© 2012 Delmar, Cengage Learning Engine Sealing, Gaskets, and Fastener Torque Chapter 51.

-

Upload

anais-male -

Category

Documents

-

view

213 -

download

0

Transcript of © 2012 Delmar, Cengage Learning Engine Sealing, Gaskets, and Fastener Torque Chapter 51.

© 2012 Delmar, Cengage Learning

Engine Sealing, Gaskets, and Fastener Torque

Chapter 51

© 2012 Delmar, Cengage Learning

Objectives• Order the correct gaskets for a variety of engine

repair jobs• Explain the theory related to torque and

clamping force• Understand the role that friction plays when

tightening parts• Describe the differences between types of head

gaskets

© 2012 Delmar, Cengage Learning

Objectives (cont'd.)• Understand the theory behind torque-to-yield

fasteners• Select the correct sealer for use in a variety of

applications

© 2012 Delmar, Cengage Learning

Introduction• This chapter deals with a very important area

– Sealing lubricants and coolants within the engine

• Leaks – Unprofessional

– Lead to serious mechanical part failures

© 2012 Delmar, Cengage Learning

Clamping Force• Avoid leaks by applying clamping force on two

parts that are held together– Clamping force results from:

• Tension or stretch on bolts securing two pieces• Springiness of a gasket between parts

– Clamping force will change if threads are not clean and undamaged

• Cleanliness is very important when assembling parts

© 2012 Delmar, Cengage Learning

Torque and Friction• Torque

– Measurement of twisting effort required to tighten a fastener

• Amount of fastener clamping force changes with use of lubricants

– 90% of torque applied in tightening a fastener is used to overcome friction

• Final 10% provides clamping force

– Fastener threads must be sealed and lightly oiled

© 2012 Delmar, Cengage Learning

Torque Wrenches• Torque is measured with a torque wrench

– Types • Beam wrench• Click (spring) wrench• Dial torque wrench

• Torque measured in foot-pounds or inch-pounds– Metric measurement is Newton-meter

• Digital torque wrenches– More expensive

• Purported to be as accurate as dial torque wrenches

© 2012 Delmar, Cengage Learning

Torque-to-Yield• Normal head bolt torque values

– Calculated safety factor 25% less than maximum• Clamping force is 75% of potential for size

• Head bolts – Produce clamping force of ±200%

• Torque-to-yield – Tighten bolts to within 2% of yield point

– Consistent clamping force and fatigue resistant

– Work well with aluminum heads

© 2012 Delmar, Cengage Learning

© 2012 Delmar, Cengage Learning

Torque by Degrees• Torque turn (i.e., torque angle)

– Ensures equal tightness of fasteners

• Method– Tighten the bolt to specified torque

– Turn it additional 35 to 180 degrees

• Torque angle gauge – Measures how far a fastener is turned

© 2012 Delmar, Cengage Learning

Fastener Clamping Load• Preload

– Clamping load on a fastener

• Ways to measure preload– Torque wrench

– Torque angle gauge

– Measure bolt stretch• Both ends must be accessible

© 2012 Delmar, Cengage Learning

Gaskets and Seals• Gaskets: installed between two surfaces to

prevent leaks– Can be purchased individually or in sets

• Modern head gaskets: difficult to seal• Non-retorque composite gasket: has facing,

coating, and core• Graphite-faced gaskets: premium• Teflon®, moly, or silicone-based antifriction

coating: seals minor surface imperfections

© 2012 Delmar, Cengage Learning

© 2012 Delmar, Cengage Learning

Gaskets and Seals (cont’d.)• Metallic head gasket: single and multilayer

– Multilayer steel gaskets more common as cylinder head gaskets

– Gasket should be appropriate for surface texture• Surface texture: measured by roughness average

• Copper head gaskets – Used for corrosive and high-vibration uses

• No-retorque gaskets – Resistant to compression

– Bolt stretch does not diminish clamping force

© 2012 Delmar, Cengage Learning

Cleaning the Head• Clean before assembly

– Use sharp scraper to clean iron head and block• Clean aluminum heads with plastic scraper

– Abrasive bristle discs can damage engine• Never use with a die grinder• Do not use them on aluminum head with

multilayer steel gasket• Do not use too coarse a grit• Do not clean “ghost marks” • Do not to clean in one area longer than another• Remove material thrown about by the discs

© 2012 Delmar, Cengage Learning

Head Gasket Installation• Head gaskets perform most difficult sealing job

– Sealing of combustion is very critical

– Clamping pressure on bolts greater than combustion pressure

• 75% of clamping load on head bolts used to seal combustion

– Match new gasket to old one or to block and head

• Cooling and oil holes do not match up: serious problems result

© 2012 Delmar, Cengage Learning

© 2012 Delmar, Cengage Learning

Other Engine Gaskets• Other gaskets are used at several locations in

the engine

© 2012 Delmar, Cengage Learning

Valve Cover, Timing Cover,and Oil Pan Service

• Valve cover gaskets: molded to shape of cover• Oil pan gaskets: made of several pieces• Sheet metal parts: often become distorted when

tightening bolts

© 2012 Delmar, Cengage Learning

Valve Cover, Timing Cover,and Oil Pan Service (cont'd.)

• Cork used in vintage applications– Shrinks in the presence of air

• Rubberized cork – Does not shrink

• Silicone and neoprene gaskets are the best– Expensive, but sometimes reusable

• Paper gaskets – Require sealer

• Intake manifold gaskets– Must be resistant to air and water leaks

© 2012 Delmar, Cengage Learning

Valve Cover, Timing Cover,and Oil Pan Service (cont'd.)

• Exhaust manifold gaskets – Not usually found on new cast iron heads

• Gaskets used once parts are separated for service

– Bottom of exhaust manifold uses O-ring gasket

• Chemical gaskets– Silicone or chemical sealers

• Not used for head gasket or fuel systems gasket

– Anaerobic sealers cure without air• Used only on precision machine parts

© 2012 Delmar, Cengage Learning

Gasket Sealers• Gasket sealers purposes

– Help gaskets seal

– Hold gaskets in place

– Substitute for gaskets

• hardening gasket cements – Do not use as sealers in automotive applications

• Anaerobic adhesive sealers (i.e., threadlockers)– Blue: parts may need disassembly

– Red: parts not intended to be disassembled

© 2012 Delmar, Cengage Learning

Silicone-RTV Sealant• Room temperature vulcanizing (RTV) (i.e.,

silicone rubber)– Cures when exposed to air

– Many gaskets can be eliminated by using a bead of RTV applied by a robot

– Sets faster in warm temperatures and high humidity

• Develops skin in 15 minutes• Sets completely in a day

© 2012 Delmar, Cengage Learning

Silicone-RTV Sealant (cont'd.)• Low-volatile RTV

– Used on vehicles equipped with oxygen sensors

• High-temperature RTV– Adding iron oxides to RTV increases its

temperature rating by 50-100°F

• Teflon® tape or liquid thread sealer– Threads can be sealed with Teflon® tape

• Rubber cement sealers – Popular and easy to use

– Thicken with exposure to air

© 2012 Delmar, Cengage Learning

© 2012 Delmar, Cengage Learning

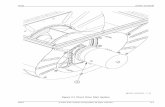

Seals• Dynamic seals (i.e., chevron seals)

– Seal moving parts

• Seal installation– Several items of concern

• Front seals– Usually lip-type seals with a garter spring

• Camshaft seals on OHC heads– Located behind camshaft sprocket(s)

© 2012 Delmar, Cengage Learning

© 2012 Delmar, Cengage Learning

Rear Main Seals• Leaking rear seal

– Can destroy a clutch

• Newer engines use neoprene lip seal– Be sure crankshaft rear sealing surface is clean

and smooth

– Sealer must be applied to flywheel bolts to prevent oil leakage from interior of oil pan

© 2012 Delmar, Cengage Learning

© 2012 Delmar, Cengage Learning

Transmission Front Pump Seal• Keeps transmission oil from leaking between

torque converter and transmission oil pump– Becomes brittle with age

– If seal fails: transmission fluid leaks from between engine and transmission

– Often replaced as preventative when engine overhauled