© 2016 Swinton Technology Ltd. - AXAMER SOLUTIONS · Swinton Technology has teamed up with...

Transcript of © 2016 Swinton Technology Ltd. - AXAMER SOLUTIONS · Swinton Technology has teamed up with...

© 2016 Swinton Technology Ltd.

TruST Features

TruST Metering Supervisory Computer

TruST is a custom built Metering Supervisory Computer offered exclusively by Swinton Technology Ltd. With a proven global install base TruST excels in providing an intuitive metering focal point for site engineers, operators and technicans. As TruST is maintained entirely by Swinton Technology we offer a wide range of customisation, and we continue to develop the range of features TruST has to offer.

Core Features

• Integrates with all major flow computer types• Communicates with a wide range of measurement devices• Extensive library of mimics, to suit most metering applications• Secure access through staged approvals and individual logins• Alarm and report management to industry standards• Duty standby, pay check and fully redundant architectures• Supervisory driven valve control via flow computer or PLC• Third party data links over Modbus, OPC or other protocols• A range of prover, sampler and batch sequencing applications

Custom Features

• Fully integrated Prognosis DP meter diagnostics• Integrated GCAS - Gas Chromatograph Analyisis Software• Supports a Precise virtual flow computing solution• Independent stream and station totalisation• Customised metering displays, alarms and reports• Supervisory generated flow and time weighted averages• Automated stream switching or flow balancing• Flow computer constants management and download

1

Flow Computing

Flow Computer Independent

At Swinton Technology we don’t manufacture flow computer hardware, leaving us free to offer the most suitable flow computer technology to match our customers needs.

TruST is unique in its ability to integrate with a range of different flow computer types, making it an effective choice for all oil or gas measurement installations. Our engineers are experienced in the configuration of a wide range of flow computers including the S600+, OMNI 6000, Flow-X, and the SFC 3000. TruST has already been proven with each of these flow computers, and has the capacity to be adopted alongside an even wider range of flow measurement devices using Modbus Serial, TCP/IP or OPC protocols.

Whether it’s to suit site operating conditions, previous experience with a familiar technology, budgets, size requirements, life cycle commitments, or any other factors. We are always happy to work with clients in helping to identify the best technology solution for them.

Unlike generic SCADA packages TruST is designed specifically for the management of flow measurement systems. At Swinton Technology we have years of experience in developing metering applications, and this knowledge has been utilised to ensure TruST offers our clients a comprehensive, reliable and high quality metering supervisory solution.

2

Designed For Metering

Enhanced Metering Performance

As you would expect from any good supervisory system, TruST offers the ability to collate information from various flow computers into one central graphical user interface. However, TruST offers more than just a window to view your flow computer data.

TruST can provide secure stream and station totalisation, independent from those values produced at the flow computer level. The supervisory reads up core measurement data from the flow computer and uses this to perform its own calculations. Generally this will include hourly, previous hour, daily, previous day, and cumulative totals for each metering stream and station. However, totals can be provided over any defined period, allowing additional totals to be generated beyond the capability of the flow computer alone.

The TruST totalisation system has been designed to synchronise with the flow computers at the end of a period. This ensures that there is no period end discrepancy between flow computer and supervisory totals. Using 64 bit numbering TruST prevents the loss of any significant values that may be rounded by other 32 bit packages. In case of flow computer failure all metering data is securely stored in the TruST database, including any historic period reports, alarms, or supervisory generated totals. The storage capacity is in excess of any flow computer available on the market.

Flow and time weighted averages can also be provided by TruST, and again configured to specific end user requirements. Key process data for individual streams can be averaged over any defined period. Station averages can be also be provided, wherby process data across a number of streams are calculated, displayed and reported for the benefit of the operator.

3

Designed For Metering

4

Supervisory Control

Prestige offers features to enhance both measurement performance and metering system control.

The metering supervisory system communicates with each flow computer using Ethernet TCP/IP links. TruST acts as the primary device and initiates all data transfers with the flow computers. Constants data is stored in the TruST database, and these values can be automatically downloaded to a flow computer on cold start. This saves operators time during flow computer change over and avoids values being entered incorrectly.

As the master device TruST can also provide command and control of motor operated valves via its userinterface, with valve icons on mimics available to open and close MOVs on manual operator request. TruST communicates directly with the flow computer or PLC responsible for the associated valve movement, issuing valve control commands and receiving status feedback.

Interlock sequencing of valves can also be configured in TruST, allowing functions such as stream switching and flow balancing to be automated by the supervisory. Stream switching is based on the monitoring of flow rates to bring streams on and offline once pre-set limits are recorded. For flow balancing, TruST monitors the station flow rate and re-positions valves to achieve equal flow across a select number of streams.

Remote access can also be provided over a company network, to enable access to the supervisory systemsdata on any number of client machines (with appropriate permissions set up). All metering data can be exported in .CSV format for manipulation and external storage without affecting the raw data stored in the TruST metering database.

Precise Virtual Flow Computing

Using our own ST103A Data Acquisition Module as a high precision I/O device, TruST can provide fiscally accurate flow measurement for oil and gas metering, removing the requirement for installing a traditional type of flow computer. Removing the additional layer of flow computer hardware allows our clients to save both capital and operational expenditure, whilst still retaining accuracy in their measurement. The Precise virtual solution provides measurement accuracy in accordance with ISO, API, EI and OIML standards.

The virtual flow computer uses an IEC-61131-3 configuration environment and can attach to any Modbus enabled I/O. Unlike many virtual flow computing solutions Precise incorporates a high accuracy “clock”, which allows accurate totals to be generated well within the uncertainty levels required by many industry standards.

Available as a fully integrated feature in the TruST metering supervisory computer, virtual flow computing data is presented and reported in the same fashion as with any other type of flow computer. The same data is shown to the operator, on the same mimics and displays, with the same alarms raised, and with the same reports being generated.

What is the ST103A?

The ST103A is a small 24v low power DIN rail mounted device, which avoids common space restrictions often encountered with traditional flow computer types. Despite its size the ST103A can manage a wide array and quantity of field inputs, including analogue, digital, frequency, pulse and PRT signals. The ST103A can even act as a Remote Telemetery Unit (RTU), providing an interface to metering equipment for PLCs, DCS and other third party systems.

5

GCAS - Gas Chromatograph Analysis Software

Swinton Technology has teamed up with I-Vigilant Technologies to provide GCAS. A gas chromatograph analysis software package providing routine condition based monitoring and live uncertainty calculations.TruST is the only metering supervisory computer to offer integrated GCAS, displaying the status of your gas chromatograph’s performance alongside your ‘in-use’ gas composition and fiscal metering data.

With integrated GCAS software, your TruST metering supervisory computer:

1. Provides up to date uncertainty values for your gas chromatograph.2. Gives daily confirmation of your GCs measurement performance.3. Detects GC errors as soon as possible (or even before they occur).4. Allows validation of the GC as required by EUETS Commission Regulation No601/20125. Reduces the need for carrying out routine GC maintenance checks.6. Avoids the need to manually validate your routine GC calibration results.7. Offers remote support to further reduce the risk of financial exposure. With a patented method for calculating reproducibility, GCAS gives routine uncertainty values for your gas chromatograph which are not available through any other commercial software application. Using the GCAS method, live representative uncertainty values can be calculated for Calorific Value, Molecular Weight, Wobbe Index, Relative and Standard Density.

More information about GCAS is available online: http://www.swintontechnology.com/metering-solutions/gas-chromatograph-analysis-software

Condition Based Monitoring

Condition Based Monitoring

Prognosis - DP Meter Diagnostics Software

TruST is unique in offering fully integrated ‘Prognosis’ DP meter diagnostics software. Prognosis is the world’s first and only condition based monitoring diagnostics system for differential pressure meters.

Swinton Technology in partnership with DP Diagnostics LLC has developed patented techniques to provide real-time meter system accuracy assurance and immediate warnings of suspect meter performance. The diagnostics can be applied to any standard DP meter measuring single phase liquid, single phase gas or wet gas flows as long as a suitable downstream straight wall pressure tap is available.

The following typical system faults will trigger an alarm within the Prognosis system:

1. Incorrect inlet or throat diameter in use2. Two-phase flow3. Excessive flow disturbance upstream of the meter4. Contamination build-up around the meter5. Blocked impulse lines6. Saturated DP transmitter7. Drifting DP transmitter

More information about Prognosis is available online: http://www.swintontechnology.com/metering-solutions/prognosis

8. A buckled orifice plate9. An orifice plate installed backwards10. A worn or damaged orifice leading edge11. A damaged cone element12. Incorrectly spanned DP transmitter13. Incorrect discharge coefficient in use14. Debris trapped at meter throat.

6

User Interface

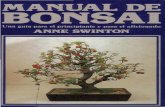

Example mimics and displays from existing TruST metering computer systems.

7

Displays and Mimics

Metering System Overview

System Overview: Berth Control and Tanker Loading

Clients Include

Swinton Technology Ltd

Swinton House Unit 1901 Asia Pacific SDN BHD Hertford Way HDS Tower, Cluster F 60, Jalan 17/155C York Road Business Park Jumeirah Lakes Tower 57000 Bukit Jalil Malton, North Yorkshire Dubai Kuala Lumpur United Kingdom UAE Malaysia T +44 (0)1653 698844 T +971 4 422 0596 T +603 8994 9716 F +44 (0)1653 605679 F +971 4 421 8483 F +603 8994 9717

Contact

8