

0 5 10 15 20

Bolt displacement at base [mm]

P u l l L o a d [ k N ]

Block A

Plain strand-1

Plain strand-2

Bulbed strand-1

Bulbed strand-2

Figure 5 Load-displacement curves(Block A)

0

50

100

150

200

250

300

0 5 10 15 20

Bolt displacement at base [mm]

P u l l L o a d [ k N ]

Block B

Bulbed strand

Plain strand

Figure 6 Load-displacement curves(Block B)

Plain strand Plain strand

Bulbed strand Bulbed strand

8/10/2019 0045-Aoki.pdf

http://slidepdf.com/reader/full/0045-aokipdf 3/4

8/10/2019 0045-Aoki.pdf

http://slidepdf.com/reader/full/0045-aokipdf 4/4

48 ISRM 2003 – TECHNOLOGY ROADMAP FOR ROCK MECHANICS

pull load level (this could not be detected due to the layout

of AE sensors, see Figure 1); secondly, it occurred at thesecond bulb at greater pull load level and the shear stress

was concentrating at the position of the third bulb.It is interesting to note that the axial stress distributions

are quite linear for the pull test results of bulbed strands

although local stress concentration is occurring at each bulb.

Mechanism of Shear Resistance of Cablebolts

The axial force generated along the cablebolt embedded in

the test block (or rock in situ) is related to the shear stress

working on the cablebolt-grout interface and the grout-rock

one. The mechanism at the cablebolt-grout interface is only

discussed here for simplicity.

The stress balance at an infinitesimal segment of a

fully-grouted cablebolt is depicted in Figure 11. When the

cablebolt is pulled, shear stress τ is generated at the

cablebolt-grout interface in an infinitesimal segment of

thickness dz. Consider the axial loads of p+dp and p areacting on each cross-sectional side of the segment. The

increment in axial force dp is given as:

dz Ddp π τ = (1)

where D is diameter of the cablebolt. Thus, the shear stress

is defined by the variation in axial load along the cablebolt.

Figures 7 and 8 indicated that the axial load

distributions were linear in a large sense at both low

(100kN) and high (150 or 200kN) pull load levels. This

designates that the shear stress τ is regarded constant as

given by:

( ) D M π τ −= (2)

where M is the gradient of the linear distribution on the

axial load.

The relative displacement between the cablebolt and

grout is large at position in shallow depth from the wall in

the test block and is small at position in deep depth. Hence,

the shear stress is constant regardless of the depth from the

wall. This indicated that the cablebolt-grout interface hadthe constant shear resistance with displacement after the

grout bond failure. Henceforth, the gradient M is called

grout bond strength.The grout bond strengths determined from the axial

force distributions of each test condition by means of linearregression method are summarized in Table 3. Regarding

Block A, the grout bond strength for bulbed strand was

approximately 35% greater than that for plain strand. Onthe other hand, they are close for Block B and this is

attributed to the low confinement effect working on the

grout-rock interface due to the low stiffness and low

strength of Block B.

Some of the authors have applied such-determined

grout bond strengths to numerical analyses to simulate pull

tests of long embedded cablebolts and the analysis results

were in good coincidence with the test results.5)

Conclusions

Main findings obtained in this study are listed below:

• Each of the axial force distribution along the embedded

cablebolt obtained from the pull tests conducted in thisstudy was in quite a linear form.

• AE events indicated local grout bond failure and stress

concentration at bulbs for the tests of bulbed strand but

overall linear axial stress distributions were observed.

• The gradient of the linear axial force distribution was

found to stand for the constant grout bond strength

based on the consideration of the stress balance around

the cablebolt and grout.

• Regarding Block A standing for medium hard rock, the

grout bond strength for bulbed strand was

approximately 35% greater than that for plain strand.On the other hand, they are close for Block B standing

for weak rock. This is attributed to the different

confinement effect due to the different stiffness and

strength of the types of test blocks.

References

1) Kobayashi, T., et al. An evaluation of pre-reinforcementperformed from the TBM pilot for tunnel of large cross

section using fully grouted cable bolts. Proceedings of the31th Symposium of Rock Mechanics, pp.201-205. (in

Japanese)

2) Shimizu, N., et al. Field experiments of fully groutedcablebolting for pre-reinforcement of rock mass around an

underground powerhouse. Proceedings of the 11th Japan

Symposium on Rock Mechanics, F20, 2002. (in Japanese)

3) Nakahara, F., et al. Bonding properties and shear

reinforcing effects of fully grouted cable bolts. Proceedings

of the 31th Symposium of Rock Mechanics, pp.62-66. (in

Japanese)4) Obara Y., et al. Laboratory pull-out test of cable bolts.

Proceedings of the 11th Japan Symposium on Rock

Mechanics, F11, 2002. (in Japanese)

5) Aoki, T., et al. Pull tests of long- and short-embedded

cablebolts and their numerical simulations. Rock

Engineering Problems and Approaches in UndergroundConstruction, Proc. 3rd Korea-Japan Joint Symposium on

Rock Mechanics, Choi et al. (eds), pp.479-486, 2002

Figure 11 Stress balance at an infinitesimal segmentof a cablebolt

Table 3 Grout bond strength

Block Plain strand[MPa] Bulbed strand[MPa]

A 1.7 2.3

B 1.55 1.61